Preparation method of high-strength lightweight aggregate concrete

A lightweight aggregate concrete and lightweight aggregate technology, applied in the field of building materials, can solve the problems of shortened service life, poor toughness, inconvenient crushing of lightweight aggregates, etc., and achieve the effect of preventing dust spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The implementation of the present invention will be described by specific specific examples below.

[0065] The invention provides a method for preparing high-strength lightweight aggregate concrete, comprising the following steps;

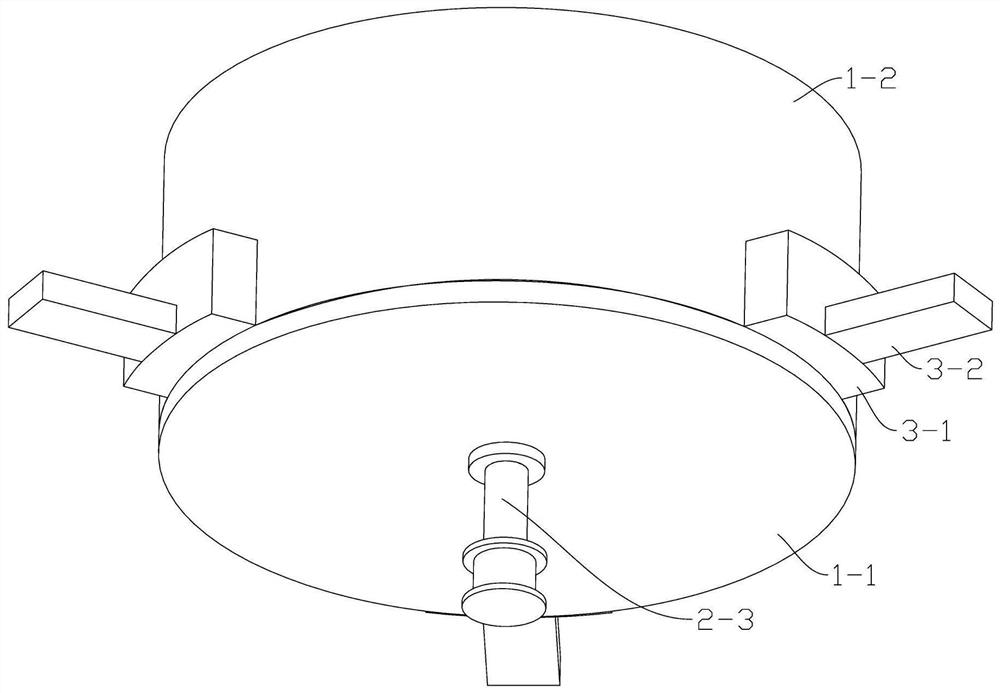

[0066] Step 1: Fill the light aggregate into the storage part of the grinding device, and then seal the storage part to prevent dust from spilling;

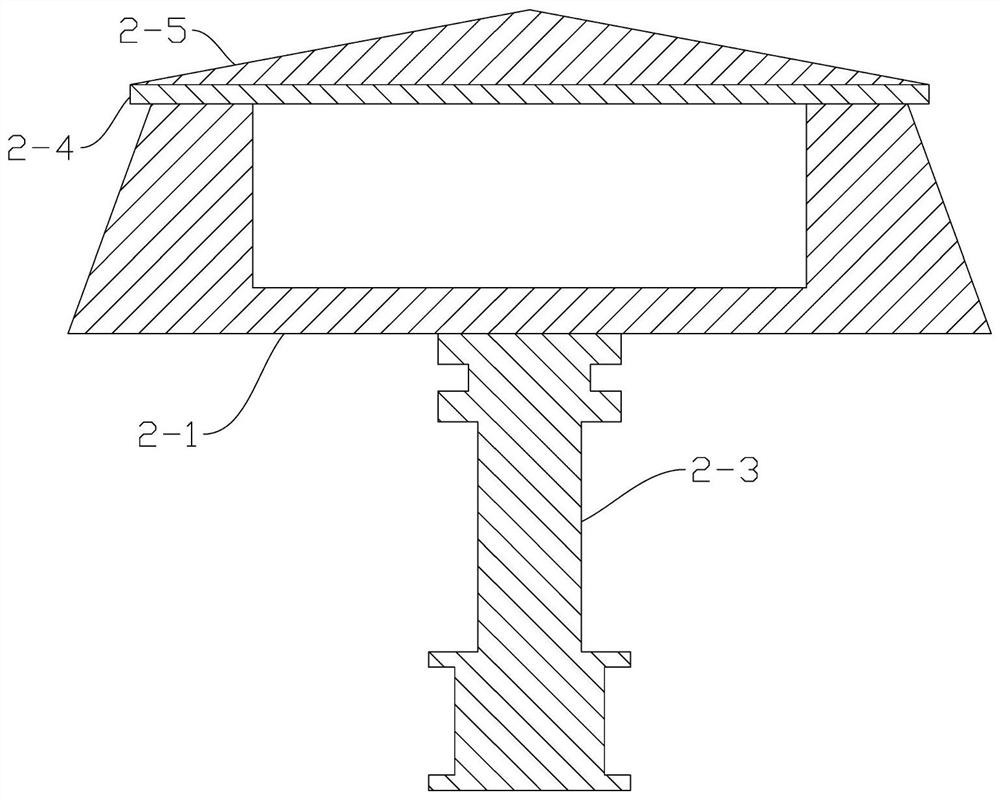

[0067] Step 2: The crushing part in the grinding device is used in conjunction with the bonding component to crush the large light aggregate;

[0068] Step 3: Use the circulation method to discharge and collect the materials of acceptable size in the storage unit.

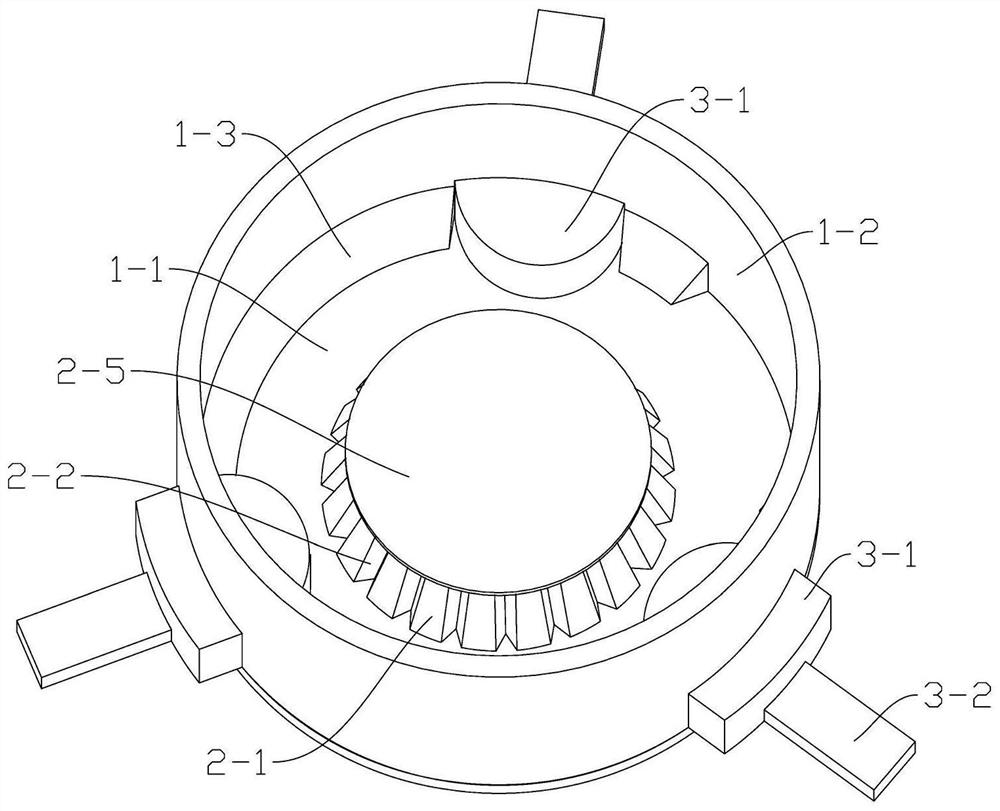

[0069] See figure 1 Shown:

[0070] By moving the crushing part relative to the storage part, the crushing part is controlled to push the concrete material to move to the bonding component, so that the crushing part cooperates with the bonding component to crush the bulk light aggregate;

[0071] Further, by moving the pulveriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com