Automatic automobile loading system for aggregate

An automotive and automatic technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of spilling outside the carriage, long loading time, and many post workers, to prevent dust spillage, prevent material splashing, and reduce post workers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

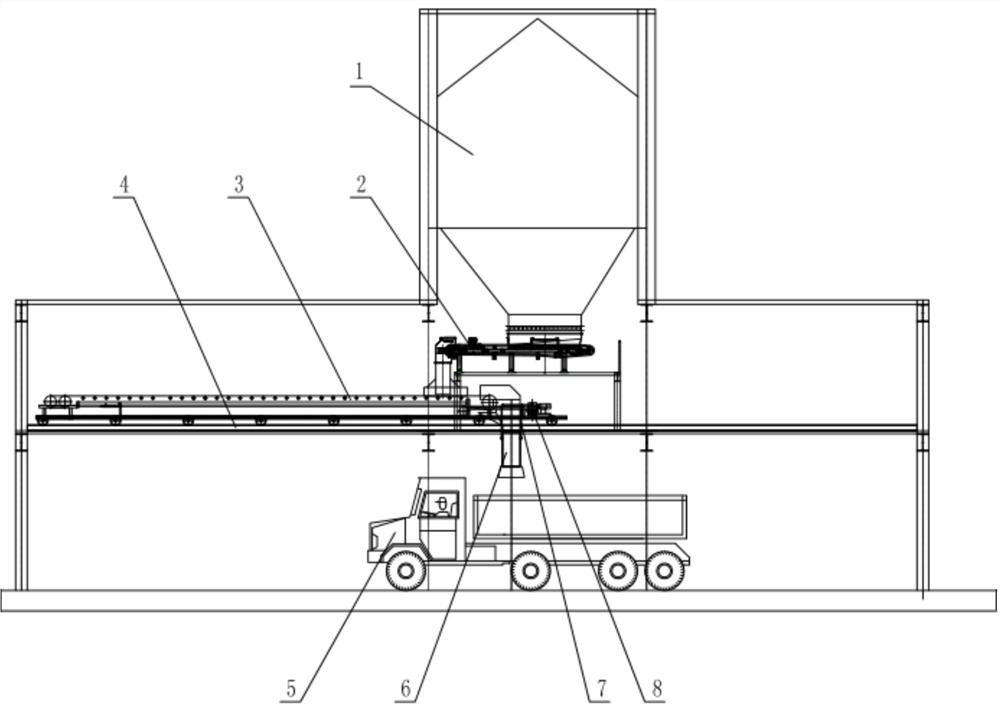

[0017] combined with figure 1 The automatic loading system for aggregate vehicles includes a loading bin 1 and a mobile loading machine, a quantitative feeder 2 is provided at the bottom of the outlet of the loading bin 1, and the mobile loading machine is arranged on the quantitative feeder 2. The lower part of the outlet end; the mobile loading machine includes a warehouse distribution belt conveyor 3, a walking track 4 and a mobile bulk head; the mobile bulk head is installed below the feeding hopper of the warehouse distribution belt conveyor 3; the mobile bulk head includes a telescopic feeding pipe 6 , steel wire rope 7 and winch 8, the feeding pipe 6 is a multi-section sleeve nested together, a suspension point is provided on the outermost sleeve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com