A gas-hydraulic compound drive type speed-increasing cylinder device

A driving type, speed-increasing cylinder technology, applied in the direction of fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of limited driving stroke and unadjustable speed, and achieve the effect of improving driving stroke, compact structure and increasing maximum speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

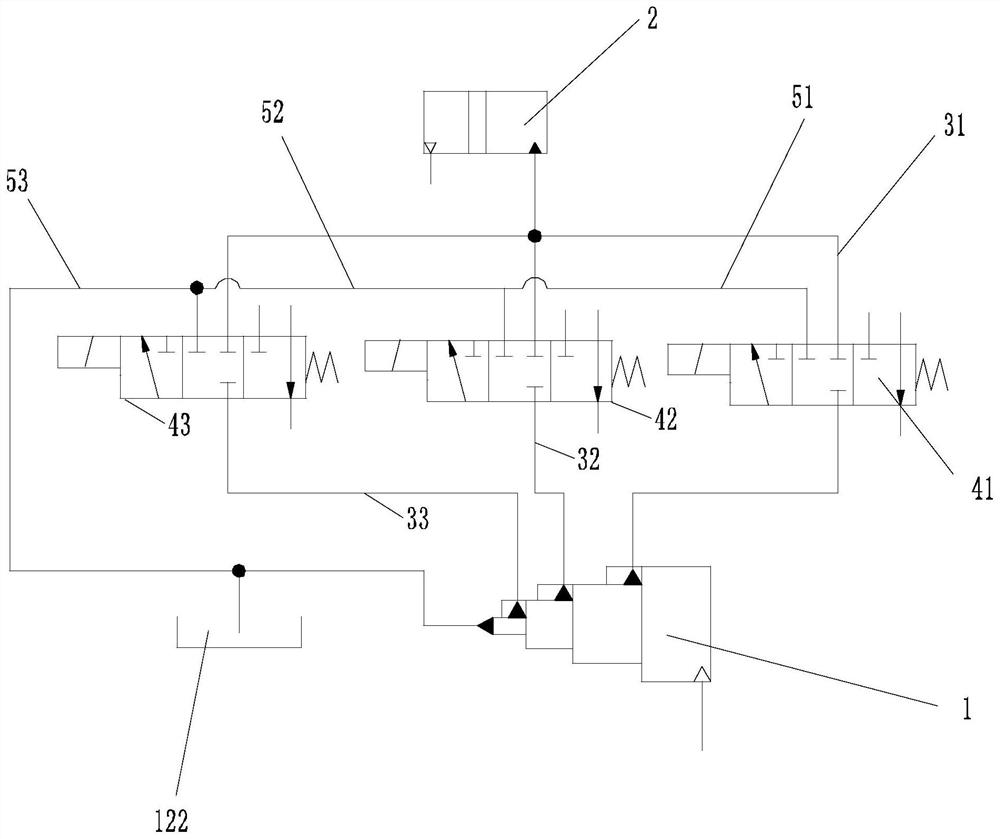

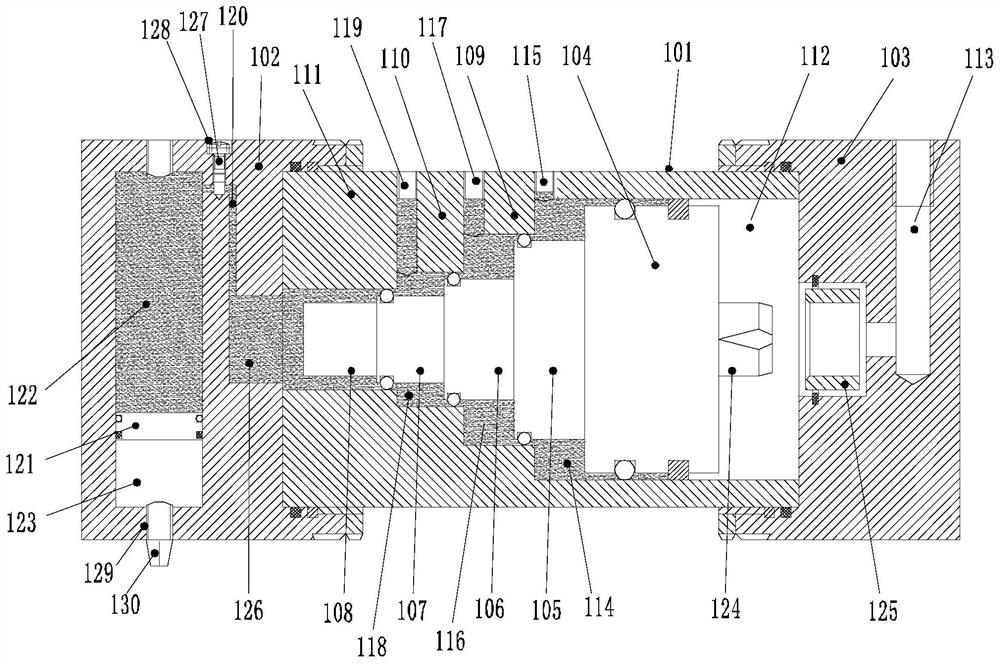

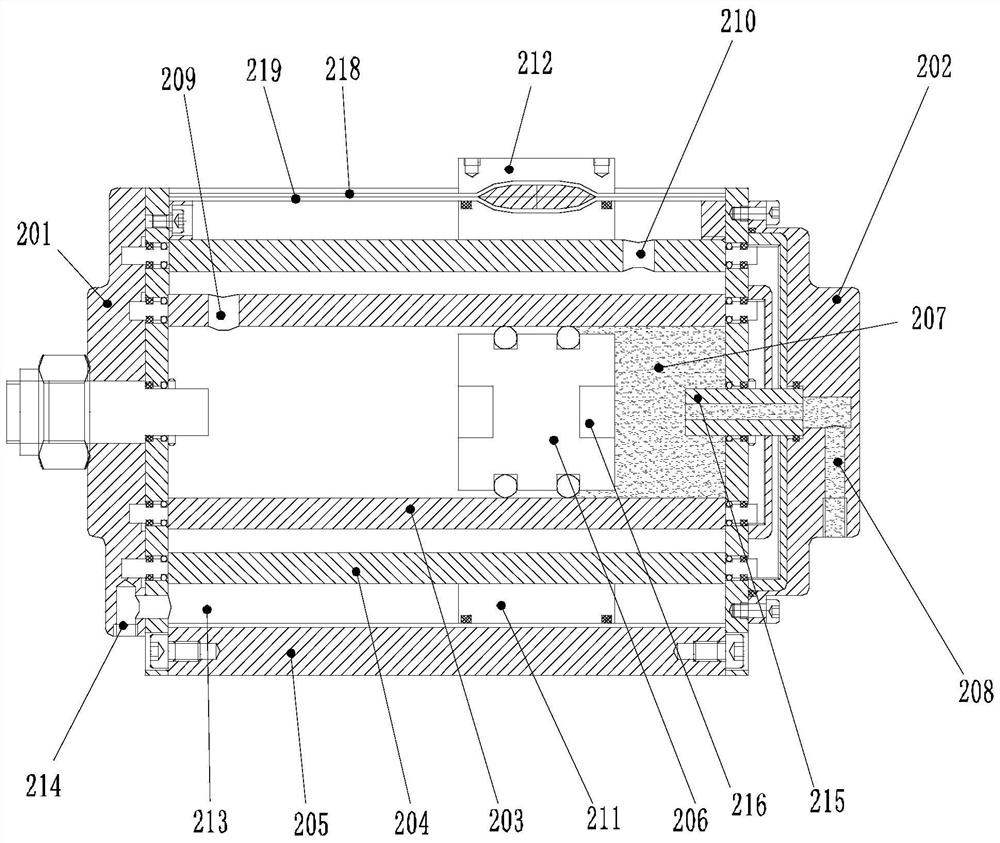

[0026] like Figure 1 to Figure 4 Shown: This embodiment provides a gas-liquid composite drive type speed-increasing cylinder device, including a drive cylinder 1 and a speed cylinder 2; the drive cylinder 1 provides driving force, and the speed cylinder 2 forms different speed-ups.

[0027] The drive cylinder 1 includes a cylinder barrel I101, a front end cover I102 and a rear end cover I103 connected to the front and rear ends of the cylinder barrel I101; the cylinder barrel I101 is provided with a variable area piston that reciprocates along its axial direction. The piston is a segmented structure and includes a first piston segment 104, a second piston segment 105, a third piston segment 106, and a fourth piston segment 107, which are fixedly connected in sequence from back to front and whose longitudinal cross-sectional areas are sequentially reduced. The inner wall of I101 protrudes inward and forms a first ring platform 109, a second ring platform 110 and a third ring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com