A method for measuring the efficiency of an independent condensing steam-driven induced draft fan

A measuring method and technology for induced draft fans, which are applied in steam engine installations, engine components, machines/engines, etc., can solve the problem that the output power of small steam turbines cannot be directly and accurately measured, which affects the calculation accuracy of induced draft fan efficiency. and other problems, to achieve the effect of less parameters and low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0042] Implementation Example 1

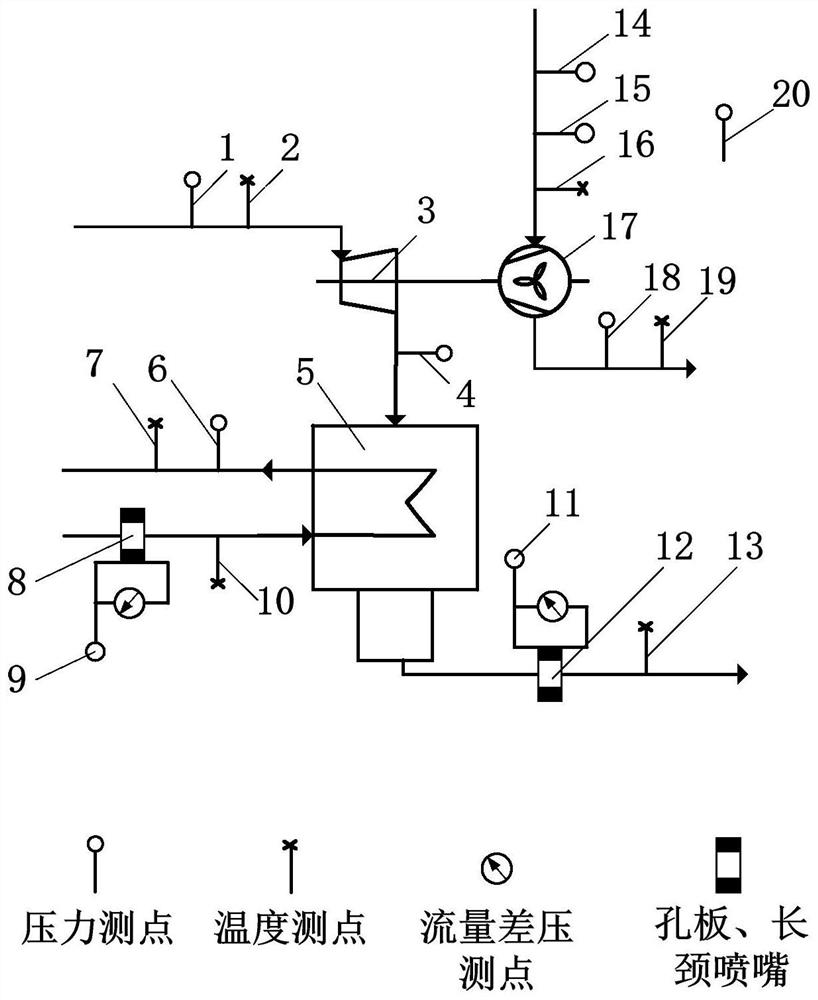

[0043] like figure 1 As shown, the present invention is a method for measuring the efficiency of an independent condensing steam-driven induced draft fan. The system based on the method includes a condenser 5, a small steam turbine 3 and a steam-driven induced draft fan 17 arranged coaxially; The small steam turbine inlet steam pressure transmitter 1 and the small steam turbine inlet steam temperature measuring element 2 are arranged on the steam inlet pipeline. The steam outlet pipeline is provided with a small steam turbine exhaust absolute pressure transmitter 4; the circulating water outlet pipe of the condenser 5 is provided with a condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com