Motor cooling member

A technology for cooling components and motors, applied to cooling/ventilation devices, electrical components, electric components, etc., which can solve problems such as increased pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

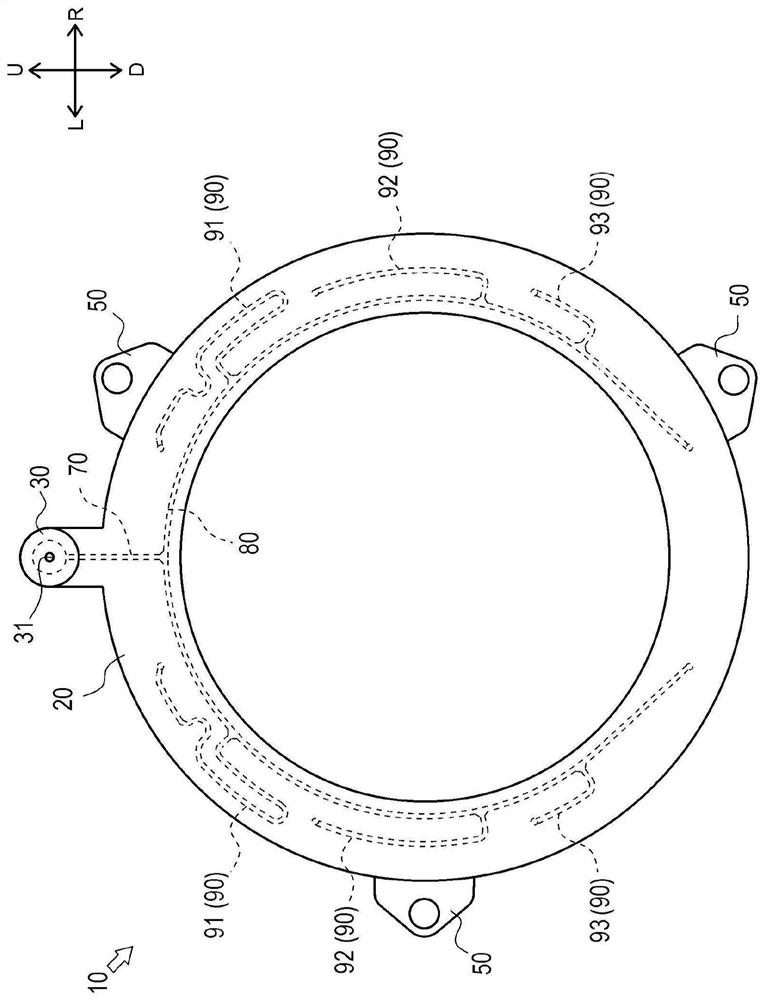

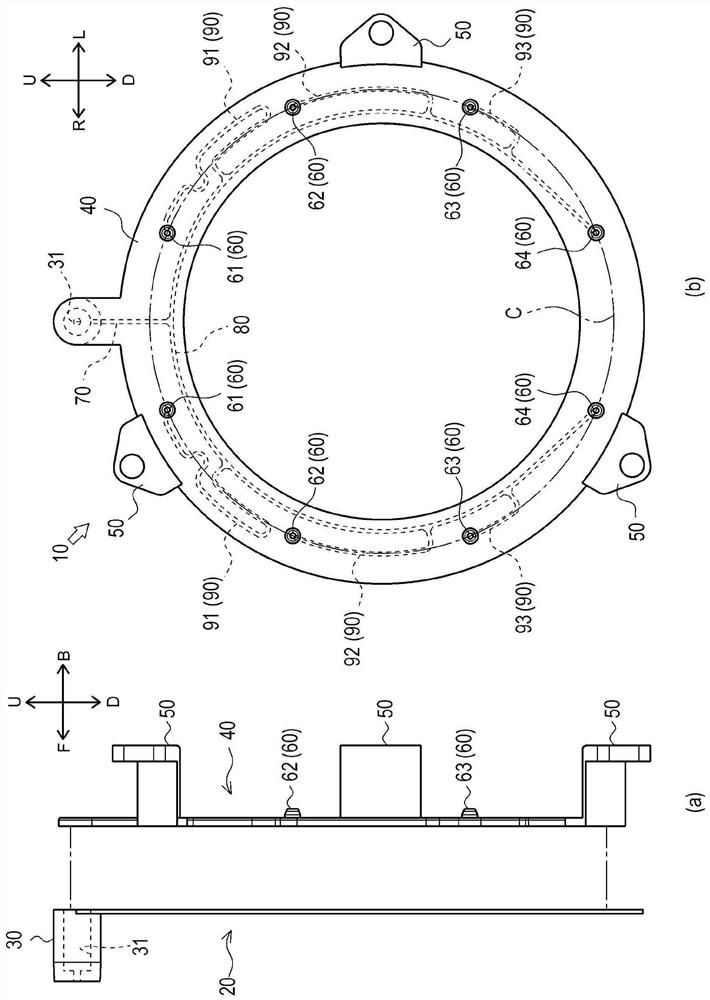

[0030] Hereinafter, the directions indicated by arrow U, arrow D, arrow F, arrow B, arrow L, and arrow R in the figure are respectively defined as an upward direction, a downward direction, a front direction, a rear direction, a left direction, and a right direction for description. .

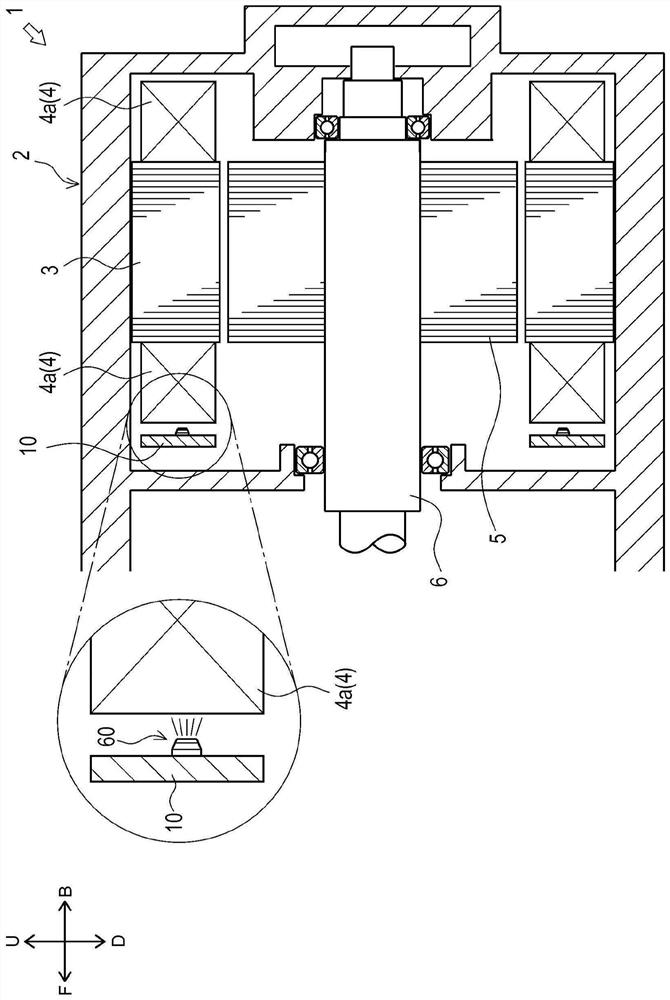

[0031] First, use figure 1 The outline of the structure of the motor 1 provided with the cooling member 10 of 1st Embodiment of this invention is demonstrated.

[0032] The motor 1 of the present embodiment is used in a driving device of an automobile (a hybrid vehicle (HV), an electric vehicle (EV), or the like). The motor 1 mainly has a housing 2 , a stator 3 , a coil 4 , a rotor 5 , a rotating shaft 6 , and a cooling member 10 .

[0033] The case 2 accommodates other components (the stator 3 and the like) constituting the motor 1 . A stator 3 is fixed inside the housing 2 . The stator 3 is formed in a substantially cylindrical shape. The stator 3 is arranged such that its axis faces the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap