Patents

Literature

37results about How to "Increase the inner area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

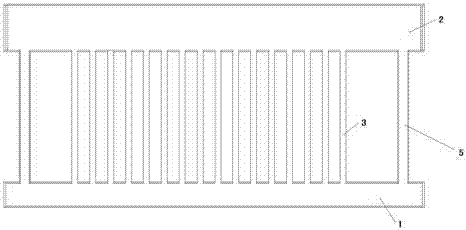

Heat pipe with multi-hole flow stabilizing devices

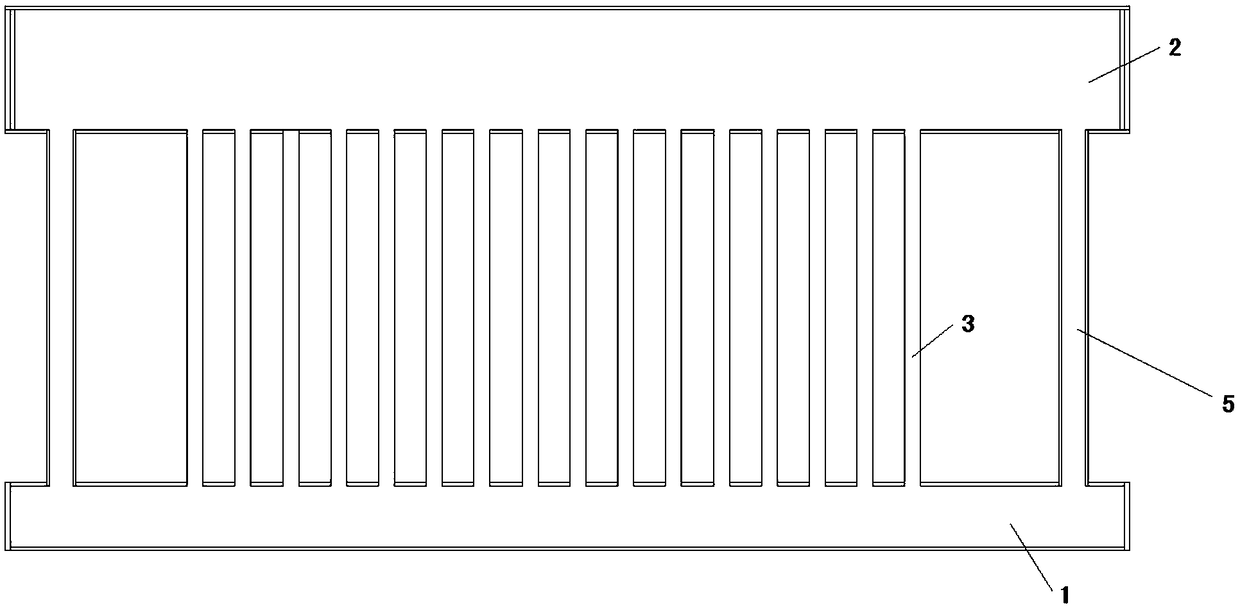

ActiveCN107044789AReduce vibrationImprove heat transfer performanceIndirect heat exchangersVapor liquidNoise level

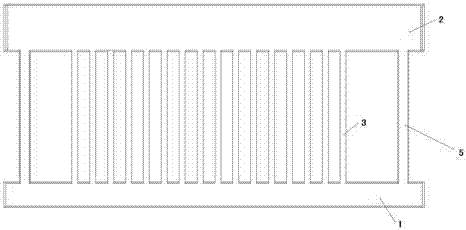

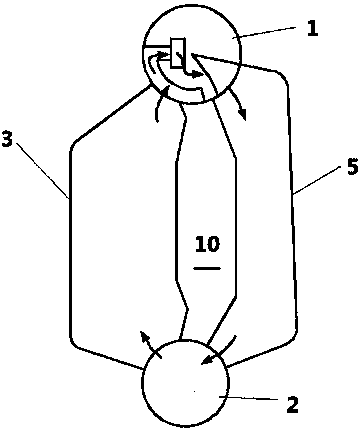

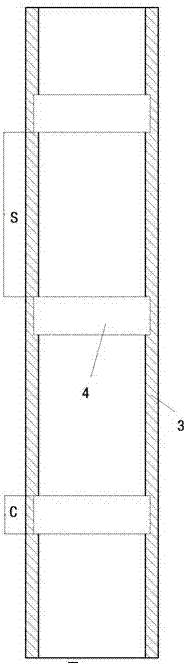

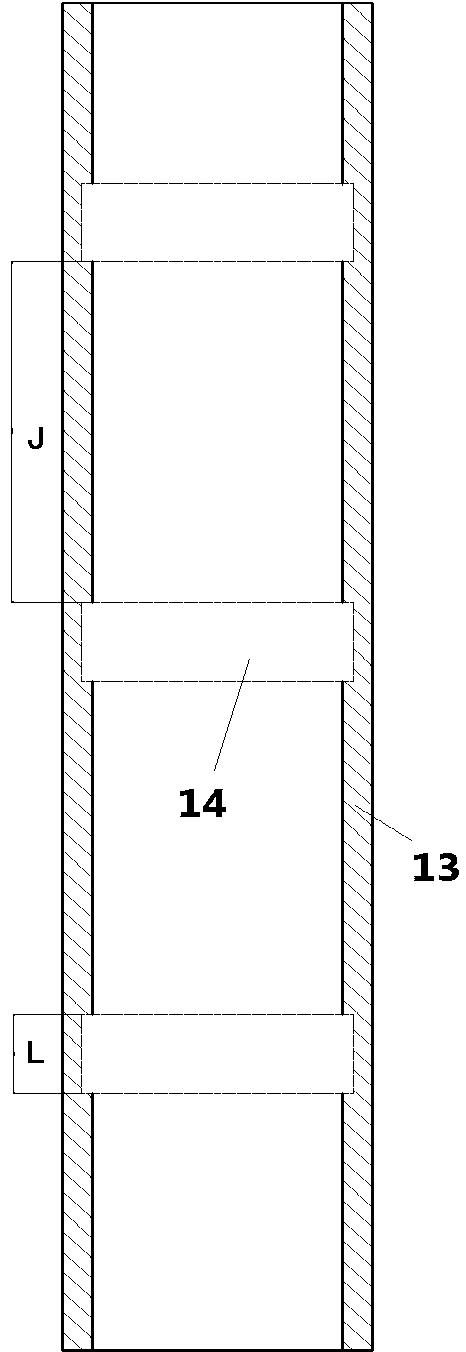

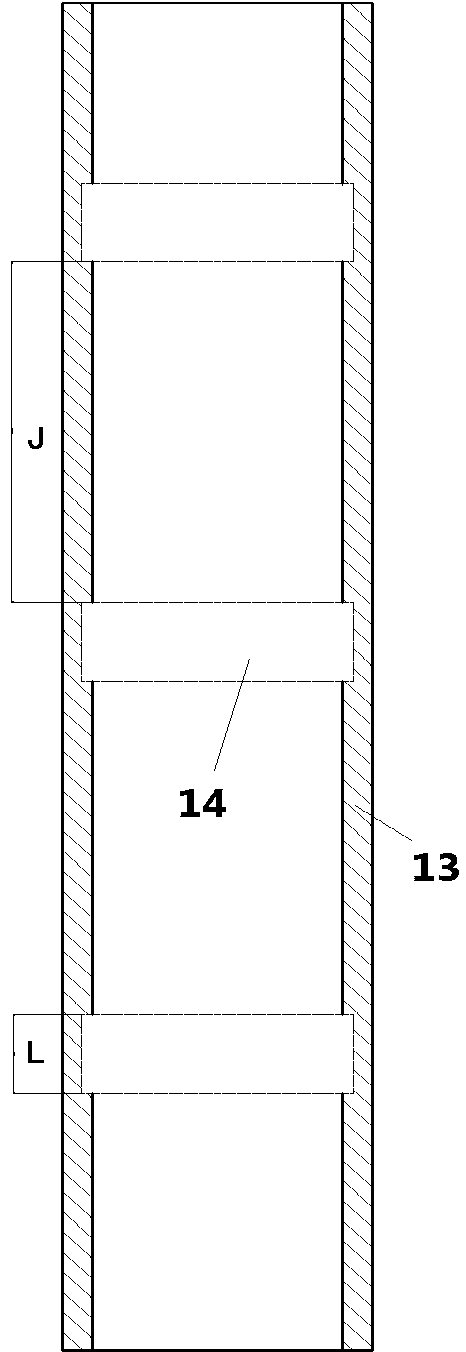

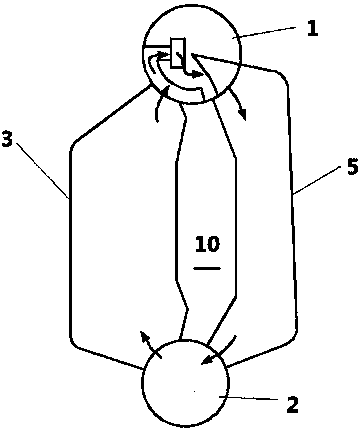

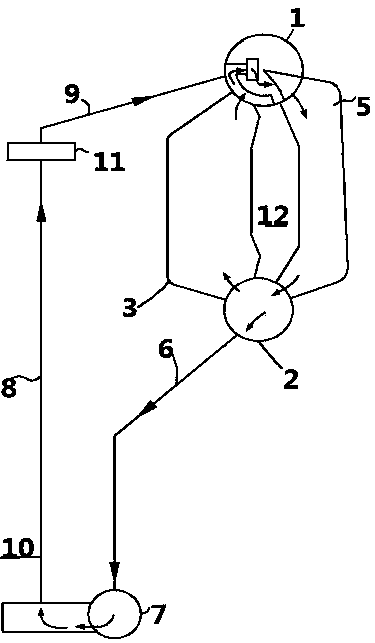

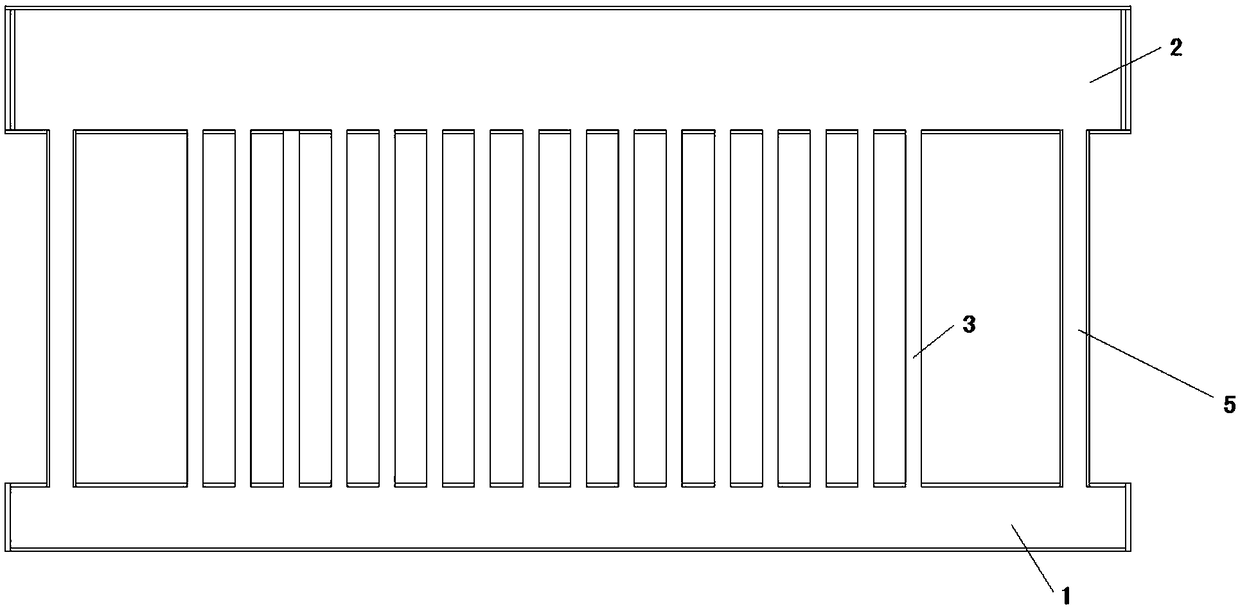

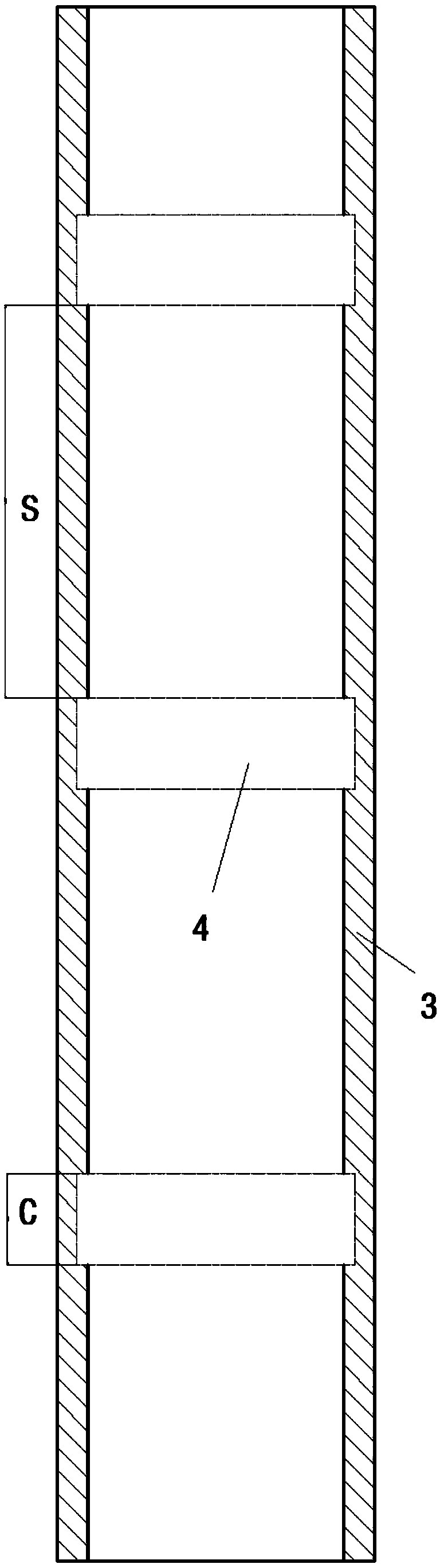

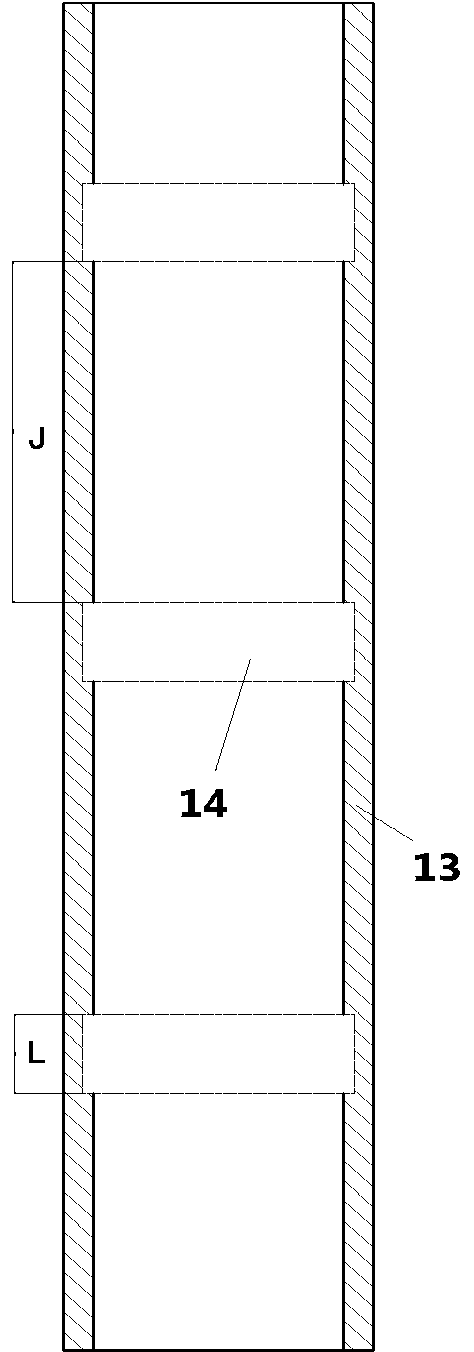

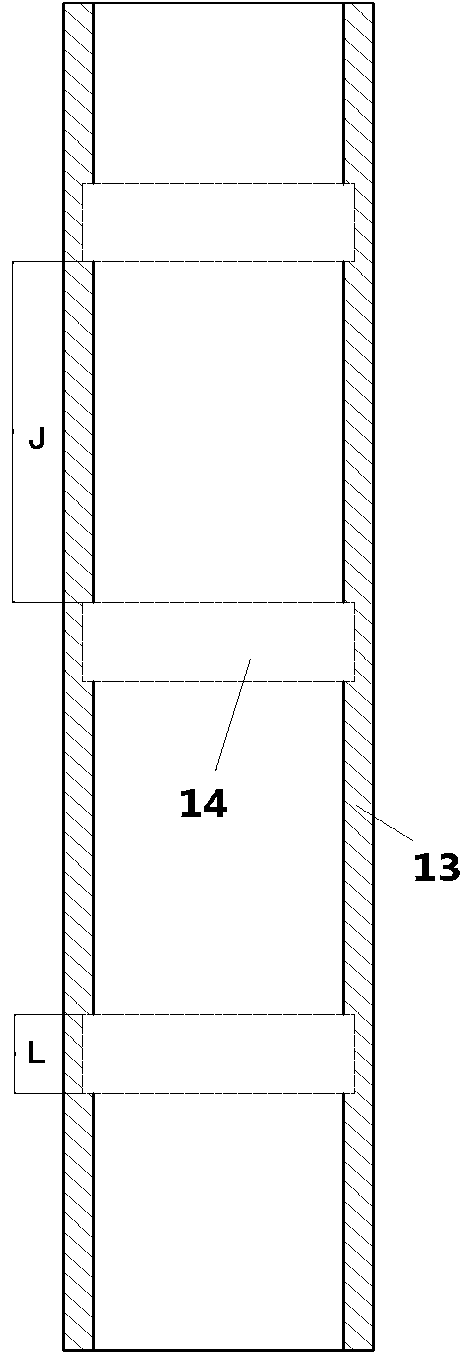

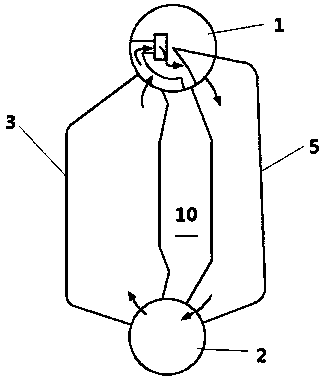

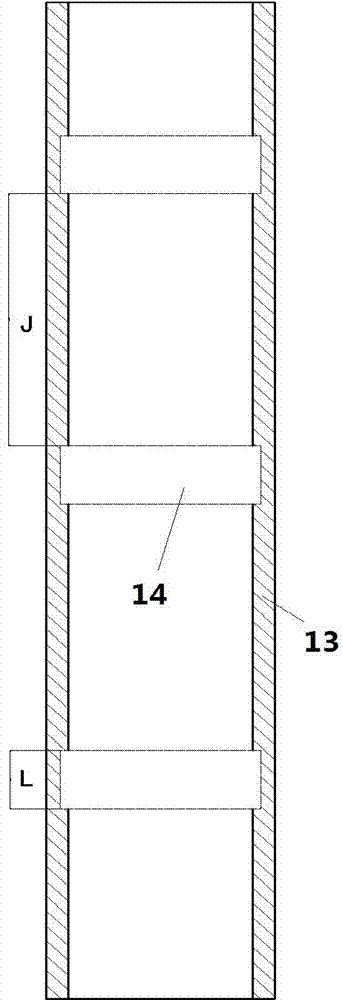

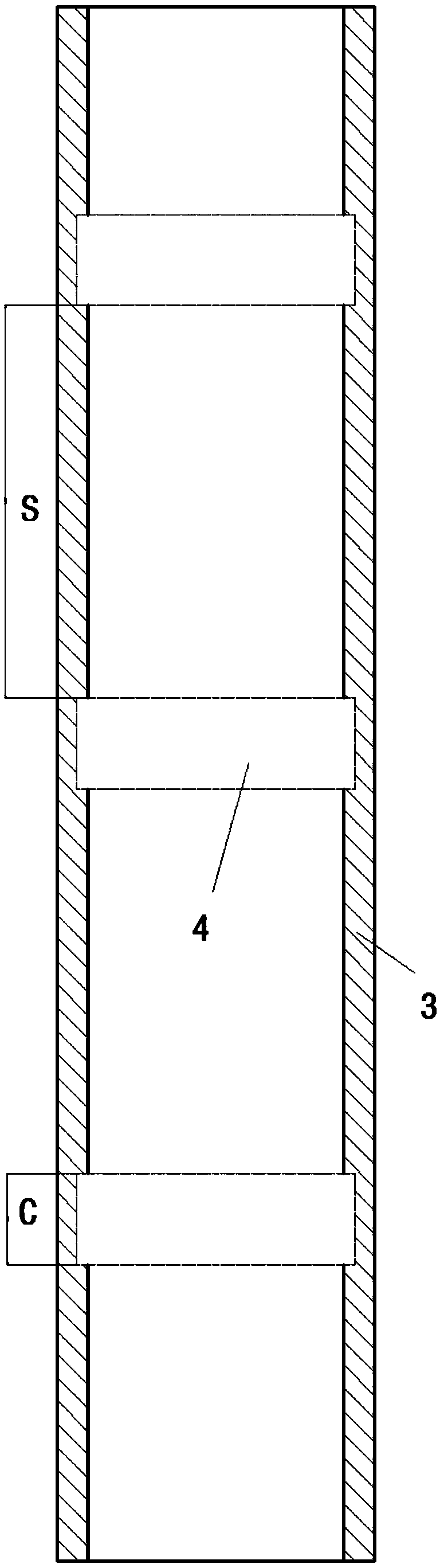

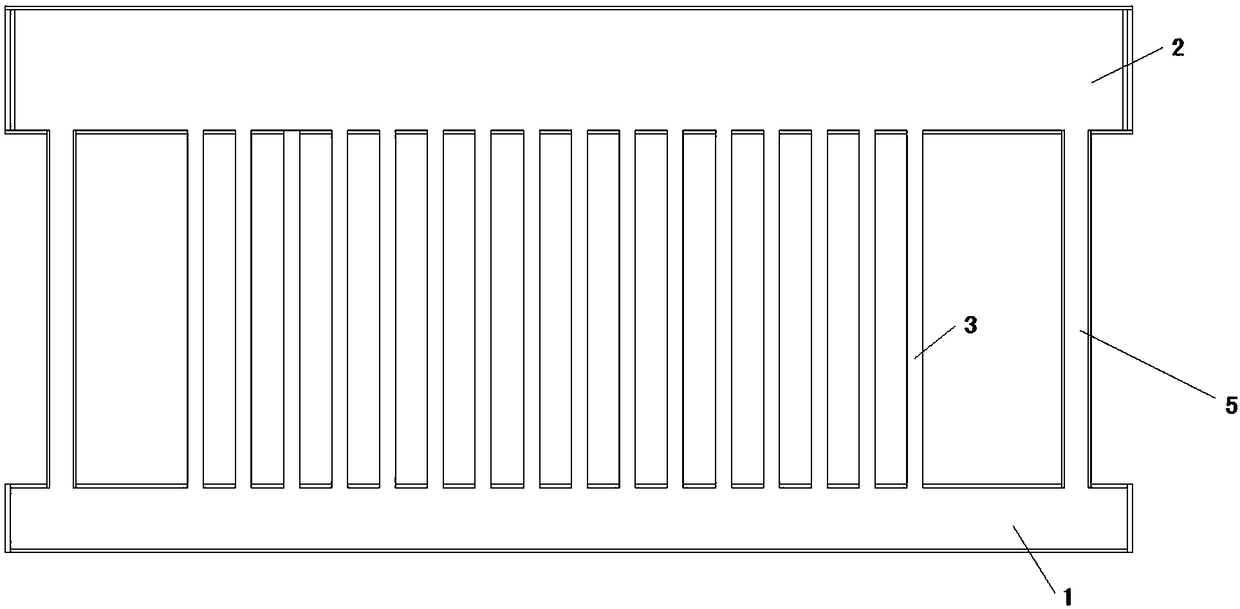

The invention provides a heat pipe which comprises an evaporation collecting pipe, a condensation collecting pipe, ascending pipes and return pipes, wherein the ascending pipes are communicated with each of the evaporation collecting pipe and the condensation collecting pipe; the evaporation collecting pipe is positioned at the lower part; the condensation collecting pipe is positioned at the upper part; a fluid absorbs heat and evaporates in the evaporation collecting pipe, the vapor passes through the ascending pipes to enter the condensation collecting pipe and is condensed in the condensation collecting pipe after being subjected to heat exchange, and the condensed fluid returns back into the evaporation collecting pipe through the return pipes; the flow stabilizing devices are arranged in each of the same ascending pipe; the lengths of the flow stabilizing devices are constantly increased in the height directions of the ascending pipes;. According to the heat pipe with multi-hole flow stabilizing devices, the lengths of the flow stabilizing devices are changed, so that when vapor-liquid two-phase flows exist in the ascending pipes, heat transfer is enhanced, the vibration of the ascending pipes is weakened, and the noise level is reduced.

Owner:山东路德交通科技有限公司

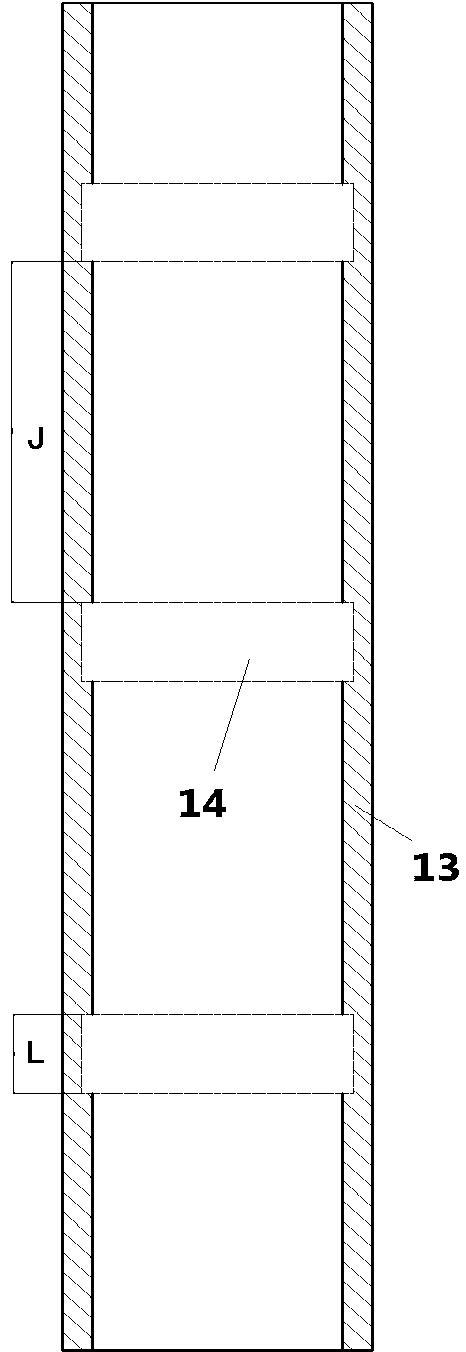

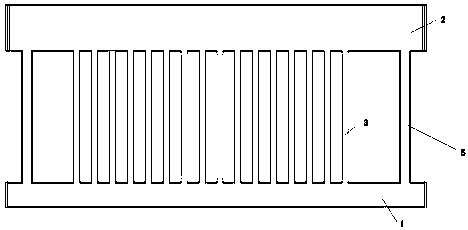

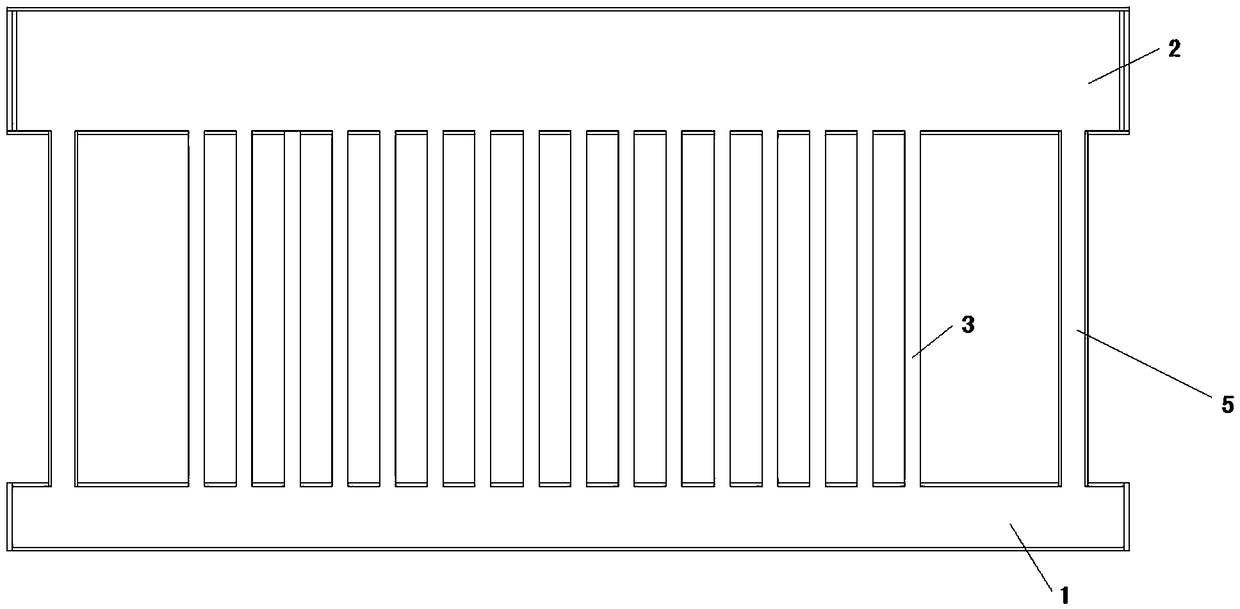

Steam boiler

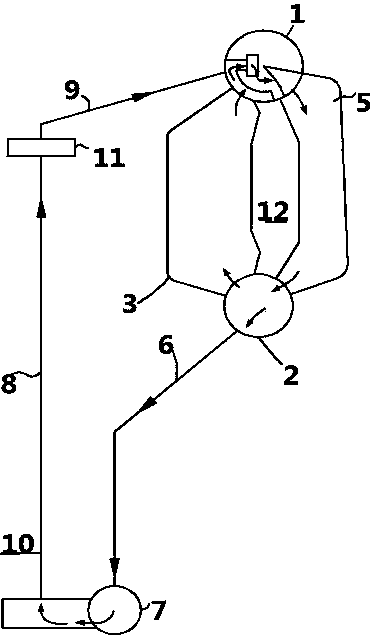

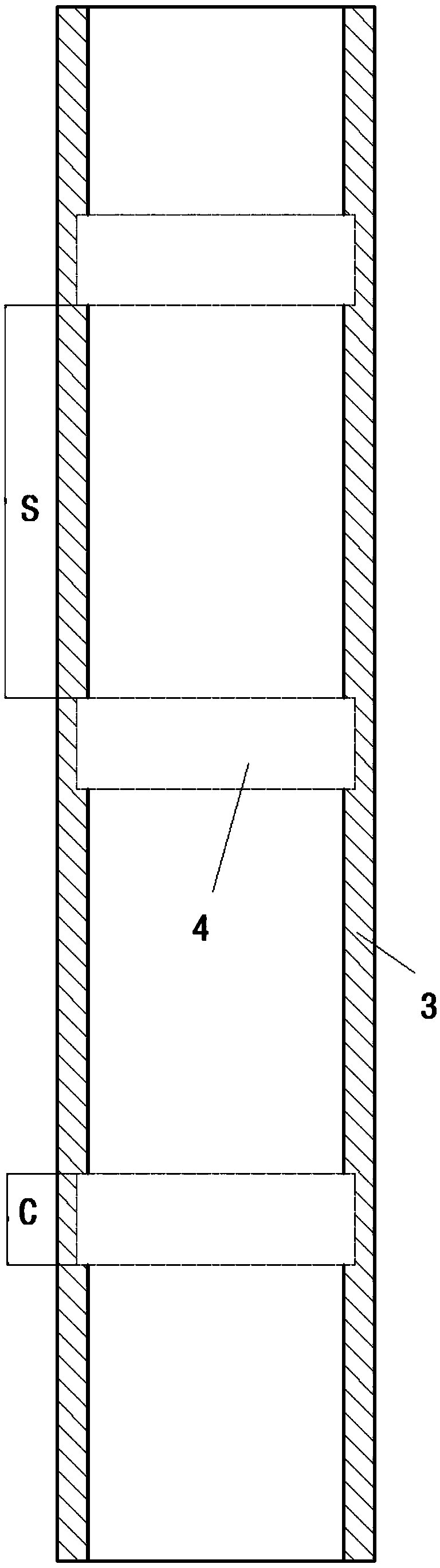

ActiveCN108332181ASpeed up the flowHas the effect of reducing vibration and noiseBoiler water tubesWater circulation promotionEngineeringHeat transfer

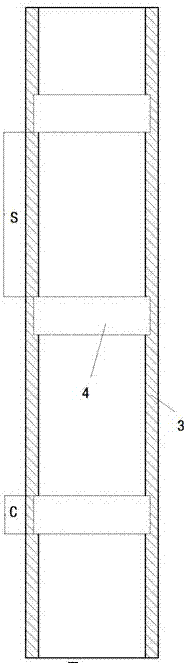

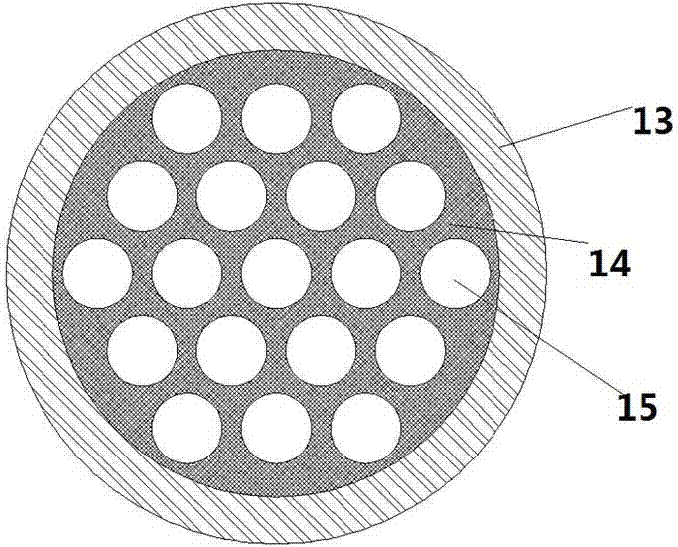

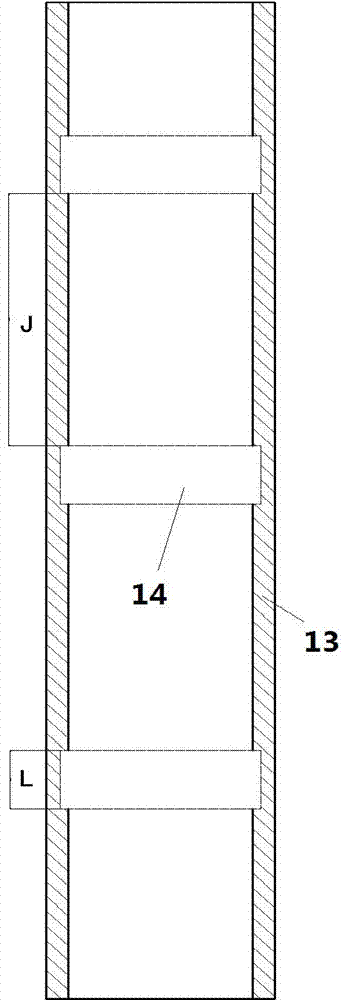

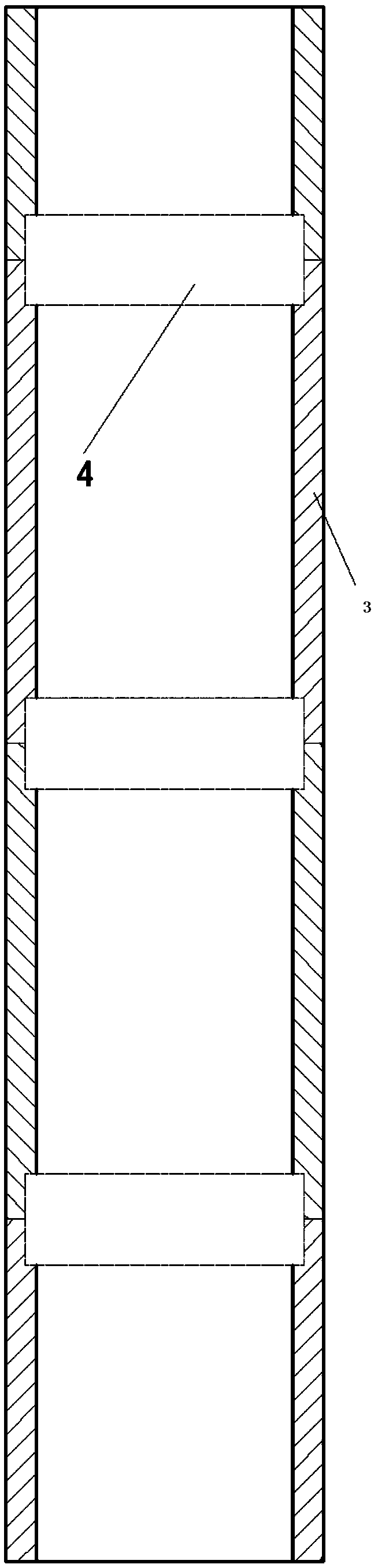

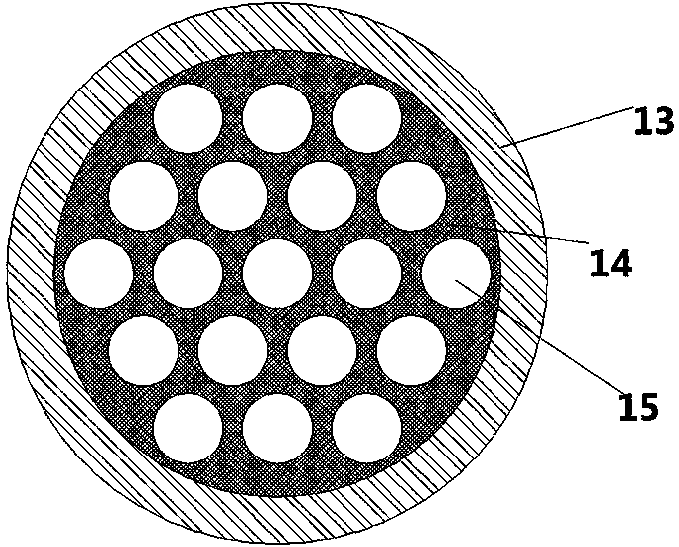

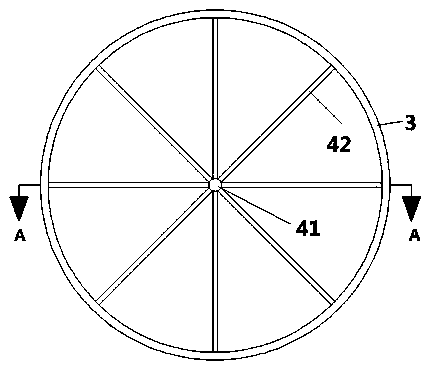

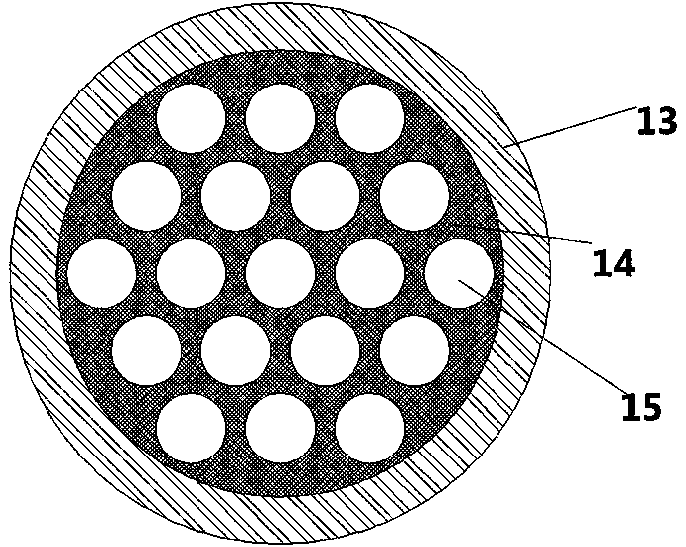

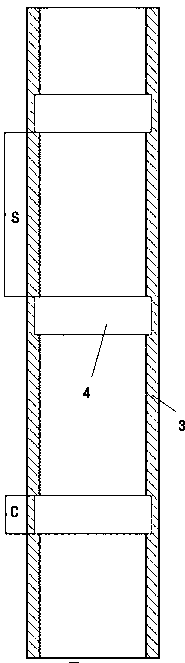

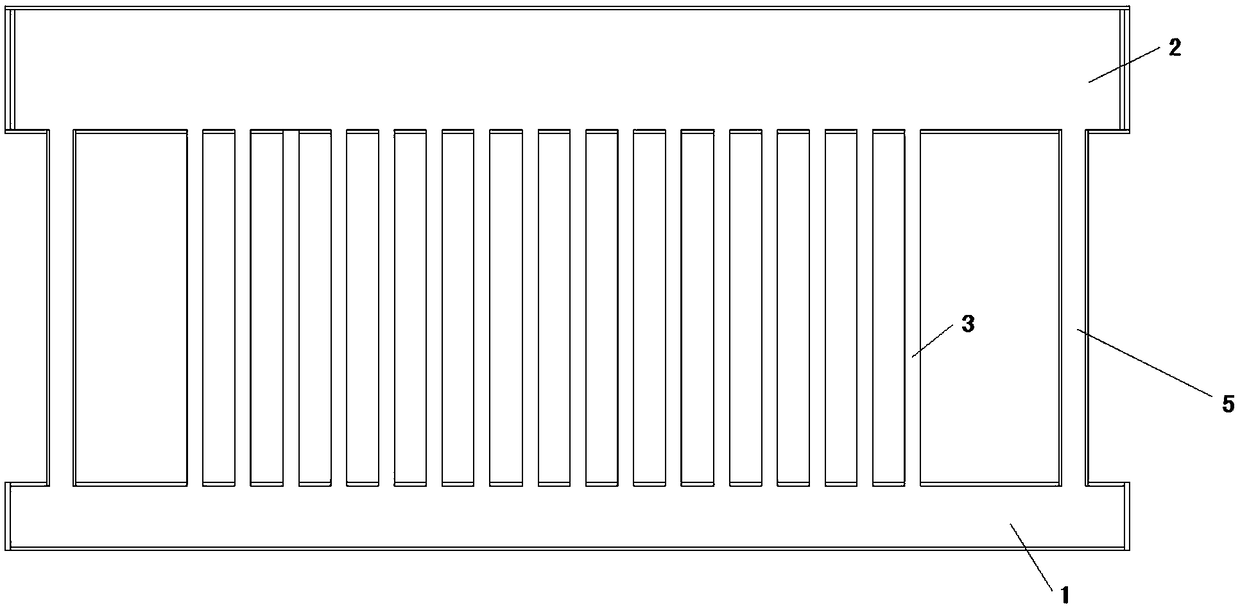

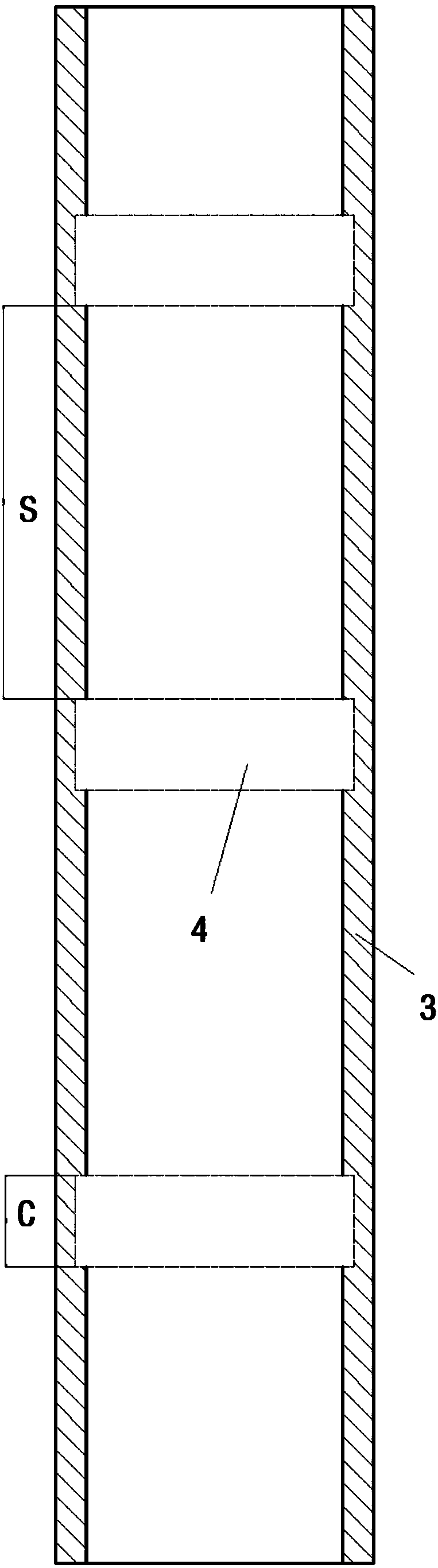

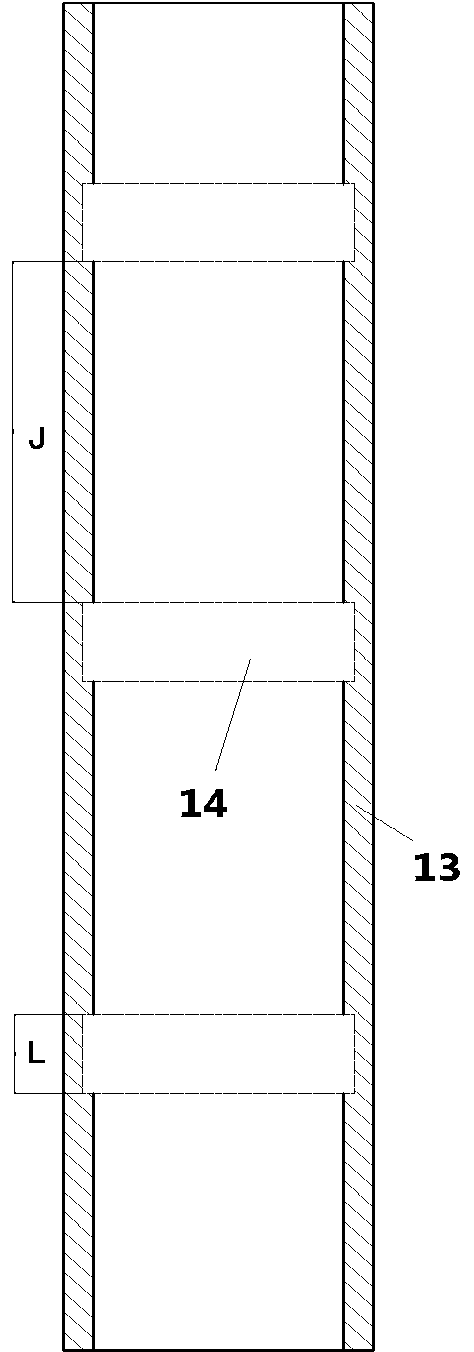

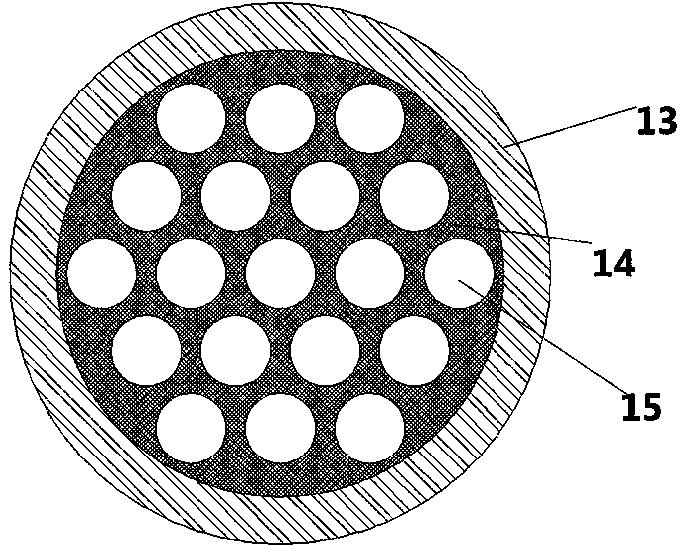

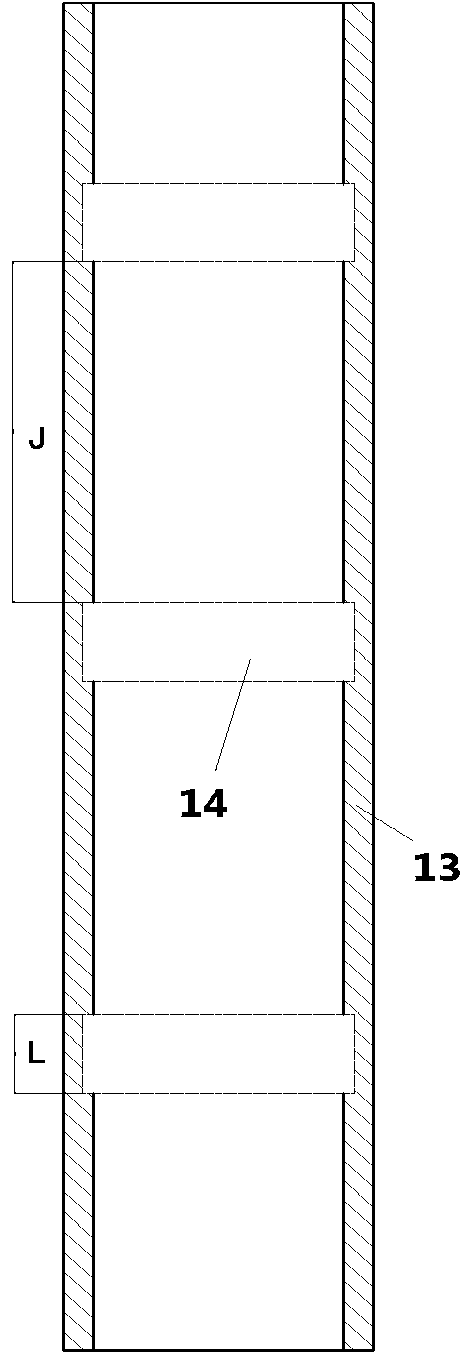

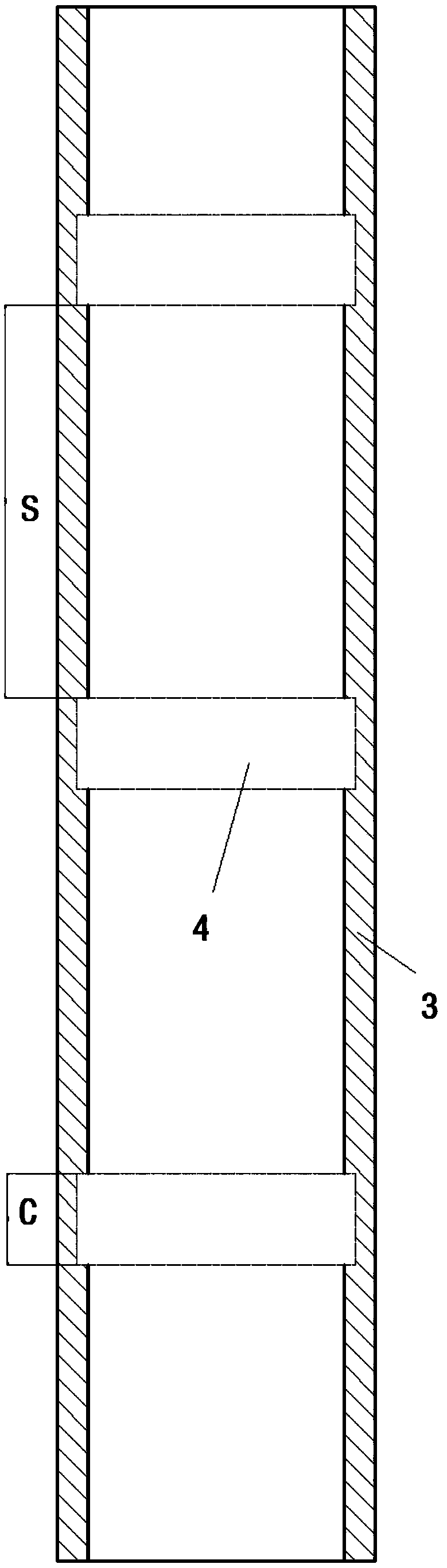

The invention provides a steam boiler which comprises an upper boiler barrel, a lower boiler barrel, ascending pipes and descending pipes; the ascending pipes and the descending pipes are connected between the upper boiler barrel and the lower boiler barrel; flow stabilization devices are arranged in the ascending pipes; each flow stabilization device comprises a core body axially arranged the center of the corresponding ascending pipe and a plurality of radial rods extending along the center rod to the radial directions; a plurality of fins extending from the radial rod downwards are arrangedon each radial rod; the fins are provided with sharp parts; and the sharp parts face downwards. With the adoption of the novel structure steam boiler with the flow stabilization devices, when gas-liquid two-phase flowing exists in the ascending pipes, heat transfer is improved, vibration of the ascending pipes is weakened, and the level of noise is lowered.

Owner:青岛吉云德和商贸有限公司

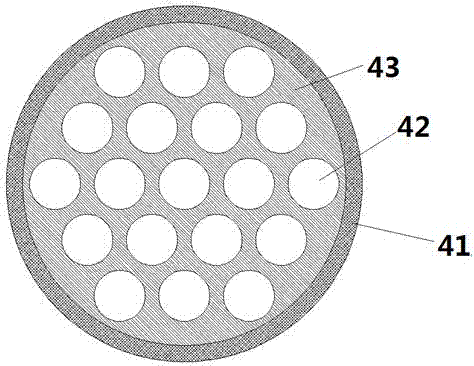

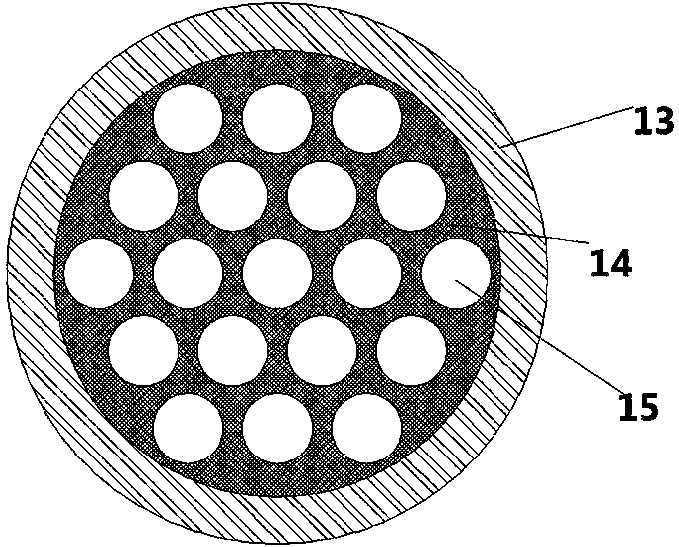

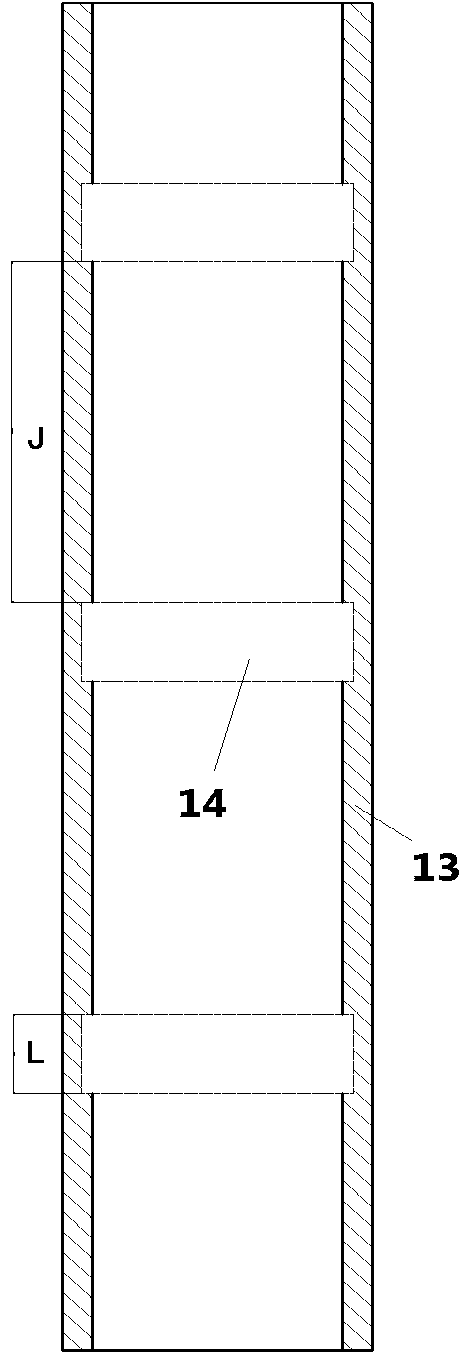

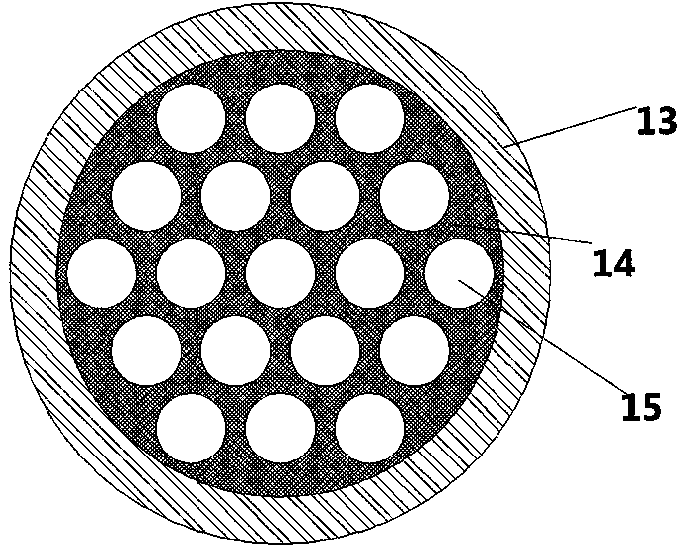

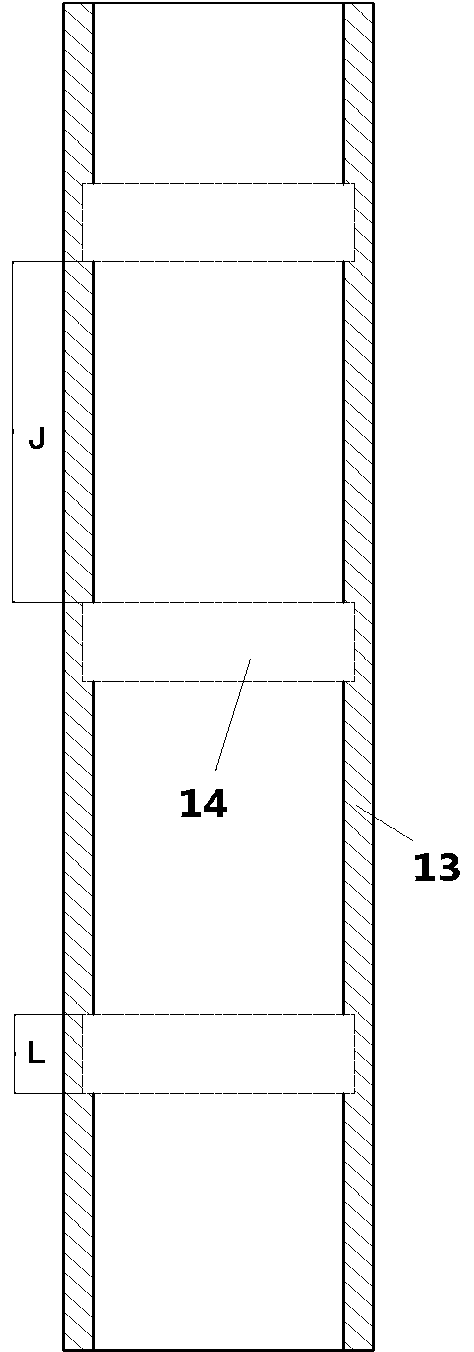

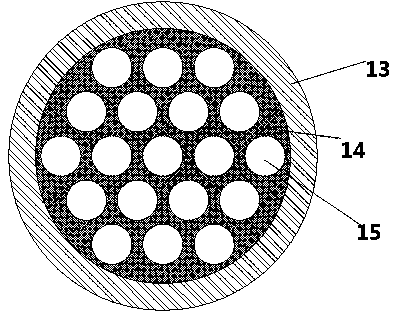

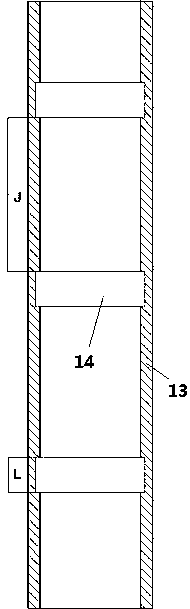

Heat pipe

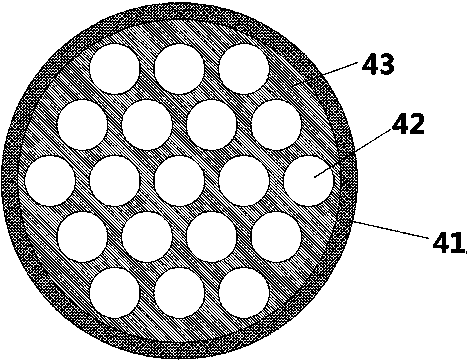

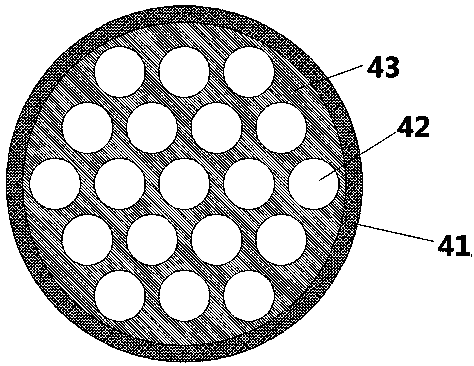

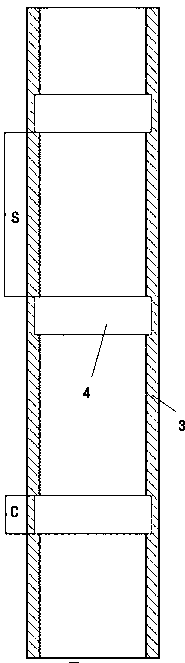

ActiveCN107062959AInhibit refluxSpeed up the flowSafety devices for heat exchange apparatusIndirect heat exchangersNoise levelEvaporation

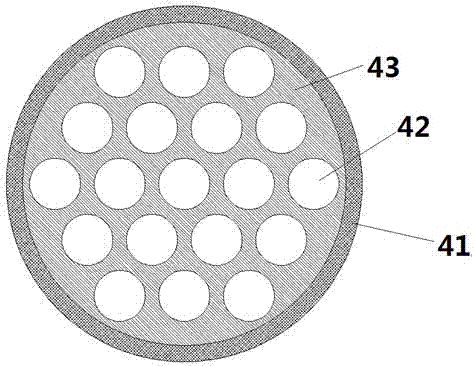

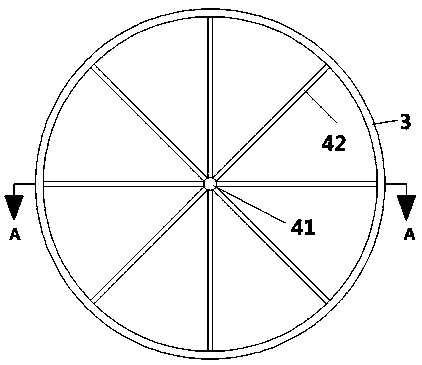

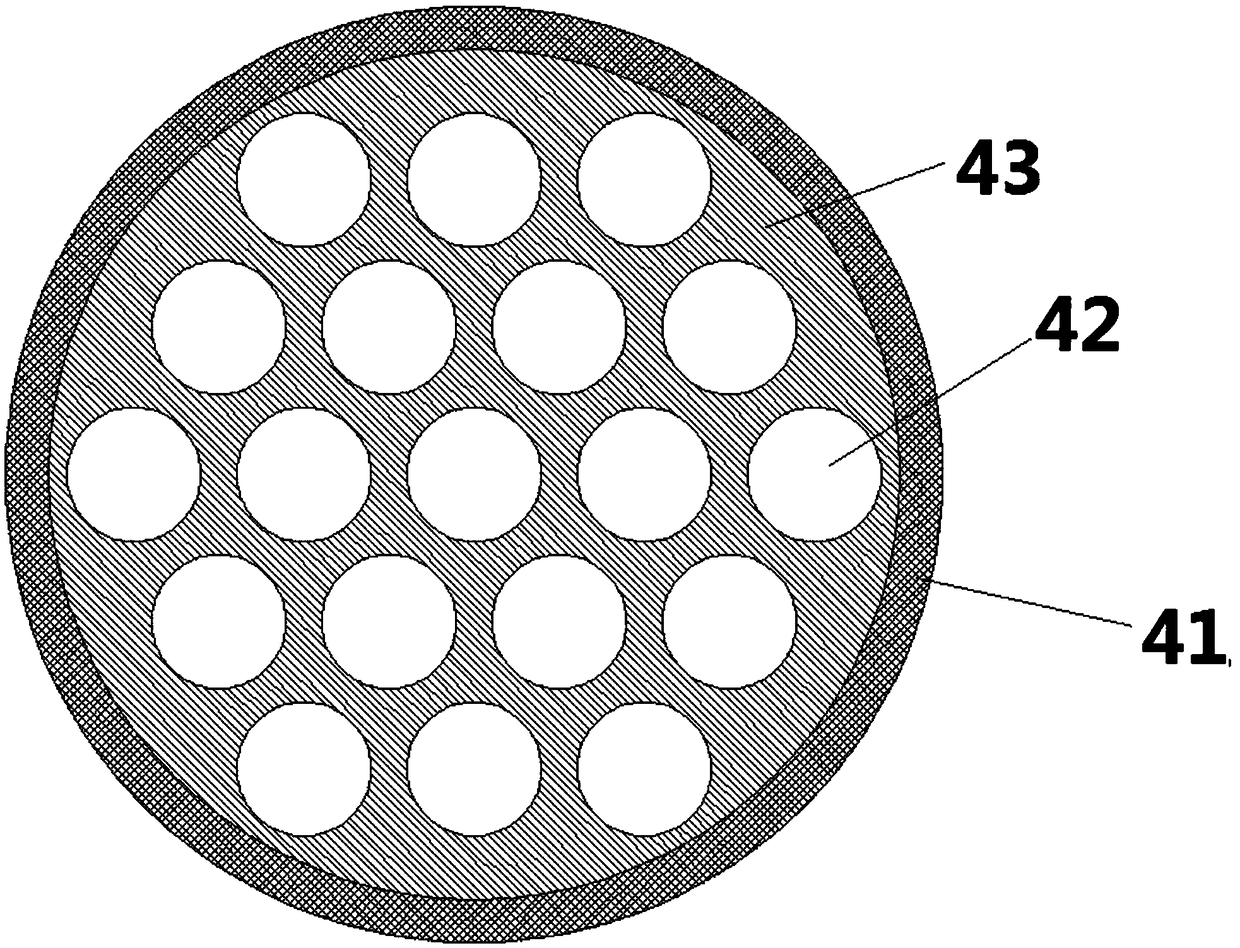

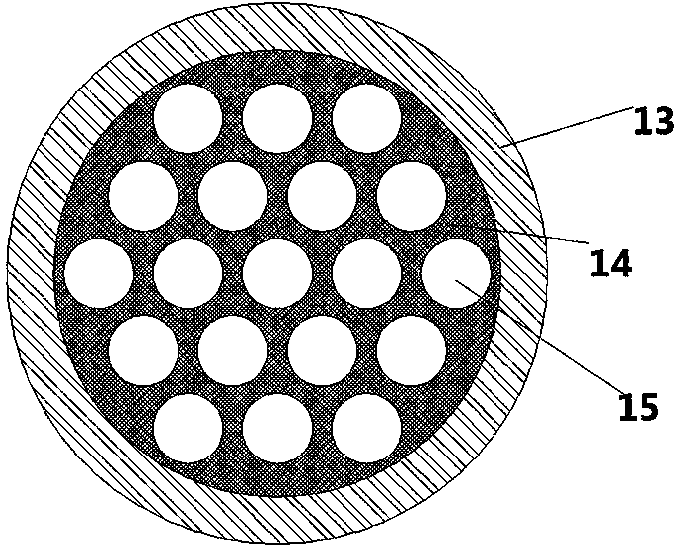

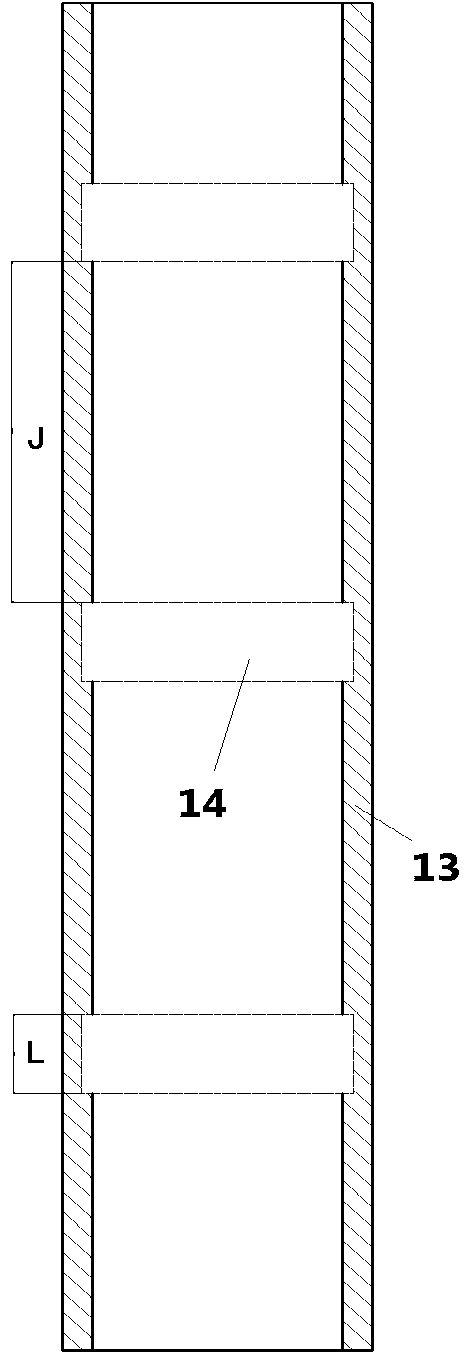

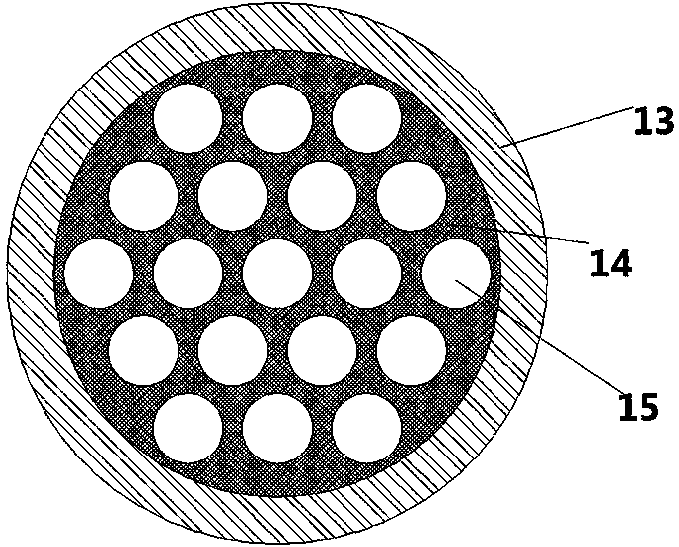

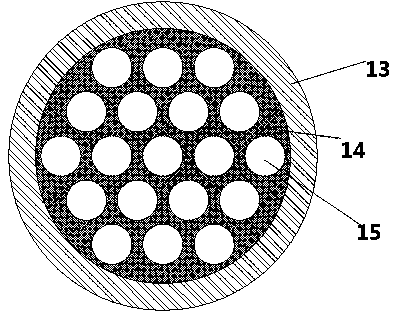

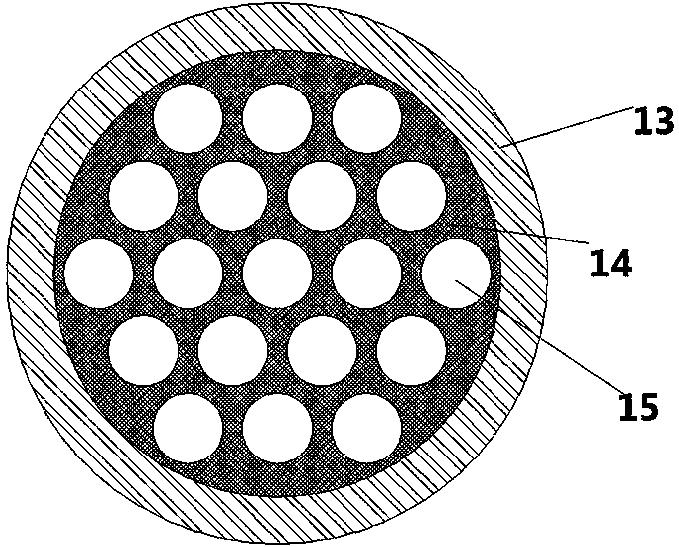

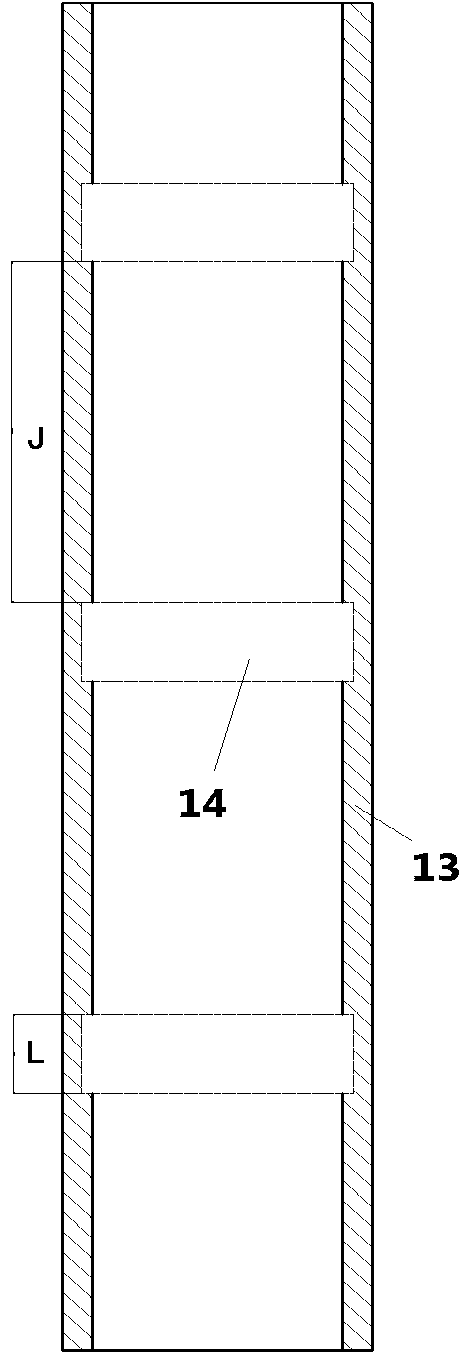

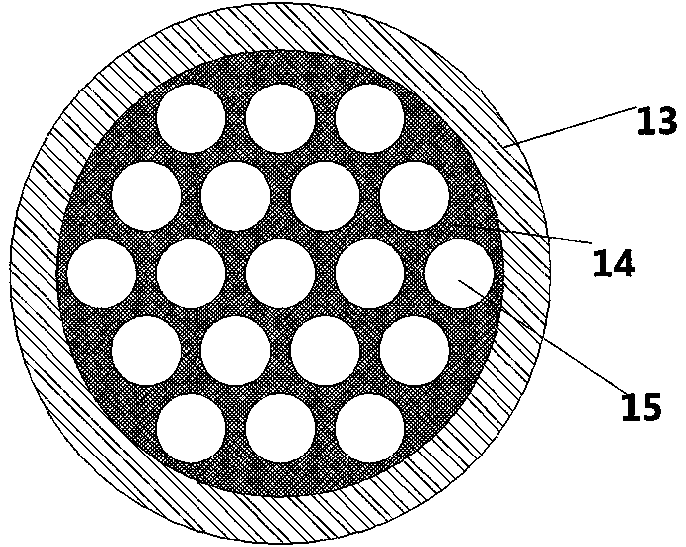

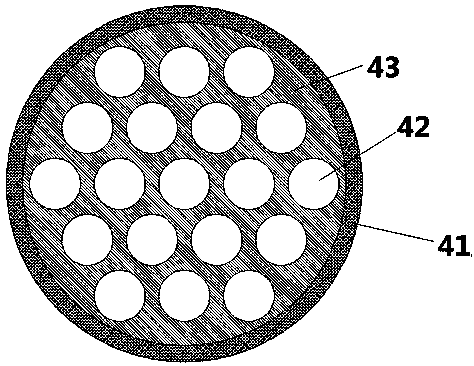

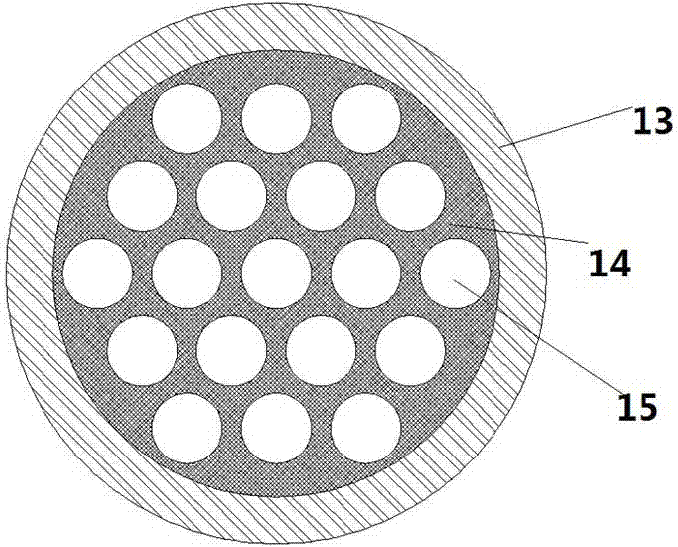

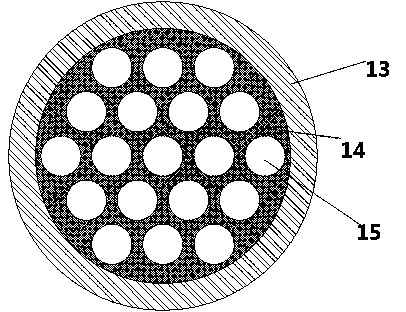

The invention provides a heat pipe which comprises an evaporation header, a condensation header, a rising pipe and a backflow pipe. The rising pipe is communicated with the evaporation header and the condensation header, the evaporation header is located at the lower portion, the condensation header is located at the upper portion, fluid absorbs heat and evaporates in the evaporation header, passes through the rising pipe to enter the condensation header and conducts heat exchange and condensation in the condensation header, and condensation fluid returns to the evaporation header through the backflow pipe; and a current stabilizer is arranged in the rising pipe and comprises a core body and a shell, the core is arranged in the shell, the shell is fixedly connected with the inner wall of the rising pipe, the core is an integrated structure piece extending in the length direction of the shell, and a plurality of through holes are formed in the structure piece. According to the heat pipe with the current stabilizer of the new structure, when vapor-liquid two-phase flow exists in the rising pipe, heat transfer strengthening is achieved; and meanwhile, vibration of the rising pipe is weakened, and the noise level is reduced.

Owner:JIANGSU TONGSHENG HEAT EXCHANGER

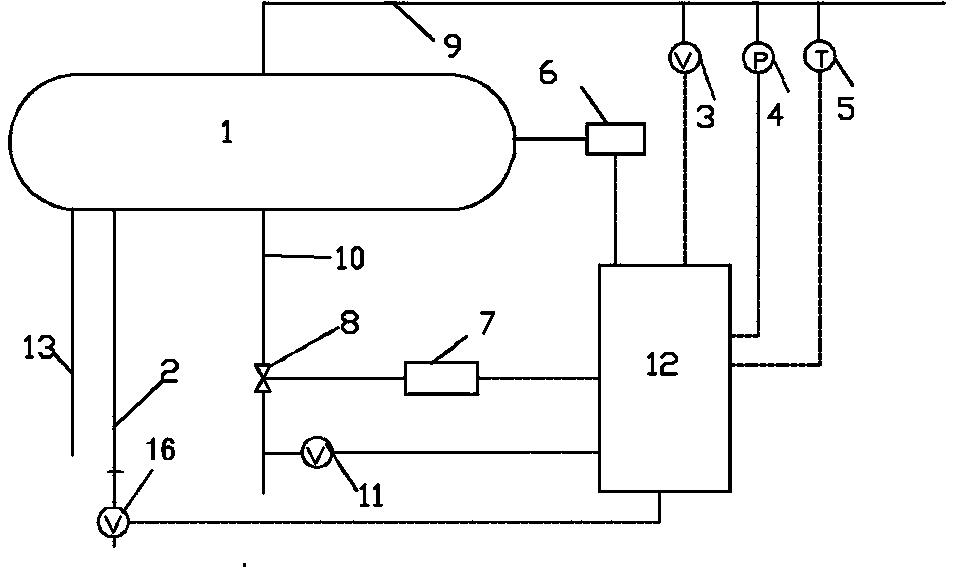

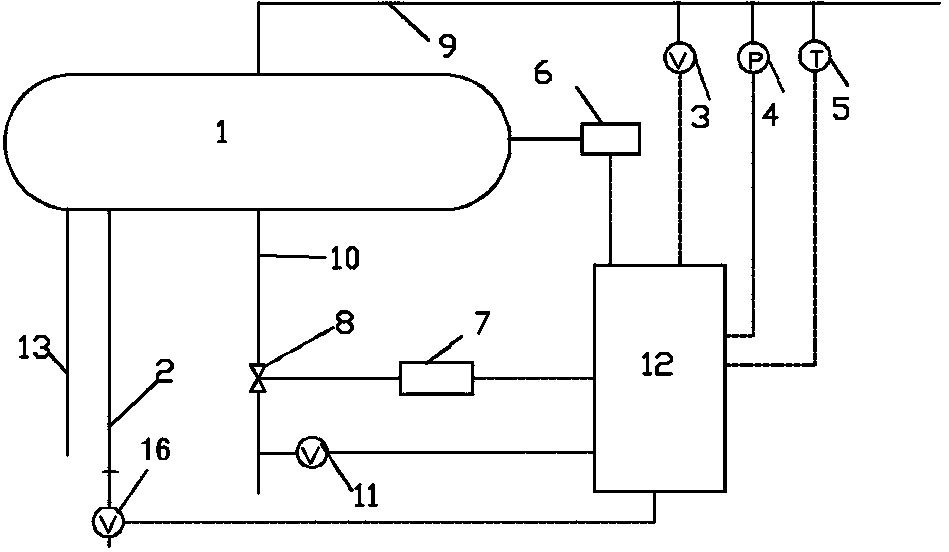

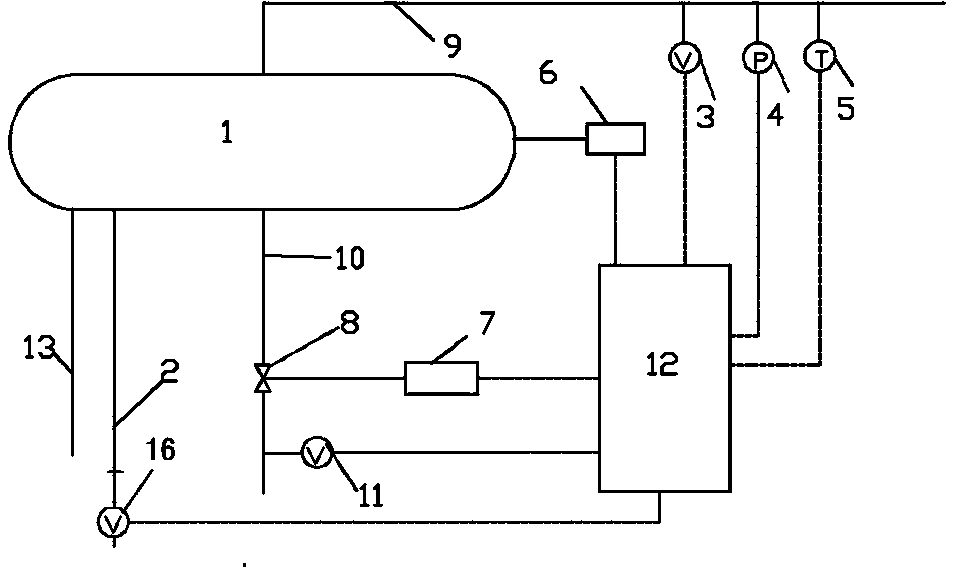

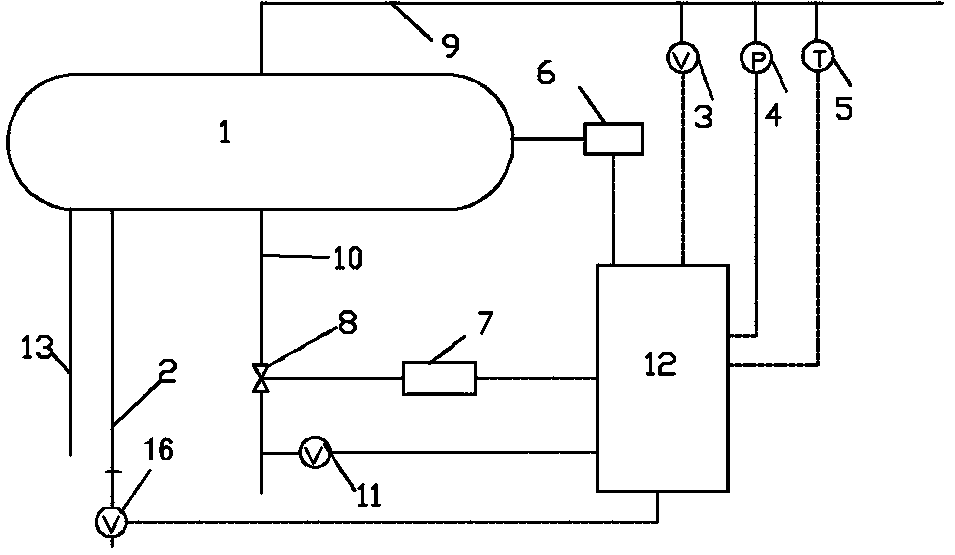

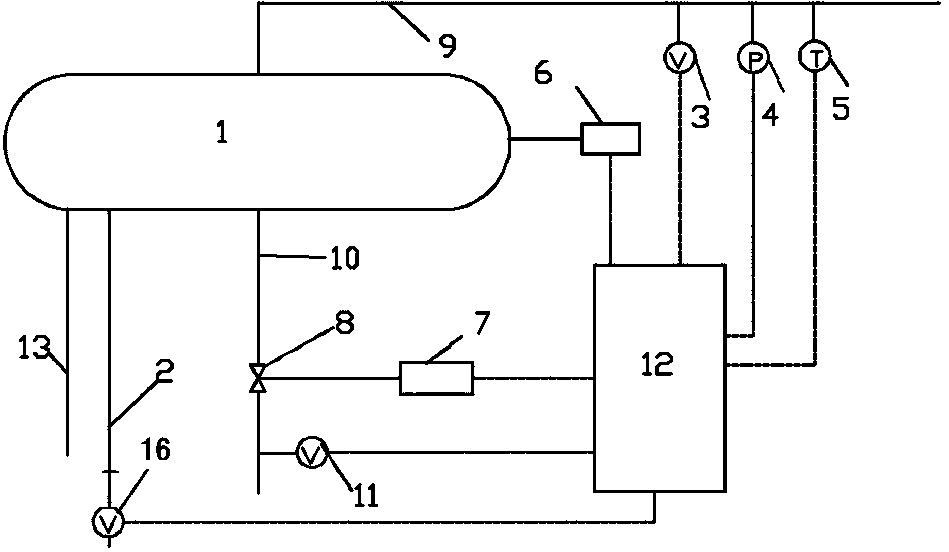

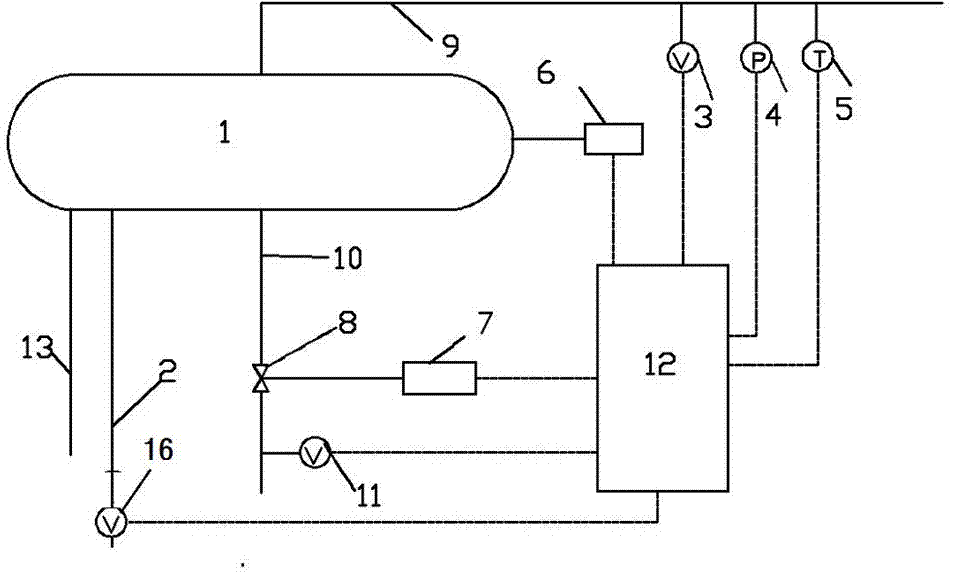

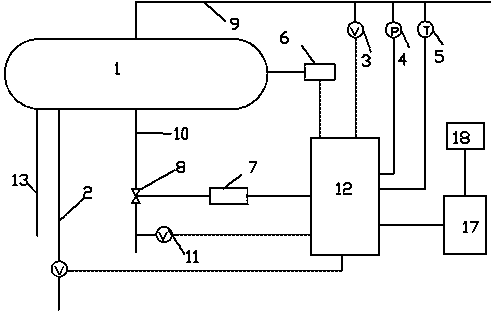

Cloud-computing boiler blow-off system

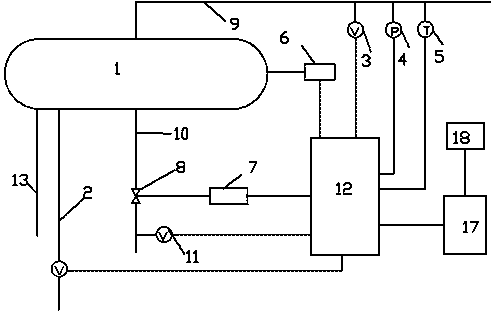

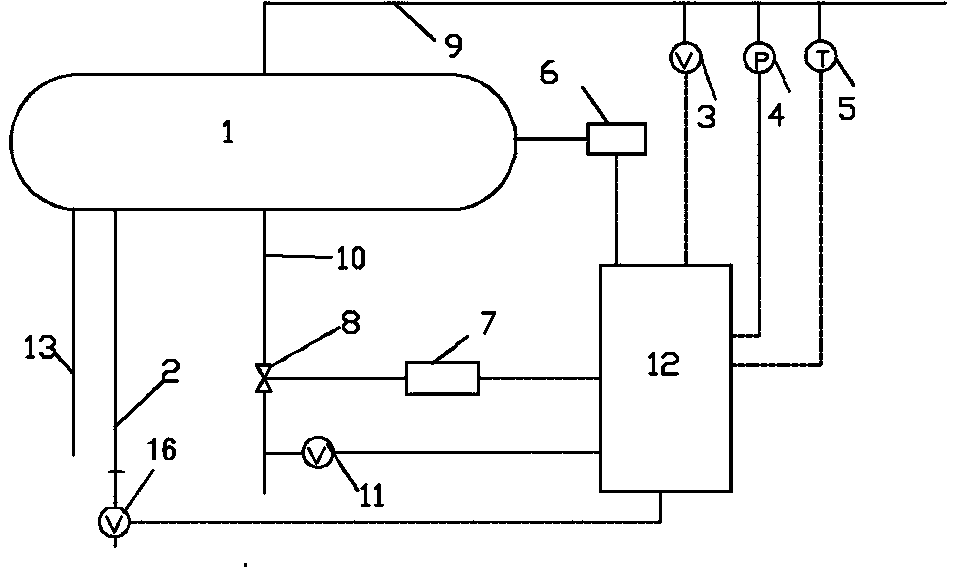

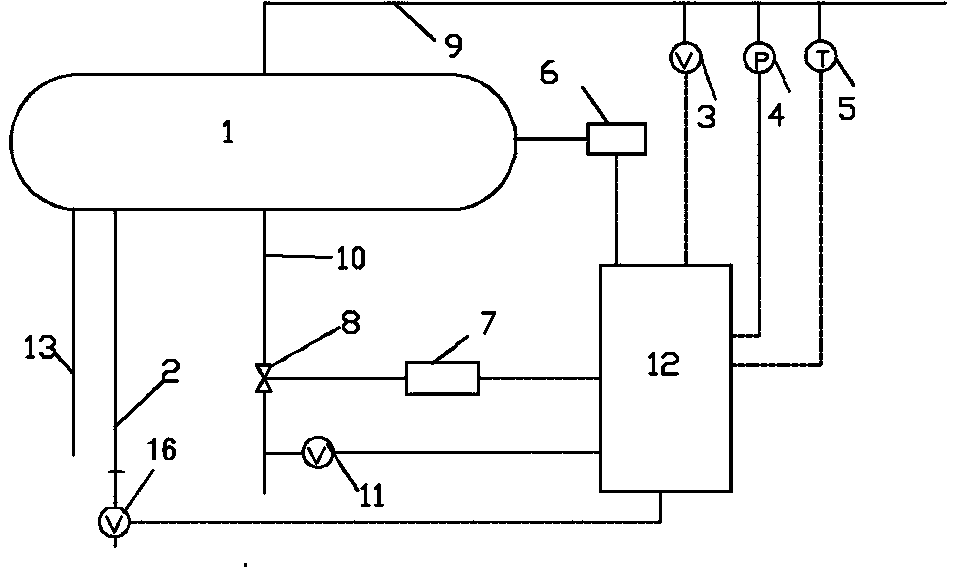

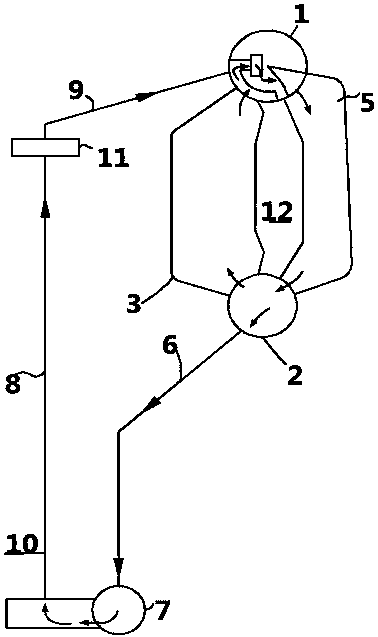

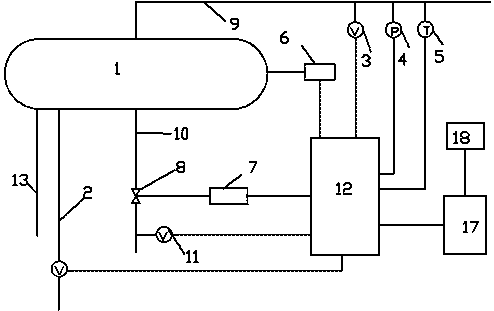

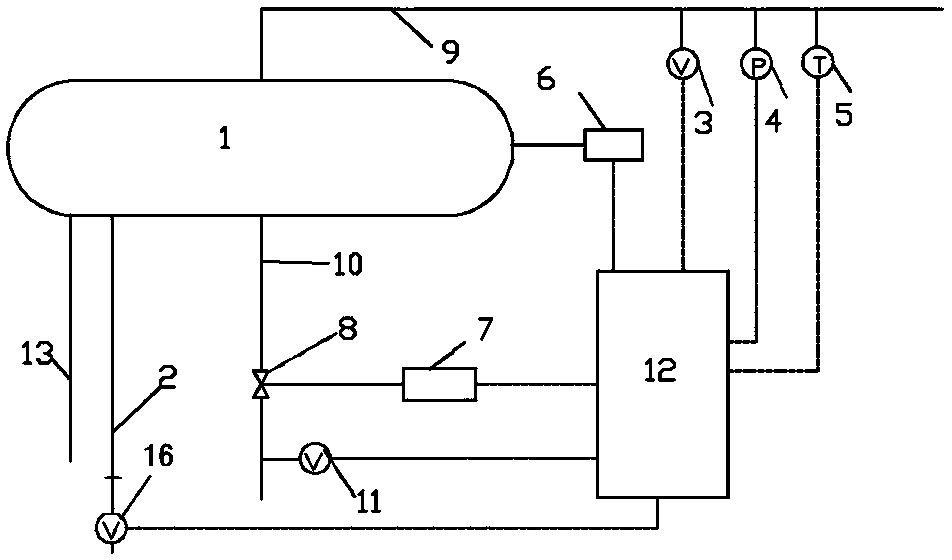

InactiveCN107101191AKeep abreast of the operation status in timeAvoid wastingBoiler cleaning apparatusBoiler controlData connectionAutomatic control

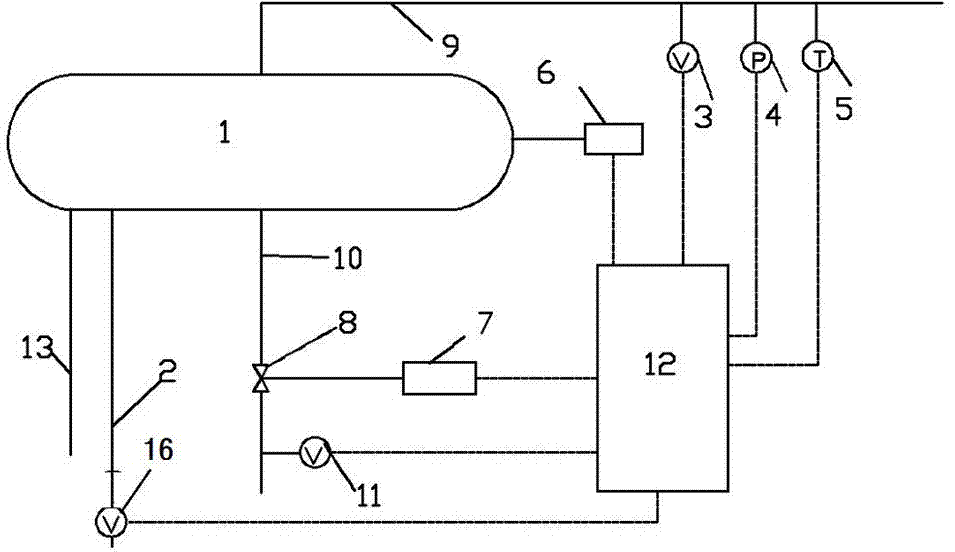

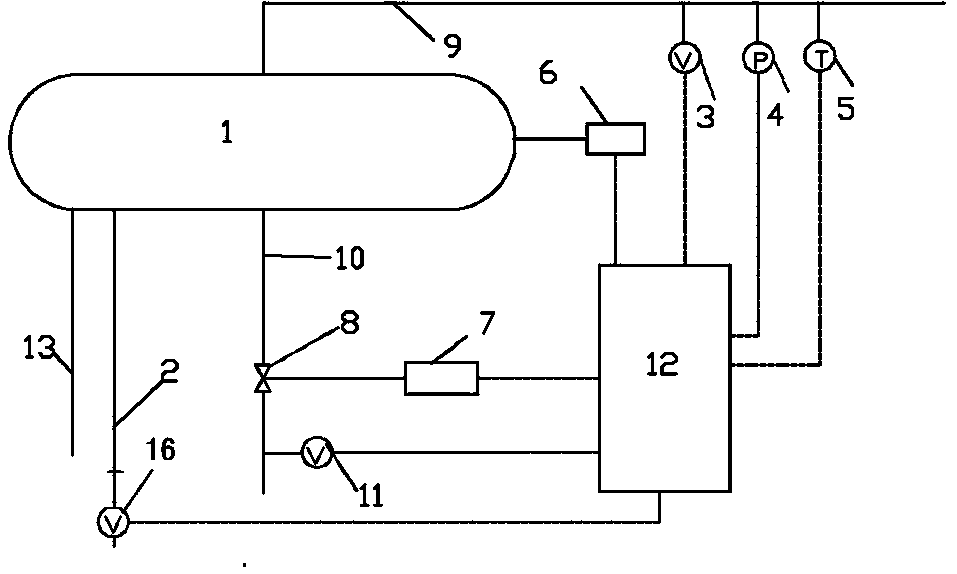

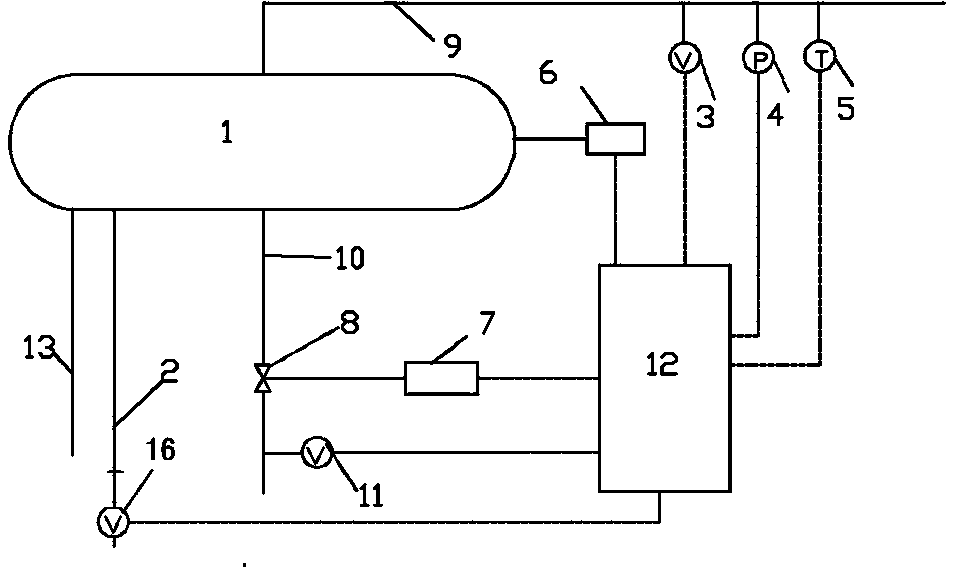

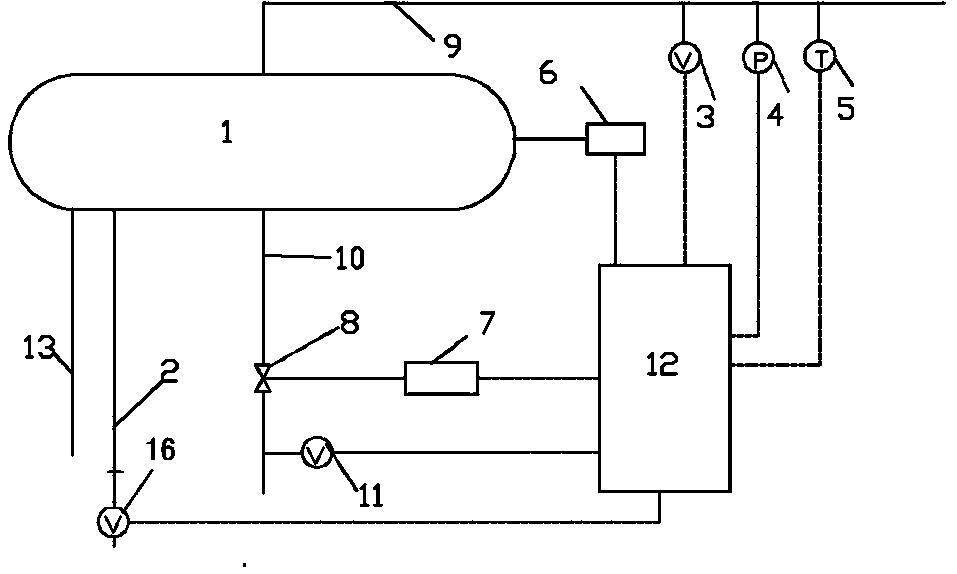

The invention provides a cloud-computing boiler blow-off system. According to the cloud-computing boiler blow-off system, automatic control is carried out according to the amount of steam generated by boilers and the amount of water input to the boilers, the boilers are periodically subjected to blow-off operation, and a central diagnosis monitor automatically sets the blow-off amount according to the ratio of the mass of the steam to the mass of the water input to the boilers; and the monitoring diagnosis controller is in data connection with a cloud server so that the monitored data can be transmitted to the cloud server conveniently, the cloud server is connected to a client side, and the client side can obtain the monitored data through the cloud server. According to the cloud-computing boiler blow-off system, the amount of the input water and the amount of the generated steam of each boiler are monitored in real time so that the dynamic ratio relation of the amount of the input water and the amount of the generated steam can be obtained, the blow-off amount of the boilers can be automatically calculated according to the dynamic ratio relation, the blow-off time and the blow-off speed can be adjusted according to the blow-off amount, the operation condition of the boiler blow-off system can be timely mastered by the client side, the blow-off parameters can be adjusted timely through the client side, and therefore a large amount of heat energy waste caused by faults of the boiler blow-off system can be prevented.

Owner:ZHONGBEI UNIV

Hot pipe of which pipe through holes are communicated with one another

ActiveCN108871019AInhibit refluxSpeed up the flowSafety devices for heat exchange apparatusIndirect heat exchangersGas phaseEvaporation

Owner:盐城韩资工业园产业发展有限公司

A steam boiler system with intelligent control of blowdown time

InactiveCN106989379BReduce lagExcellent pollution controlBoiler cleaning apparatusBoiler controlHysteresisAutomatic control

The invention provides an intelligently-controlled boiler system. The system is controlled automatically according to the steam quantity generated by boilers and the water quantity input into the boilers, the boilers are subjected to regular sewage discharging, the sewage discharging speed maintains unchanged, a central diagnosis monitor sets the sewage discharging time automatically according to the specific value between the steam mass and the mass of the water input into the boilers, and thus the discharge capacity is controlled automatically. The input water quantity and the generated steam quantity of each boiler are monitored in real time, the dynamic ratio relation between the input water quantity and the generated steam quantity is obtained, the discharge capacity of the boilers is calculated automatically according to the dynamic proportion relation, and the sewage discharging time is adjusted according to the discharge capacity. Compared with the prior art, hysteresis quality is reduced due to the fact that the sewage discharging time is calculated automatically, and the optimal sewage discharging control can be achieved.

Owner:ZHONGBEI UNIV

A boiler system that intelligently stores sewage data through cloud computing

InactiveCN107289441BKeep abreast of the operation status in timeAvoid wastingBoiler cleaning control devicesSteam boilersData connectionAutomatic control

The invention provides an automatic control boiler system. The system performs automatic control according to the quantity of steam generated by a boiler and the quantity of water input into the boiler; the boiler termly discharges pollutions; a steam drum comprises a water quality analyzer for measuring the quality of the water in the steam drum; the water quality analyzer is in data connection with a monitoring diagnosis controller for receiving measured data; the boiler termly discharges pollutions; a central diagnosis monitor stores a reference data PH value J, the pollution discharge time T and the pollution discharge speed V; the reference data is the pollution discharge quantity V*T satisfying the demand when the PH value of water in the steam drum is J; and the boiler achieves a function of automatically correcting the reference data according to the measured PH data in the steam drum. The boiler also achieves the function of automatically correcting the reference data; the reference data is automatically corrected according to the detected water quality pollution discharge conditions to guarantee the control accuracy; a client can timely master the operation conditions of a boiler pollution discharge system; and pollution discharge parameters are adjusted timely through the client to prevent a lot of heat energy wastes caused by faults of the boiler pollution discharge system.

Owner:ZHONGBEI UNIV

A cloud computing boiler sewage system

InactiveCN107101191BKeep abreast of the operation status in timeAvoid wastingBoiler cleaning apparatusBoiler controlData connectionAutomatic control

The invention provides a cloud-computing boiler blow-off system. According to the cloud-computing boiler blow-off system, automatic control is carried out according to the amount of steam generated by boilers and the amount of water input to the boilers, the boilers are periodically subjected to blow-off operation, and a central diagnosis monitor automatically sets the blow-off amount according to the ratio of the mass of the steam to the mass of the water input to the boilers; and the monitoring diagnosis controller is in data connection with a cloud server so that the monitored data can be transmitted to the cloud server conveniently, the cloud server is connected to a client side, and the client side can obtain the monitored data through the cloud server. According to the cloud-computing boiler blow-off system, the amount of the input water and the amount of the generated steam of each boiler are monitored in real time so that the dynamic ratio relation of the amount of the input water and the amount of the generated steam can be obtained, the blow-off amount of the boilers can be automatically calculated according to the dynamic ratio relation, the blow-off time and the blow-off speed can be adjusted according to the blow-off amount, the operation condition of the boiler blow-off system can be timely mastered by the client side, the blow-off parameters can be adjusted timely through the client side, and therefore a large amount of heat energy waste caused by faults of the boiler blow-off system can be prevented.

Owner:ZHONGBEI UNIV

A Steam Boiler System with Intelligent Control of Blowdown Base Data

InactiveCN107143840BGuaranteed accuracyReduce regulation errorBoiler water tubesBoiler cleaning apparatusData connectionAutomatic control

Owner:ZHONGBEI UNIV

a steam boiler

ActiveCN108332181BSpeed up the flowHas the effect of reducing vibration and noiseBoiler water tubesWater circulation promotionEngineeringHeat transfer

Owner:青岛吉云德和商贸有限公司

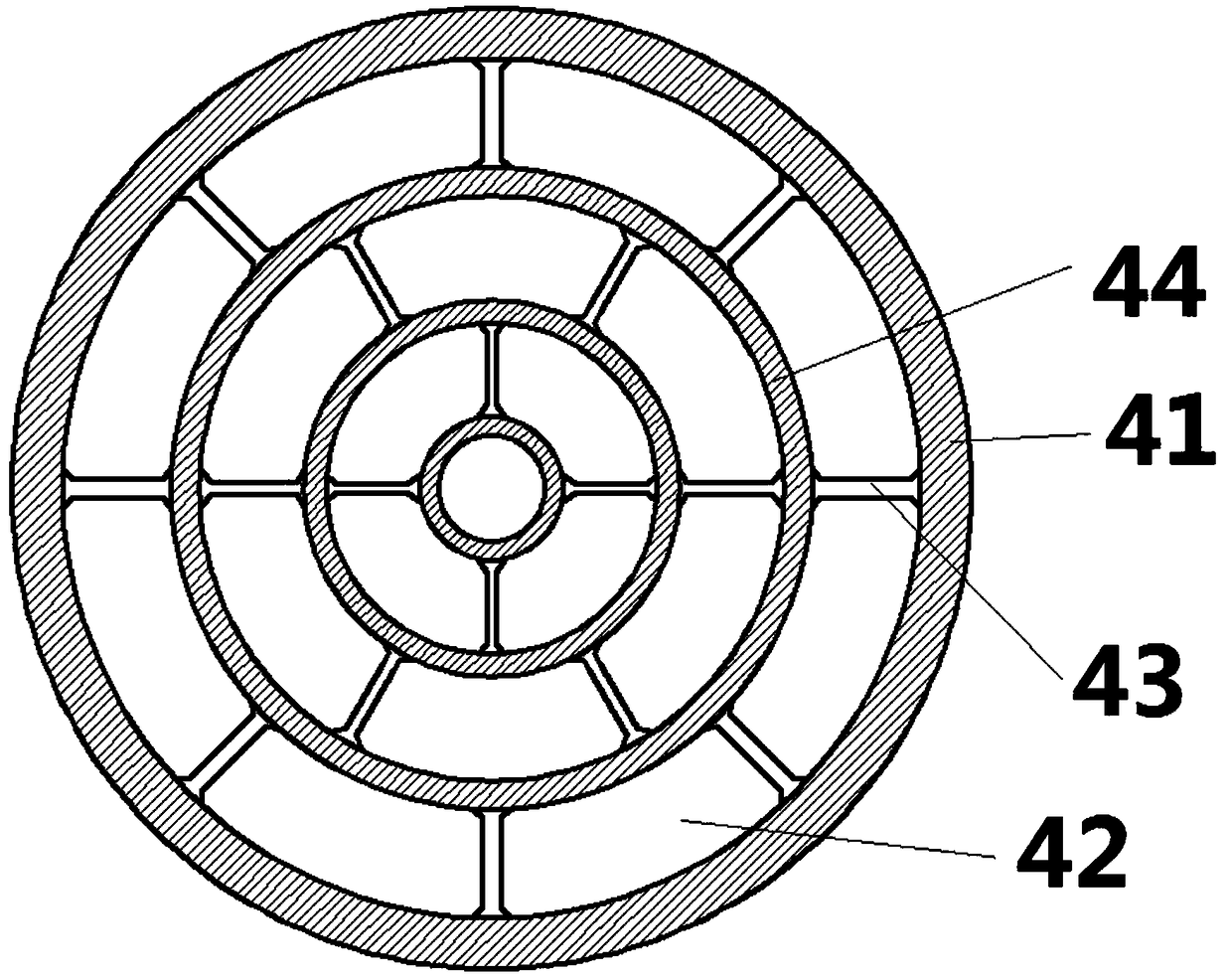

Loop Heat Pipe with Annular Divider with Varying Hydraulic Diameter

InactiveCN107167009BReduce vibrationReduce noise levelIndirect heat exchangersVapor liquidNoise level

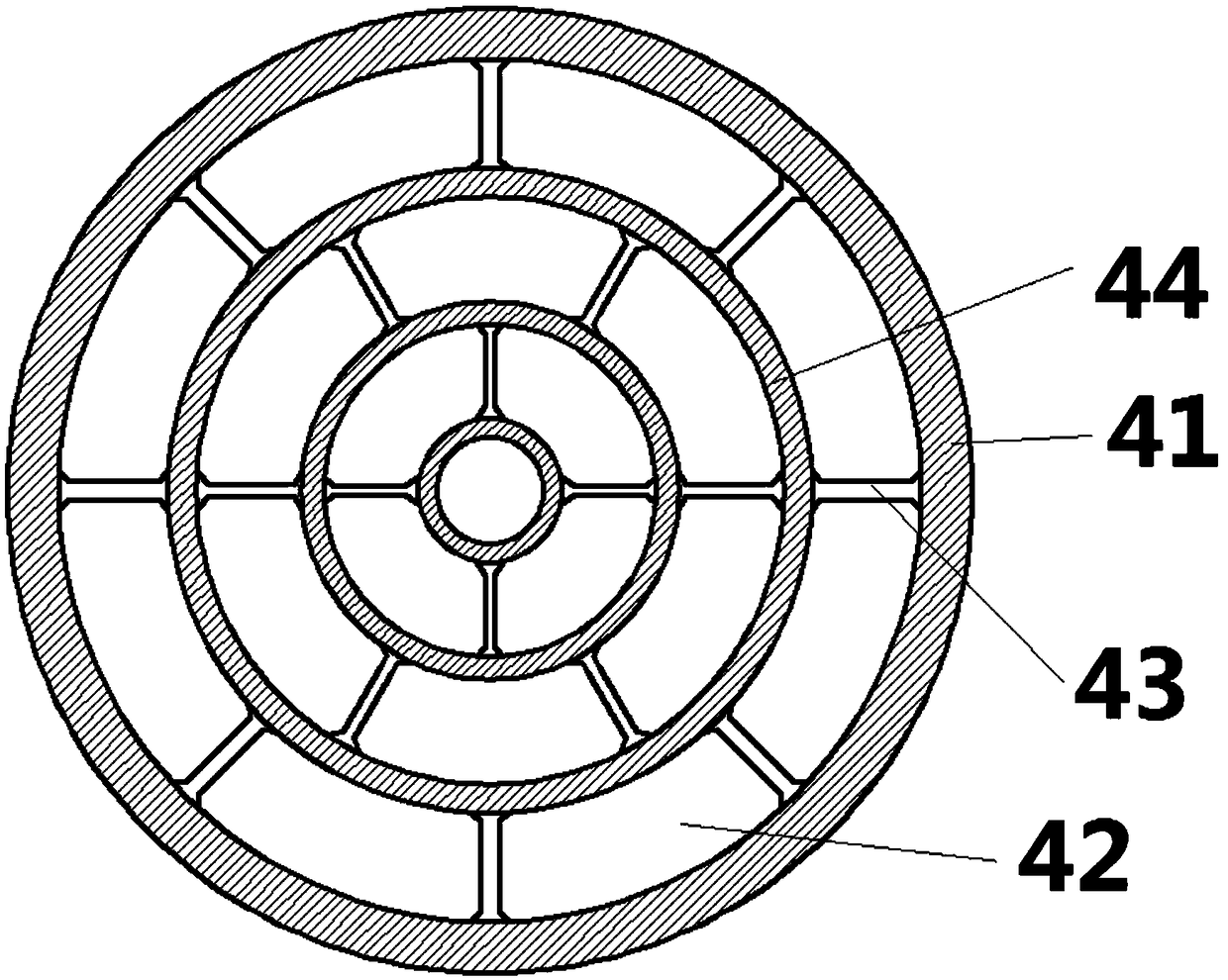

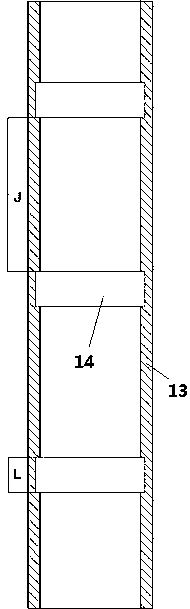

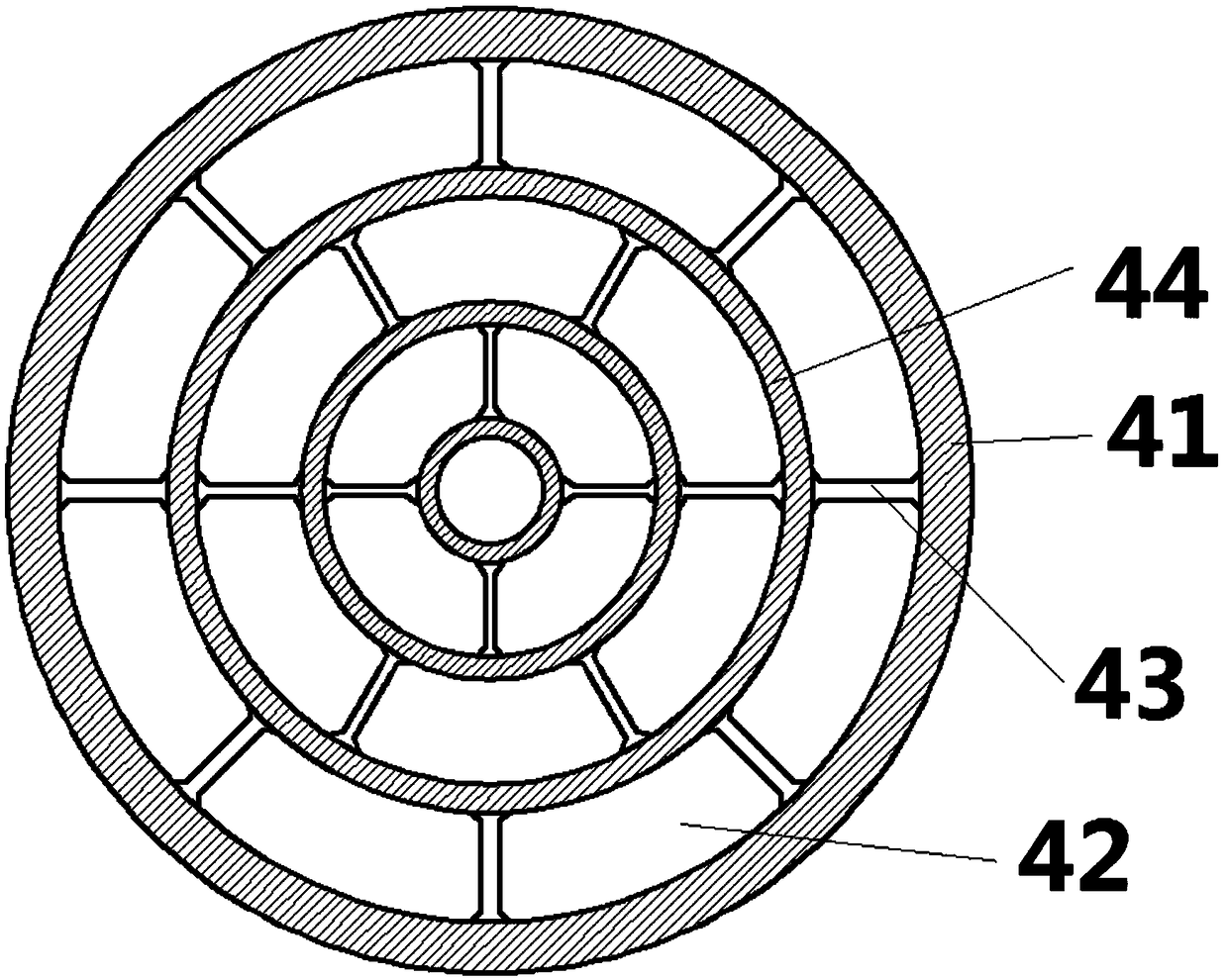

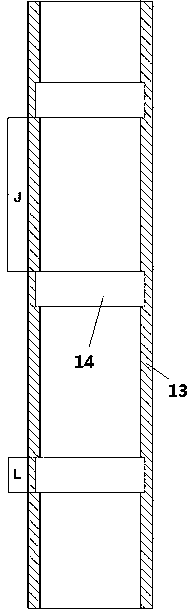

The invention provides a heat pipe, comprising an evaporation header, a condensation header, a rising pipe and a return pipe, the rising pipe communicates with the evaporation header and the condensation header, the evaporation header is located at the lower part, and the condensation header The tube is located at the upper part, the fluid absorbs heat and evaporates in the evaporation header, enters the condensation header through the rising pipe, condenses after exchanging heat in the condensation header, and the condensed fluid returns to the evaporation header through the return pipe; the rising pipe is set As for the separating device, multiple separating devices are arranged in the same riser pipe, and the hydraulic diameters of the annular holes in different separating devices are getting smaller and smaller from the inlet of the riser pipe to the outlet of the riser pipe. In the present invention, through the change of the hydraulic diameter of the annular hole of the separation device, when there is a vapor-liquid two-phase flow in the riser pipe, the heat transfer is enhanced, the vibration of the riser pipe is weakened, and the noise level is reduced.

Owner:SHANDONG UNIV

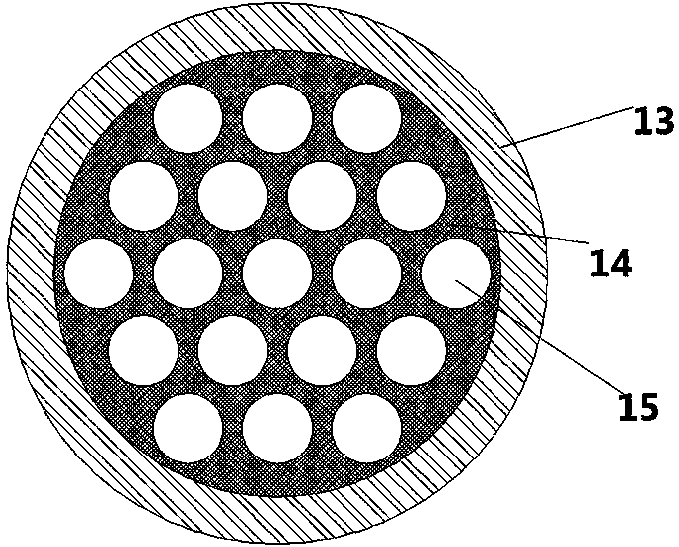

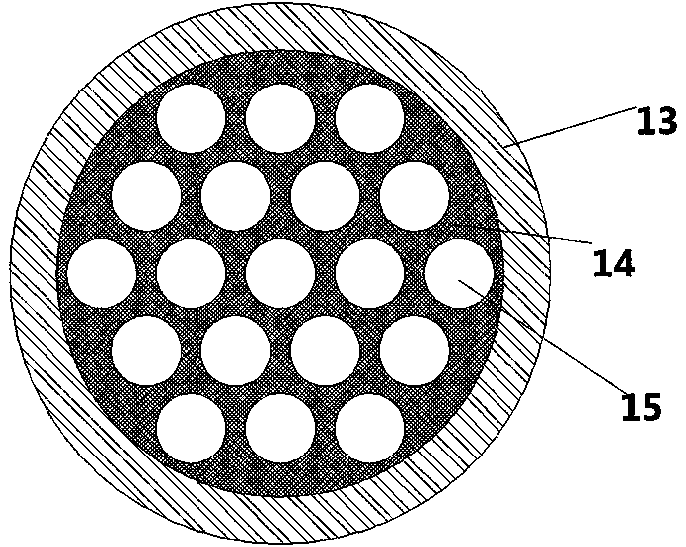

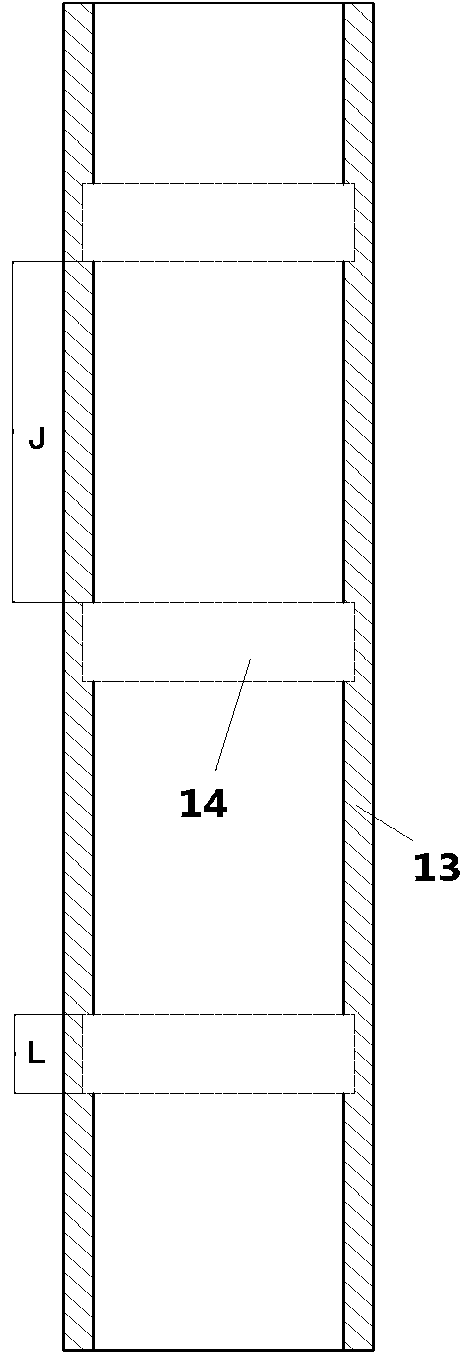

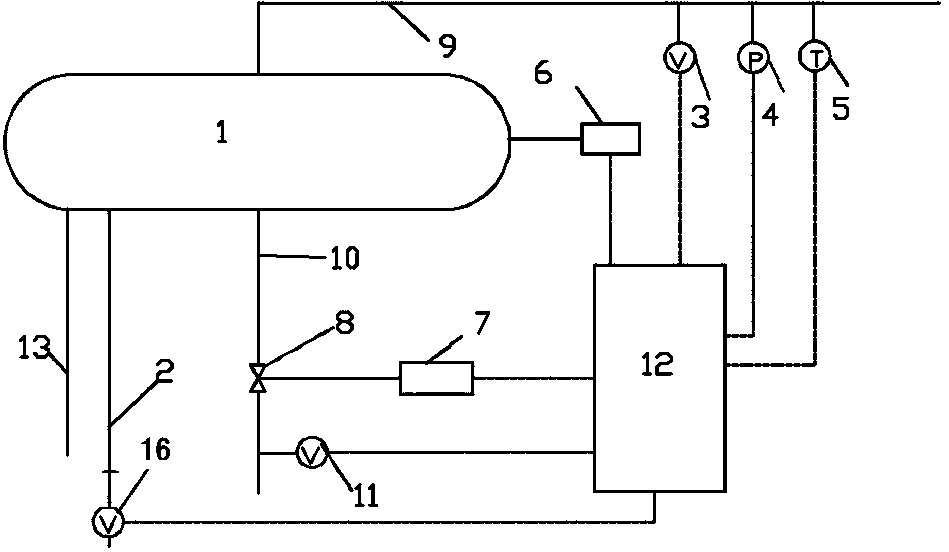

Cloud computing steam boiler system capable of controlling current stabilization of steam and liquid

InactiveCN108954287AKeep abreast of the operation status in timeAvoid wastingBoiler controlBoiler cleaning control devicesThermal energyAutomatic control

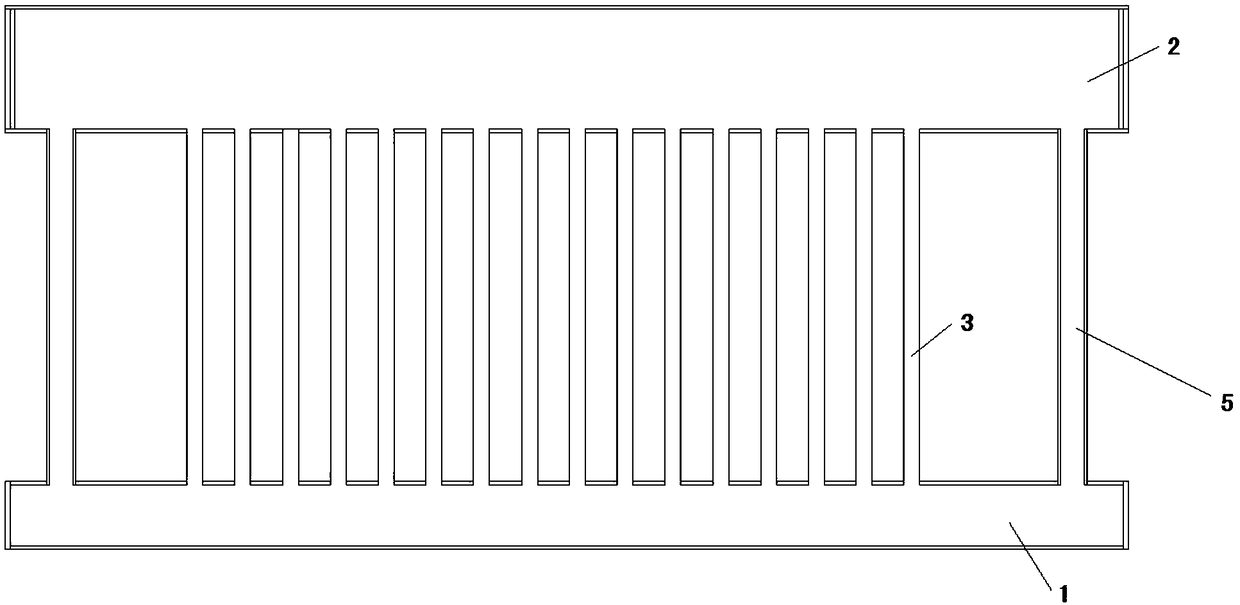

The invention provides a boiler system. The boiler system performs automatic control according to the amount of steam generated by a boiler and the amount of water fed into the boiler; sewage is discharged from the boiler at regular intervals; a steam pocket comprises a water quality analyzer which is used for measuring the quality of water in the steam pocket; the steam pocket is connected to anascending pipe and a descending pipe; a plurality of cutting heat exchange parts are arranged in the ascending pipe at intervals and extend in the height direction of the ascending pipe; and a plurality of holes are formed in the cutting heat exchange parts and run through the cutting heat exchange parts in the height direction of the ascending pipe. The boiler has the effects of flow rate stabilization, vibration absorption and noise reduction and avoids the wasting of lots of energy sources caused by the failure of the boiler sewage discharge system.

Owner:ZHONGBEI UNIV

Boiler system with intelligent control of blowdown time by cloud computing

InactiveCN107289439BKeep abreast of the operation status in timeAvoid wastingBoiler cleaning control devicesSteam boilersData connectionAutomatic control

The invention provides an automatic control boiler system. The system comprises a monitoring diagnosis controller and a boiler; a steam drum comprises a water quality analyzer; the water quality analyzer comprises a PH value testing unit for measuring the PH value of water in the steam drum; the water quality analyzer is in data connection with the monitoring diagnosis controller to receive measured PH data; the boiler termly discharges pollutions; the pollution discharge speed is kept invariable; a central diagnosis monitor automatically sets a pollution discharge time according to the measured PH value to automatically control the pollution discharge quantity; the monitoring diagnosis controller is in data connection with a cloud server for transferring monitored data to the cloud server; the cloud server is connected with a client; and the client can obtain the monitored data through the cloud server. Through real-time monitoring of the PH data of each boiler, the pollution discharge time is automatically adjusted according to a dynamic proportional relation; the client can timely master the operation conditions of a boiler pollution discharge system; and pollution discharge parameters are adjusted timely through the client to prevent a lot of heat energy wastes caused by faults of the boiler pollution discharge system.

Owner:ZHONGBEI UNIV

A steam boiler system with intelligent control of sewage discharge speed

InactiveCN107166365BReduce lagExcellent pollution controlBoiler cleaning control devicesSteam boilersHysteresisAutomatic control

The invention provides an intelligent boiler control system. The system conducts automatic control according to the amount of steam generated by boilers and the amount of water input into the boilers, the boilers regularly discharge dirt, the dirt discharging speed is kept unchangeable, a center diagnosis monitor automatically sets the dirt discharging speed according to the specific value between the steam mass and the mass of water input into the boilers, and accordingly the dirt discharging amount is automatically controlled. According to the system, through real-time monitoring of the input water amount and the generated steam amount of each boiler, the dynamic proportion relation between the input water amount and the generated steam amount is obtained, the dirt discharging amount of the boilers is automatically calculated according to the dynamic proportion relation, and the dirt discharging speed is adjusted according to the dirt discharging amount. According to the intelligent boiler control system, due to the fact that the dirt discharging time is automatically calculated, compared with the prior art, hysteresis quality is reduced, and optimal dirt discharging control can be achieved.

Owner:ZHONGBEI UNIV

PH value-based boiler system with pollution discharge time rule change intelligently controlled

InactiveCN109373303AAvoid lostImprove sewage efficiencyBoiler cleaning apparatusBoiler controlDischarge efficiencyAutomatic control

Owner:ZHONGBEI UNIV

A boiler system with cloud computing sewage discharge speed

InactiveCN107166362BKeep abreast of the operation status in timeAvoid wastingBoiler controlBoiler cleaning control devicesData connectionAutomatic control

The invention provides a boiler system. According to the system, automatic control can be performed according to the amount of steam generated by a boiler and the amount of water input to the boiler, the boiler is subjected to sewage discharge periodically, the sewage discharge speed is kept unchanged, a central diagnosis monitor automatically sets the sewage discharge speed according to the ratio of the mass of the steam to the mass of the water input to the boiler and is in data connection with a cloud server so as to transmit monitored data to the cloud server, the cloud server is connected to a client side, and the client side can obtain the monitored data through the cloud server, manually inputs the sewage discharge speed according to the obtained data, transmits the data to a monitoring and diagnosing controller through the cloud server and manually adjusts the sewage discharge amount through the monitoring the diagnosing controller. The system has the advantages that the input water quantity and the generated steam quantity of each boiler are monitored in real time, the dynamic ratio relation of the input water quantity and the generated steam quantity is obtained, the sewage discharge amount of the boiler can be automatically calculated according to the dynamic ratio relation, the sewage discharge speed can be adjusted according to the sewage discharge amount, the operation condition of a boiler sewage discharge system can be timely mastered by the client side, the sewage discharge parameters can be adjusted timely through the client side, and a large amount of heat energy waste caused by faults of the boiler sewage discharge system can be prevented.

Owner:ZHONGBEI UNIV

A boiler system with cloud computing intelligent control of sewage discharge speed

InactiveCN107289440BKeep abreast of the operation status in timeAvoid wastingBoiler cleaning control devicesSteam boilersData connectionAutomatic control

The invention provides an automatic control boiler system. The system comprises a monitoring diagnosis controller and a boiler; a steam drum comprises a water quality analyzer; the water quality analyzer comprises a PH value testing unit for measuring the PH value of water in the steam drum; the water quality analyzer is in data connection with the monitoring diagnosis controller to receive measured PH data; the boiler termly discharges pollutions; the pollution discharge time is kept invariable; and a central diagnosis monitor automatically sets a pollution discharge speed according to the measured PH value to automatically control the pollution discharge quantity. Through real-time monitoring of the PH data of each boiler, the pollution discharge quantity of the boiler is automatically calculated according to a dynamic proportional relation; the pollution discharge speed and the pollution discharge time are adjusted according to the pollution discharge quantity; a client can timely master the operation conditions of a boiler pollution discharge system; and pollution discharge parameters are adjusted timely through the client to prevent a lot of heat energy wastes caused by faults of the boiler pollution discharge system.

Owner:ZHONGBEI UNIV

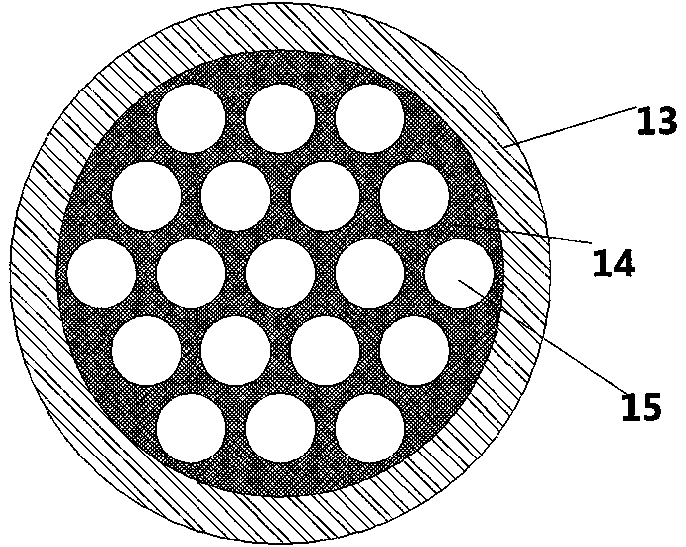

A loop heat pipe of a porous flow stabilization device

ActiveCN107131783BReduce vibrationImprove heat transfer performanceSafety devices for heat exchange apparatusHeat exhanger conduitsRefluxNoise level

The invention provides a heat pipe. The heat pipe comprises an evaporation header, a condensation header, an ascending pipe and a reflux pipe; the ascending pipe communicates with the evaporation header and the condensation header; the evaporation header is positioned at the lower part; the condensation header is positioned at the upper part; a fluid absorbs heat for evaporation in the evaporation header, is fed in the condensation header by the ascending pipe, and is condensed in the condensation header after heat exchange; the condensed fluid is returned to the evaporation header through the reflux pipe; current stabilizing devices are arranged in the ascending pipe; multiple current stabilizing devices are arranged in the same ascending pipe; and in the height direction of the ascending pipe, gaps between the adjacent current stabilizing devices are continuously reduced. Through the gap change of the current stabilizing devices, when steam-liquid two-phase flowing exists in the ascending pipe, the heat transfer is intensified, meanwhile, the vibration of the ascending pipe is weakened, and the noise level is lowered.

Owner:西安新港分布式能源有限公司

a steam boiler

InactiveCN106949449BSpeed up the flowHas the effect of reducing vibration and noiseBoiler water tubesWater-tube boilersNoise levelEngineering

Owner:ZHONGBEI UNIV

A loop heat pipe with the height direction of the annular partition device changing

InactiveCN107062960BReduce vibrationImprove heat transfer performanceSafety devices for heat exchange apparatusIndirect heat exchangersNoise levelEvaporation

Owner:SHANDONG UNIV

A boiler system that intelligently controls the blowdown rate according to the pH value

InactiveCN107166364BReduce lagExcellent pollution controlBoiler cleaning apparatusBoiler controlData connectionAutomatic control

The invention provides an automatic control system. The system comprises a monitoring diagnosis controller and a boiler; the boiler comprises a blow-down pipe arranged at the lower end of a boiler drum; a blow-down valve is arranged on the blow-off pipe; one end of the blow-down valve is connected with a valve adjusting device; the valve adjusting device is in data connection with the monitoring diagnosis controller for transferring valve openness data to the monitoring diagnosis controller and receiving an instruction from the monitoring diagnosis controller to adjust the openness of the blow-down valve; the drum comprises a water quality analyzer; the water quality analyzer comprises a pH value testing unit for measuring the pH value of water in the drum; the water quality analyzer is in data connection with the monitoring diagnosis controller for receiving the measured pH data; boiler blow-down is termly performed; the blow-down time is kept invariable; and a central diagnosis monitor automatically sets the blow-down speed according to the measured pH value to automatically control the blow-down quantity. As the blow-down speed is automatically calculated, compared with the prior art, the system has the advantages that the lagging is reduced, and the optimal blow-down control can be realized.

Owner:ZHONGBEI UNIV

Steam boiler system with intelligent blowdown benchmark data control function

InactiveCN107143840AGuaranteed accuracyReduce regulation errorBoiler water tubesBoiler cleaning apparatusData connectionAutomatic control

The invention provides an automatic boiler control system. The automatic boiler control system performs automatic control according to the quantity of steam generated by a boiler and the quantity of water input into the boiler, sewage of the boiler is discharged periodically, a steam pocket further comprises a water quality analyzer which is used for measuring the quality of water in the steam pocket, the water quality analyzer is in data connection with a monitoring and diagnosing controller to receive measured data, and the boiler also has the function of automatically correcting benchmark data according to the quality of water in the steam pocket. As the boiler further has the automatic benchmark data correction function and can automatically correct the benchmark data according to the detected water sewage disposal situation, so that the regulation and control accuracy is guaranteed.

Owner:ZHONGBEI UNIV

A loop heat pipe

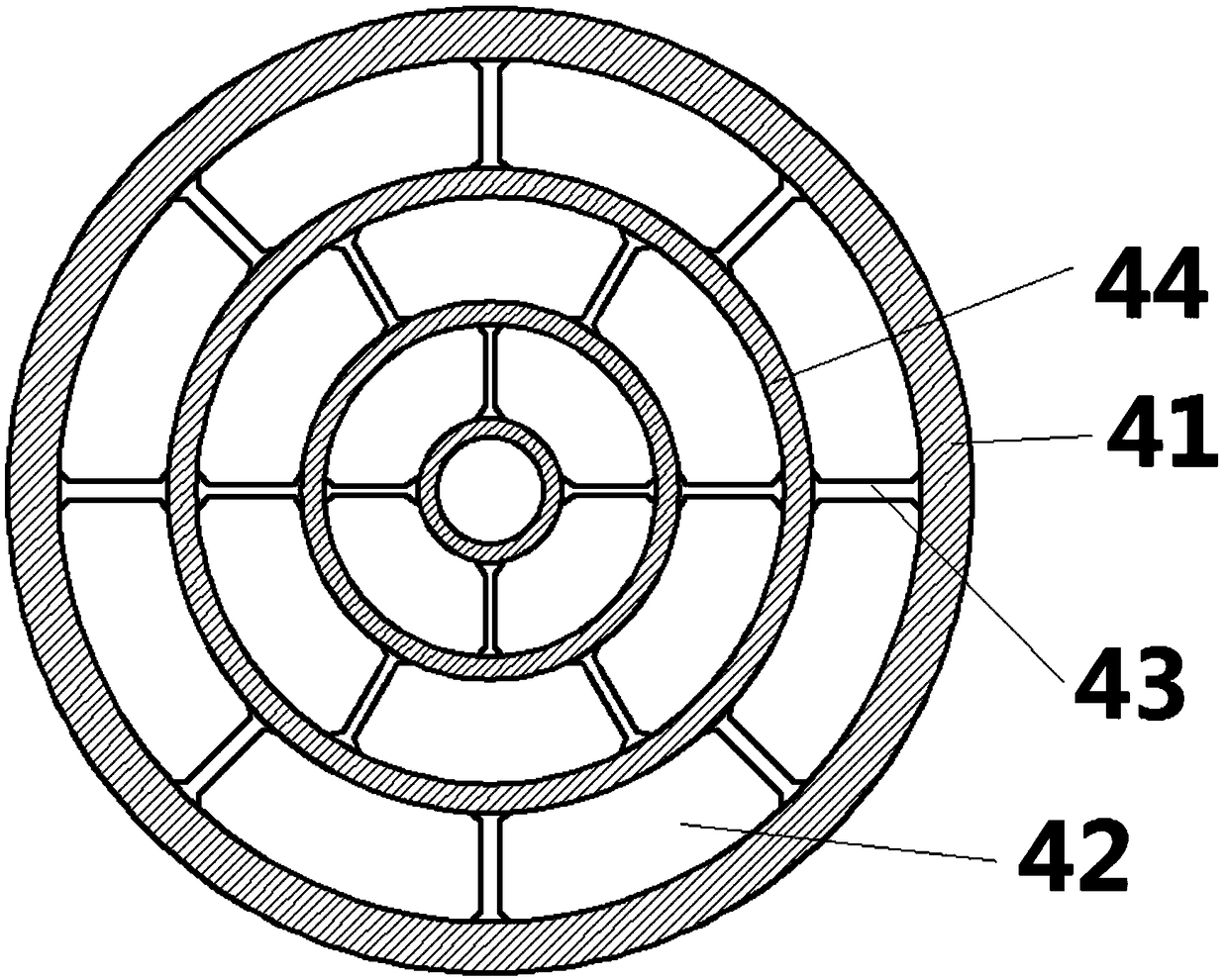

InactiveCN107167010BInhibit refluxSpeed up the flowIndirect heat exchangersVapor liquidMicro-loop heat pipe

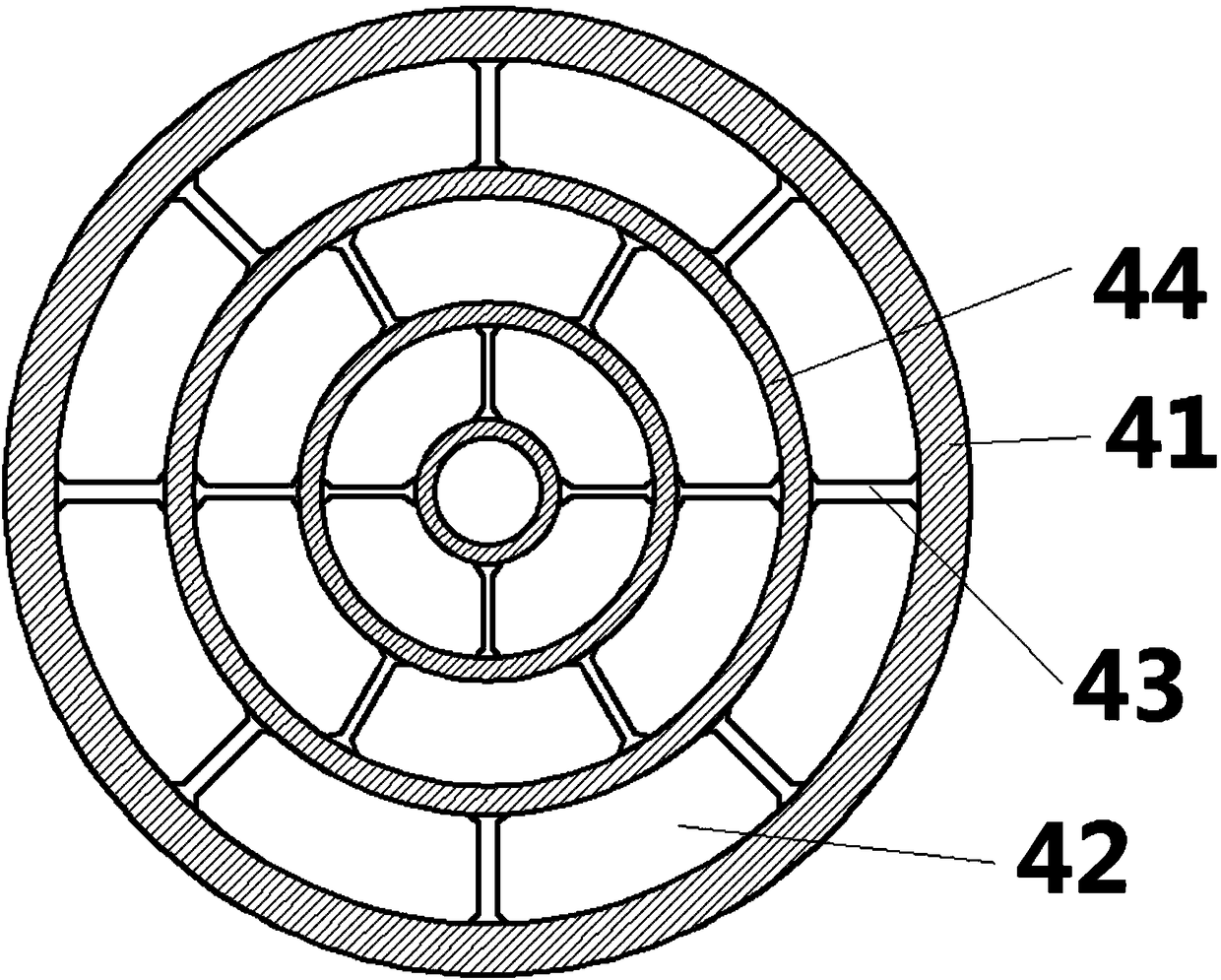

The invention provides a loop heat pipe, comprising an evaporation header, a condensation header, a rising pipe and a return pipe, the rising pipe communicates with the evaporation header and the condensation header, the evaporation header is located at the lower part, and the The condensing header is located at the upper part, the fluid absorbs heat and evaporates in the evaporating header, enters the condensing header through the rising pipe, condenses after exchanging heat in the condensing header, and the condensed fluid returns to the evaporating header through the return pipe; the rising A partition device is arranged inside the tube, the partition device includes a core body and a shell, the core body is arranged in the shell body, the shell body is connected and fixed to the inner wall of the heat exchange tube, the core body includes a plurality of concentric tubes and fins, the The ribs connect adjacent concentric tubes. The invention provides a loop heat pipe with a new structure, which can enhance heat transfer, weaken the vibration of the riser and reduce the noise level when there is a vapor-liquid two-phase flow in the riser.

Owner:SHANDONG UNIV

Cloud computing boiler system capable of automatically regulating blowdown according to steam-water ratio

InactiveCN108980809AKeep abreast of the operation status in timeAvoid wastingBoiler cleaning apparatusBoiler controlData connectionBoiler blowdown

The invention provides a boiler system. The boiler system has the advantages that automatic control is performed according to the quantity of steam generated by a boiler and the quantity of water fedinto the boiler, the boiler performs blowdown regularly, and a central monitoring diagnosis controller automatically sets blowdown quantity according the mass ratio of the steam to the water; the monitoring diagnosis controller is in data connection with a cloud server so as to conveniently transmit monitored data to the cloud server, the cloud server is connected with a client, and the client canobtain the monitored data through the cloud server; the client can timely master the operation condition of a boiler blowdown system, blowdown parameter regulation can be performed timely through theclient, and a large amount of energy waste caused by boiler blowdown system failure is prevented.

Owner:ZHONGBEI UNIV

A loop heat pipe with an annular divider with variable spacing in the height direction

InactiveCN107144161BReduce vibrationImprove heat transfer performanceIndirect heat exchangersEvaporationProcess engineering

The invention provides a heat pipe, comprising an evaporation header, a condensation header, a rising pipe and a return pipe, the rising pipe communicates with the evaporation header and the condensation header, the evaporation header is located at the lower part, and the condensation header The tube is located at the upper part, the fluid absorbs heat and evaporates in the evaporation header, enters the condensation header through the rising pipe, and condenses after exchanging heat in the condensation header, and the condensed fluid returns to the evaporation header through the return pipe; the rising pipe is set Separation device, a plurality of separation devices are set in the same riser pipe, and a plurality of separation devices are set in the same riser pipe, along the height direction of the riser pipe, the distance between adjacent separation devices is continuously reduced . In the present invention, by changing the spacing of the separating device, when there is vapor-liquid two-phase flow in the riser pipe, the heat transfer is enhanced, the vibration of the riser pipe is weakened, and the noise level is reduced.

Owner:SHANDONG UNIV

Heat pipe of a porous flow stabilization device

ActiveCN107044789BReduce vibrationImprove heat transfer performanceIndirect heat exchangersVapor liquidNoise level

The invention provides a heat pipe which comprises an evaporation collecting pipe, a condensation collecting pipe, ascending pipes and return pipes, wherein the ascending pipes are communicated with each of the evaporation collecting pipe and the condensation collecting pipe; the evaporation collecting pipe is positioned at the lower part; the condensation collecting pipe is positioned at the upper part; a fluid absorbs heat and evaporates in the evaporation collecting pipe, the vapor passes through the ascending pipes to enter the condensation collecting pipe and is condensed in the condensation collecting pipe after being subjected to heat exchange, and the condensed fluid returns back into the evaporation collecting pipe through the return pipes; the flow stabilizing devices are arranged in each of the same ascending pipe; the lengths of the flow stabilizing devices are constantly increased in the height directions of the ascending pipes;. According to the heat pipe with multi-hole flow stabilizing devices, the lengths of the flow stabilizing devices are changed, so that when vapor-liquid two-phase flows exist in the ascending pipes, heat transfer is enhanced, the vibration of the ascending pipes is weakened, and the noise level is reduced.

Owner:山东路德交通科技有限公司

Boiler system with intelligent ph value control of blowdown time

InactiveCN107166366BReduce lagExcellent pollution controlBoiler cleaning apparatusBoiler controlHysteresisData connection

The invention discloses an automatic control boiler system which comprises a monitoring diagnosis controller and a boiler. The boiler comprises a pollution discharge pipe arranged at the lower end of a boiler steam pocket. The pollution discharge pipe is provided with a blow-down valve. One end of the blow-down valve is connected with a valve adjusting device. The valve adjusting device is in data connection with the monitoring diagnosis controller, so that valve opening data are transmitted to the monitoring diagnosis controller, meanwhile, an instruction is received from the monitoring diagnosis controller, and the opening of the blow-down valve is adjusted. The steam pocket further comprises a water quality analyzer. The water quality analyzer comprises a PH value measuring unit so as to measure the PH value of water in the steam pocket. The water quality analyzer is in data connection with the monitoring diagnosis controller so as to obtain measured PH data. The boiler discharges pollution at regular intervals, the pollution discharge speed is kept constant, a central diagnosis monitor automatically sets pollution discharge time according to the measured PH value, and therefore the pollution discharge amount is automatically controlled. Since pollution time is automatically calculated, compared with the prior art, hysteresis is reduced, and optimal pollution discharge control can be achieved.

Owner:ZHONGBEI UNIV

A boiler system that automatically controls cloud computing pH and sewage discharge

InactiveCN107218589BKeep abreast of the operation status in timeAvoid wastingBoiler indication operationsBoiler cleaning apparatusData connectionAutomatic control

The invention provides an automatically-controlled boiler system. The automatically-controlled boiler system comprises a monitoring and diagnosing controller and boilers; each boiler comprises a blow-off pipe arranged at the lower end of a boiler drum, the boiler drum further comprises a water quality analyzer, the water quality analyzer comprises a PH value testing unit used for measuring the PH value of water in the boiler drum, and the water quality analyzer is in data connection with the monitoring and diagnosing controller so as to receive measured PH data; and the monitoring and diagnosing controller is in data connection with a cloud server so as to transmit the monitored data to the cloud server, the cloud server is connected with a client side, and the client side can obtain the monitored data through the cloud server. According to the boiler system, the blow-off amount of the boilers is automatically calculated by monitoring the PH data of the boilers in real time, the blow-off time and the blow-off speed are adjusted according to the blow-off amount, the operation condition of a blow-off system of the boilers can be timely mastered by the client side, the blow-off parameters can be timely adjusted through the client side, and a large amount of heat energy waste caused by faults of the blow-off system of the boilers can be prevented.

Owner:ZHONGBEI UNIV

Intelligent control cutting heat exchange steam boiler system

InactiveCN109140415AGuaranteed accuracyReduce regulation errorBoiler water tubesBoiler cleaning apparatusData connectionAutomatic control

The invention provides a boiler system. The system boiler carries out automatic control according to the steam quantity produced by a boiler and the water quantity input into the boiler. The boiler discharges pollution at regular intervals. A steam pocket further comprises a water quality analyzer so as to measure the water quality in the steam pocket, and the water quality analyzer is in data connection with a monitoring diagnosis controller so as to receive measured data. The boiler further has the function of automatically correcting benchmark data according to the measured water quality inthe steam pocket, and the pollution discharge capacity is automatically controlled according to measured data. According to the boiler, the pollution discharge capacity of the boiler is automaticallycalculated, and the pollution discharge time and the pollution discharge speed are adjusted according to the pollution discharge capacity.

Owner:ZHONGBEI UNIV

Heat pipe

InactiveCN108827047AReduce vibrationImprove heat transfer performanceIndirect heat exchangersEvaporationHeat pipe

The invention provides a heat pipe which comprises an evaporation header, a condensation header, an ascension pipe and a return pipe, wherein a separating device is arranged in the ascension pipe; a groove is formed in the ascension pipe; and the shell of the separating device is arranged in the groove. Through the manner, the ascension pipe provided with the separating device is simple in manufacture and reduced in cost.

Owner:SHANDONG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com