Patents

Literature

171results about How to "Achieve steady flow effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

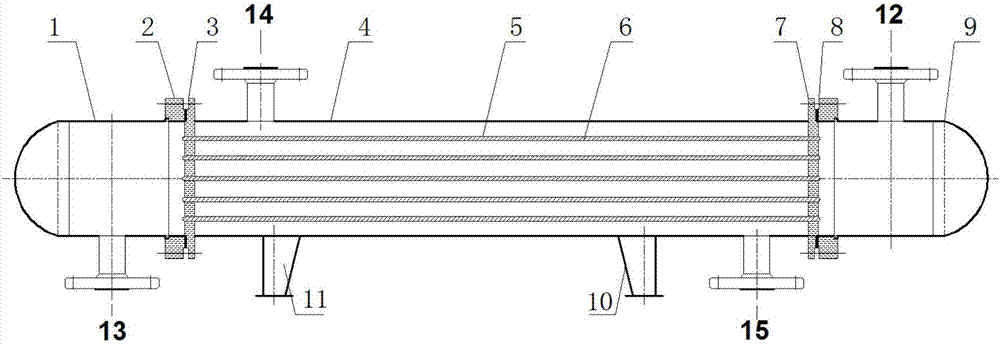

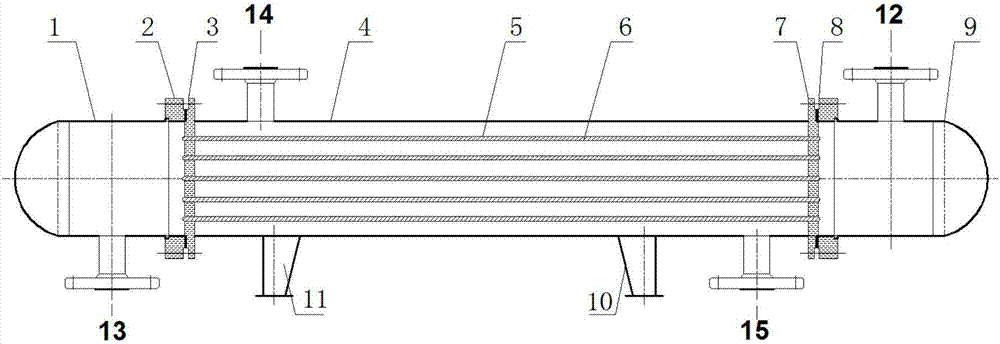

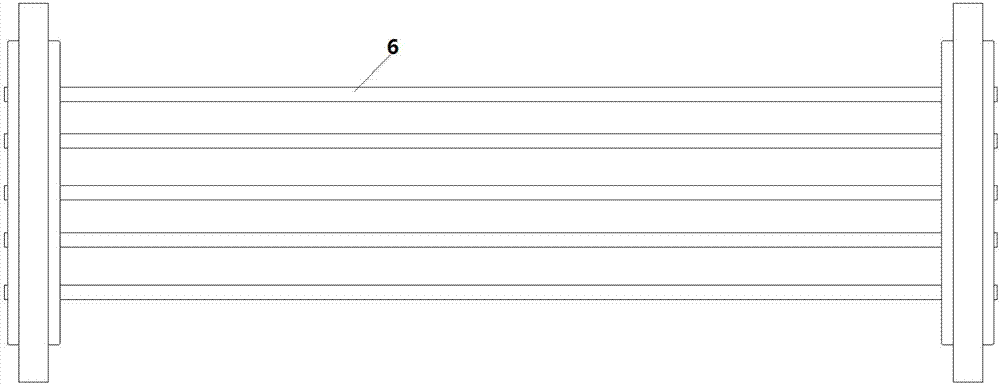

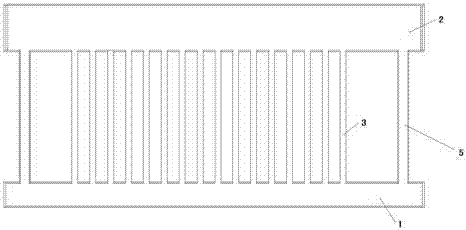

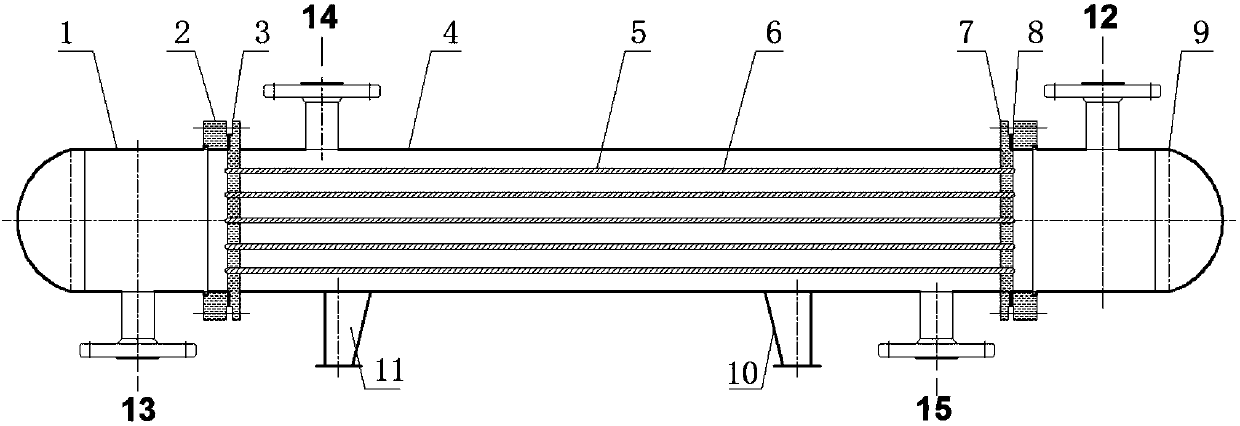

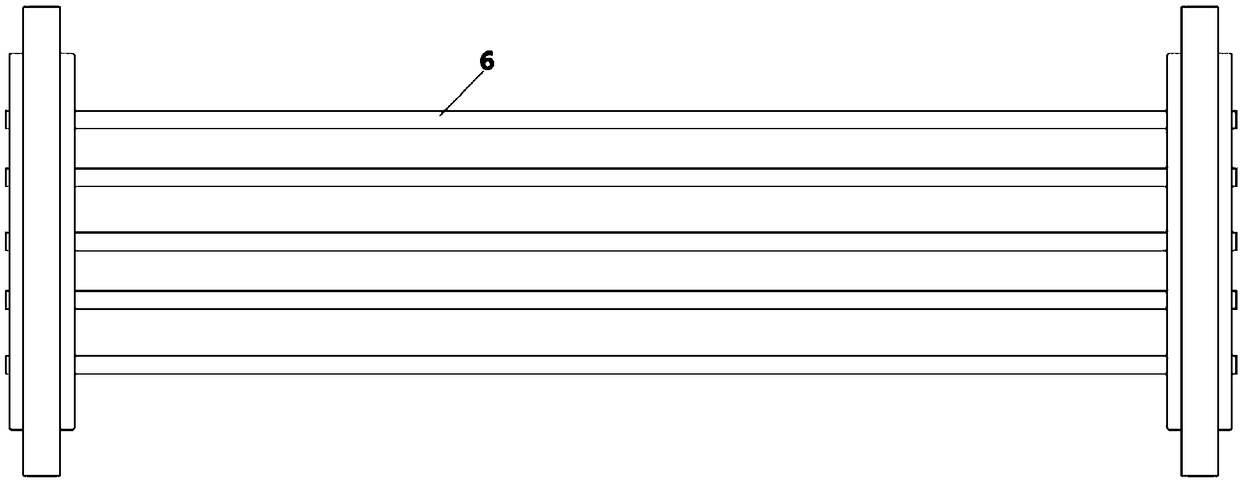

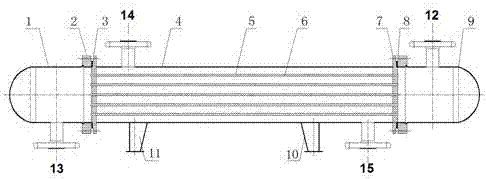

Length-variable condensable annular separation device heat exchanger

ActiveCN106969652AShorten the lengthReduce vibrationStationary tubular conduit assembliesHeat transfer modificationVapor liquidNoise level

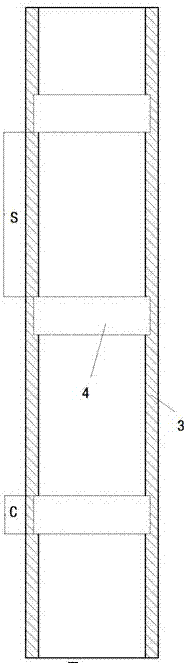

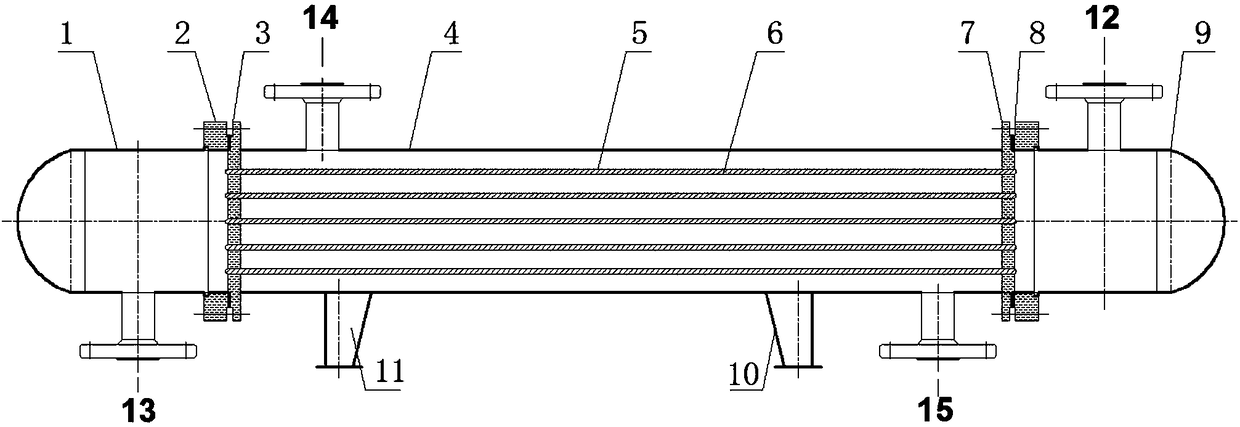

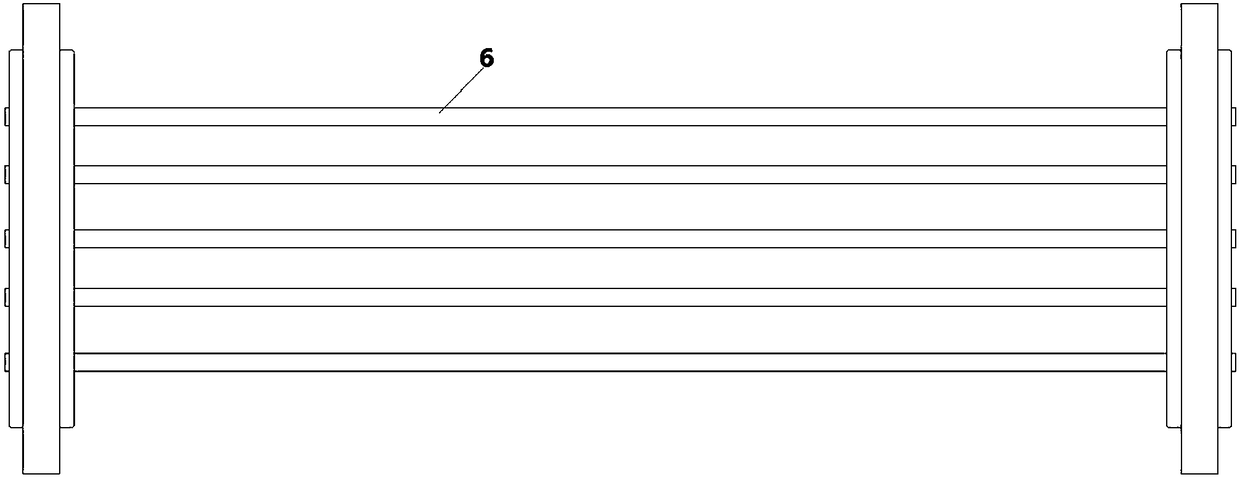

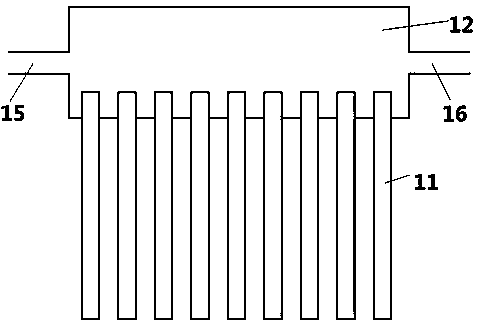

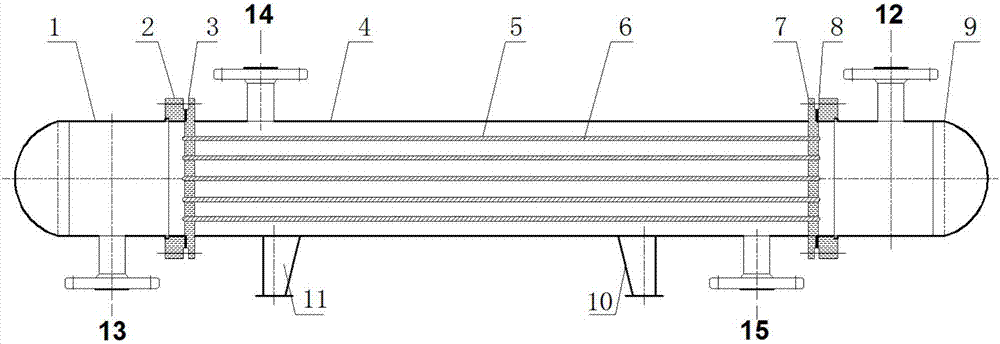

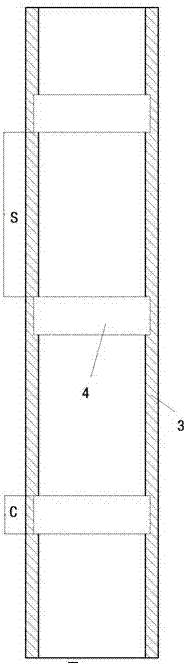

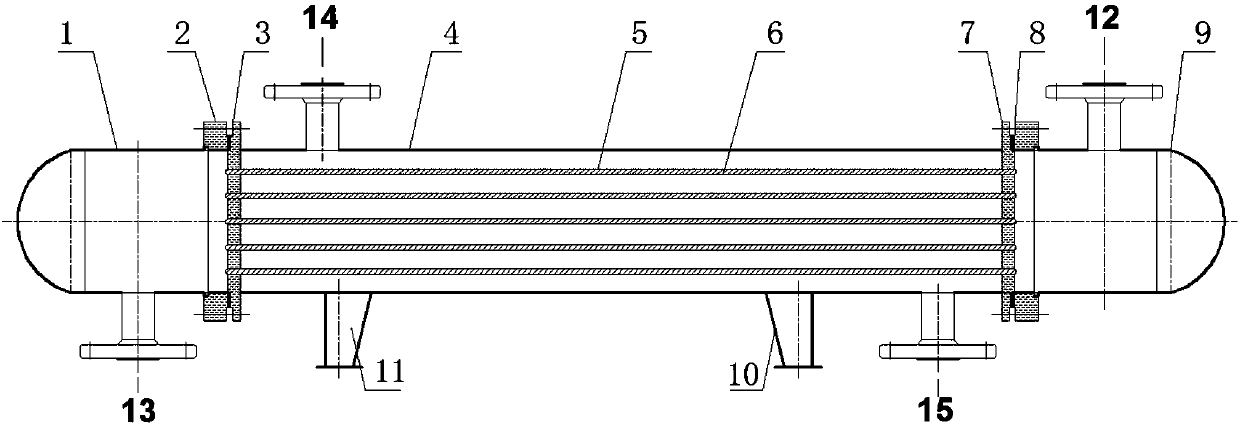

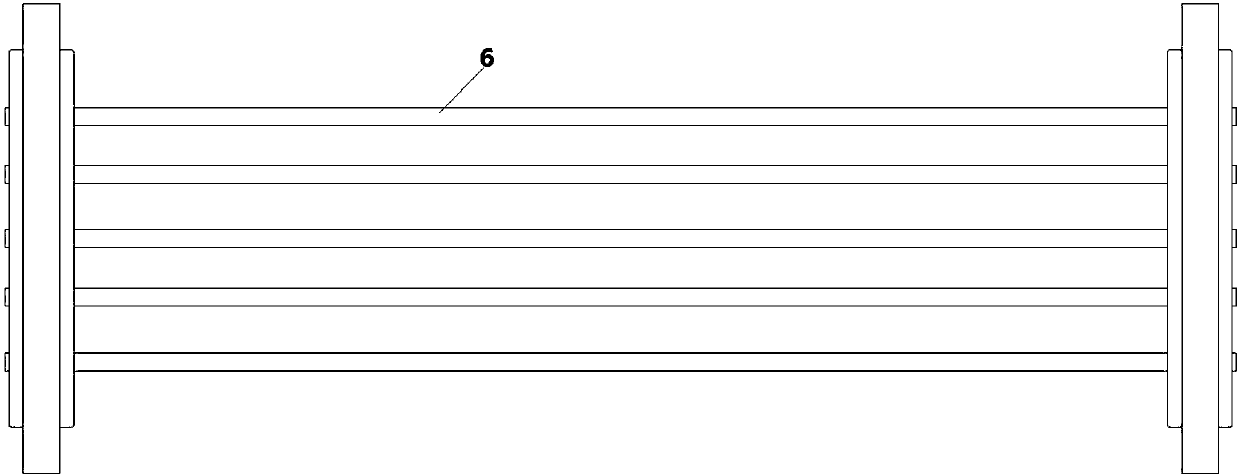

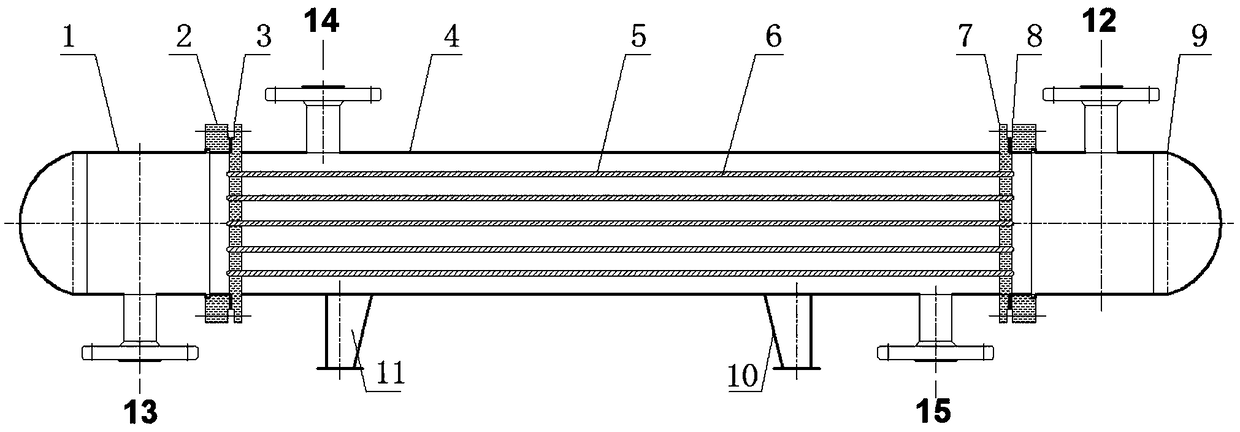

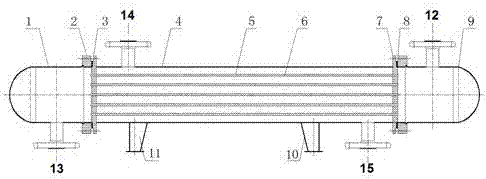

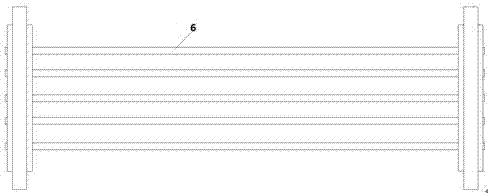

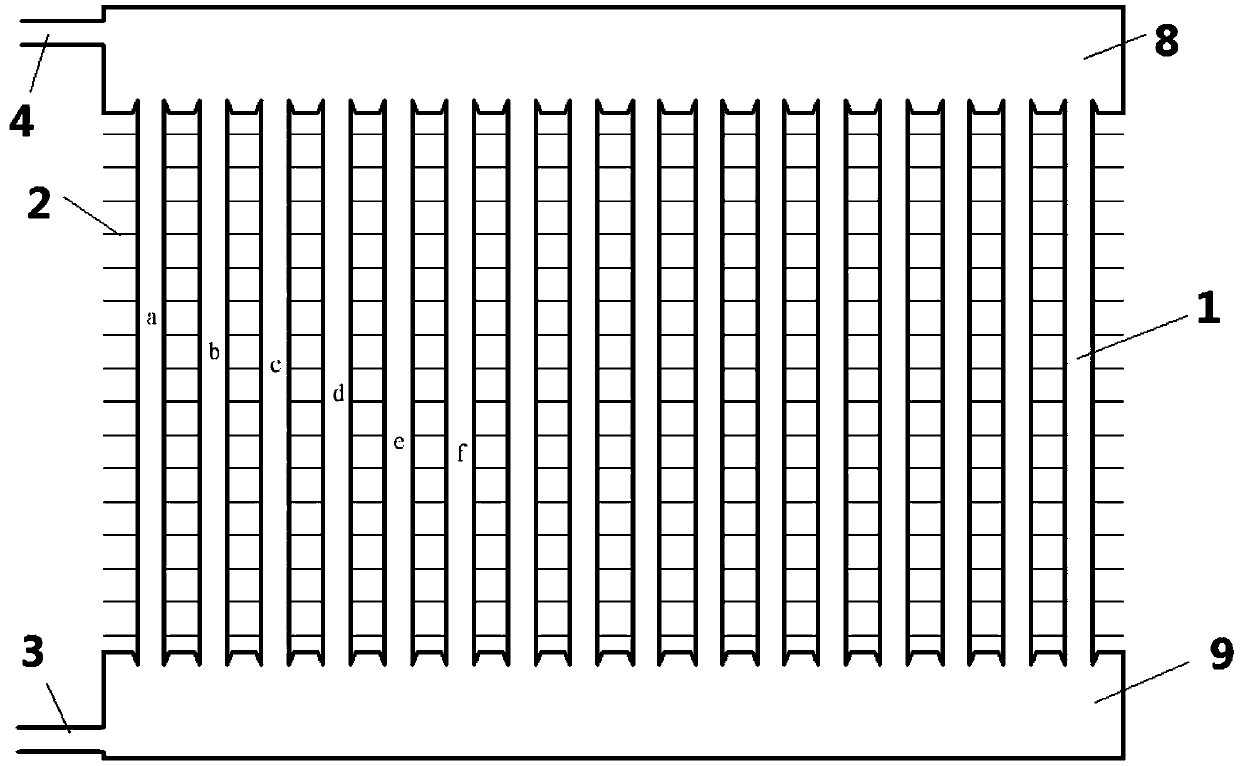

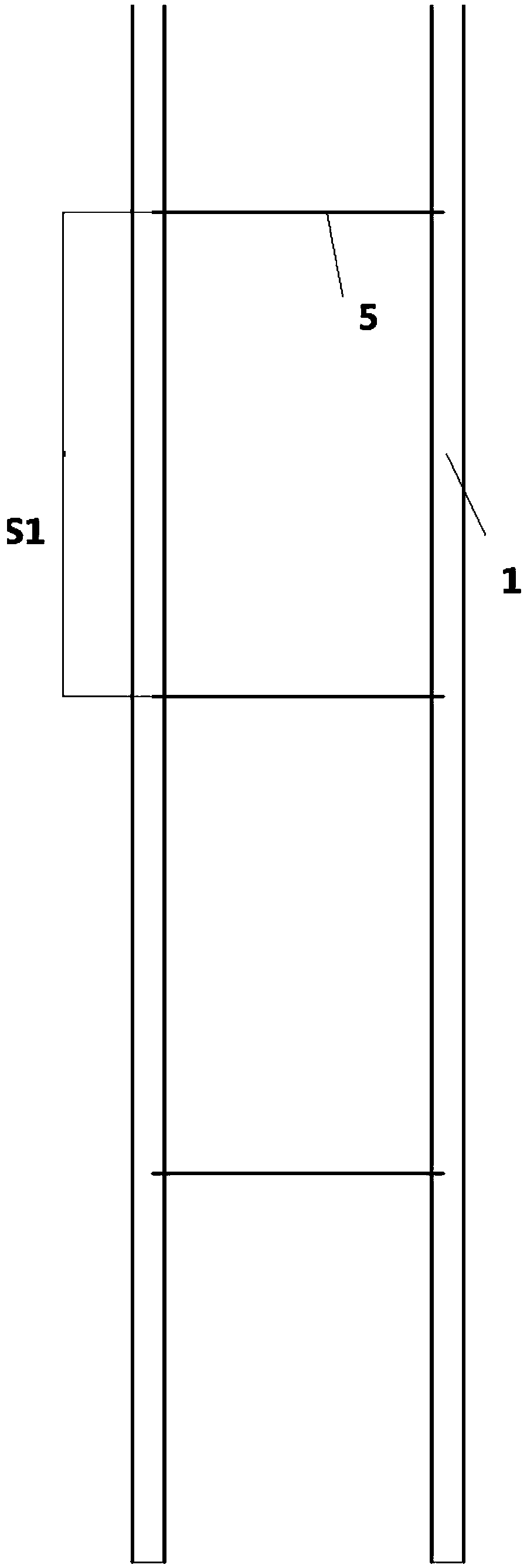

The invention provides a vapor-liquid two-phase flow tube shell type heat exchanger. The heat exchanger comprises a shell, wherein sealing heads are arranged at two ends of the shell respectively; tube plates are arranged in connection positions between the sealing heads and the shell; heat exchange tubes are connected with the tube plates at two ends; vapor phase in vapor-liquid two-phase flow can be condensed into liquid phase in the heat exchange process; the vapor-liquid two-phase flow flows in a tube process; separation devices used for decreasing vibration and reducing noise are arranged in the heat exchange tubes; a plurality of separation devices are arranged in the same heat exchange tube; the length of the separation devices is gradually reduced along the flowing direction of flow in the heat exchange tubes. According to the vapor-liquid two-phase flow tube shell type heat exchanger, the vibration of the tubes can be decreased to a maximum extent due to the length change of the separation devices when the vapor-liquid two-phase flow flows in the tubes; the noise level is reduced; meanwhile, the flowing resistance is reduced; the heat exchange uniformity is improved.

Owner:SHANDONG UNIV

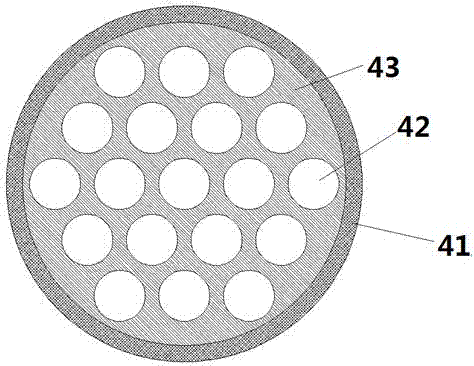

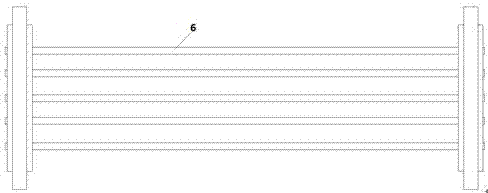

Heat pipe with multi-hole flow stabilizing devices

ActiveCN107044789AReduce vibrationImprove heat transfer performanceIndirect heat exchangersVapor liquidNoise level

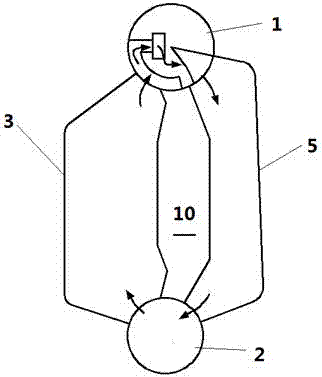

The invention provides a heat pipe which comprises an evaporation collecting pipe, a condensation collecting pipe, ascending pipes and return pipes, wherein the ascending pipes are communicated with each of the evaporation collecting pipe and the condensation collecting pipe; the evaporation collecting pipe is positioned at the lower part; the condensation collecting pipe is positioned at the upper part; a fluid absorbs heat and evaporates in the evaporation collecting pipe, the vapor passes through the ascending pipes to enter the condensation collecting pipe and is condensed in the condensation collecting pipe after being subjected to heat exchange, and the condensed fluid returns back into the evaporation collecting pipe through the return pipes; the flow stabilizing devices are arranged in each of the same ascending pipe; the lengths of the flow stabilizing devices are constantly increased in the height directions of the ascending pipes;. According to the heat pipe with multi-hole flow stabilizing devices, the lengths of the flow stabilizing devices are changed, so that when vapor-liquid two-phase flows exist in the ascending pipes, heat transfer is enhanced, the vibration of the ascending pipes is weakened, and the noise level is reduced.

Owner:山东路德交通科技有限公司

Damping steam boiler

ActiveCN107143837AReduce vibrationImprove heat transfer performanceBoiler water tubesSteam generation using pressureHeat transmissionNoise level

The invention provides a damping steam boiler. The damping steam boiler comprises an upper boiler barrel, a lower boiler barrel, rising pipes and falling pipes, wherein the rising pipes and the falling pipes are connected between the upper boiler barrel and the lower boiler barrel. The rising pipes are internally provided with flow stabilizers, and the multiple flow stabilizers are arranged in the same rising pipe; and the space between every two adjacent flow stabilizers is constantly reduced in the fluid flowing direction of the rising pipes. According to the damping steam boiler, through gap changing of the flow stabilizers, when steam-liquid two phase flowing exists in the rising pipes, heat transmission is reinforced; and meanwhile, vibration of the rising pipes is weakened, and the noise level is reduced.

Owner:连云港虹洋热电有限公司

Steam boiler with through hole diameters being changeable

ActiveCN107062187AReduce vibrationReduce noise levelBoiler water tubesSteam generation using pressureNoise levelEngineering

The invention provides a steam boiler. The steam boiler comprises an upper boiler barrel, a lower boiler barrel, ascending pipes and descending pipes, wherein the ascending pipes and the descending pipes are arranged between the upper boiler barrel and the lower boiler barrel; the ascending pipes are internally provided with flow stabilizing devices, the same ascending pipe is internally provided with a plurality of the flow stabilizing devices, and the diameters of through holes of the flow stabilizing devices are smaller and smaller in the fluid flowing direction of the ascending pipes. The steam boiler is provided with the flow stabilizing devices of novel structures, and through the change of the diameters of the through holes, when gas-liquid two-phase flowing exists in the ascending pipes, heat transfer is strengthened; and meanwhile, vibration of the ascending pipes is weakened, and the noise level is lowered.

Owner:王芸芸

Current stabilizer spacing change type non-condensable gas tubular heat exchanger

ActiveCN108204751AReduce vibrationReduce noise levelStationary tubular conduit assembliesHeat transfer modificationEngineeringElectrical and Electronics engineering

The invention provides a tube-shell heat exchanger. The tube-shell heat exchanger comprises a housing, wherein sealing heads are arranged at two ends of the housing; tube plates are arranged at positions where the sealing heads are connected to the housing; heat exchange tubes are connected to the tube plates at two ends; gas phase in gas-liquid two-phase current is insoluble or slightly-soluble gas, namely, gas cannot dissolve in liquid in the heat exchanging process. The tube-shell heat exchanger is characterized in that current stabilizers for absorbing vibration and reducing noise are arranged in the heat exchange tubes; a plurality of current stabilizers are arranged in one heat exchange tube; the spacing between adjacent current stabilizers gradually increases in the flowing direction of the liquid in the heat exchange tubes until reaching some position, and then the spacing between the adjacent current stabilizers gradually decreases from the some position. According to the heatexchanger, the vibration of pipelines can be minimized based on the spacing change of the current stabilizers while the pipelines are subjected to gas-liquid two-phase flowing, and moreover, the noise level is decreased, and meanwhile, the flowing resistance is reduced.

Owner:山东卓奥环保科技股份有限公司

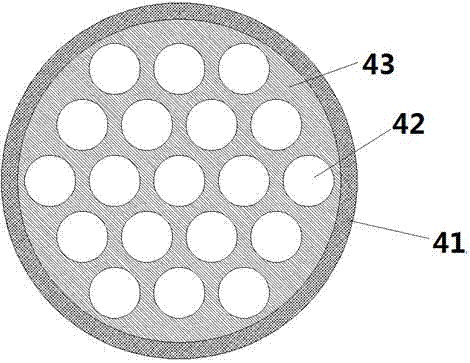

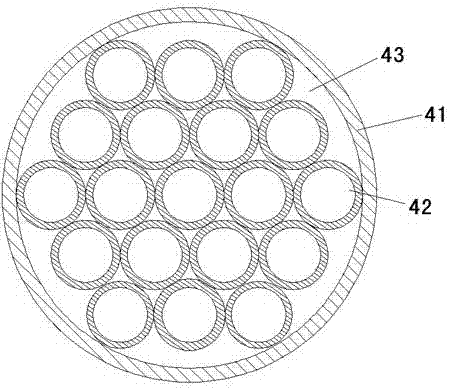

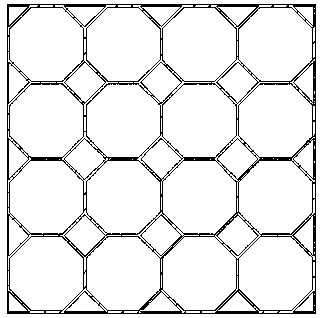

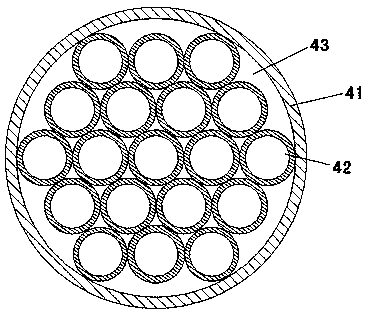

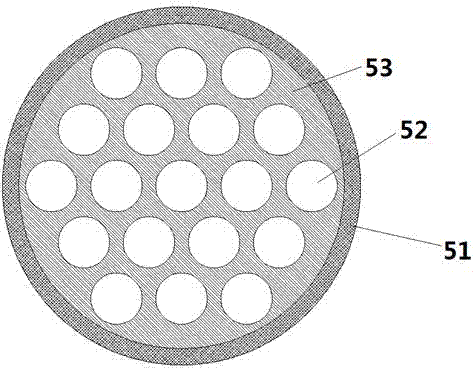

Steam boiler

ActiveCN107084380ASpeed up the flowStable flowBoiler water tubesWater-tube boilersEngineeringHeat transfer

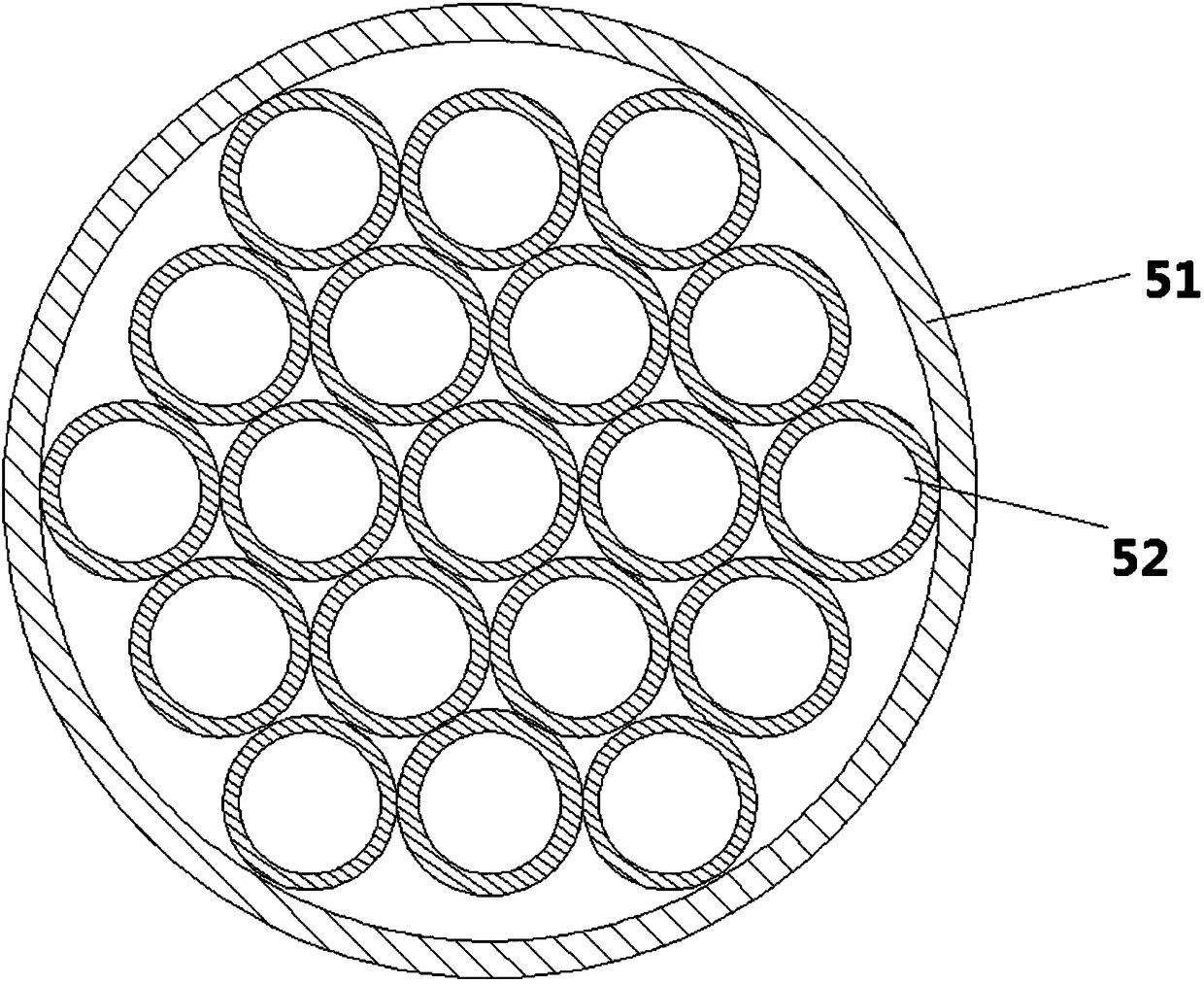

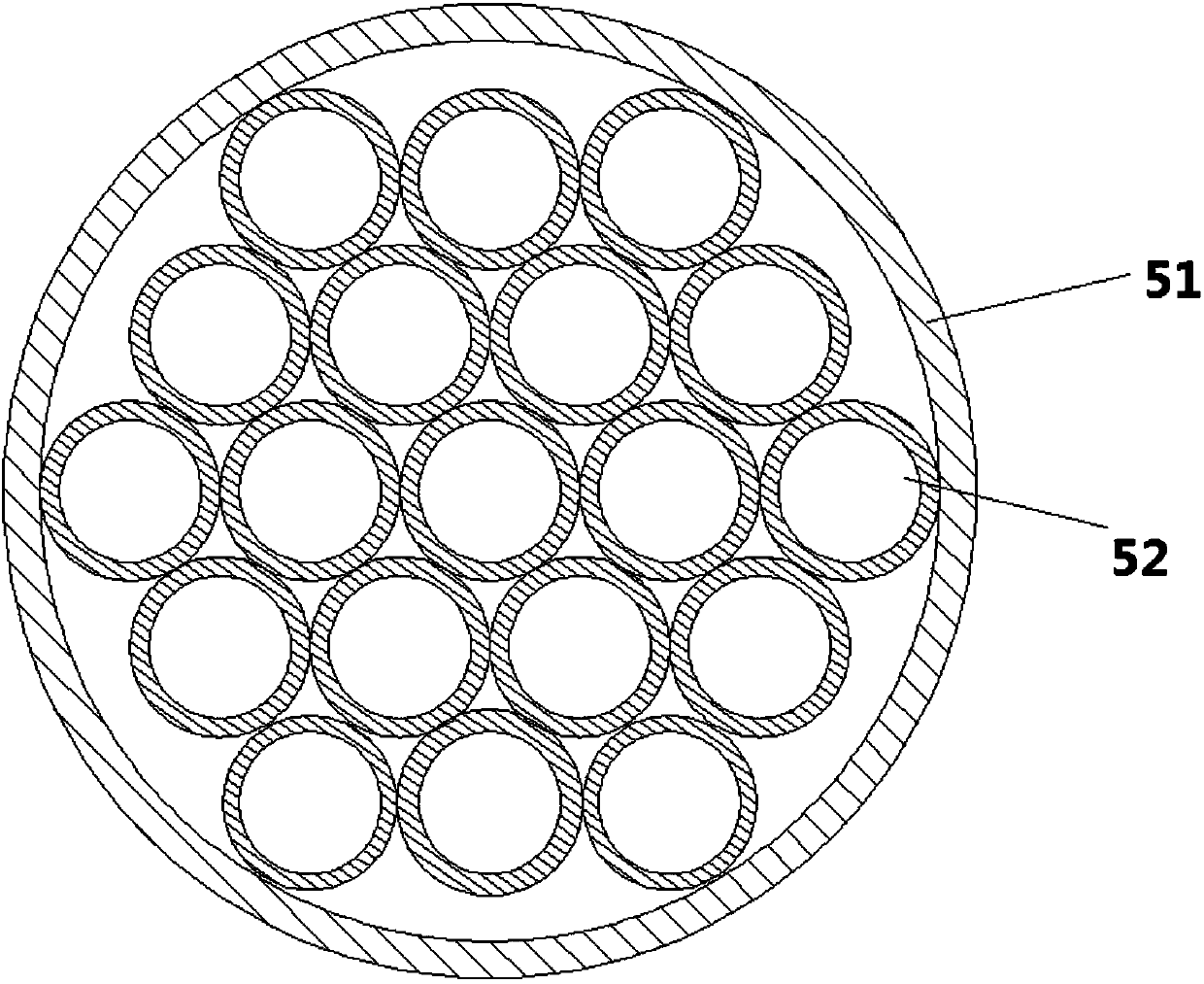

The invention provides a steam boiler which comprises an upper boiler barrel, a lower boiler barrel, ascending pipes and descending pipes. The ascending pipes and the descending pipes are connected between the upper boiler barrel and the lower boiler barrel. Flow stabilizing devices are arranged in the ascending pipes. Each flow stabilizing device comprises a core body and a shell, wherein the core body is arranged in the shell, the shell is connected and fixed to the inner wall of the corresponding ascending pipe, and the core body is formed by adjacently connecting a plurality of pipes in a combined mode. According to the steam boiler, the flow stabilizing devices are of novel structures; and when vapor-water two-phase flow exists in the ascending pipes, heat transfer is enhanced, meanwhile, the vibration of the ascending pipes is weakened, and the noise level is reduced.

Owner:蚌埠弘景科技有限公司

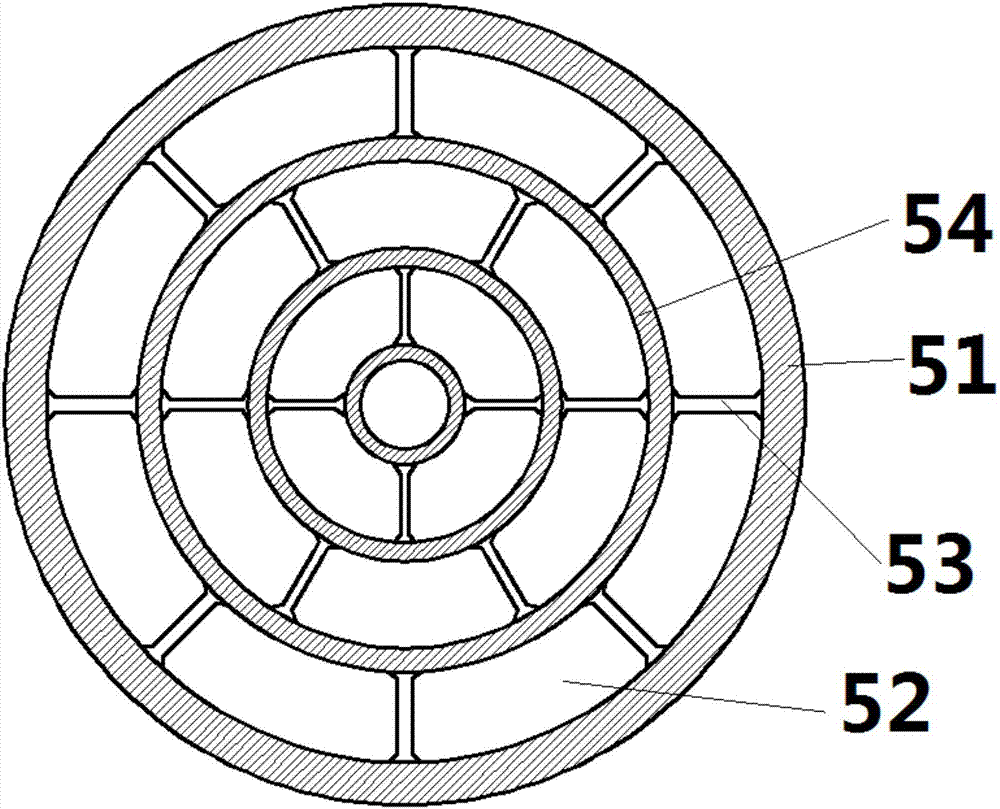

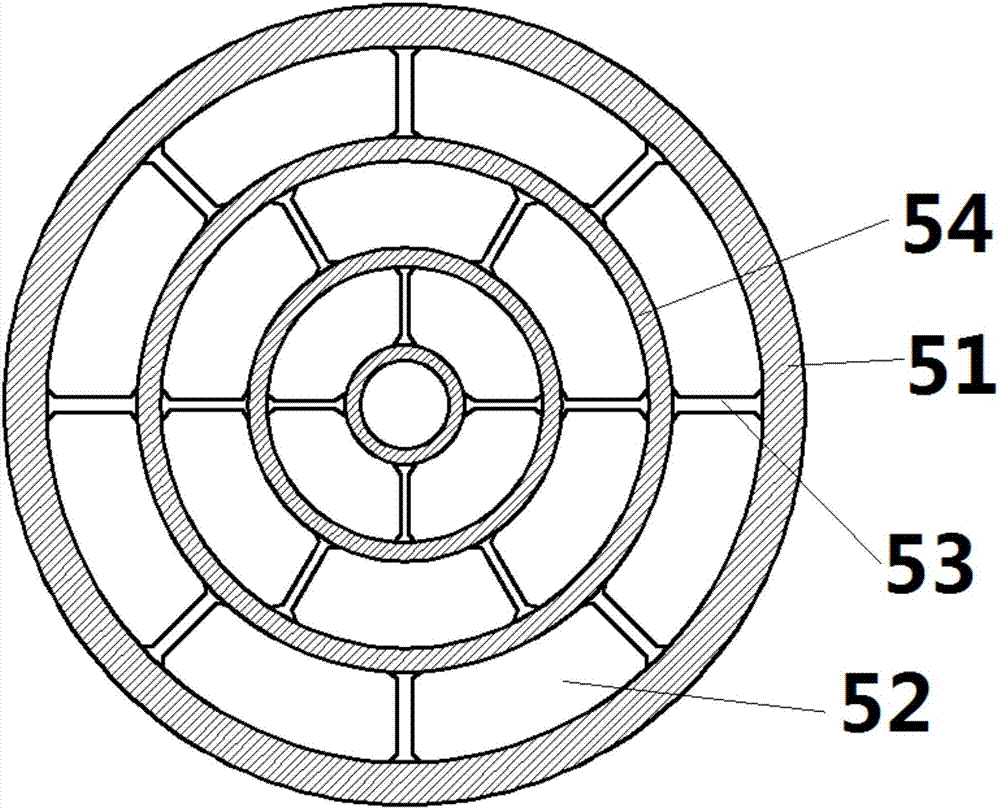

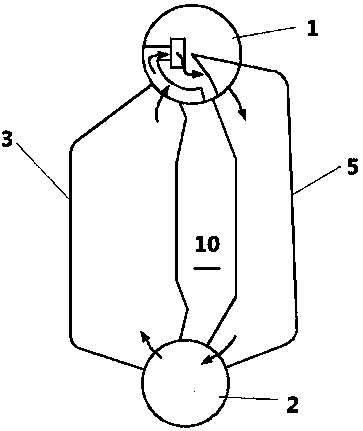

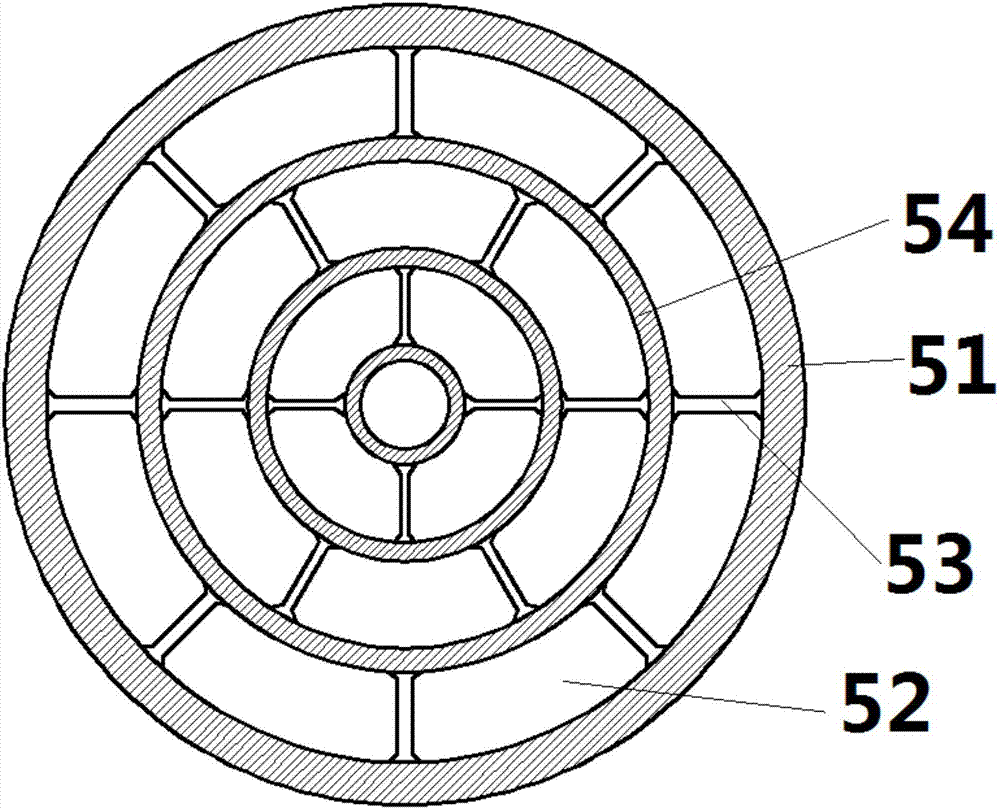

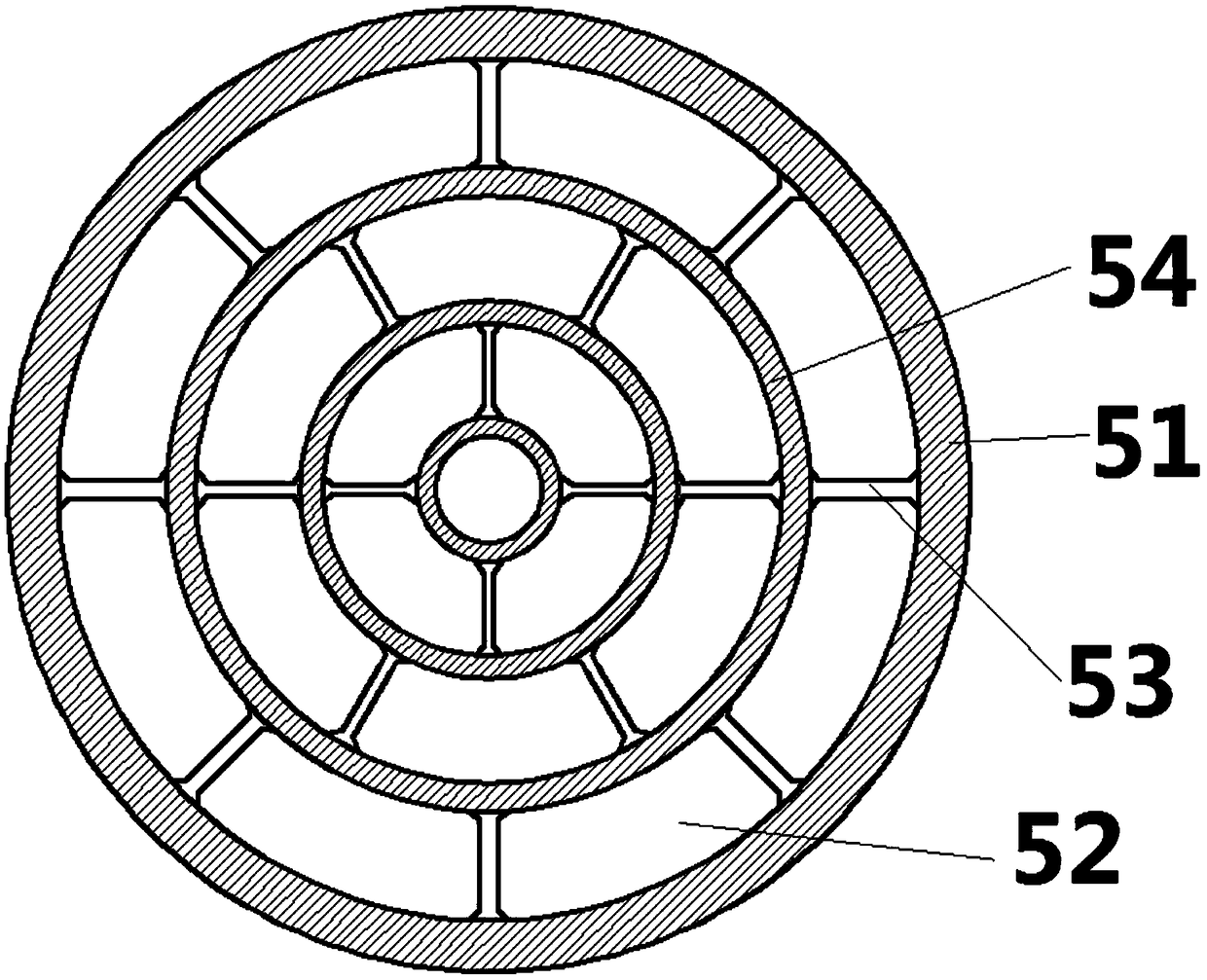

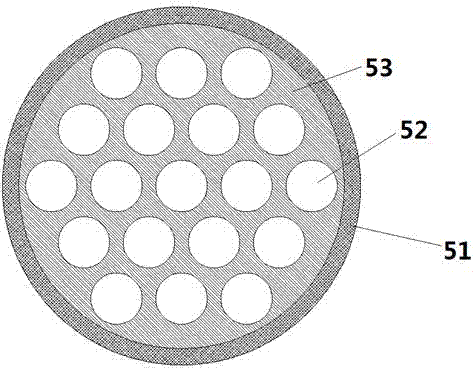

Condensable heat exchanger with annular separation devices

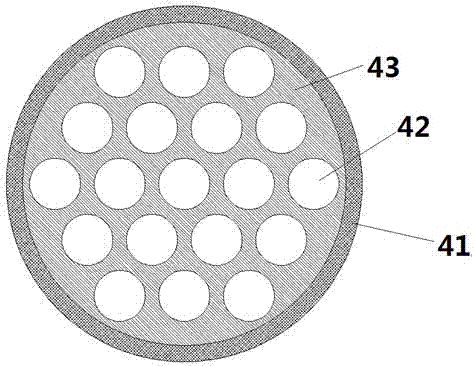

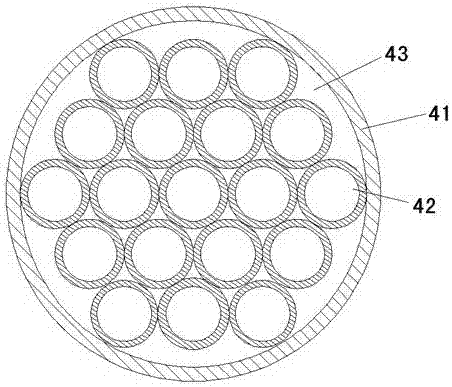

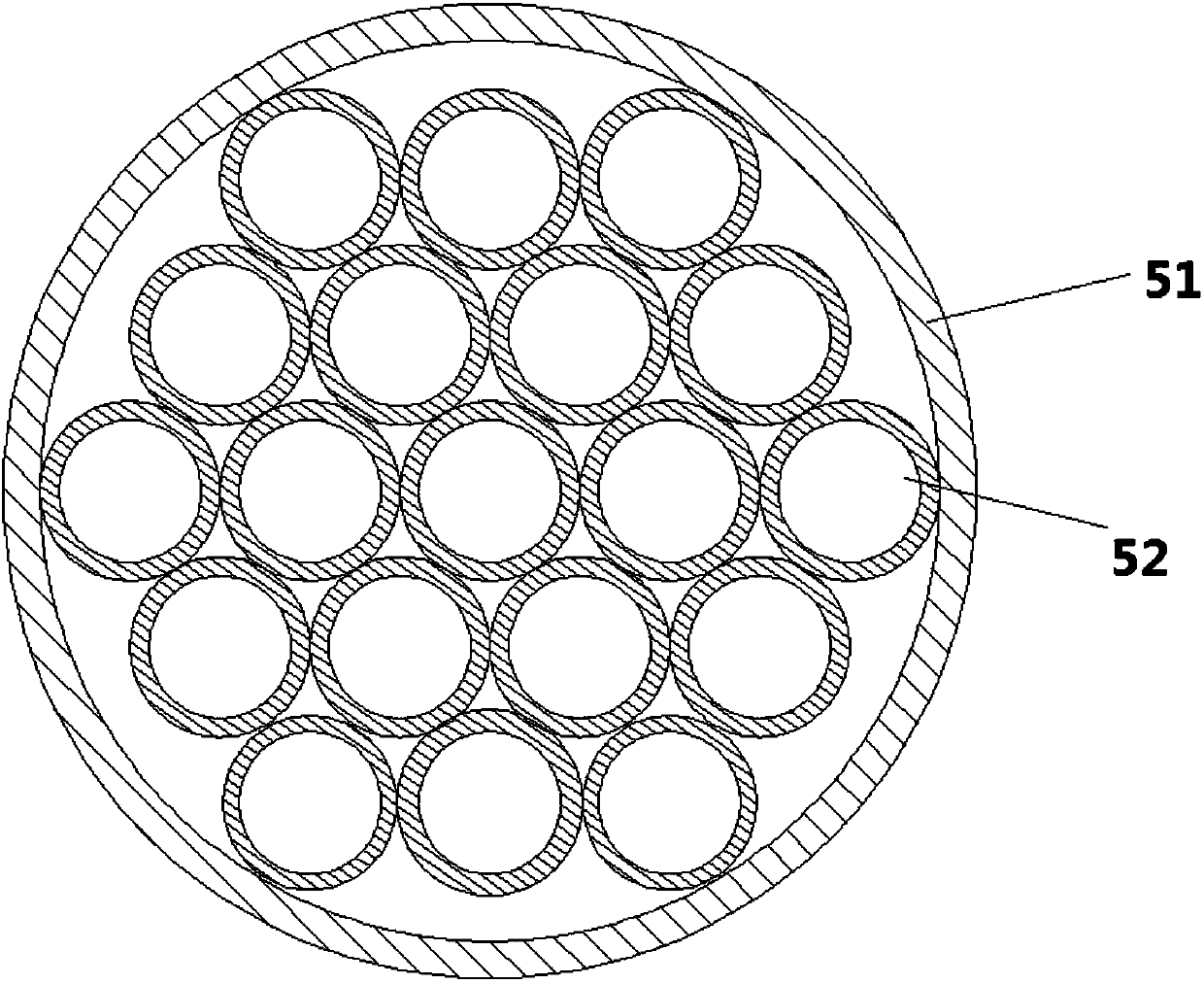

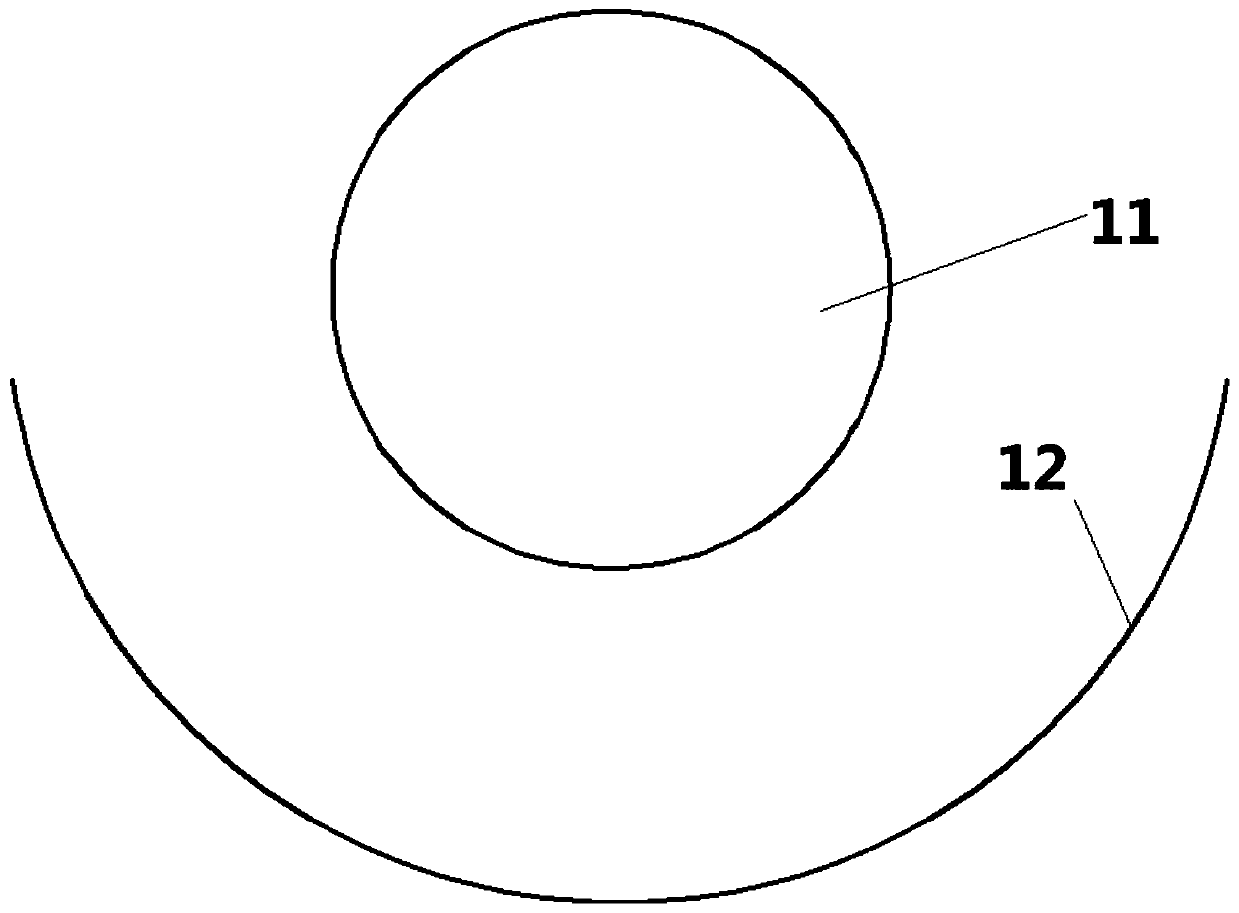

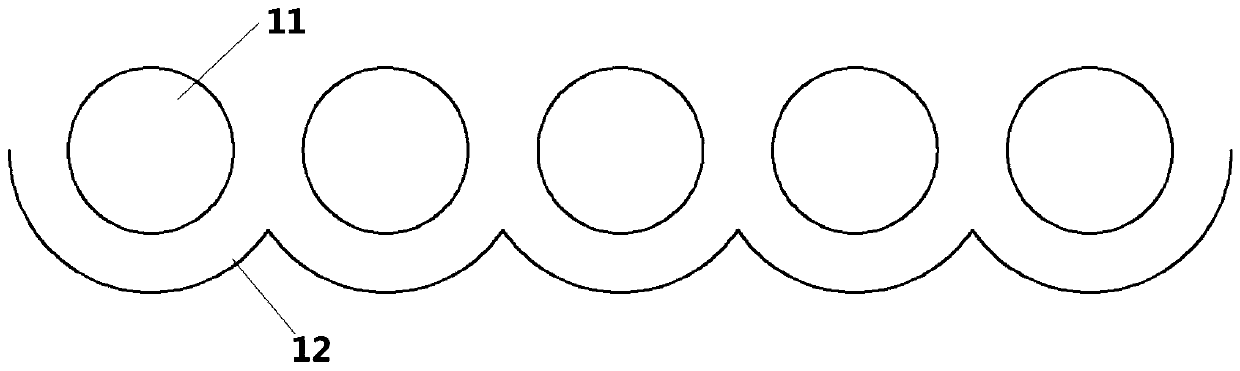

ActiveCN107044788AInhibit refluxStable flowStationary tubular conduit assembliesHeat transfer modificationEngineeringLiquid phase

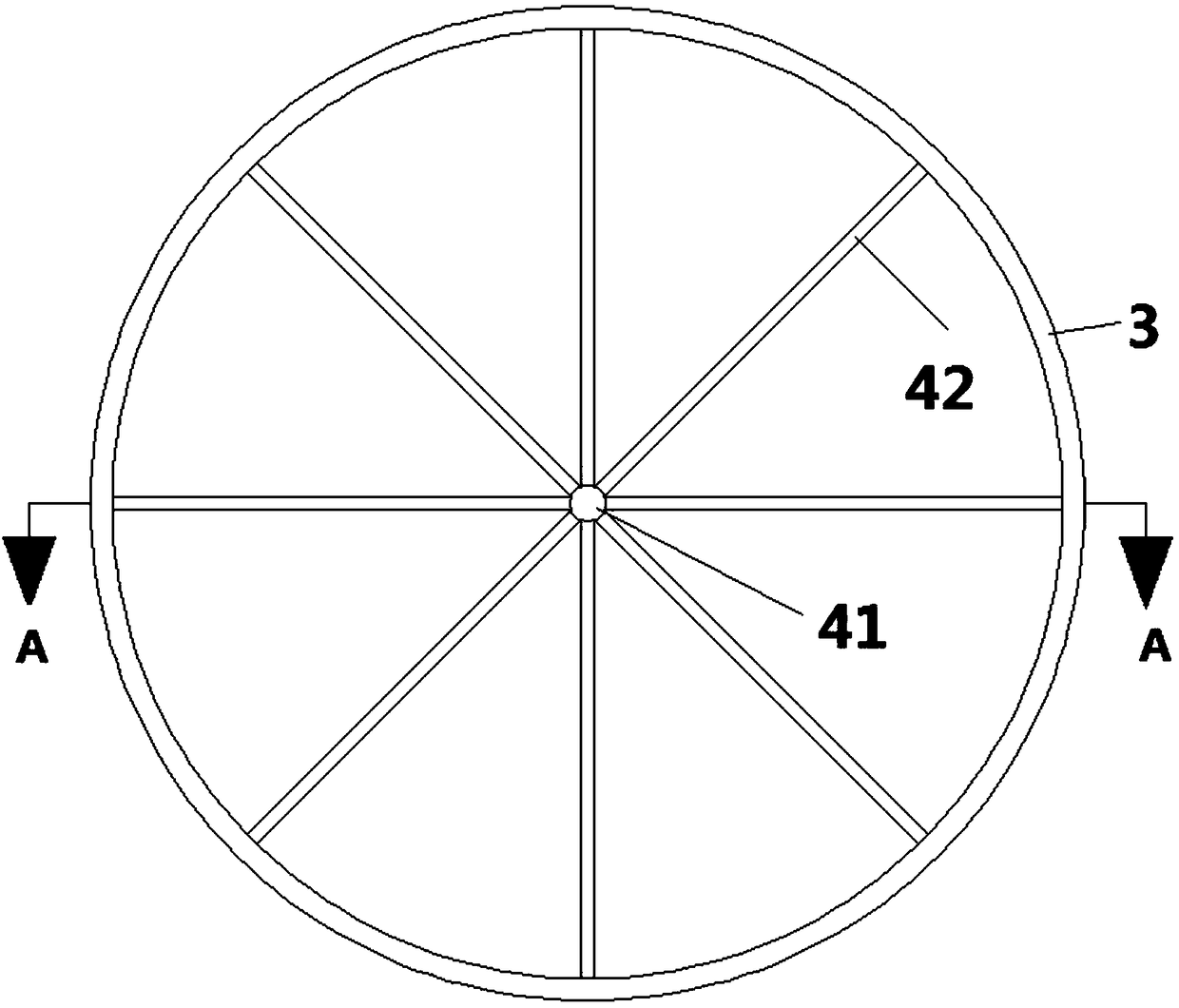

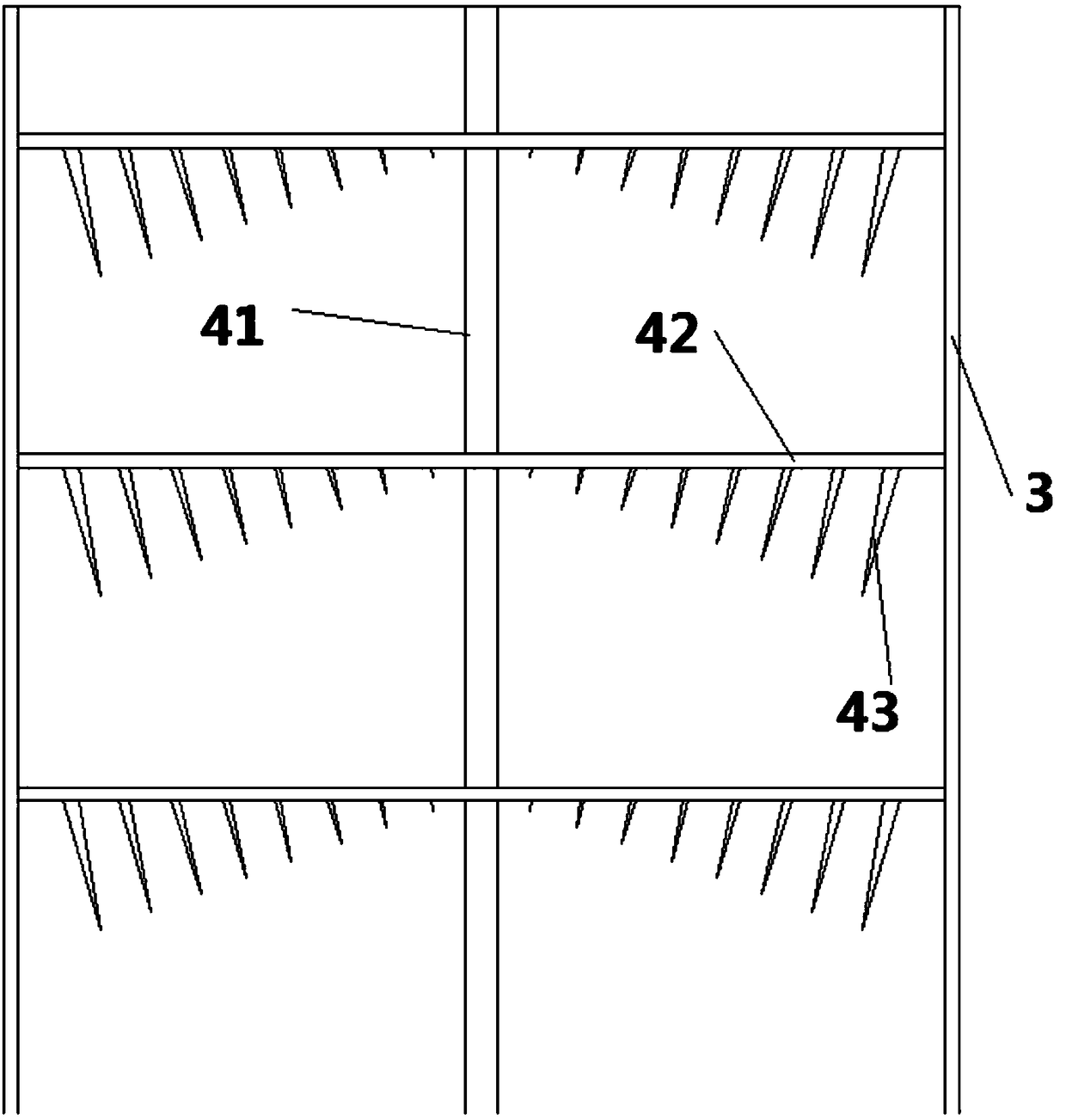

The invention provides a condensable heat exchanger with annular separation devices. The condensable heat exchanger comprises a shell. End sockets are arranged at the two ends of the shell correspondingly. A pipe plate is arranged at the connecting position of each end socket and the shell. A heat exchange pipe is connected with the pipe plates at the two ends. A steam phase in steam-phase and liquid-phase flow can be condensed to form a liquid phase in the heat exchange process, and the steam-phase and liquid-phase flow flows in a pipe pass. The separation devices are arranged in the heat exchange pipe. Each separation device comprises a core and a housing, wherein the core is arranged in the housing, the housing is connected with and fixed to the inner wall of the heat exchange pipe, the core comprises a plurality of concentric pipes and fins, and the fins are connected with the adjacent concentric pipes. According to the heat exchanger of a novel structure and with the separation devices, heat transfer is intensified when the steam-phase and liquid-phase flow flows in the pipe, meanwhile, pipe vibration is weakened, and the level of noise is lowered.

Owner:SHANDONG UNIV

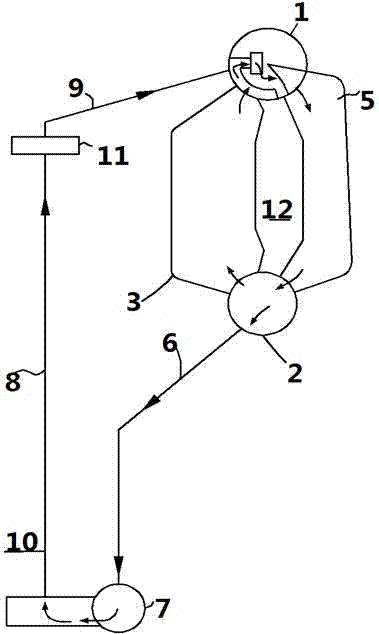

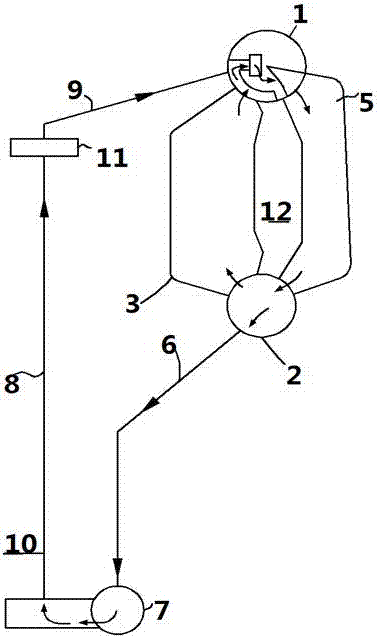

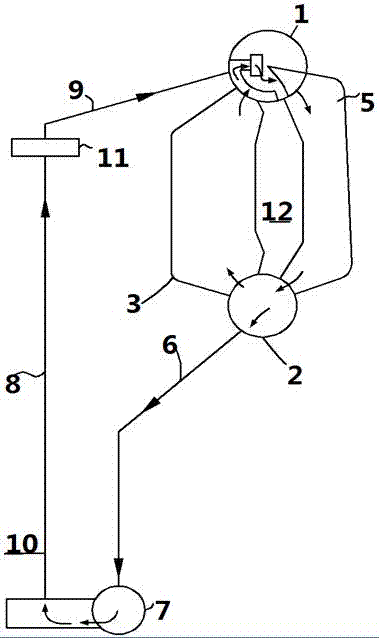

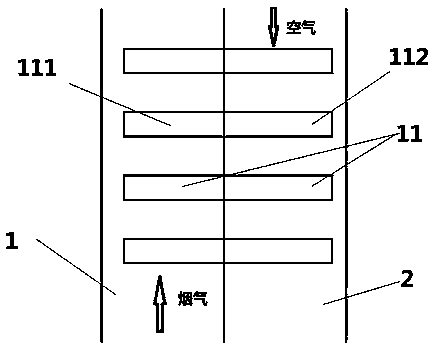

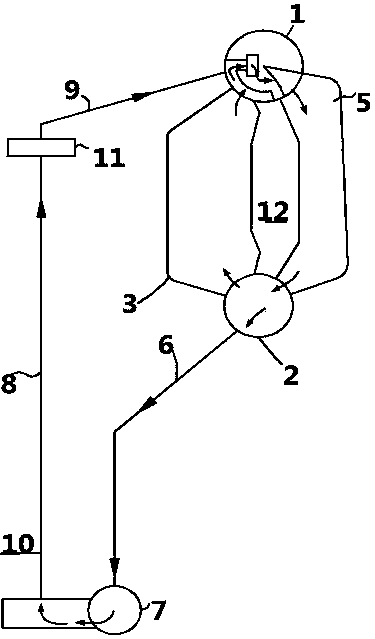

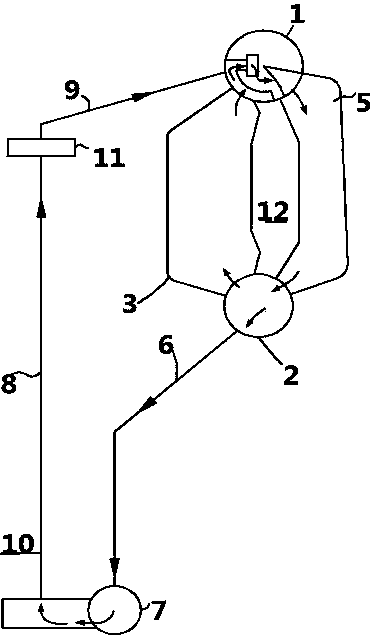

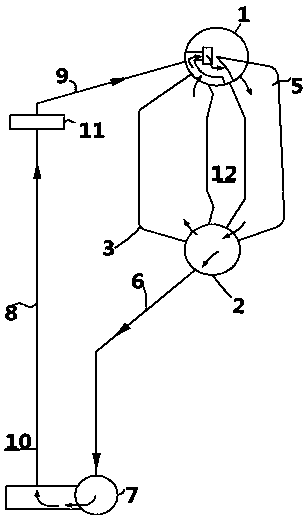

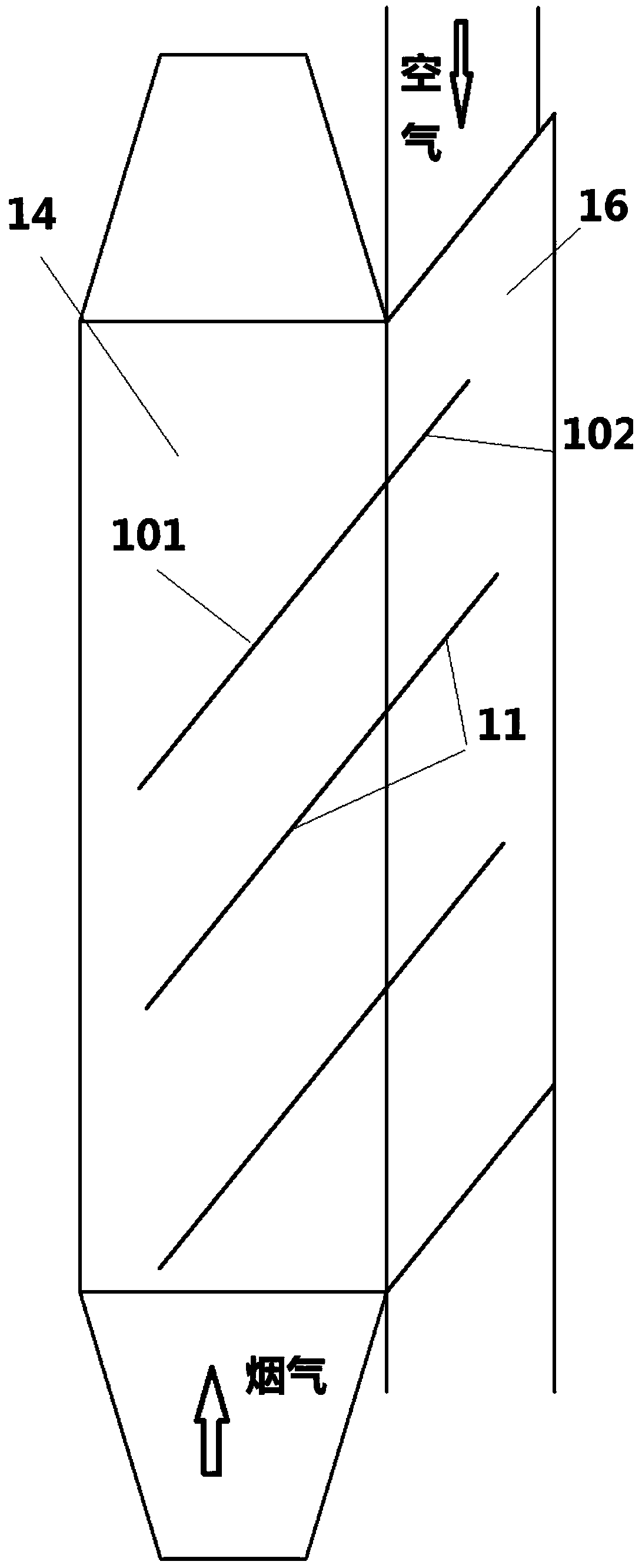

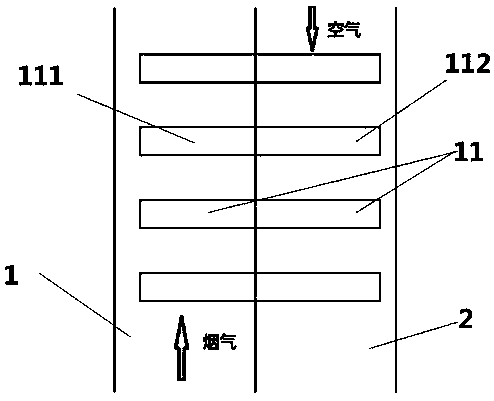

Power plant boiler flue gas waste heat utilization system with balanced flow

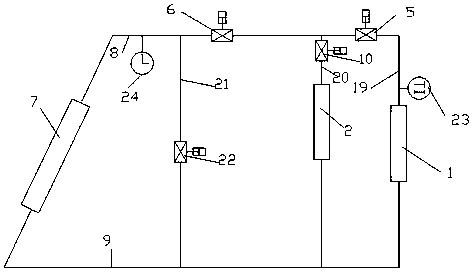

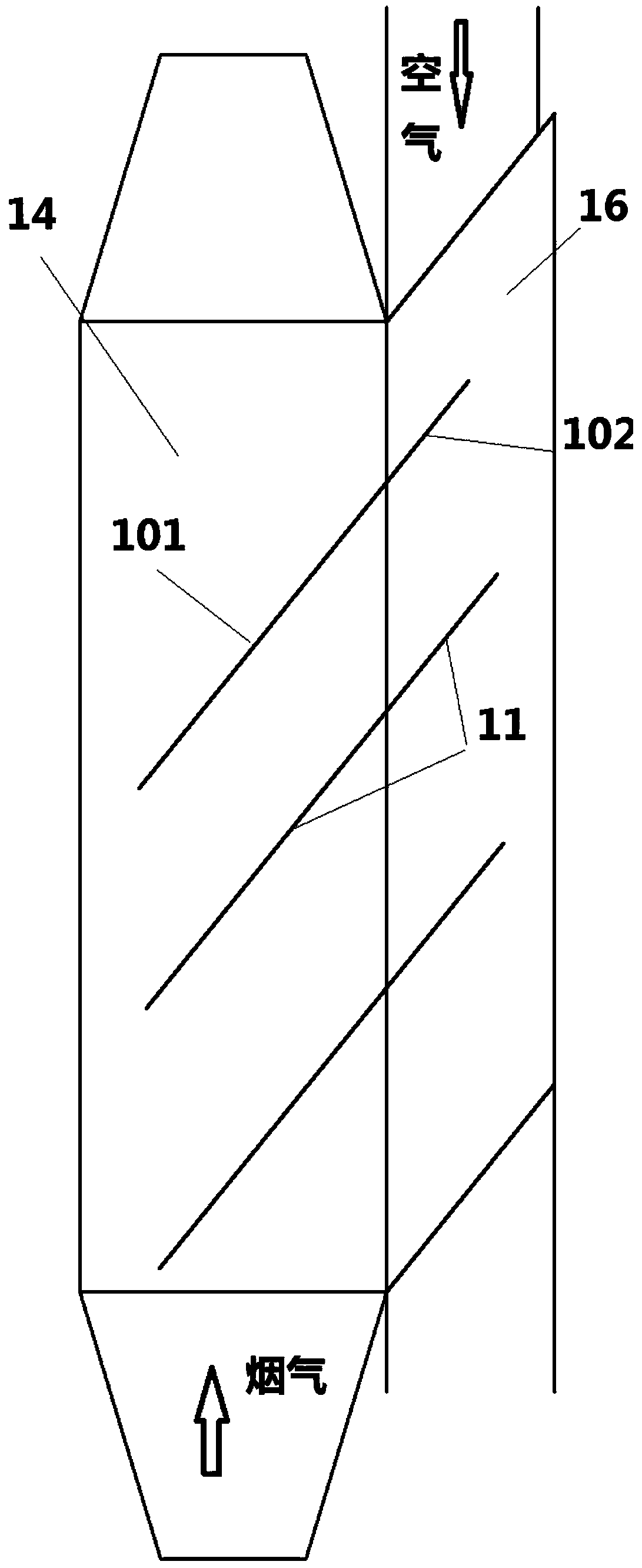

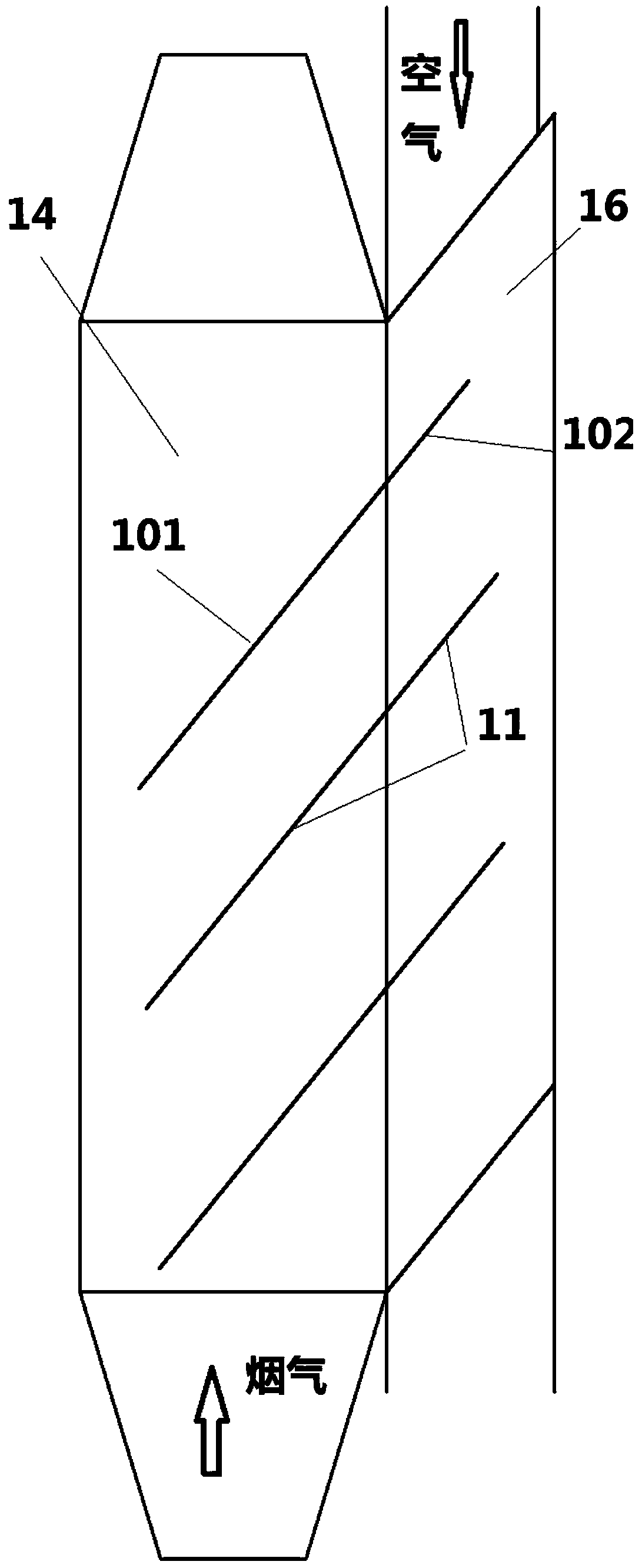

InactiveCN109519953AUniform pressureReduce short circuitIndirect heat exchangersBoiler furnaceProcess engineering

The invention provides a power plant boiler flue gas waste heat utilization system. The power plant boiler flue gas waste heat utilization system comprises a plurality of parallel heat pipes, a flue gas passage and an air passage, the heat pipes comprise evaporating ends and condensing ends, and the condensing ends are formed in the air passage; the evaporating ends are formed in the flue gas passage; the evaporating ends absorb waste heat of flue gas in the flue gas passage, and the heat is transferred to air in the air passage through the condensing ends; and the preheated air enters a boiler furnace for combustion supporting, and flow uniformizing pipes are arranged between the at least two adjacent heat pipes. According to the power plant boiler flue gas waste heat utilization system,a waste heat utilization device with a novel type structure is provided, and by arranging the flow sharing pipes between the heat pipes, evenness of the pressure, even distribution of the fluid flow and even distribution of fluid moving resistance in all the heat pipes are guaranteed.

Owner:山东电力高等专科学校

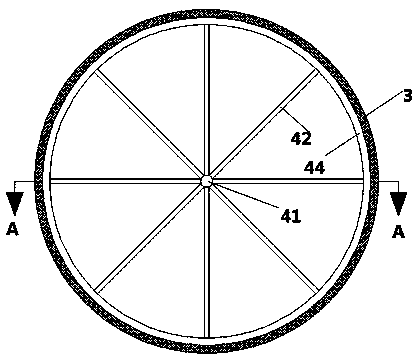

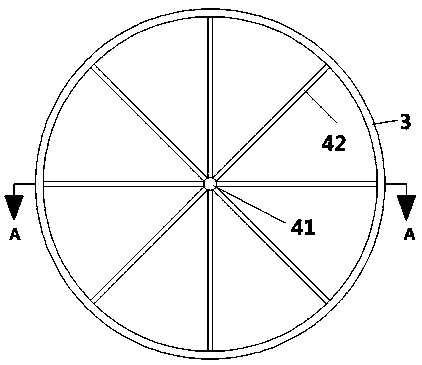

Steam boiler

ActiveCN108332179ASpeed up the flowStable flowSteam generation using pressureSteam boilersEngineeringHeat transfer

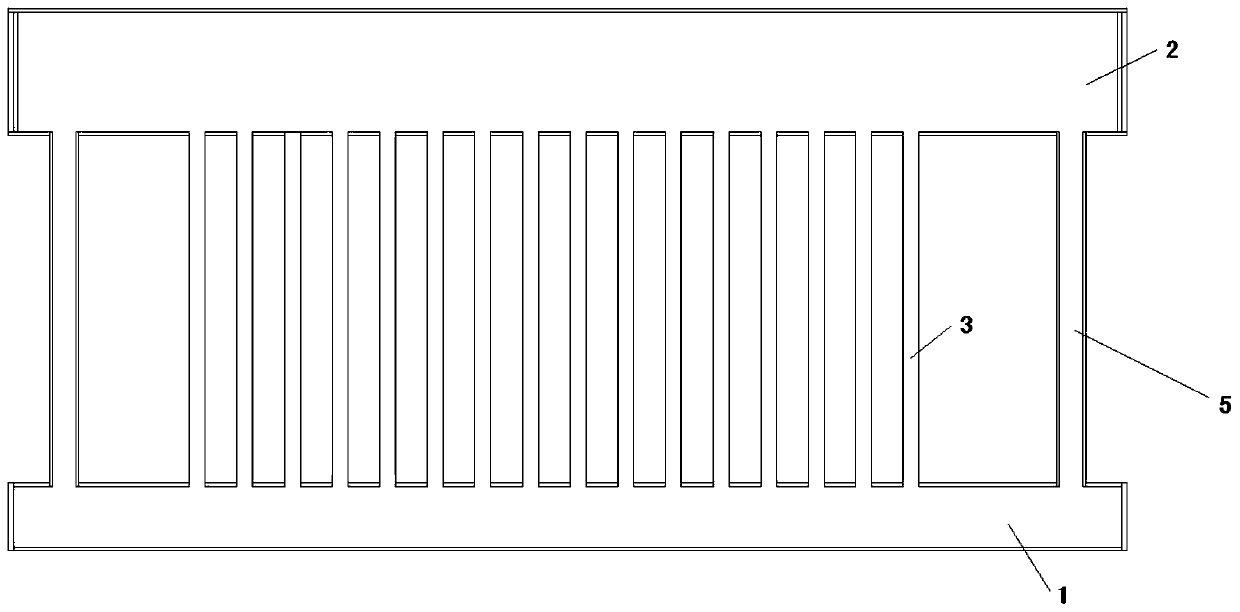

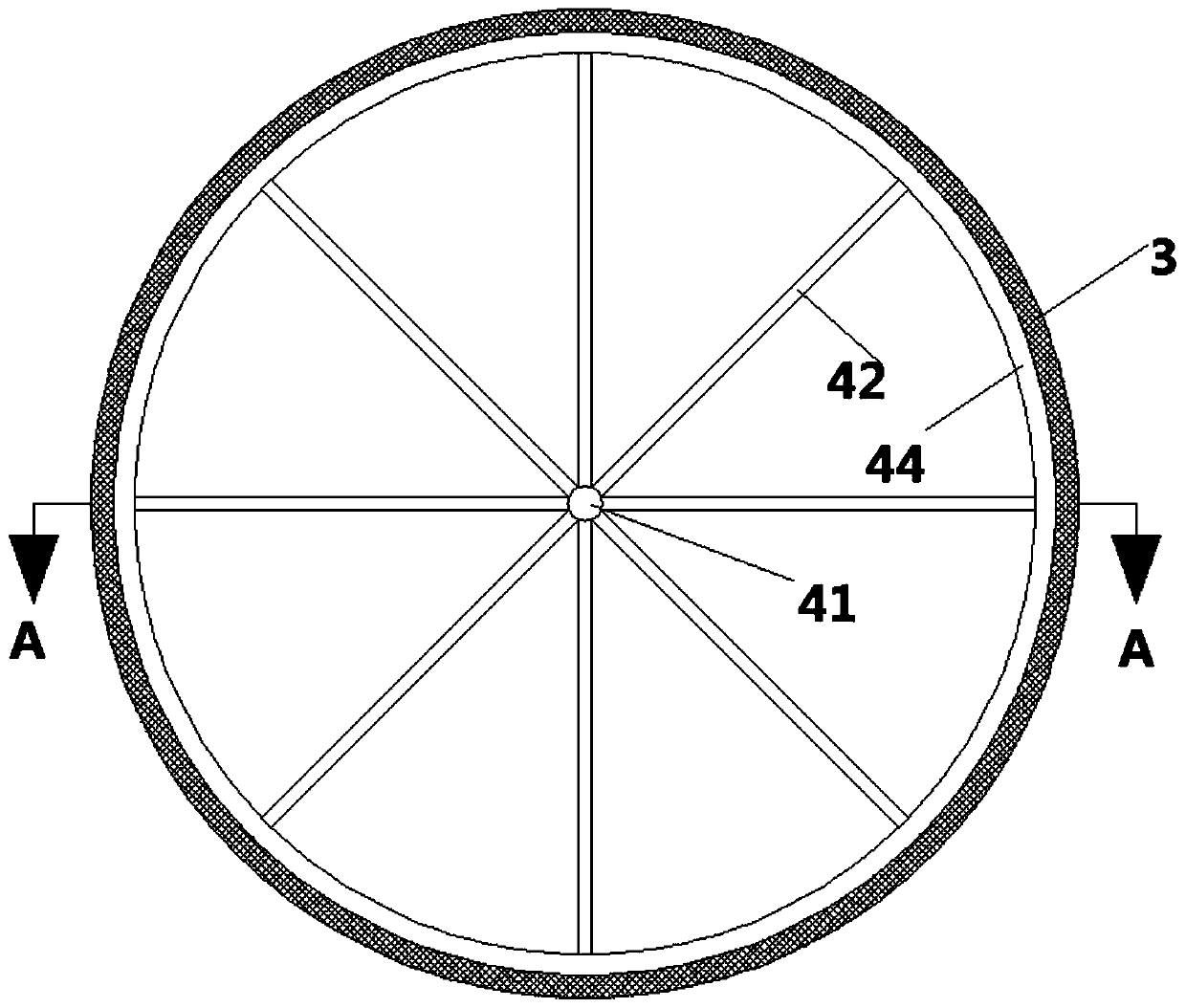

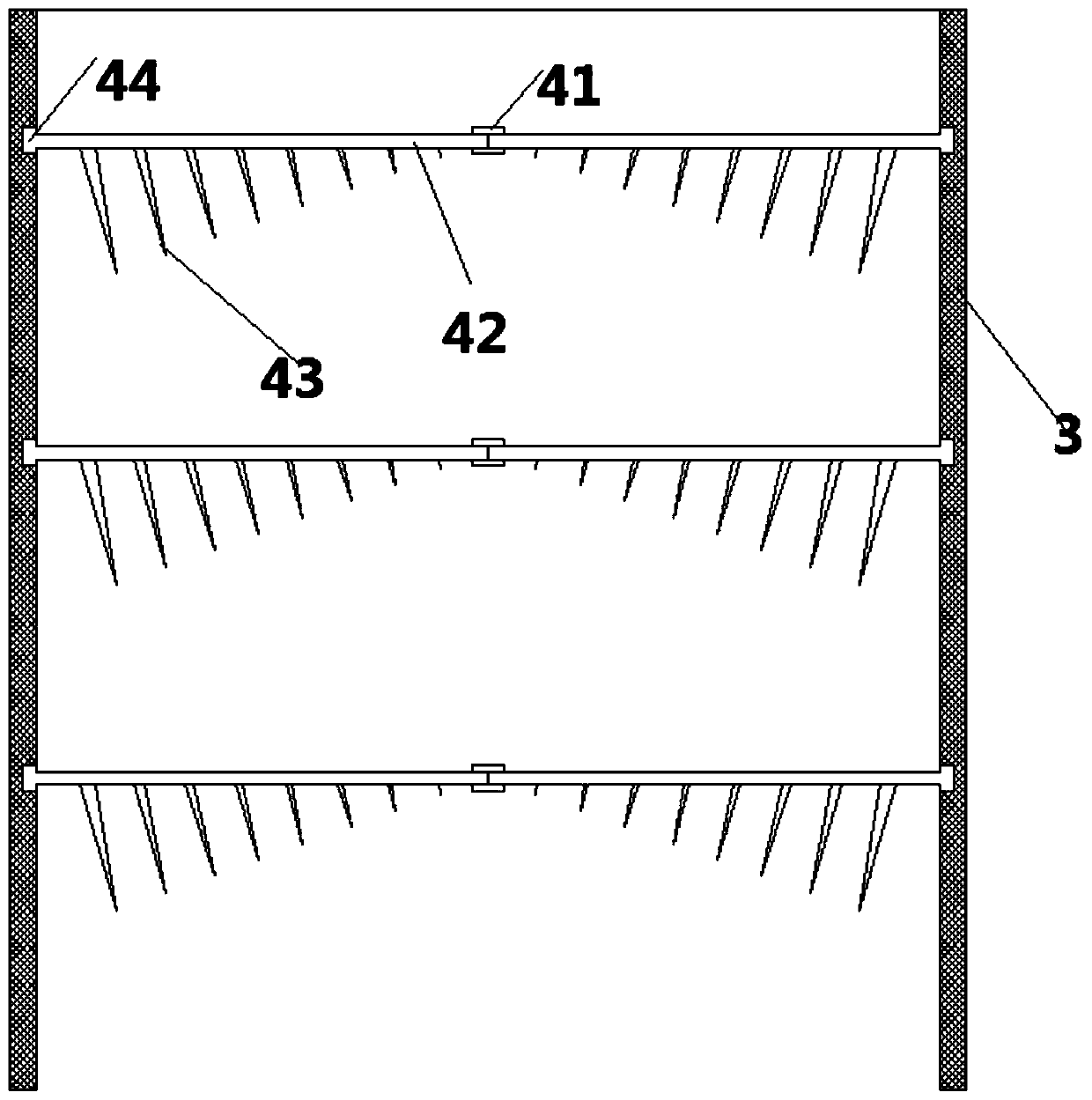

The invention provides a steam boiler which comprises an upper boiler barrel, a lower boiler barrel, ascending pipes and descending pipes; the ascending pipes and the descending pipes are connected between the upper boiler barrel and the lower boiler barrel; flow stabilization devices are arranged in the ascending pipes; each flow stabilization device comprises a core body and a shell; the core bodies are arranged in the shells; the shells are connected with and fixed to the inner walls of the ascending pipes; each core body comprises a plurality of radial rods extending from the center of thecore body to the radial directions; a plurality of fins extending from the radial rod down are arranged on each radial rod; the fins are provided with sharp parts; and the sharp parts face downwards.With the adoption of the novel structure steam boiler with the flow stabilization devices, when gas-liquid two-phase flowing exists in the ascending pipes, heat transfer is improved, vibration of theascending pipes is weakened, and the level of noise is lowered.

Owner:罗定市佳得利食品有限公司

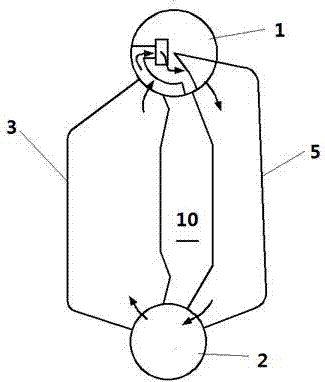

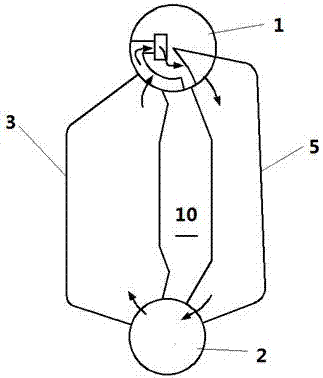

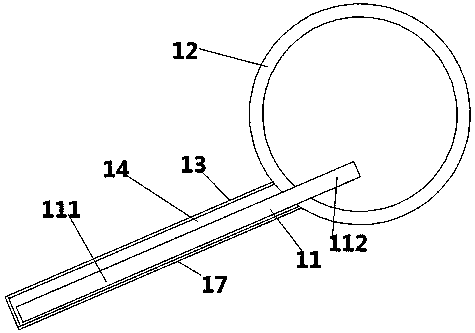

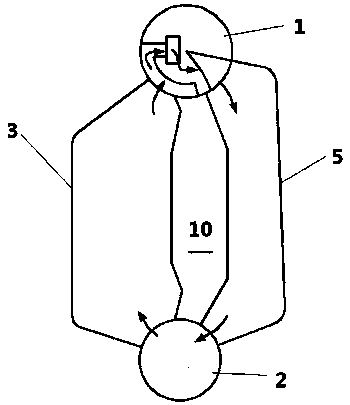

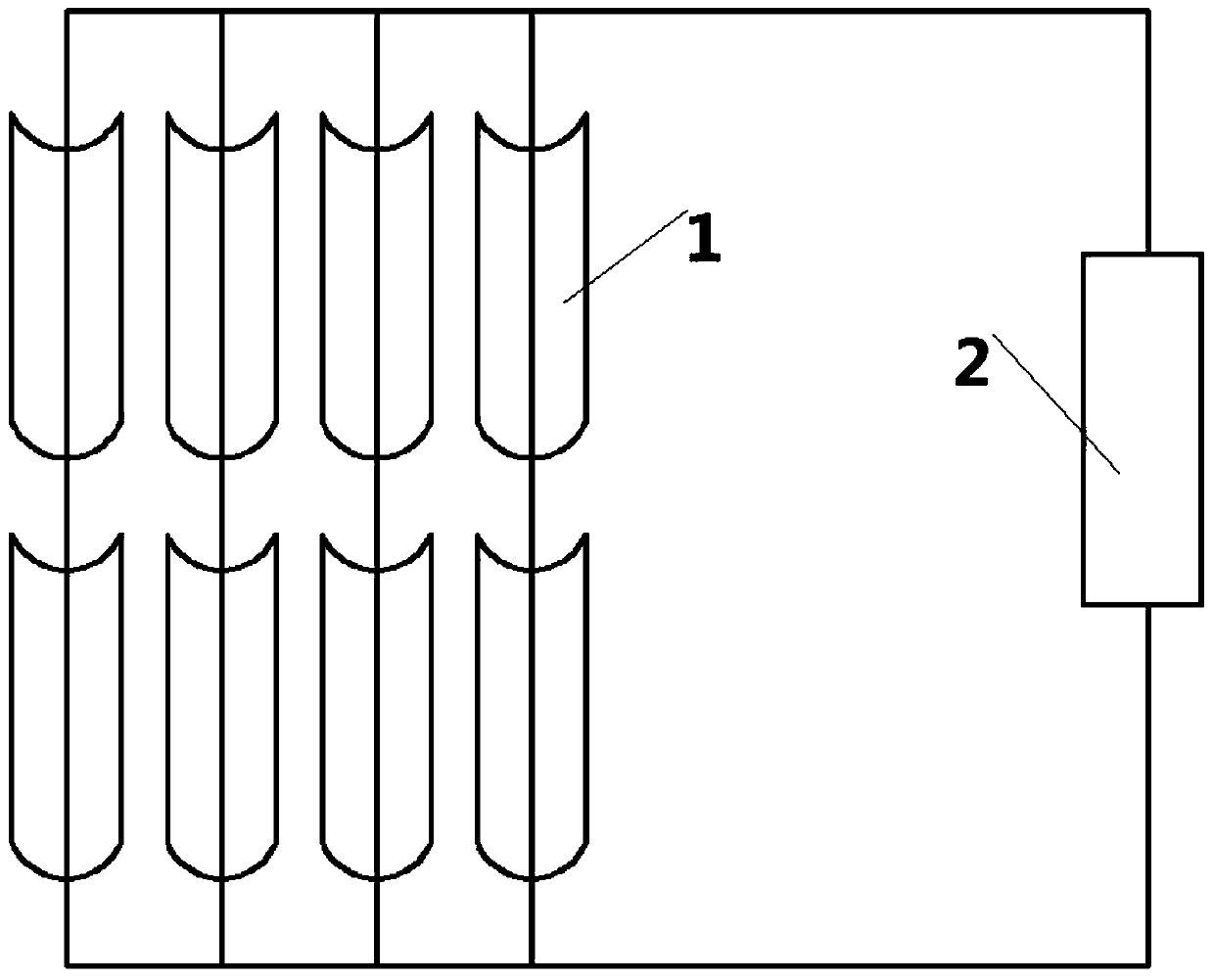

Loop heat pipe

InactiveCN109387104ASpeed up the flowStable flowIndirect heat exchangersHeat transfer modificationNoise levelEvaporation

The invention provides a loop heat pipe comprising an evaporation header, a condensation header, a riser tube and a return tube; the riser tube is in communication with the evaporation header and thecondensation header, the evaporation header is located at a lower portion, and the condensation header is located at an upper portion; the fluid absorbs heat in the evaporation header and evaporates,passes through the riser tube and enters the condensing header, and condenses after heat exchange in the condensing header, and the condensed fluid returns to the evaporation header through the returntube; a flow stabilization device is disposed in the riser tube, and the flow stabilization device comprises a central rod disposed along a central axis of the riser tube and a plurality of radial rods extending radially along the central rod; the radial rod is provided with a plurality of fins extending downward from the radial rod, the fins having a tip with the tip facing downward. The invention provides a loop heat pipe of a new type of flow stabilization device. By providing the radial rod and the downward tip fin, when there is a vapor-liquid two-phase flow in the riser tube, the heat transfer is enhanced, and the vibration of the riser tube is weakened, and the noise level is lowered.

Owner:SHANDONG UNIV

Solar system controlled by intelligent communication

ActiveCN109945528AMeet normal work needsAvoid wastingSolar heating energySolar heat collector controllersData connectionClosed loop

The invention provides a solar system controlled by intelligent communication. The solar system comprises a water heater, a heat reservoir, a total pipe valve and a central controller, wherein the total pipe valve is arranged on a total pipeline at the upstream of the water heater and the heat reservoir; the central controller realizes data connection with the total pipe valve; a hot fluid sensoris arranged in the total pipeline at the upstream of the total pipe valve; the hot fluid sensor is used for detecting whether hot fluid flows through the total pipeline; and the central controller isused for controlling the opening and closing of the total pipe valve of the data detected by the hot fluid sensor. According to the solar system provided by the invention, the opening and closing is intelligently controlled according to the fluid so that the closed loop function is realized between the heat reservoir and the water heater according to actual condition; when no fluid exists, the water heater is heated by utilizing the heat stored by the hot fluid so as to meet the actual work requirements of the water heater, thus solar energy can be fully utilized, and waste of too much heat isprevented.

Owner:山东信开源科技创新发展有限责任公司

Annular separating device heat exchanger with non-condensable gas

ActiveCN107036478AInhibit refluxSpeed up the flowHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerGas phase

The invention provides an annular structure separating device shell-and-tube heat exchanger with non-condensable gas. The heat exchanger comprises a shell body, heads are arranged at the two ends of the shell body correspondingly, a tube plate is arranged on the connection position of each head and the shell body, heat exchange tubes are connected with the tube plates at the two ends, and the gaseous phase in two-phase gas-liquid flow is an insoluble or slightly soluble gas, namely the gas does not dissolve in liquid in the heat exchange process; and separating devices are arranged in each heat exchange tube, each separating device comprises a core body and a shell, the cores are arranged in the shells, each shell is fixedly connected with the inner wall of the corresponding heat exchange tube, each core body comprises a plurality of concentric tubes and fins, and the fins connect adjacent concentric tubes. According to the annular structure separating device shell-and-tube heat exchanger with non-condensable gas, a heat exchanger with separating devices with a novel structure is provided, when two-phase gas-liquid flow exists in a pipeline, compared with the background technology, the heat exchanger further enhances heat transfer, weakens vibration of the pipeline and reduces the noise level.

Owner:SHANDONG UNIV

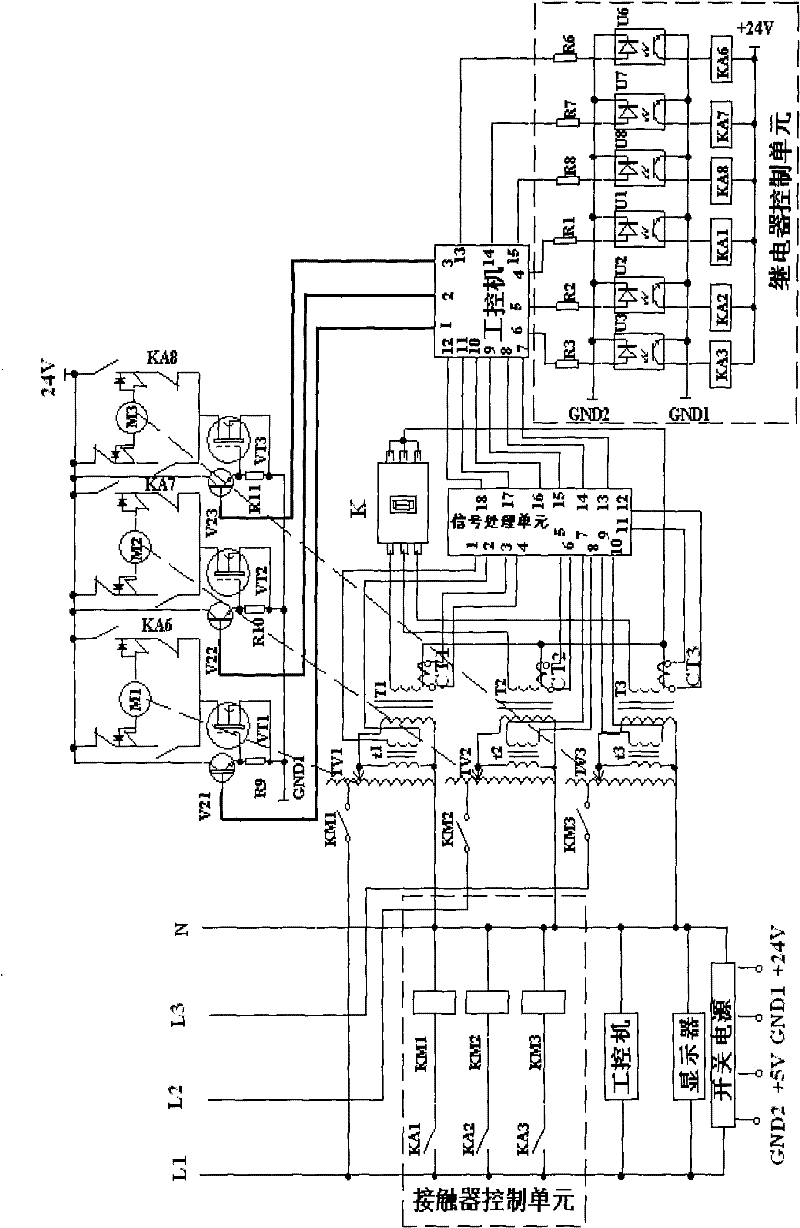

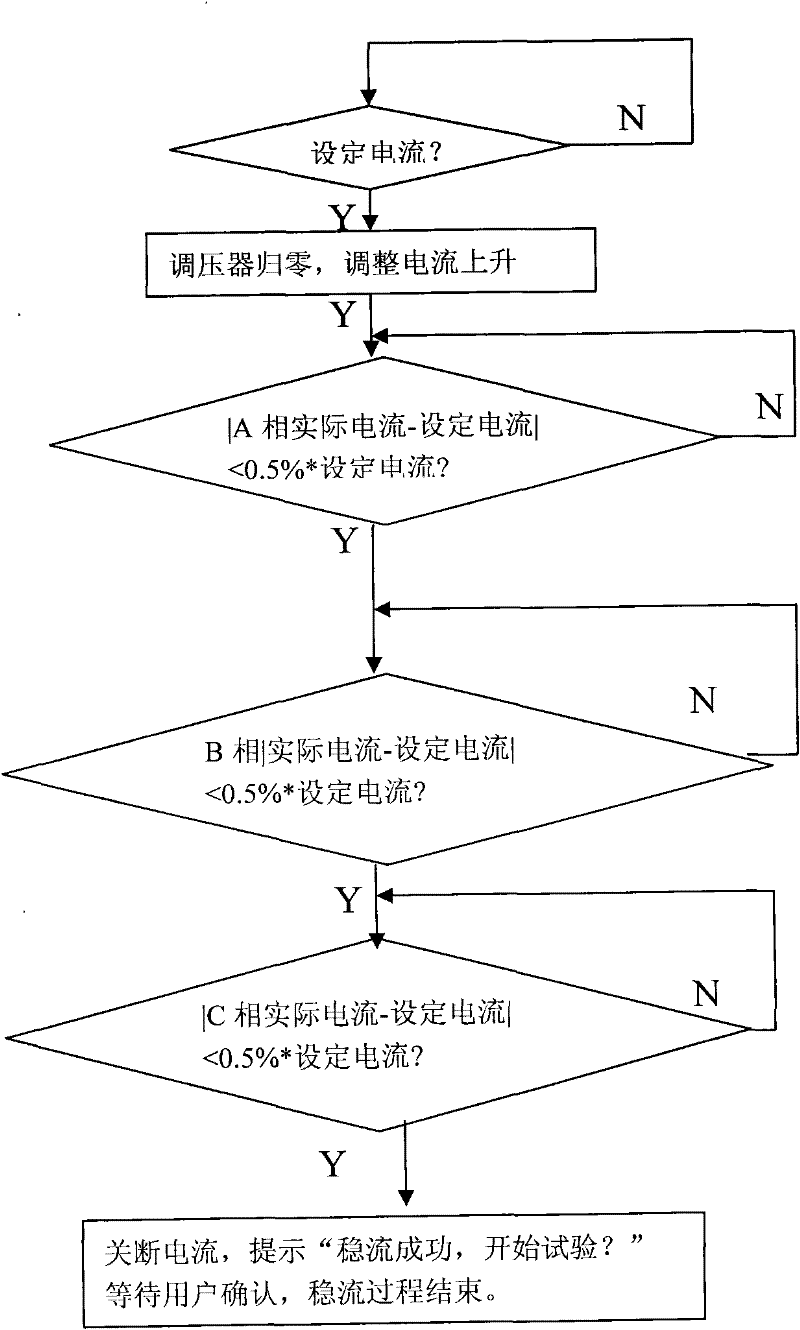

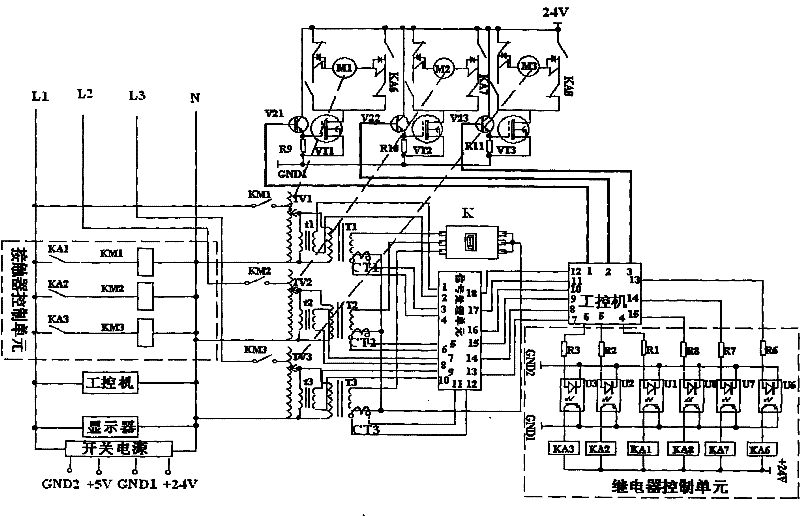

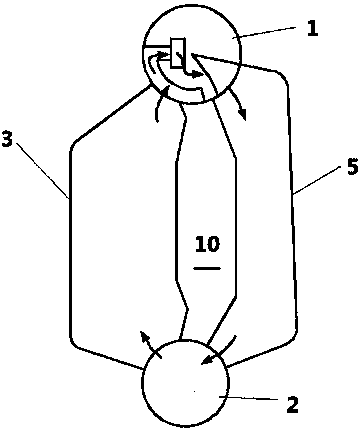

Intelligent frame breaker overload instant test-bed and control method

InactiveCN102175970AQuick responseFast steady flowCircuit interrupters testingPhase currentsTransformer

The invention relates to an intelligent frame breaker overload instant test-bed and a control method. The test-bed comprises an industrial control computer, an industrial touch display screen, and a stabilized power source; the industrial touch display screen is connected with the industrial control computer through a matched cable; the stabilized power source comprises a switch power source connected between 220 V power sources in parallel; an output port of the industrial control computer is connected to a signal processing unit and connect with a relay control circuit, a contactor control circuit, a motor control circuit and three automatic stabilized current circuits. For controlling a conduction time of a voltage-regulating motor, a transformer firstly computes voltage according to current required by a current acquiring signal, then computes the conduction time of the motor; three phases are repeatedly regulated to achieve the current-stabilization effect; furthermore, a testingcircuit is in starlike jointing method, other two phases can be influenced when any one phase current is adjusted; in addition, the testing circuit can act while feeding back a signal, thereby improving a current-stabilization speed; the current-stabilization time is within 2 seconds and the current-stabilization precision is high.

Owner:尹国祥 +5

Steam boiler

ActiveCN108332181ASpeed up the flowHas the effect of reducing vibration and noiseBoiler water tubesWater circulation promotionEngineeringHeat transfer

The invention provides a steam boiler which comprises an upper boiler barrel, a lower boiler barrel, ascending pipes and descending pipes; the ascending pipes and the descending pipes are connected between the upper boiler barrel and the lower boiler barrel; flow stabilization devices are arranged in the ascending pipes; each flow stabilization device comprises a core body axially arranged the center of the corresponding ascending pipe and a plurality of radial rods extending along the center rod to the radial directions; a plurality of fins extending from the radial rod downwards are arrangedon each radial rod; the fins are provided with sharp parts; and the sharp parts face downwards. With the adoption of the novel structure steam boiler with the flow stabilization devices, when gas-liquid two-phase flowing exists in the ascending pipes, heat transfer is improved, vibration of the ascending pipes is weakened, and the level of noise is lowered.

Owner:青岛吉云德和商贸有限公司

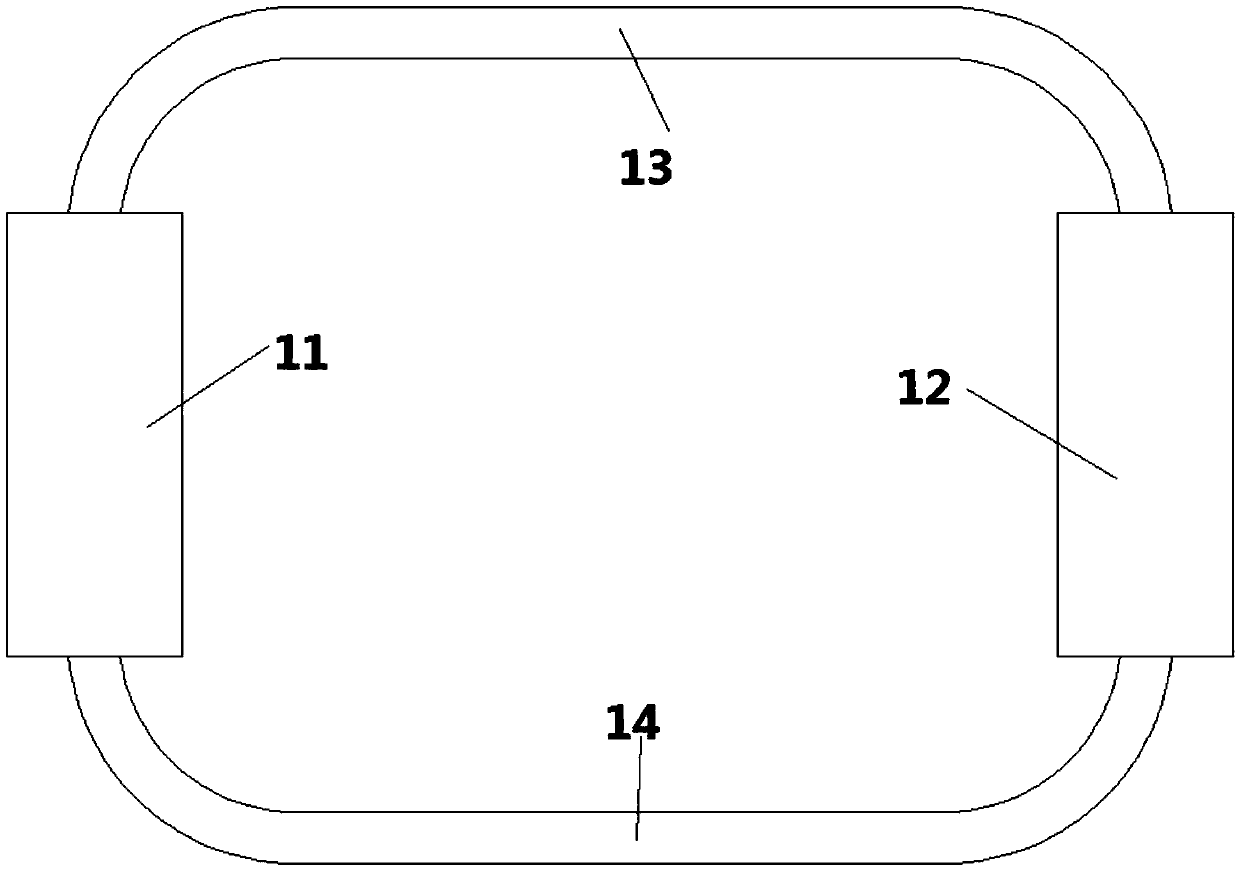

Heat pipe

ActiveCN107062959AInhibit refluxSpeed up the flowSafety devices for heat exchange apparatusIndirect heat exchangersNoise levelEvaporation

The invention provides a heat pipe which comprises an evaporation header, a condensation header, a rising pipe and a backflow pipe. The rising pipe is communicated with the evaporation header and the condensation header, the evaporation header is located at the lower portion, the condensation header is located at the upper portion, fluid absorbs heat and evaporates in the evaporation header, passes through the rising pipe to enter the condensation header and conducts heat exchange and condensation in the condensation header, and condensation fluid returns to the evaporation header through the backflow pipe; and a current stabilizer is arranged in the rising pipe and comprises a core body and a shell, the core is arranged in the shell, the shell is fixedly connected with the inner wall of the rising pipe, the core is an integrated structure piece extending in the length direction of the shell, and a plurality of through holes are formed in the structure piece. According to the heat pipe with the current stabilizer of the new structure, when vapor-liquid two-phase flow exists in the rising pipe, heat transfer strengthening is achieved; and meanwhile, vibration of the rising pipe is weakened, and the noise level is reduced.

Owner:JIANGSU TONGSHENG HEAT EXCHANGER

Rod-fin type loop heat pipe with varying sizes

InactiveCN111238274ASpeed up the flowStable flowSafety devices for heat exchange apparatusIndirect heat exchangersFluid phaseEngineering

The invention provides a rod-fin type loop heat pipe with varying sizes. The rod-fin type loop heat pipe includes an evaporation header, a condensation header, rising pipes and return pipes, flow stabilizing devices are arranged in the rising pipes, the flow stabilizing devices each include a core body and an outer shell, the core bodies are arranged in the outer shells, the outer shells are connected and fixed to the inner walls of the rising pipes, the core bodies each include a plurality of radial rods extending from the centers of the core bodies to the radial direction, and a plurality offins extending downwards from the radial rods are arranged on each radial rod; and the core bodies each include a core column arranged at the center of each core body, one ends of the radial rods arefixed into the core columns, and from the core columns of the rising pipes to the radial extension direction, the size of the fins on the same radial rods is getting larger and larger. According to the rod-fin type loop heat pipe with the varying sizes, the size of the fins on the rising pipe walls is increased, so that the ability to cut vapor phases and liquid phases near the pipe walls is enhanced. The ability to cut near the pipe walls is focused to be strengthened, and noise reduction and vibration damping can be targeted for specific situations, so that the effects of noise reduction and vibration damping are further achieved, and meanwhile, heat transfer can be further enhanced.

Owner:SHANDONG UNIV

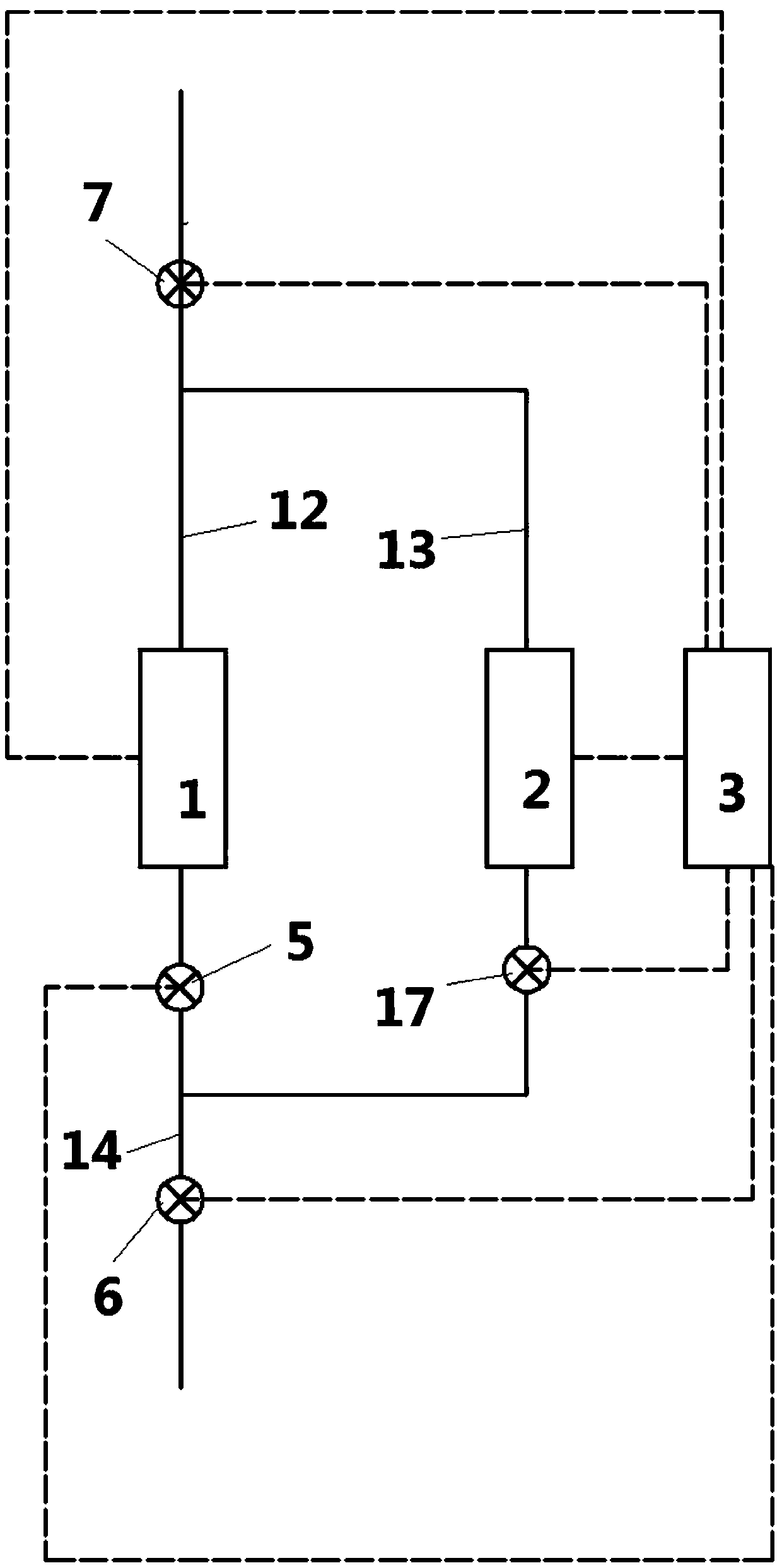

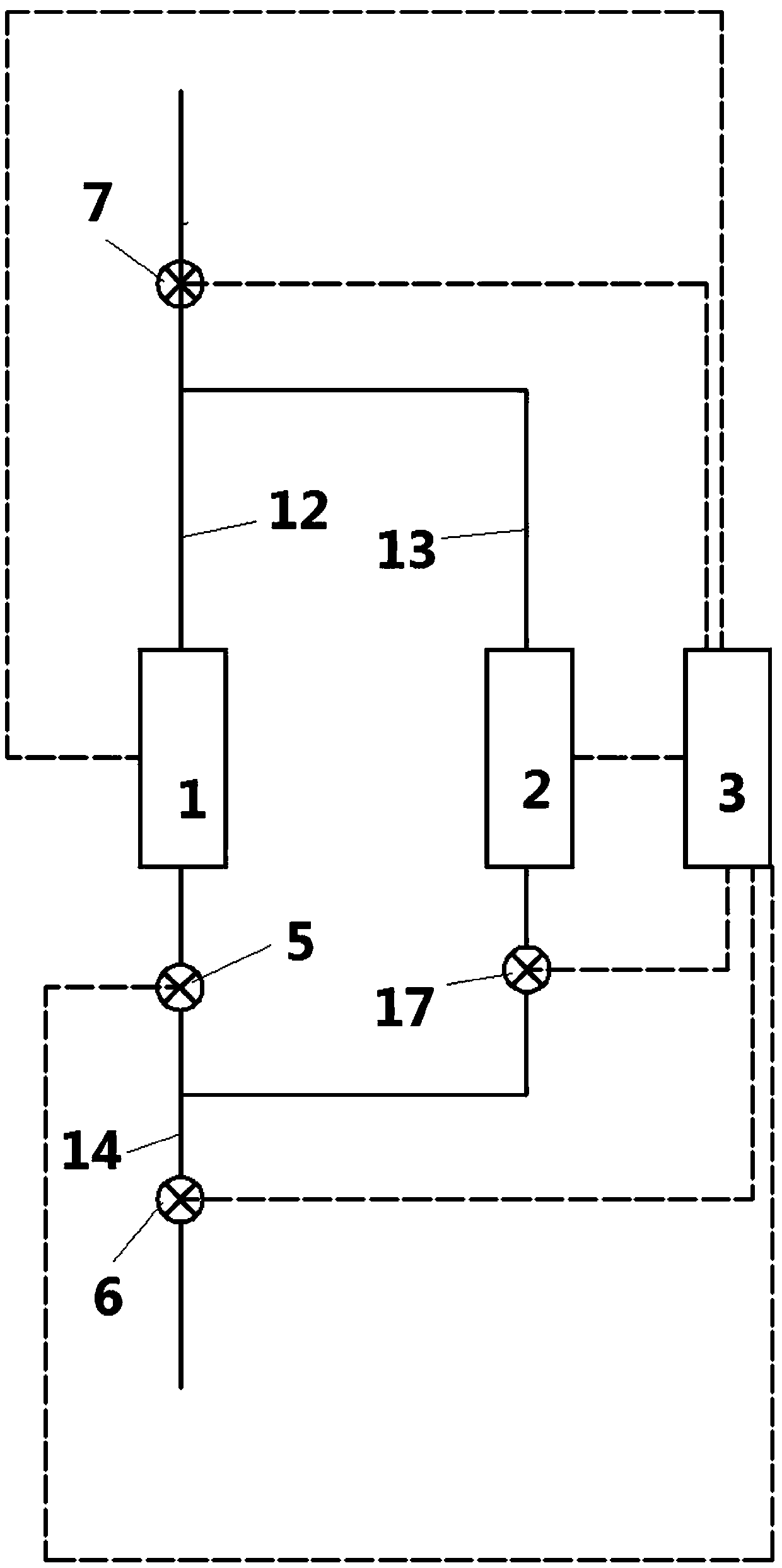

Power station boiler waste heat utilization system based on inlet flue gas temperature communication control

ActiveCN110529872AGuaranteed demandSave energyAir supply regulationIndirect heat exchangersAir preheaterData connection

The invention provides a power station boiler waste heat utilization system capable of intelligently controlling and utilizing waste heat. The system comprises an air preheater and a heat accumulator,the system further comprises a central controller. The central controller is in data connection with an air preheater valve and a heat accumulator valve, a third temperature sensor is arranged at theposition of a flue gas inlet of the air preheater, and the central controller automatically controls the valve opening of the air preheater valve and the valve opening of the heat accumulator valve according to the temperature detected by the third temperature sensor. Through the operation, when the temperature of flue gas is high and the generation requirement of preheated air is met, redundantheat is stored through the heat accumulator, and when the temperature of the flue gas is low, more flue gas can enter the air preheater to be used for preheating the air, so that the requirement of the preheated air is met, and meanwhile, energy is saved.

Owner:SUZHOU HAILU HEAVY IND

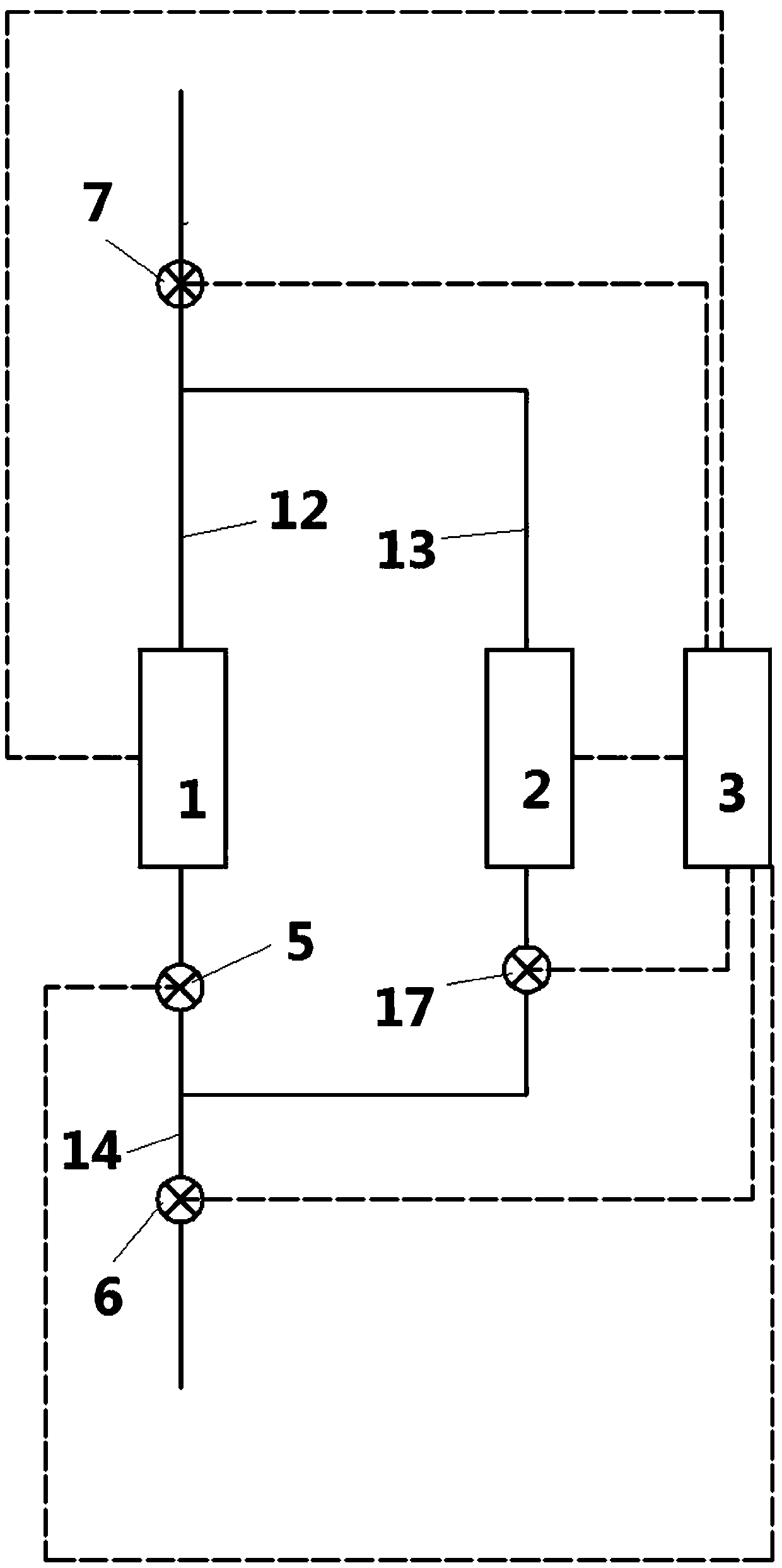

Intelligent communication controlled power station boiler waste heat utilization system

InactiveCN109959025AMeet normal work needsAvoid wastingAir supply regulationIndirect heat exchangersAir preheaterPower station

The invention provides an intelligent communication controlled power station boiler waste heat utilization system which comprises an air preheater and a heat reservoir. The system comprises an upstream valve and a downstream valve. The upstream valve is arranged on an upstream flue of the air preheater and the heat reservoir, and the downstream valve is arranged on a downstream flue of the air preheater and the heat reservoir. The system also comprises a central controller which controls on-off of the upstream valve and the downstream valve according to data detected by a flue sensor. According to the system, on-off of the valves is controlled intelligently according to the flue gas flow, so that a closed loop circulating function between the heat reservoir and the air preheater is achieved according to the actual condition. Under the circumstance of no flue gas waste heat, the air preheater is heated by means of heat stored by the flue gas waste heat to meet the actual working demandof the air preheater, so that the flue gas waste heat can be utilized fully, and excessive heat waste is avoided.

Owner:XUCHANG LONGGANG POWER GENERATION

Flow stabilizer distance enlarging condensable gas heat exchanger

InactiveCN107894178AReduce vibrationReduce noise levelStationary tubular conduit assembliesHeat transfer modificationPlate heat exchangerGas phase

The invention provides a gas-liquid two-phase flow multi-tube type shell-tube heat exchanger. The gas-liquid two-phase flow multi-tube type shell-tube heat exchanger comprises a shell. Sealing heads are arranged at the two ends of the shell correspondingly. Tube plates are arranged at the connecting positions of the sealing heads and the shell. Heat exchange tubes are connected with the tube plates at the two ends, and a gas phase in gas-liquid two-phase flow can be condensed into a liquid phase in the heat exchange process. Each heat exchange tube is internally provided with flow stabilizersfor damping and noise lowering. The same heat exchange tube is internally provided with the multiple flow stabilizers. In the flowing direction of fluid in the heat exchange tubes, the distance between the adjacent flow stabilizers is gradually increased. According to the provided gas-liquid two-phase flow multi-tube type shell-tube heat exchanger, through the length changes of the flow stabilizers, when gas-liquid two-phase flow exists in a pipeline, pipeline vibration is weakened to the maximum degree, the noise level is reduced, meanwhile, flowing resistance is reduced, and the heat exchange uniformity is improved.

Owner:SHANDONG UNIV

Steam boiler method for pipe diameter design

InactiveCN108870353AReduce vibrationImprove heat transfer performanceBoiler water tubesSteam generation using pressureEngineeringHeat transfer

The invention provides a steam boiler method for pipe diameter design. The steam boiler method involves an upper boiler cylinder, a lower boiler cylinder, ascending pipes and descending pipes, whereinthe ascending pipes and the descending pipes are connected between the upper boiler cylinder and the lower boiler cylinder, the ascending pipes are internally provided with flow stabilizing devices,and each ascending pipe is internally provided with multiple flow stabilizing devices, wherein the design method comprises the steps that the distance from an inlet of one of the ascending pipes is H,the pipe diameter of each flow stabilizing device is D shown in the formula, wherein D' is first derivative of D, and D' is less than 0. The provided novel steam boiler design method has the advantages that heat transfer is strengthened, the vibration of the ascending pipes is weakened, and the noise level is reduced.

Owner:NANTONG ZHENRU MOULD TECH CO LTD

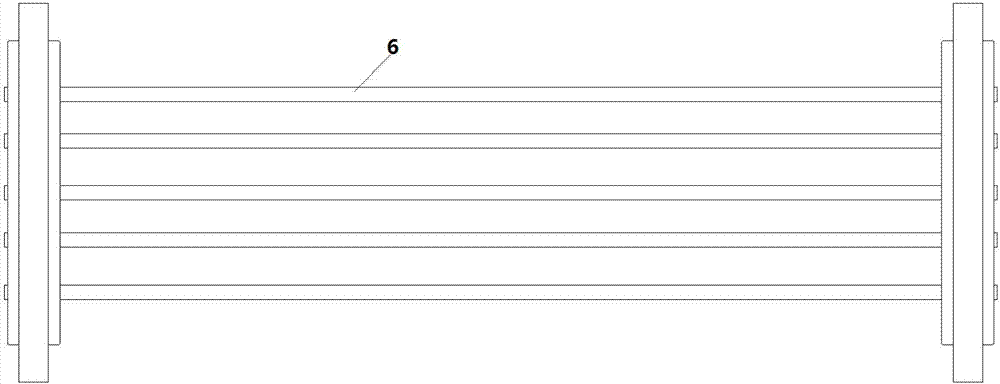

Noncondensable-gas tubular heat exchanger with lengths of flow stabilizing devices being variable

InactiveCN107869927AReduce vibrationReduce noise levelStationary tubular conduit assembliesHeat transfer modificationEngineeringFlow resistivity

The invention provides a gas-liquid two-phase flow multitube type tubular heat exchanger. The gas-liquid two-phase flow multitube type tubular heat exchanger comprises a shell. The two ends of the shell are each provided with an end enclosure. The connection position of each end enclosure and the shell is provided with a tube plate. Each heat exchange tube is connected with the tube plates at thetwo ends. A gas phase in gas-liquid two-phase flow is insoluble or indissolvable gas, and in other words, in the heat exchange process, the gas is not dissolved into liquid. The gas-liquid two-phase flow multitube type tubular heat exchanger is characterized in that the heat exchange tubes are internally provided with the flow stabilizing devices used for absorbing shock and reducing noise; each heat exchange tube is internally provided with the multiple flow stabilizing devices; and the lengths of the flow stabilizing devices are reduced to a certain position gradually in the flowing direction of fluid inside the heat exchange tubes in the first place, and then the lengths of the flow stabilizing devices are gradually increased from the certain position. According to the gas-liquid two-phase flow multitube type tubular heat exchanger, the lengths of the flow stabilizing devices are variable; when the gas-liquid two-phase flow exists in a pipe, vibration of the pipe is weakened to a greatest extent, and the noise level is lowered; and meanwhile, flow resistance is reduced.

Owner:SHANDONG UNIV

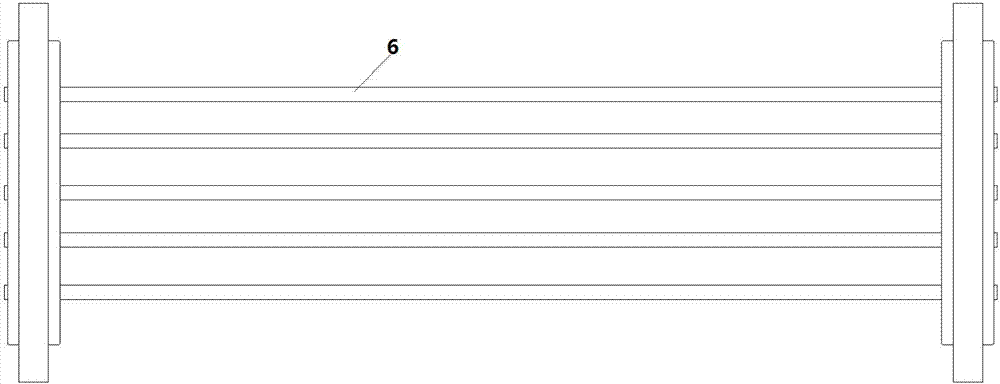

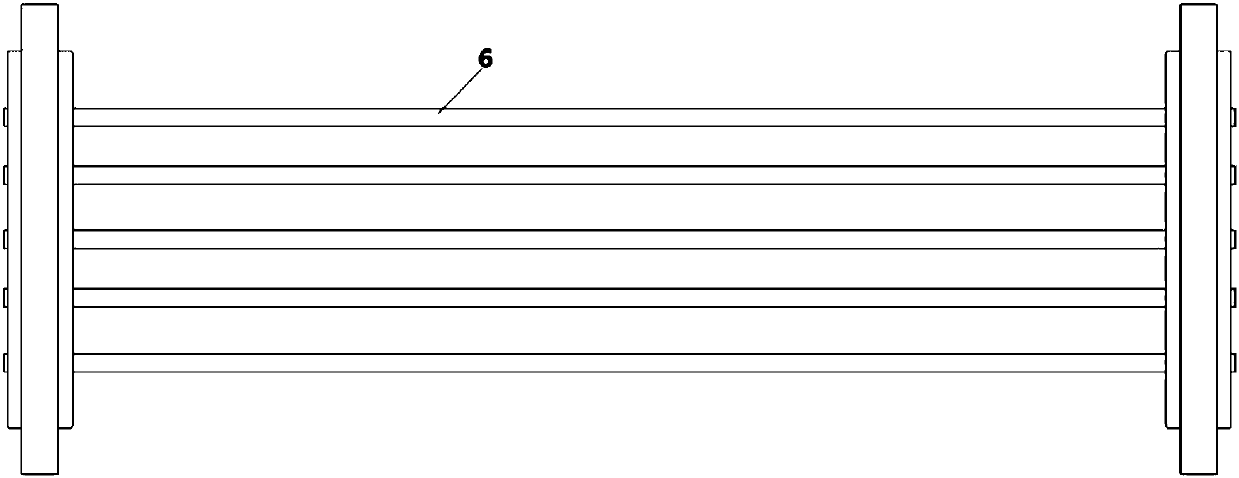

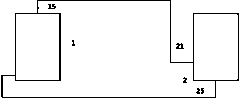

Tubular heat exchanger

ActiveCN108827036AReduce vibrationReduce noise levelHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerGas phase

The invention provides a tubular heat exchanger. The tubular heat exchanger comprises a shell, heat exchange tubes, a tube pass inlet tube, a tube pass outlet tube, a tube pass inlet connecting tube and a tube pass outlet connecting tube. A heat exchange tube bundle formed by the multiple heat exchange tubes which are arranged in parallel is connected to a front tube plate and a rear tube plate. The front end of the front tube plate is connected with a front sealing head. The rear end of the rear tube plate is connected with a rear sealing head. The tube pass inlet tube is arranged on the rearsealing head. The tube pass outlet tube is arranged on the front sealing head. The tube pass inlet connecting tube and the tube pass outlet connecting tube are both arranged on the shell. Fluid of two-phase flow enters through the tube pass inlet tube, carries out heat exchange through the heat exchange tubes, and goes out of the tube pass outlet tube. The fluid in the heat exchange tubes is thegas and liquid two-phase flow in which the gas phase is insoluble or slightly soluble gas, and in other words, the gas will not dissolve in the liquid in the process of heat exchange. The ratio of thelength L of each heat exchange tube to the diameter of the shell of the heat exchanger ranges from 6 to 10. The tubular heat exchanger is a gas and liquid two-phase flow heat exchanger of a novel structure.

Owner:SHANDONG UNIV

Power station boiler waste heat utilization system based on fume temperature communication control valve

ActiveCN110748912AMeet normal work needsAvoid wastingIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterPower station

The invention provides a power station boiler waste heat utilization system based on fume temperature communication control valve. The system comprises an air preheater and a heat storage device, a fourth temperature sensor is arranged in the flue upstream of an upstream valve, the fourth temperature sensor is used for detecting flue gas temperature in the flue, the fourth temperature sensor is indata connection with a central controller, and the central controller controls opening and closing of the upstream valve and a downstream valve based on the data detected by the fourth temperature sensor. Through the operation, when the flue gas temperature meets the requirement, excess heat can be stored in the heat storage device under the condition that the pre-heat generated by the air preheater meets the amount of air, in the absence of flue gas waste heat, the heat stored by the flue gas waste heat is utilized to heat the air preheater so as to meet the actual working requirements of the air preheater, therefore, the flue gas waste heat can be fully utilized, and the situation of excessive heat waste is avoided.

Owner:QINGDAO UNIV OF SCI & TECH

Loop heat pipe with pipe diameter of heat absorption part larger than pipe diameter of condensation part

InactiveCN110081745AForm a good cycleIncrease resistanceIndirect heat exchangersEvaporationEngineering

The invention relates to a loop heat pipe. The loop heat pipe comprises an evaporation part, a condensation part, a heat insulation part connecting the evaporation part and the condensation part, anda backflow part, wherein fluid absorbs heat and evaporates in the evaporation part, enters the condensation part through the heat insulation part, and condenses after heat exchange in the condensationpart, and the condensed fluid returns to an evaporation header through a backflow pipe. The loop heat pipe is characterized in that the evaporation part comprises a heat absorption pipe, the backflowpart comprises a condensation pipe, and the pipe diameter of the heat absorption pipe is larger than that of the condensation pipe. The loop heat pipe with the novel structure mainly increases the resistance of the condensation pipe and reduces the resistance of the evaporation part, so that steam can flow more easily from the evaporation part and the loop heat pipe can better form circulation.

Owner:SHANDONG UNIV

Length-changing non-condensable gas porous flow stabilizer heat exchanger

ActiveCN107976094AReduce vibrationReduce noise levelSafety devices for heat exchange apparatusStationary tubular conduit assembliesLength changeProduct gas

The invention provides a length-changing non-condensable gas porous flow stabilizer heat exchanger which comprises a shell. Sealing heads are arranged at the two ends of the shell correspondingly. A pipe plate is arranged at the connecting position of each sealing head and the shell. Heat exchange pipes are connected with the pipe plates at the two ends. A gas phase in gas-liquid two-phase flow isinsoluble or indissolvable gas, that is, gas cannot be dissolved in liquid in the heat exchange process. Flow stabilizers used for vibration reduction and noise reduction are arranged in each heat exchange pipe. The corresponding multiple flow stabilizers are arranged in the same heat exchange pipe. In the flowing direction of fluid in the heat exchange pipes, the lengths of the flow stabilizersare gradually decreased to a certain position, and then the lengths of the flow stabilizers are gradually increased from a certain position. According to the length-changing non-condensable gas porousflow stabilizer heat exchanger, through length changing of the flow stabilizers, when gas-liquid two-phase flowing exists in a pipeline, pipeline vibration is weakened to the largest degree, the noise level is reduced, and meanwhile flowing resistance is reduced.

Owner:广西自贸区见炬科技有限公司 +1

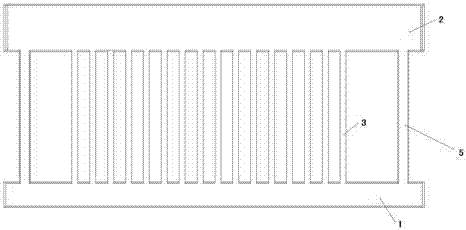

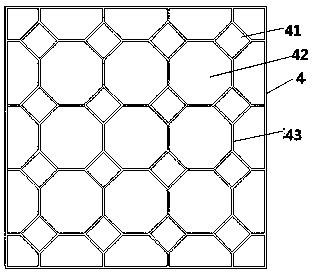

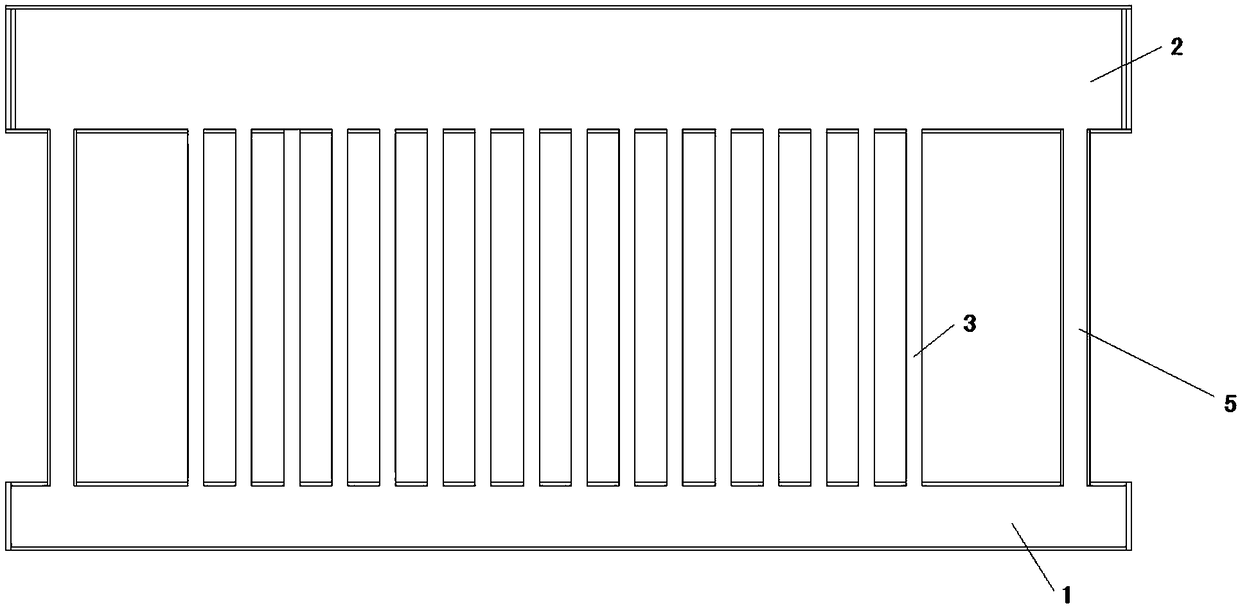

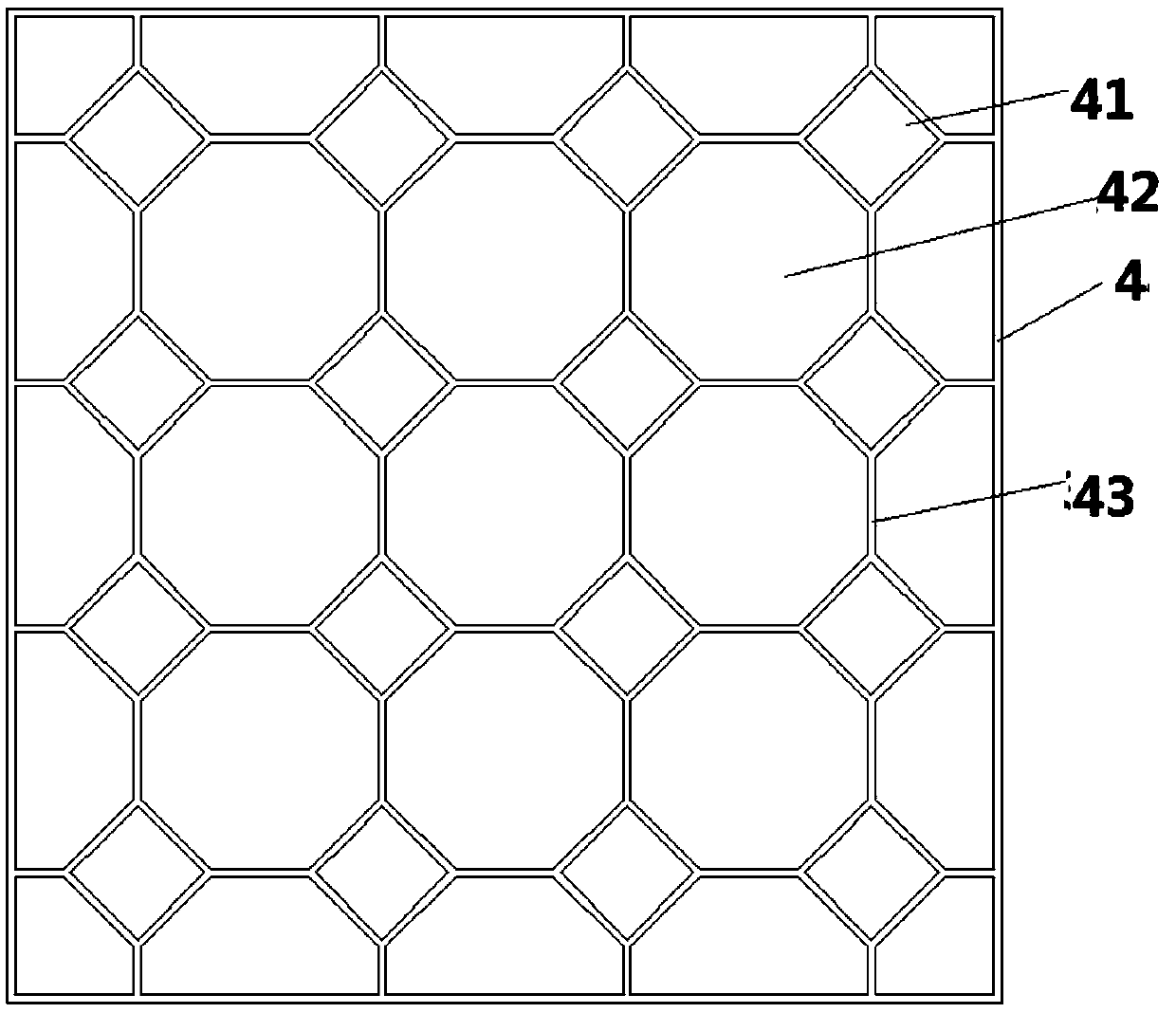

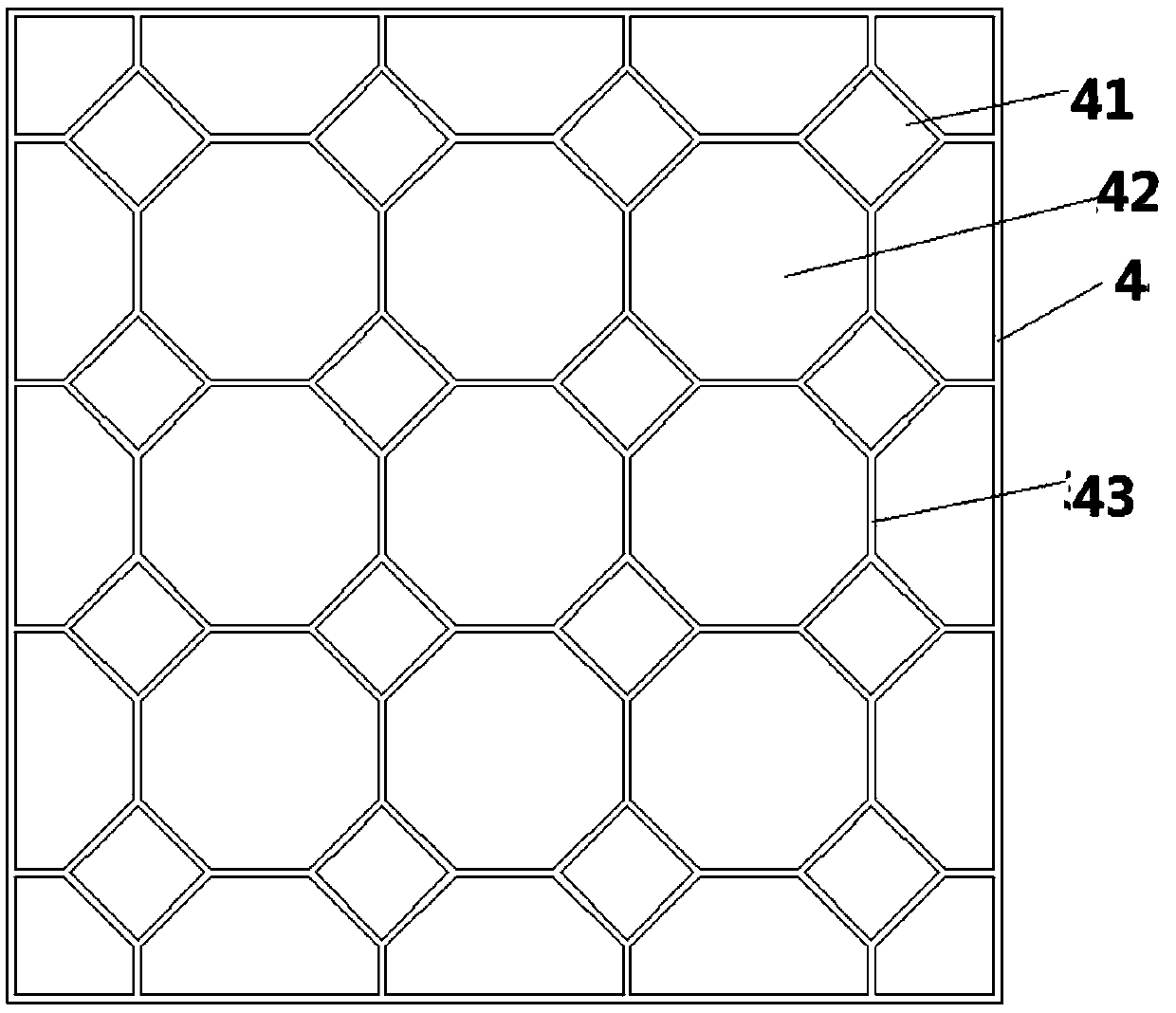

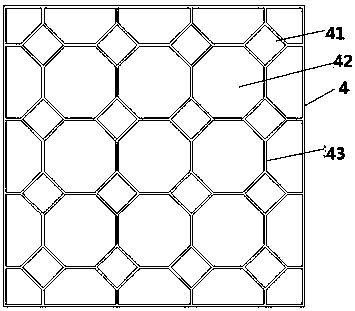

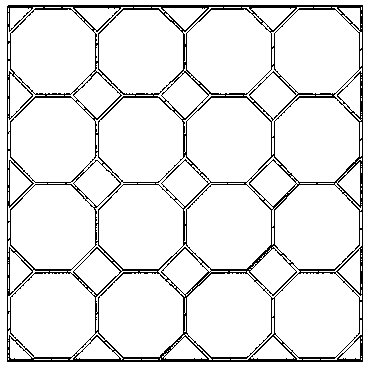

Steam heat exchanger with steady flow structures

ActiveCN109737368AAvoid or reduce short circuitInhibit refluxSteam generation heating methodsFeed water supplyEngineeringSheet structure

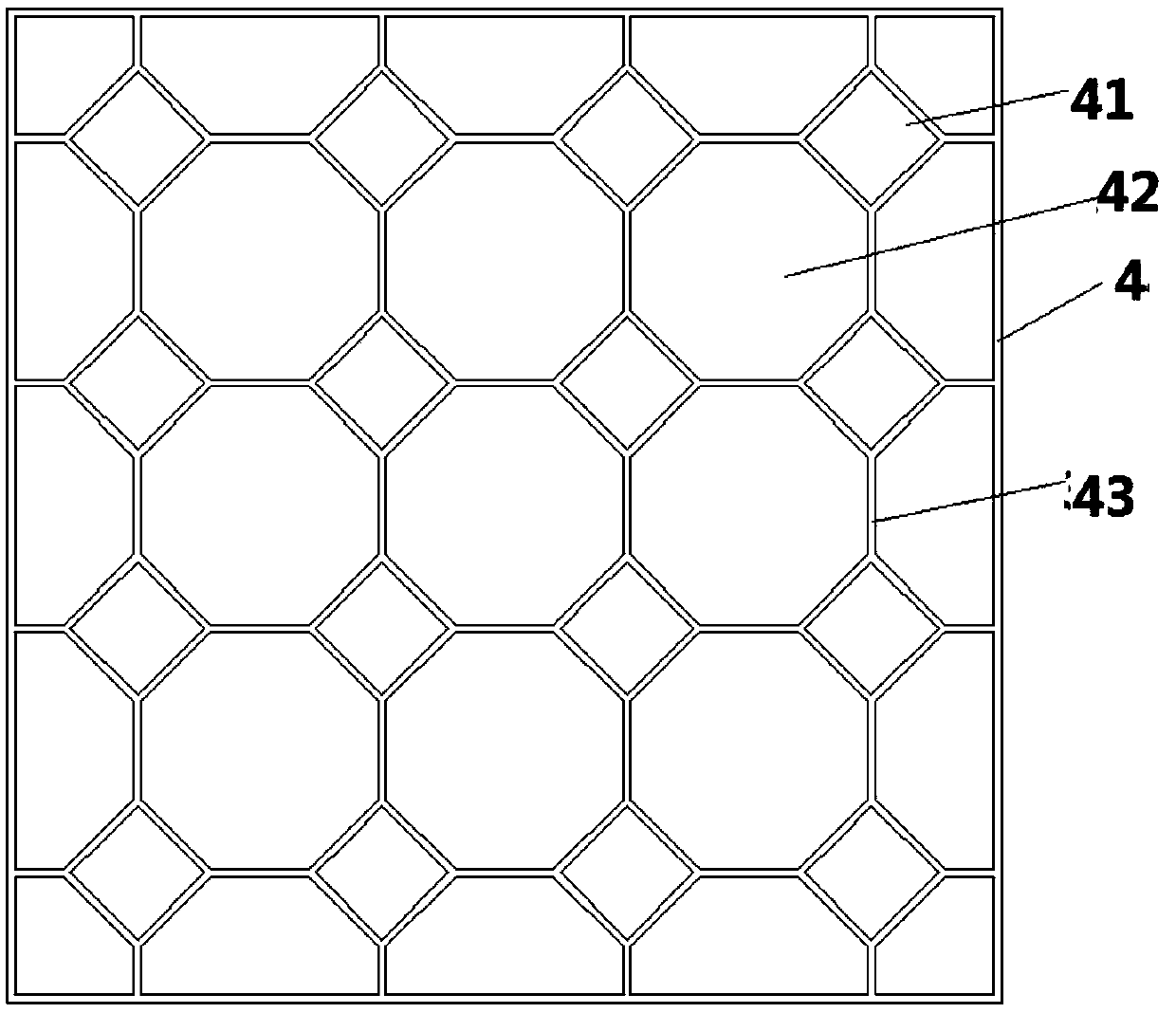

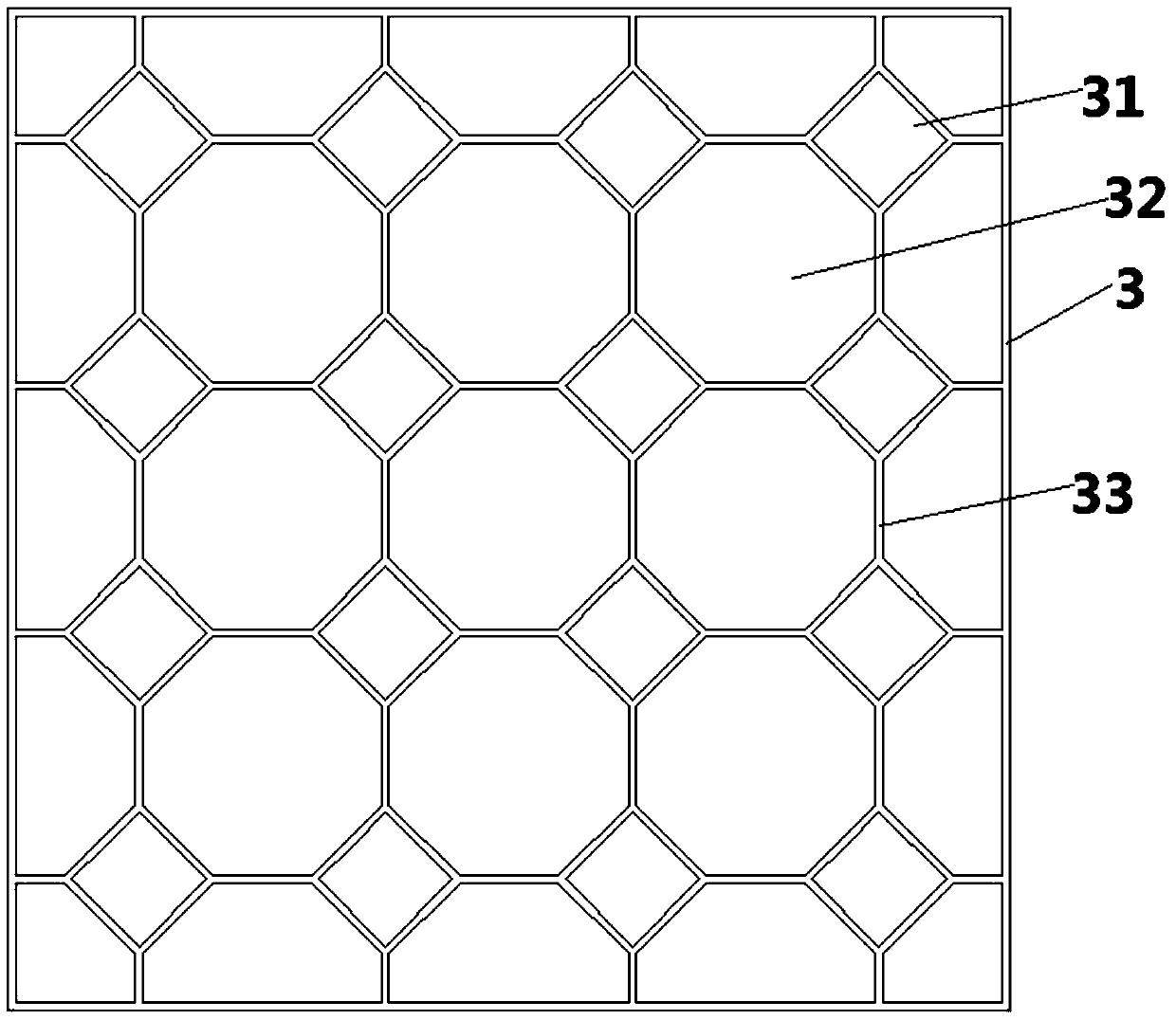

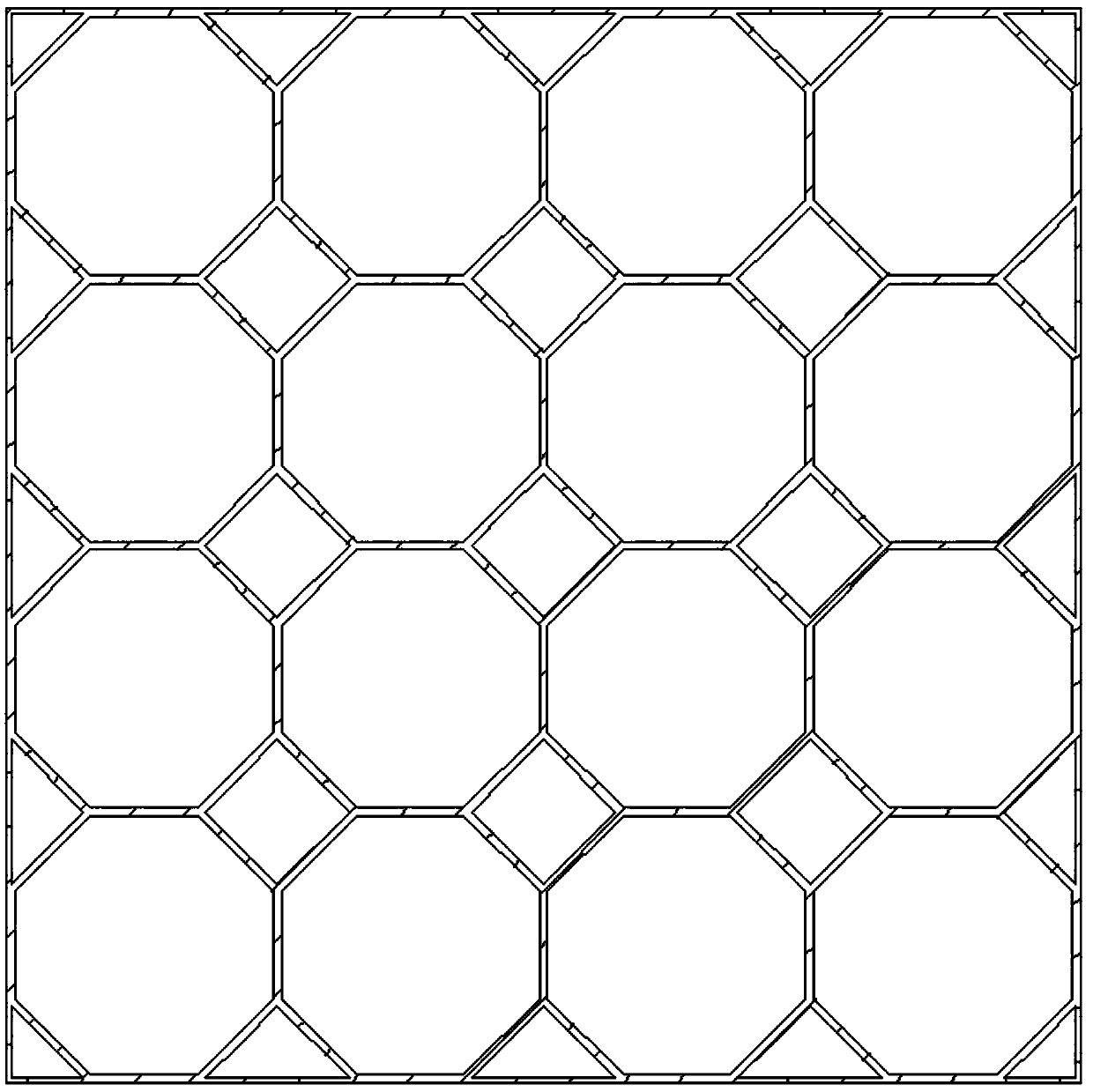

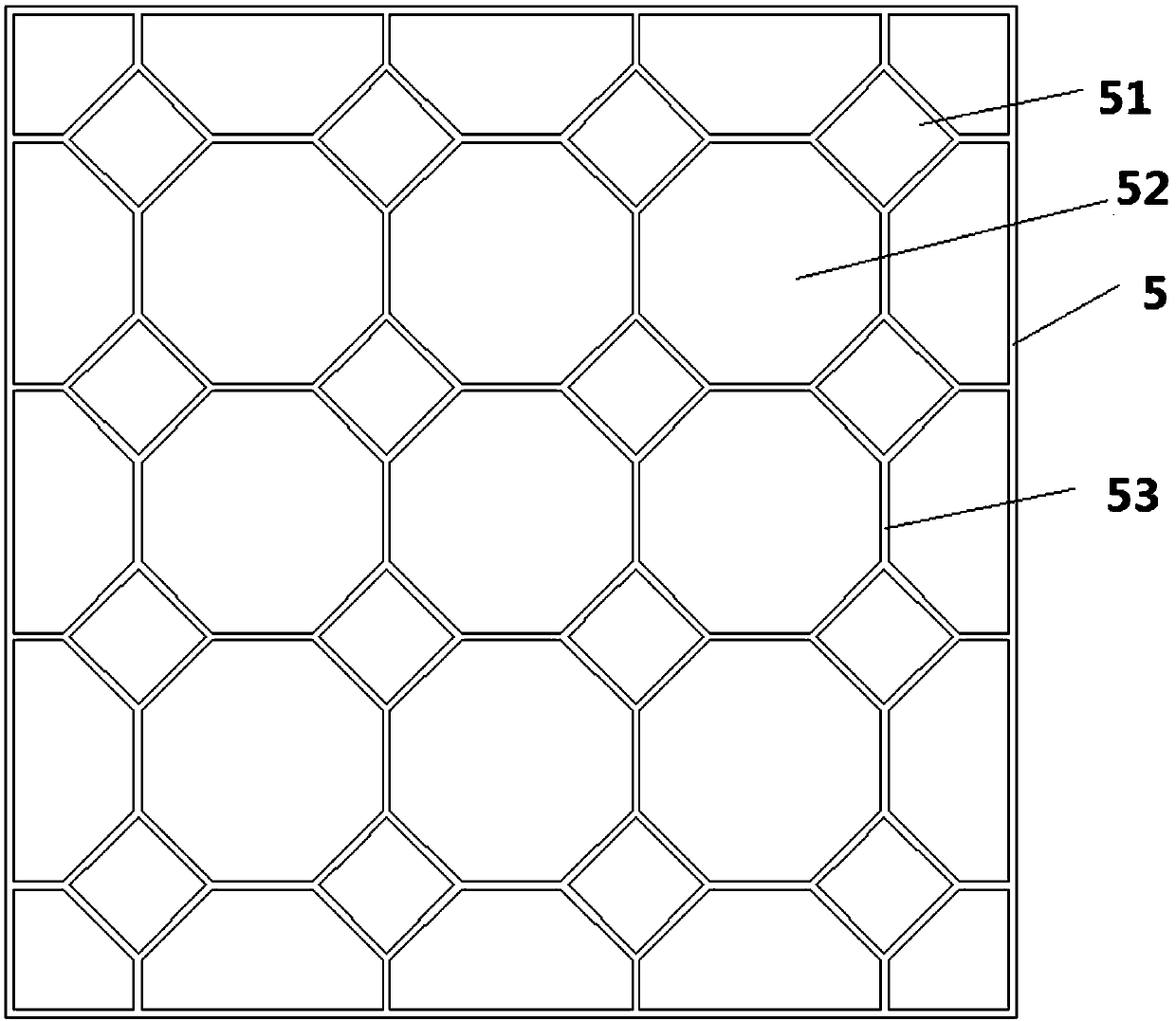

The invention provides a steam heat exchanger. The steam heat exchanger comprises a header and a steam pipe; steady flow devices are arranged inside the steam pipe and are each of a sheet structure; the sheet structures are arranged on the cross section of the steam pipe; the steady flow devices are composed of square through holes and right octagon through holes; the length of each side of the square through holes is equal to the length of each side of the right octagon through holes; the four sides of each square through hole are the sides of four different right octagon through holes; and the four spaced sides of each right octagon through hole are the sides of four different square through holes. Compared with a steady flow device in the prior art, the steam heat exchanger with the steady flow structures further improves the steady flow effect, enhances heat transfer and is easy to manufacture.

Owner:青岛鑫众合贸易有限公司

Steam heat exchanger capable of evenly distributing flow

ActiveCN109855451AEvenly distributedImprove heat transfer efficiencyStationary tubular conduit assembliesTubular elementsEngineeringStreamflow

The invention provides a steam heat exchanger capable of evenly distributing flow. The steam heat exchanger comprises an upper collecting box, a lower collecting box and heat exchange pipes arranged between the upper collecting box and the lower collecting box. A heat source in the heat exchange pipe is steam. The heat exchanger comprises an inlet pipe. The inlet pipe is arranged on the lower collecting box. Partition devices are arranged in the heat exchange pipes. Each partition device is of a sheet structure and is composed of square through holes and regular octagonal through holes. The side lengths of the square through holes in the different heat exchange pipes are different, and the longer the distances away from the inlet pipe are, the larger the side lengths of the square throughholes are. By changing the side lengths of the square through holes along with the distances away from the inlet pipe, fluid is made to flow into the heat exchange pipes which are small in flowing resistance and long in distances away from the inlet pipe, and therefore the fluid can be evenly distributed in the heat exchange pipes, the heat exchange efficiency is improved, and the service life isprolonged.

Owner:国网山东省电力公司聊城供电公司 +2

Variable-length and condensable porous heat exchanger with flow stabilizing devices

ActiveCN107966052AReduce vibrationReduce noise levelSafety devices for heat exchange apparatusStationary tubular conduit assembliesVapor phaseVariable length

The invention provides a liquid-vapor two-phase flow tubular shell type heat exchanger. The heat exchanger comprises a shell, wherein the two ends of the shell are separately provided with end sockets, tube plates are arranged at the connecting positions of the end sockets and the shell, and heat exchange pipes are connected with the tube plates at the two ends; a vapor phase in liquid-vapor two-phase flow can be condensed into a liquid phase in the heat exchange process, and the liquid-vapor two-phase flow flows in a tube pass; and flow stabilizing devices used for reducing vibration and noise are arranged in the heat exchange pipes, a plurality of flow stabilizing devices are arranged in the same heat exchange pipe, and the length of the flow stabilizing devices is gradually reduced in the flowing direction of fluid in the heat exchange pipes. According to the heat exchanger provided by the invention, through the length variation of the flow stabilizing devices, when the liquid-vaportwo-phase flow occurs in the pipeline, the vibration of the pipeline is reduced to an utmost degree, and the noise level is reduced; and at the same time, flow resistance is reduced, and the heat exchange uniformity is improved.

Owner:开封市九泓化工有限公司

Utilization system of power station boiler flue gas waste heat

InactiveCN109519954AFull flowAvoid or reduce short circuitIndirect heat exchangersPower stationBoiler furnace

The invention provides a utilization system of power station boiler flue gas waste heat. The utilization system comprises heat pipes, a flue gas passage and an air passage. The heat pipes comprise evaporating ends and condensation ends, wherein the condensation ends are arranged in the air passage; the evaporating ends absorb waste heat of flue gas in a boiler flue and transmit heat to air in theair passage through the condensation ends; and the air after being heated enters a boiler furnace for aid combustion, and stabilizing devices are arranged in the heat pipes. According to the utilization system of the power station boiler flue gas waste heat, a utilization device and method of flue gas waste heat with a novel structure is provided, a heat source is fully used, the energy consumption is reduced, and the flue gas discharging effect is improved.

Owner:山东电力高等专科学校

A Trough Solar Collector System with Stabilizer Intervals

ActiveCN109489270BImprove heat transfer effectAvoid or reduce short circuitSolar heating energySolar heat collector controllersThermodynamicsCollector device

The invention provides a trough solar heat collection system, which includes a heat collector, the heat collector includes a heat collection tube and a reflector, the heat collection tube absorbs solar energy, and heats the water in the heat collection tube. It is characterized in that the heat collection tube is set A plurality of stabilizing devices, along the flow direction of the fluid in the heat collecting tube, the spacing between the stabilizing devices becomes smaller and smaller. The present invention can maximize the heat exchange effect through the above arrangement.

Owner:山东九泽换热系统有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com