Stirring tank device with anti-blocking device for papermaking and pulping

A mixing tank and anti-blocking technology, which is applied in papermaking, mixer accessories, textiles and papermaking, etc., can solve the problems of not particularly high uniformity, limited mixing effect, and easy accumulation of large particles on it, so as to achieve good results and improve fine-grained effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

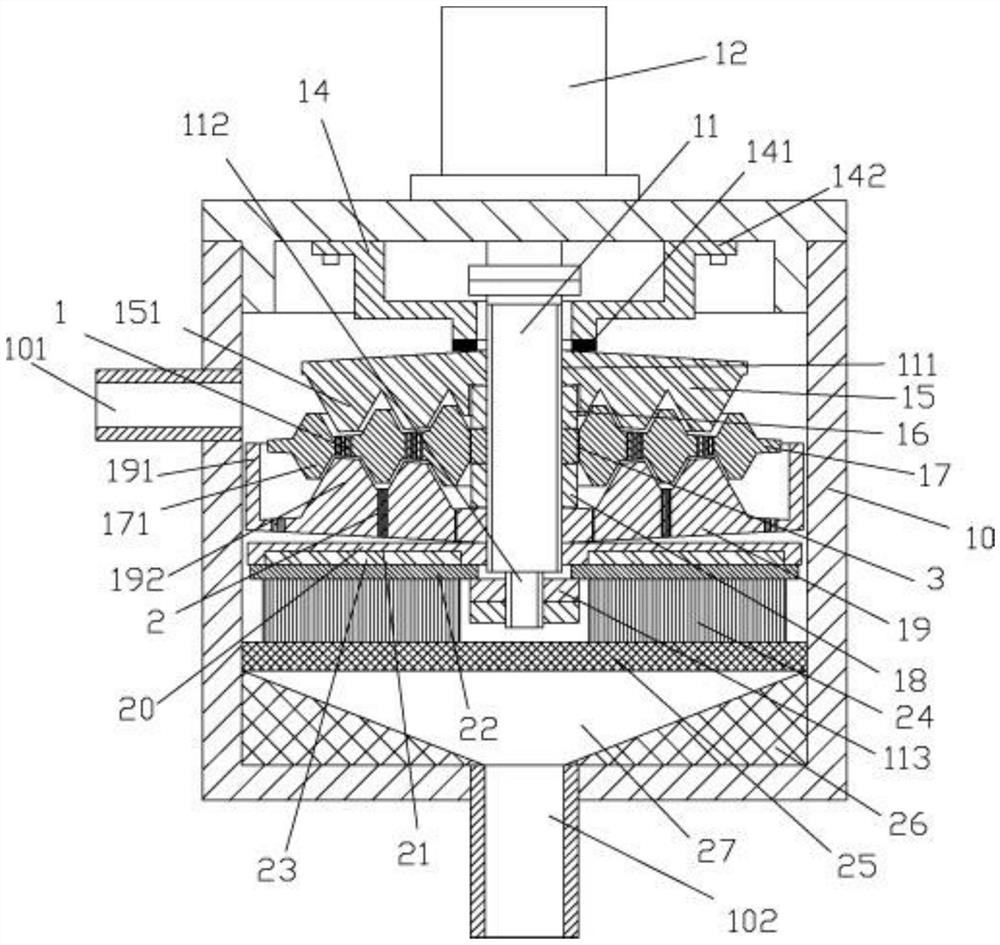

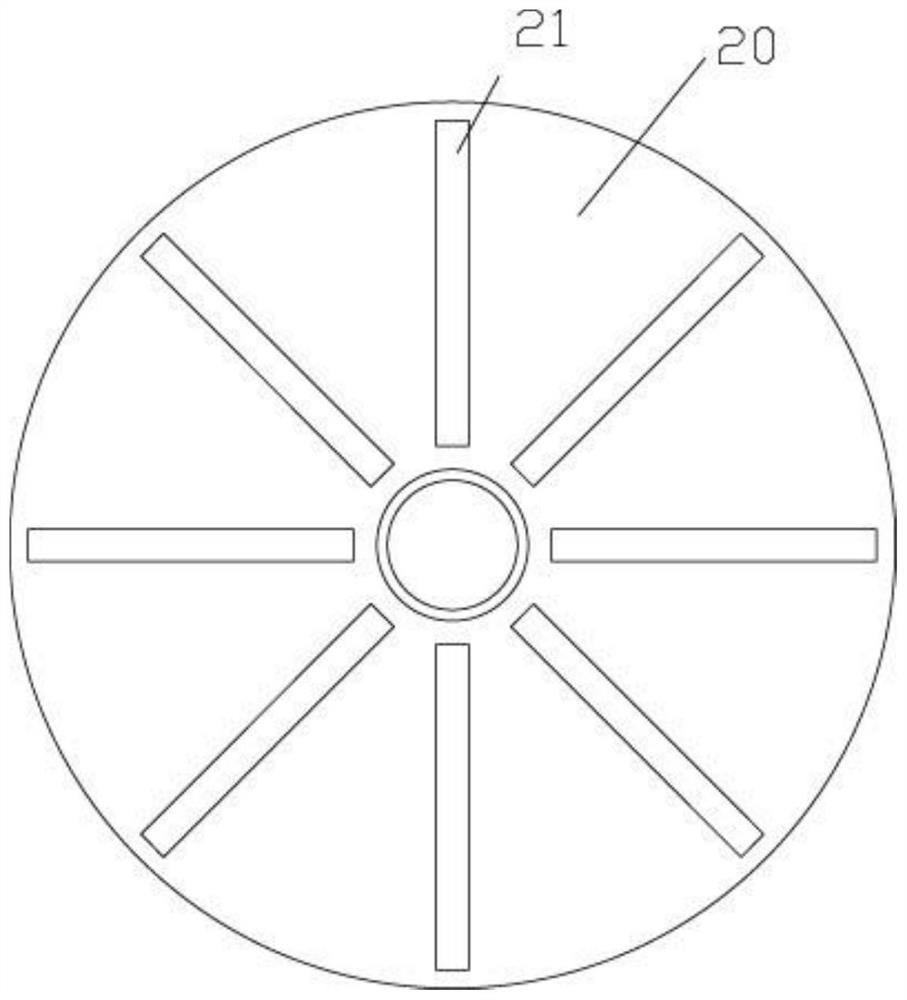

[0021] Examples, see e.g. figure 1 exist figure 2 As shown, a stirring tank device with an anti-blocking device for papermaking and pulping comprises a stirring tank 10 and a stirring shaft 11, the upper side wall of the stirring tank 10 is connected with a liquid inlet pipe 101, and the bottom plate of the stirring tank 10 is connected to Connected with a drain pipe 102, the tank cover 12 is closed on the top of the stirring tank 10, the middle part of the top surface of the tank cover 12 is fixed with a stirring motor 13, and the output shaft of the stirring motor 13 passes through the bottom surface of the top plate of the tank cover 12 and passes through the joint. The shaft is connected with a stirring shaft 11, the stirring shaft 11 is inserted into the stirring tank 10, and an external spline 111 is formed on the outer wall of the stirring shaft 11, and the stirring shaft 11 is sequentially inserted with a connecting cover 14, a first The stirring wheel 15, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com