Adjustable double-valve-element dust suppression hopper device and dust suppression method thereof

A hopper device and double-spool technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve problems such as dust spillage, fast material falling speed, environmental pollution, etc., to prevent material from overflowing, prevent dust from overflowing, and improve The effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

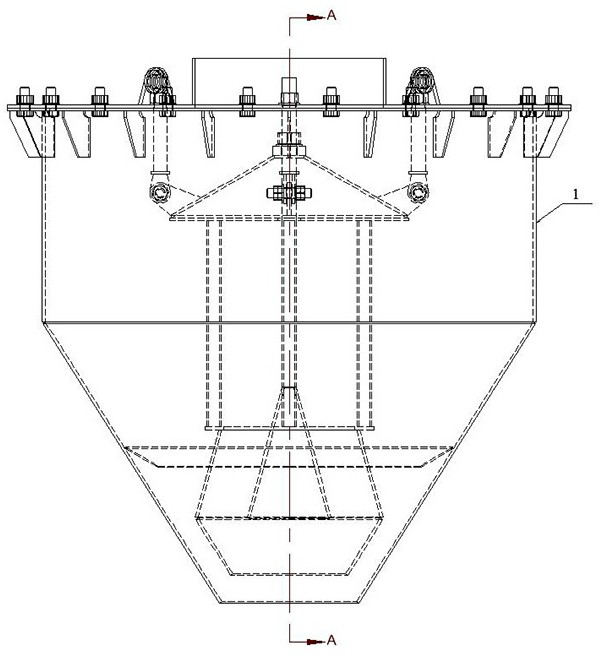

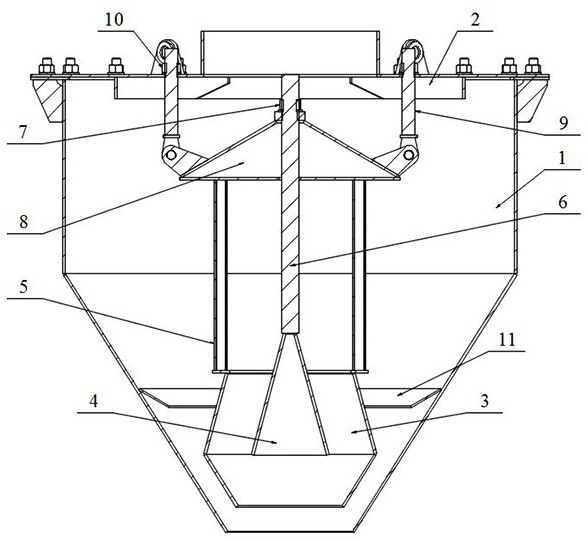

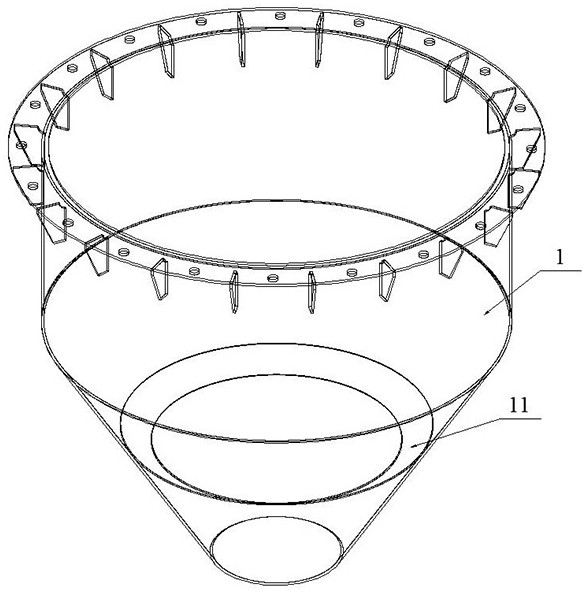

[0031] An adjustable double valve core dust suppression hopper device of the present invention comprises an outer bucket body 1, a hopper cover 2, an outer valve core 3, an inner valve core 4 and a material distribution cone; the specific structure is as follows Figure 1~5 As shown, the outer bucket body 1 is a vertically arranged funnel-shaped structure, and its upper end is a large end face; wherein, the upper half of the outer bucket body 1 is a cylinder, and the lower half of the outer bucket body is an open cone; The outer diameter of the cylinder of 1 is consistent with the outer diameter of the large end of the open cone, and the two are arranged concentrically, and are integrally formed into a funnel-shaped structure.

[0032] Such as figure 1 , figure 2 As shown, a hopper cover 2 is also embedded and horizontally fixed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com