Intelligent communication controlled power station boiler waste heat utilization system

A power station boiler and waste heat technology, applied in the direction of combustion control, indirect heat exchanger, lighting and heating equipment, etc., can solve the problems of heat exchange capacity decline, affect heat exchange efficiency, lack of intelligent control, etc., to achieve suppression of backflow, Promotes smooth flow and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

[0044]The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

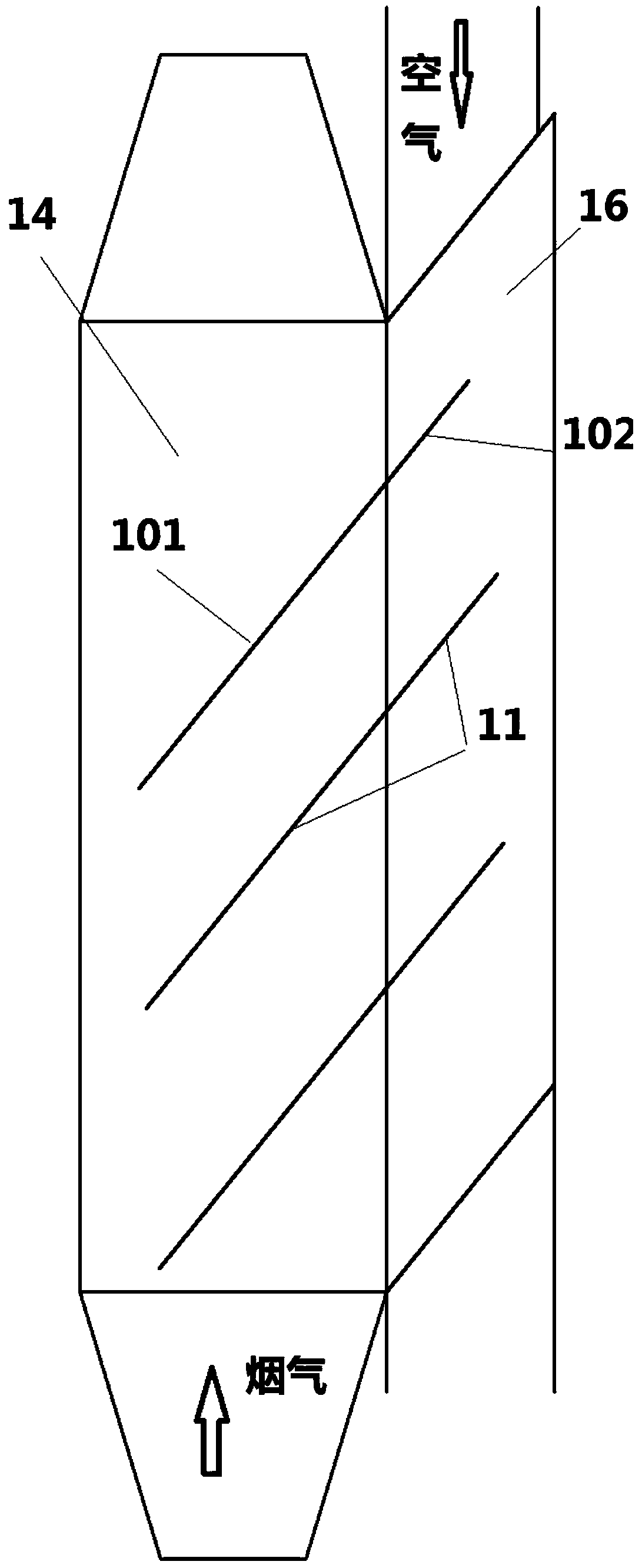

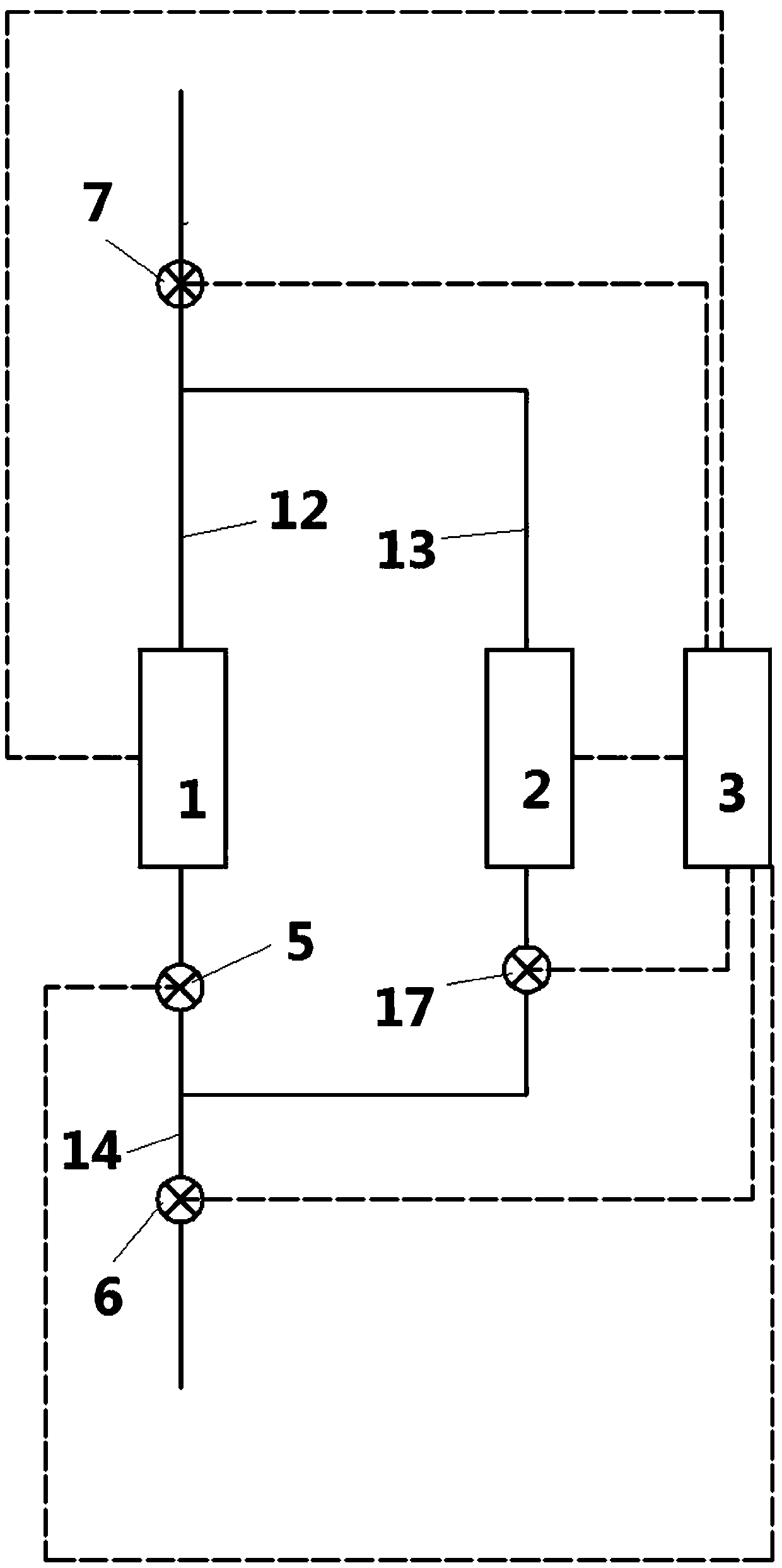

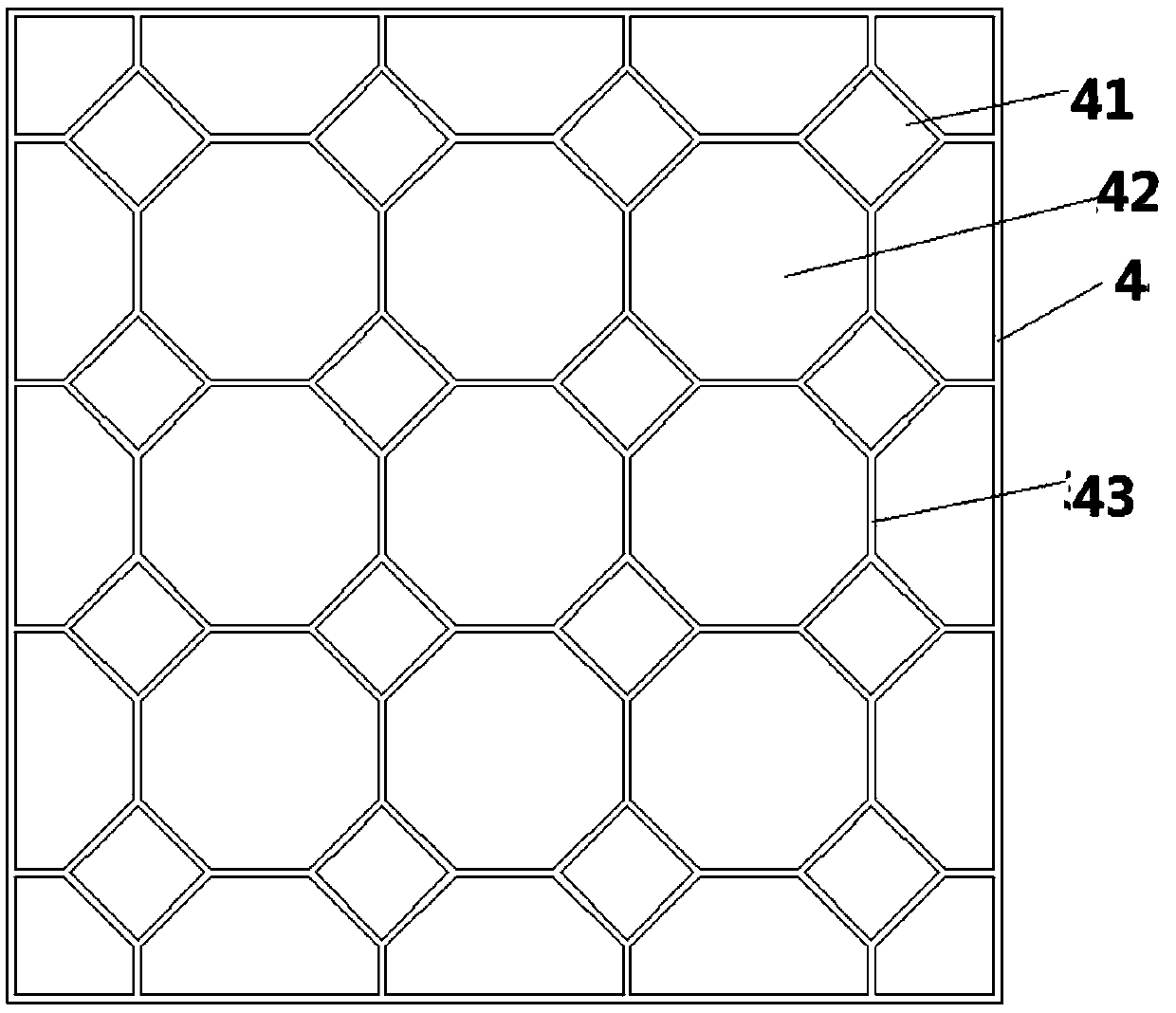

[0045] A utility boiler flue gas waste heat utilization system, the waste heat utilization system includes an air preheater 1, the air preheater 1 includes a heat pipe 10, a flue gas channel 14 and an air channel 16, and the heat pipe 10 includes an evaporation The condensing end 101 and the condensing end 102, the condensing end 102 is arranged in the air passage 12, and the evaporating end 101 is arranged in the flue. The evaporating end 101 absorbs the waste heat of the flue gas in the boiler flue, and transfers the heat to the air in the air channel 12 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com