Dust remover for recycling renewable energy sources

A technology of renewable energy and dust collectors, which is applied in the direction of adjustable capacity gas storage tanks, chemical instruments and methods, and dispersed particle filtration, etc. Good control of airflow and other issues to achieve the effect of improving work efficiency and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

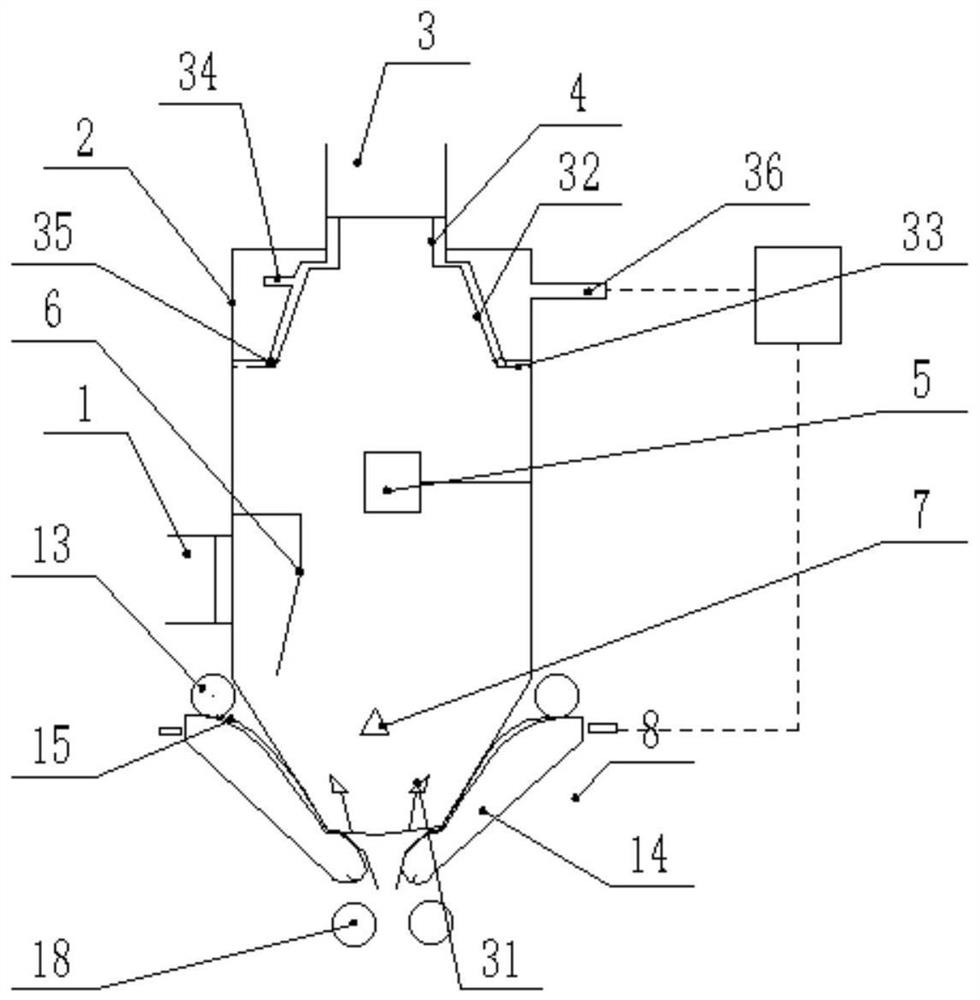

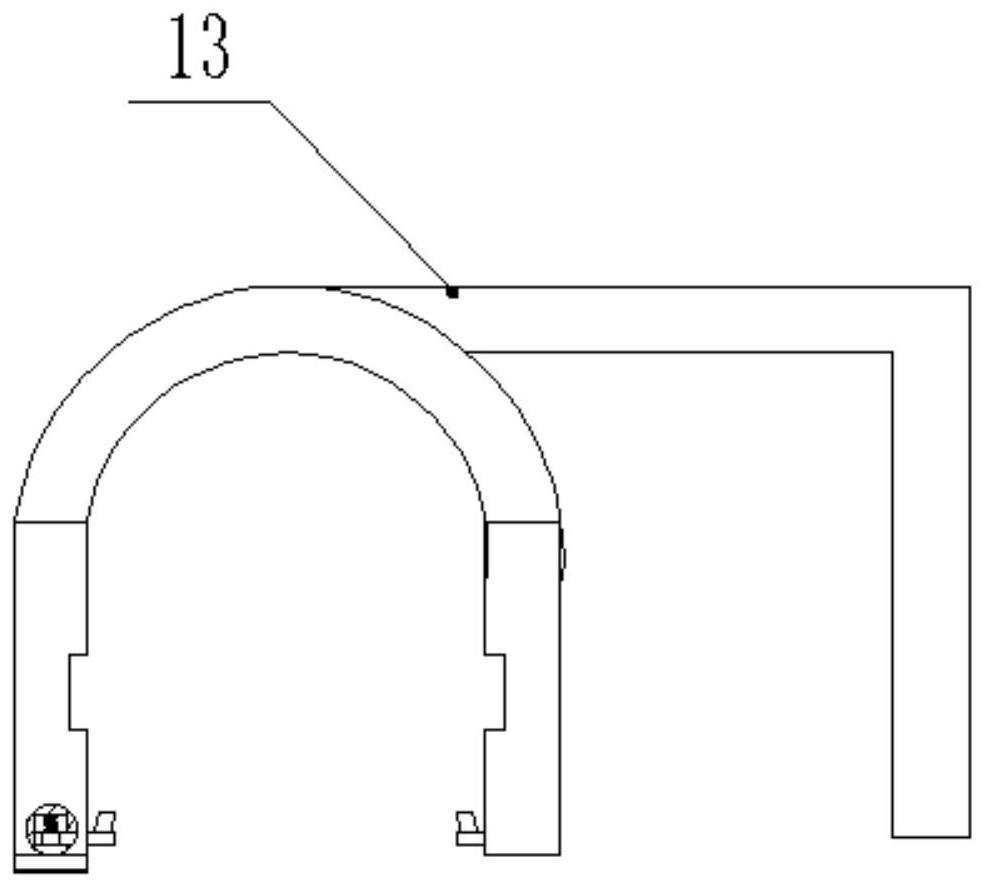

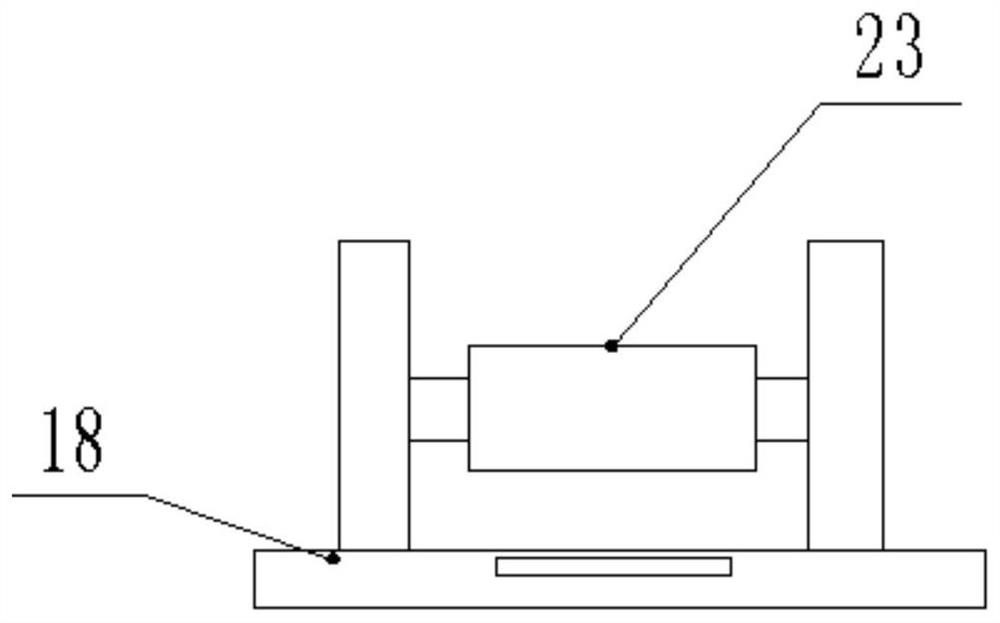

[0040] Embodiment: the gas enters the air inlet 1, passes through the baffle 6, and the dust in the gas reaches the bottom of the housing 2 and the through hole 10, and then the gas reaches the vane wheel 5 with the shaft through the deflector 7, and the vane wheel 5 with the shaft will The gas is spirally rising and filtered. The gas is desulfurized after passing through the desulfurizer 4. The gas enters the desulfurizer 4 in a spiral shape, passes through the gas filter membrane 32, and reacts with the desulfurizer inside the desulfurizer 4 to produce water, Exhaust gas and clean gas, due to the density, the clean gas exits from the air outlet 3, the water flows downward into the water channel 33, the floating ball 35 places the gas to be discharged from the water channel 33, and the exhaust gas is discharged from the exhaust port 34 to the outside of the desulfurizer 4, from the ventilation Port 36 is discharged to the gas collector, and the gas collector is separated to su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com