Atomizer with central fog suction channel and integrated atomization assembly

An atomization component and an integrated technology, applied in the field of atomizers, can solve the problems of inconvenient automatic production, poor user experience, and inability to seal with glass fiber rope or cotton rope, so as to improve the efficiency of inhaling vapor and mist, and facilitate fully automated production , good liquid storage and fluid conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

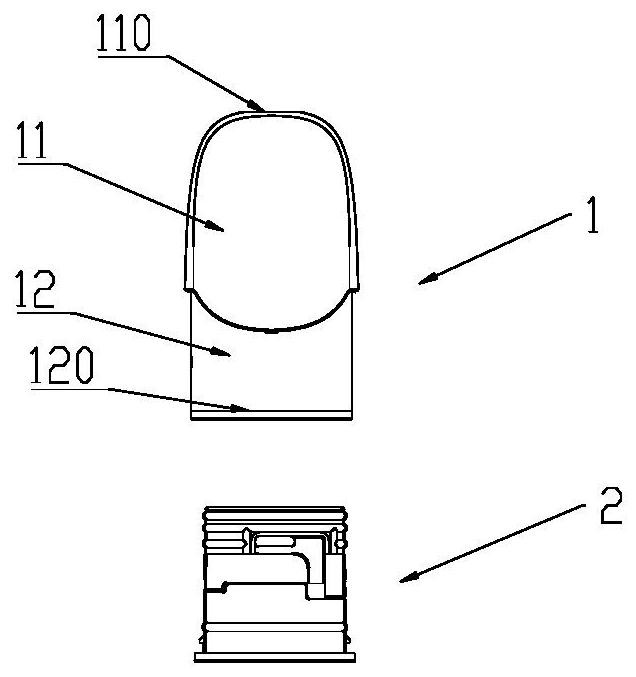

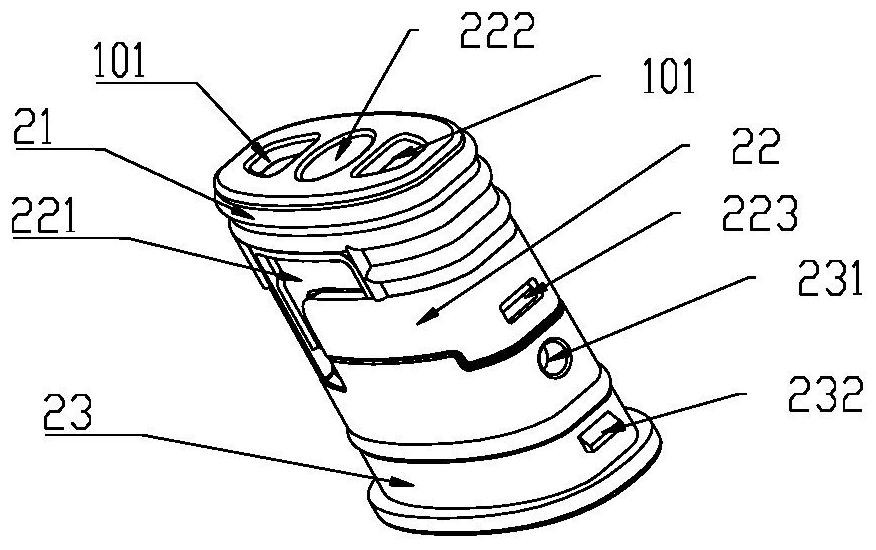

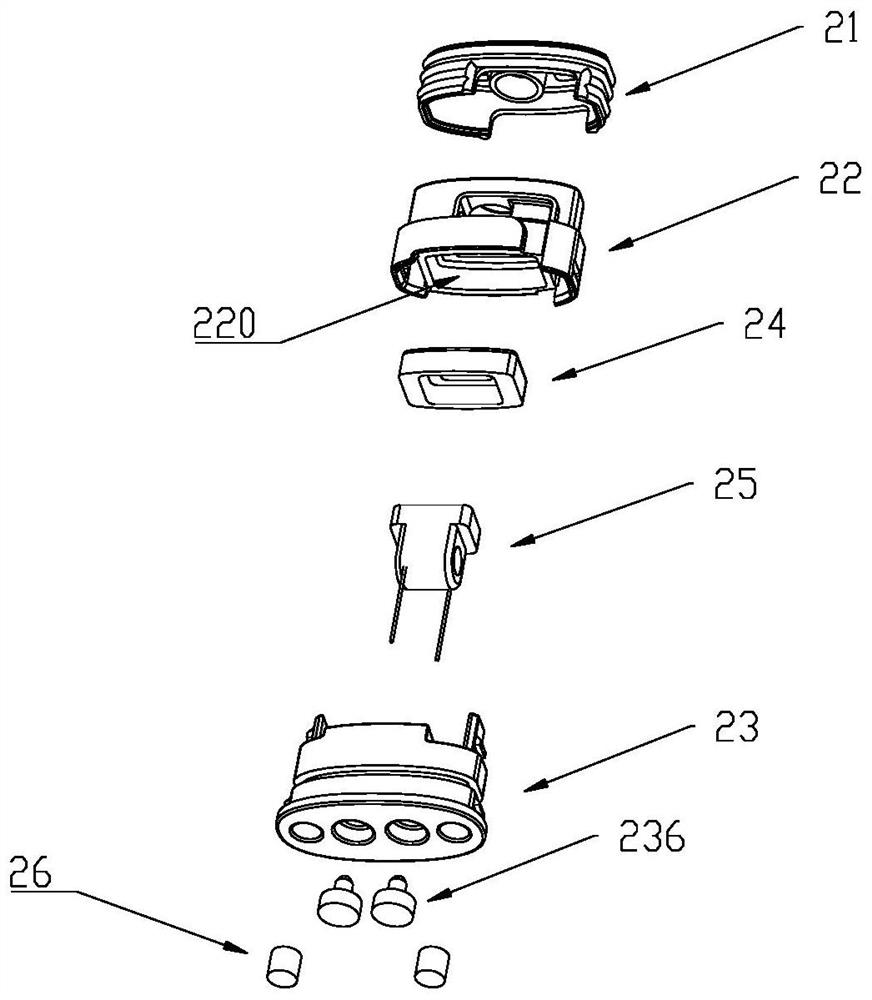

[0045] Such as figure 1 , figure 2 , Figure 9 As shown, an atomizer with a central mist suction channel and an integrated atomization assembly, including an atomization shell 1 and an integrated atomization assembly 2, the atomization shell 1 includes a suction nozzle end 11 and a connecting end 12, the suction nozzle The end 11 is provided with a suction port 110, and the connecting end 12 is provided with an opening 120. The atomizing shell 1 is connected with the battery assembly (not shown in the figure) through the connecting end 12 to form an electronic atomization device. The integrated atomizing component 2 is opened from the atomizing shell. 120 is loaded into the atomization shell 1. The inner walls of both sides of the connecting end 12 of the atomizing shell are provided with first card slots 122, and the side walls of the base 23 are provided with first convex buttons 232 that are buckled with the first card slots 122, and the buckle connection makes the integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com