Operating system for intelligent lifting engineering of roasting furnace

A technology of operating system and roasting furnace, applied in the field of roasting furnace, can solve problems such as poor performance, waste of graphite or carbon resources, roasting efficiency, failure of self-adaptive adjustment of graphite or carbon resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

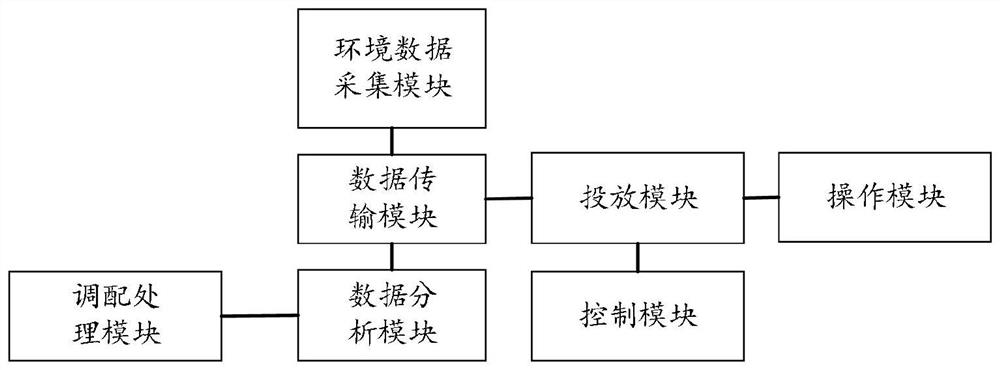

[0037] see figure 1 As shown, the present invention is an operating system for an intelligent upgrading project of a roasting furnace, including an environmental data acquisition module, a delivery module, a data analysis module, a deployment processing module, a control module, an operation module and a data transmission module;

[0038] The environmental data acquisition module is used to collect environmental collection data in the roasting furnace, the environmental collection data includes exhaust air data, transport gas data, furnace pressure data and furnace temperature data; the input module is used to collect data according to the environment The data controls the feeding amount of the roasting furnace;

[0039] The data analysis module is used to analyze the status information of the blanking in the roasting furnace according to the environmental collection data, and the specific analysis steps are as follows:

[0040] Step 1: Obtain exhaust air data, gas delivery d...

Embodiment 2

[0058] Roasting furnace A processes graphite or carbon, and ensures the temperature in roasting furnace A by adjusting the amount of graphite or carbon and the gas pressure, wherein the gas can be gas; the exhaust gas generated during graphite or carbon processing The air volume can be obtained by adjusting the opening of the fan damper and the speed of the motor;

[0059] Obtain exhaust air data, transport gas data, furnace pressure data, and furnace temperature data, and set the air volume exhausted by the roaster before loading in the exhaust air data as the first exhaust air volume, which can be 8.5m 3 / s, set the amount of gas delivered by the roaster before feeding in the gas delivery data as the first delivered gas quantity, and the first delivered gas quantity can be 300m 3 / s, set the furnace pressure before the roasting furnace blanking in the furnace pressure data to be the first furnace pressure, the first furnace pressure can be 20kpa, set the furnace temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com