Plasma alloy powder cladding equipment

A technology of alloy powder and plasma, which is applied in the coating process and coating of metal materials, can solve the problems of alloy powder waste, welding torch power waste, timing misalignment, etc., and achieve the effect of preventing power waste

Active Publication Date: 2022-06-21

南通德邦新材料科技有限公司

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The above-mentioned patents have the following disadvantages: the opening and closing of the welding torch and the powder feeder are not disclosed. With reference to the prior art, the opening and closing switch of the welding torch circuit and the electromagnetic valve on the powder feeder can be used to control, but this control makes the welding torch The opening and closing are completely independent of the powder feeding opening and closing of the powder feeder. When electric control or human control is used, the timing will be misplaced, resulting in waste of electric energy of the welding torch or waste of alloy powder.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

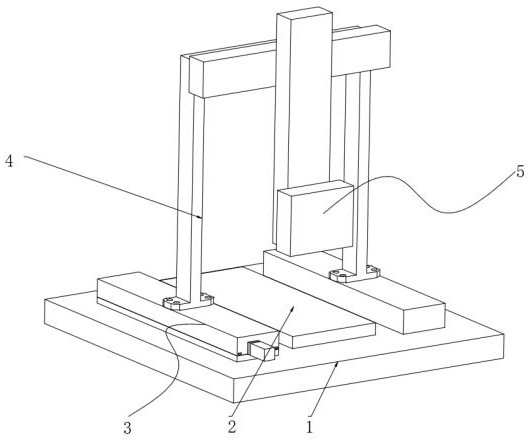

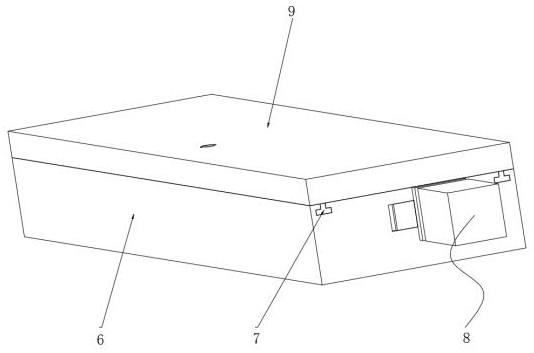

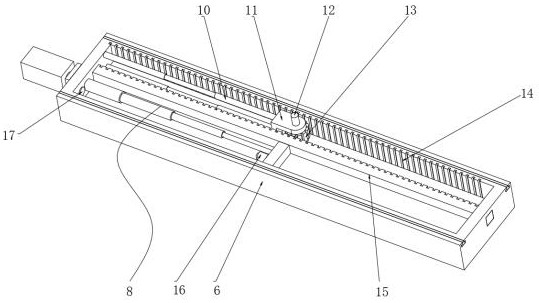

The invention discloses plasma alloy powder cladding equipment, and relates to the technical field of plasma welding. The problem of synchronism is solved. The device specifically comprises a base, the top of the base is connected with a cladding welding assembly through a three-dimensional moving part, the cladding welding assembly comprises a material containing hopper, a plasma welding gun and a supporting seat, the material containing hopper is fixedly installed on the outer wall of the supporting seat, and the plasma welding gun is fixedly installed on the outer wall of a bottom outlet of the material containing hopper; a supporting plate is fixedly installed on the outer wall of the supporting seat, an inserting plate is slidably connected to the outer wall of one side of the supporting plate through a sliding rod, the inserting plate is slidably connected to the inner wall of the containing hopper, a through hole with the same inner diameter as an outlet of the containing hopper is formed in the inner wall of the inserting plate, and a limiting plate is fixedly installed on the outer wall of the sliding rod. Powder feeding of the alloy powder and starting and stopping of the plasma welding gun are completely synchronous, and the situation of electric energy waste or alloy powder waste can be effectively prevented.

Description

technical field [0001] The invention relates to the technical field of plasma welding, in particular to a plasma alloy powder cladding equipment. Background technique [0002] Plasma alloy powder cladding technology is a cladding method that uses the plasma arc as a heat source to melt the added metal and make it and the base metal as a metallurgical combination. It uses the tungsten electrode of the welding torch as the negative electrode of the current and the base as the current. The plasma generated between the positive electrodes is used as heat, and the heat is transferred to the surface of the workpiece to be welded, and the welding powder is sent to the heat energy area, which is melted and deposited on the surface of the workpiece to be welded, so as to achieve the strengthening and protection of the surface of the part. Hardened cladding process. [0003] After searching, the Chinese patent publication number is CN205133734U, which discloses a plasma alloy powder ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C24/10

CPCC23C24/103Y02P10/25

Inventor 范平一冯奕鑫冯亚程

Owner 南通德邦新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com