Dust-fall environment-friendly concrete aggregate mixing device and use method thereof

A technology for mixing devices and concrete aggregates, which is applied in the direction of selling raw material supply devices, separation methods, chemical instruments and methods, etc., can solve problems such as harming the health of workers, sealing of feeding pipes, and raising dust, and improve environmental protection. Performance and practicality, avoid friction collision, prevent dust spill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

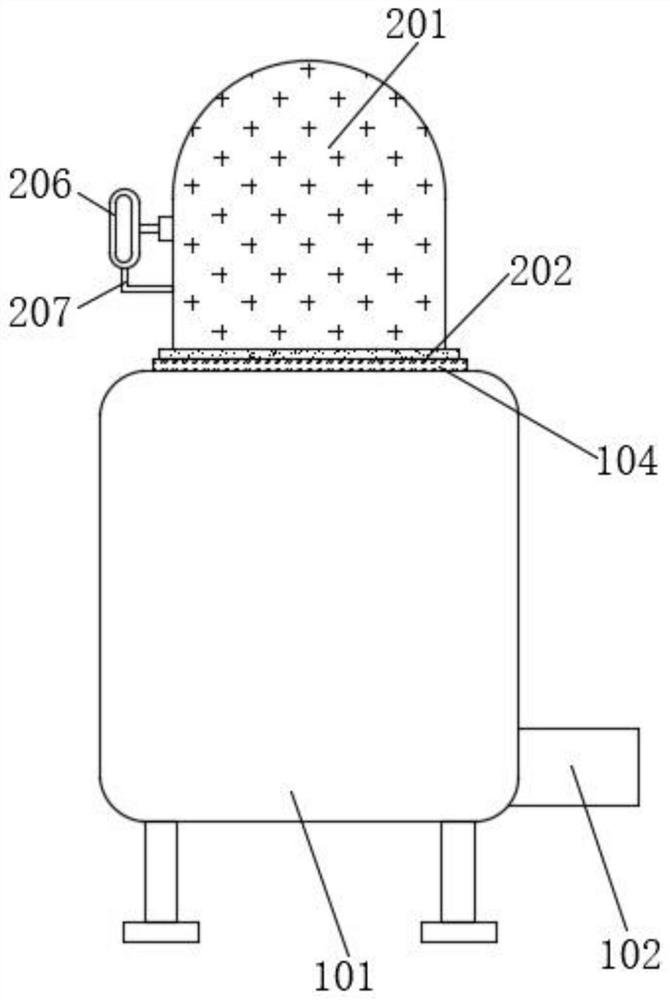

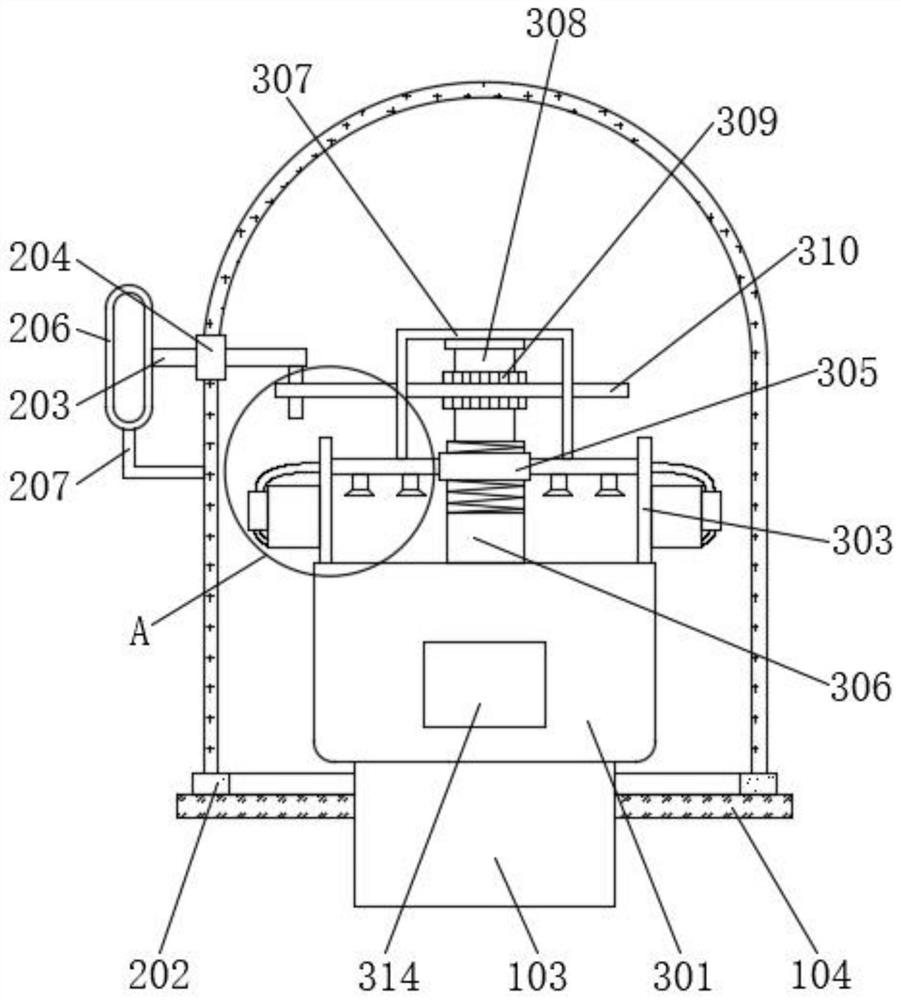

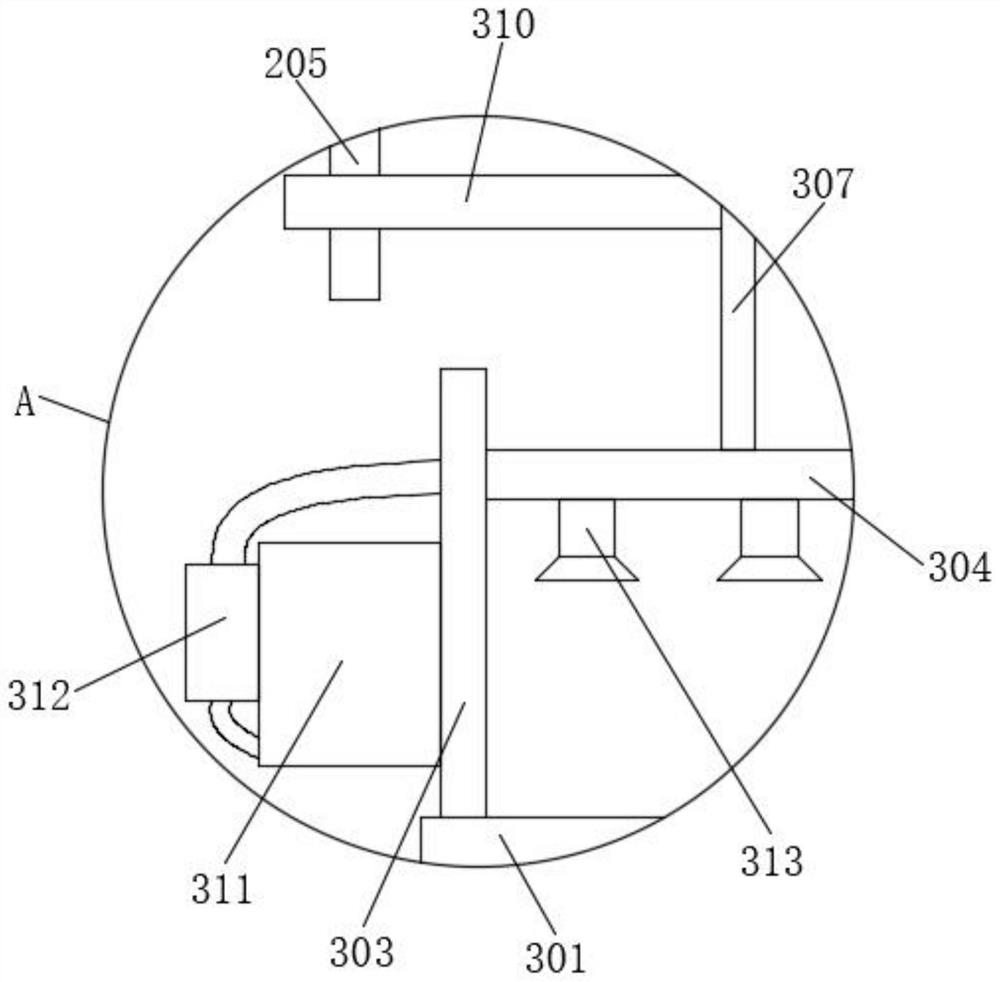

[0046] See Figure 1-2 A dust-free environmentally-protected concrete aggregate mixing device, including a mixing tank 101 provided with a mixing mechanism, an outer wall of the mixing tank 101 side, and the tube 102 is connected, and the top end of the mixing box 101 communicates with a feed tube 103. The top end of the mixing tank 101 is fixed to the outer side of the feed tube 103, and the dustproofing assembly is provided above the mixing tank 101, and the dustproof linkage includes dust cover 201, dust cover 201 The bottom end is fixedly connected to the base magnetic absorbing ring 202, and the base magnetic absorbing ring 202 is made of magnet, and the top magnetic absorbing ring 104 is made of pig iron, so that the dust cover 201 passes through the bottom magnetic absorbing ring 202, a top magnetic absorbing ring 104 The magnetic force force is connected to the mixing tank 101, so that the dust cover 201 and the mixing tank 101 are stabilized and sealed in the premise of re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com