Na2CO3 and NaHCO3 double-horizontal-section classification mining model and process

A horizontal section and model technology, applied in mining equipment, ground mining, mining equipment, etc., can solve problems such as increasing separation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

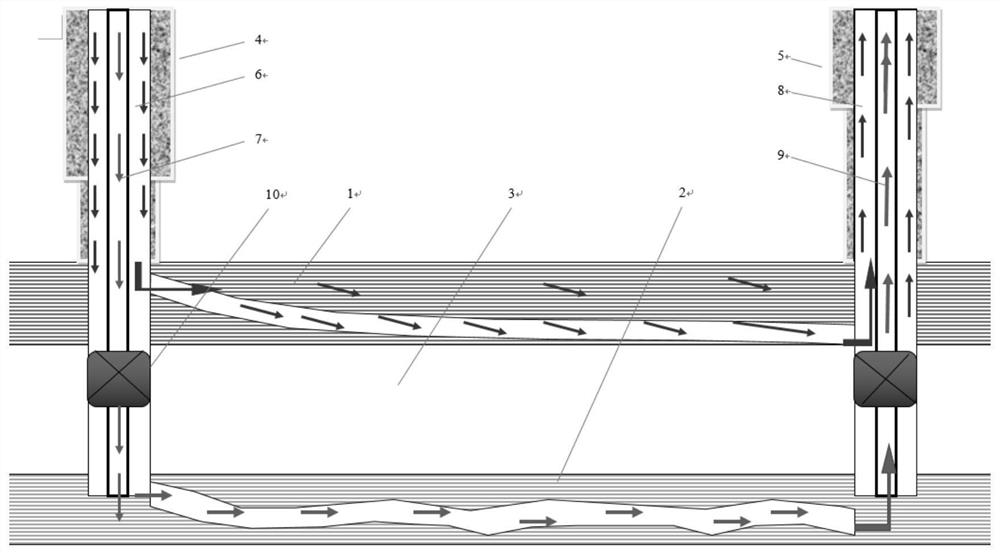

[0027] a kind of Na 2 CO 3 and NaHCO 3 According to the dual-horizon classification mining model, the first ore body layer 1, the second ore body layer 2, and the first ore body layer 1 and the second ore body layer 2 are distributed according to the depth from the surface from shallow to deep. It is separated by surrounding rock section 3, which also includes water injection well 4 and brine returning well 5, both of which run through the first ore body section 1, surrounding rock section 3 and second ore body section 2 ;

[0028]The water injection well 4 includes the water injection pipe 6 that runs through the first ore body section 1, the surrounding rock section 3 and the second ore body section 2, and the water injection center pipe 7 that is arranged in the water injection pipe 6; The brine return pipe 8 of the ore body section 1, the surrounding rock section 3 and the second ore body section 2, the brine return central pipe 9 arranged in the brine return pipe 8, th...

Embodiment 2

[0034] Classified Mining Na 2 CO 3 and NaHCO 3 The process includes the following steps:

[0035] S1. Select the mining section, the cumulative thickness of the first ore body section 1 and the second ore body section 2 is ≥0.5m, the thickness of the surrounding rock section 3 is ≥5m, and the surrounding rock section 3 has no permeability;

[0036] S2, set up water injection well 4 and return brine well 5, and insert water injection pipe 6 and water injection center pipe 7 in water injection well 4, insert return brine pipe 8 and return brine center pipe 9 in return brine well 5, and pass The water injection center pipe 7 and the brine return center pipe 9 are lowered into the packer 10, and the packer 10 is lowered to the corresponding position of the surrounding rock section 3, and then the seat seal is pressed once, and the water injection center pipe 7 and the second mine The layer section 2 of the ore body is connected with the brine return central pipe 9 separately to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com