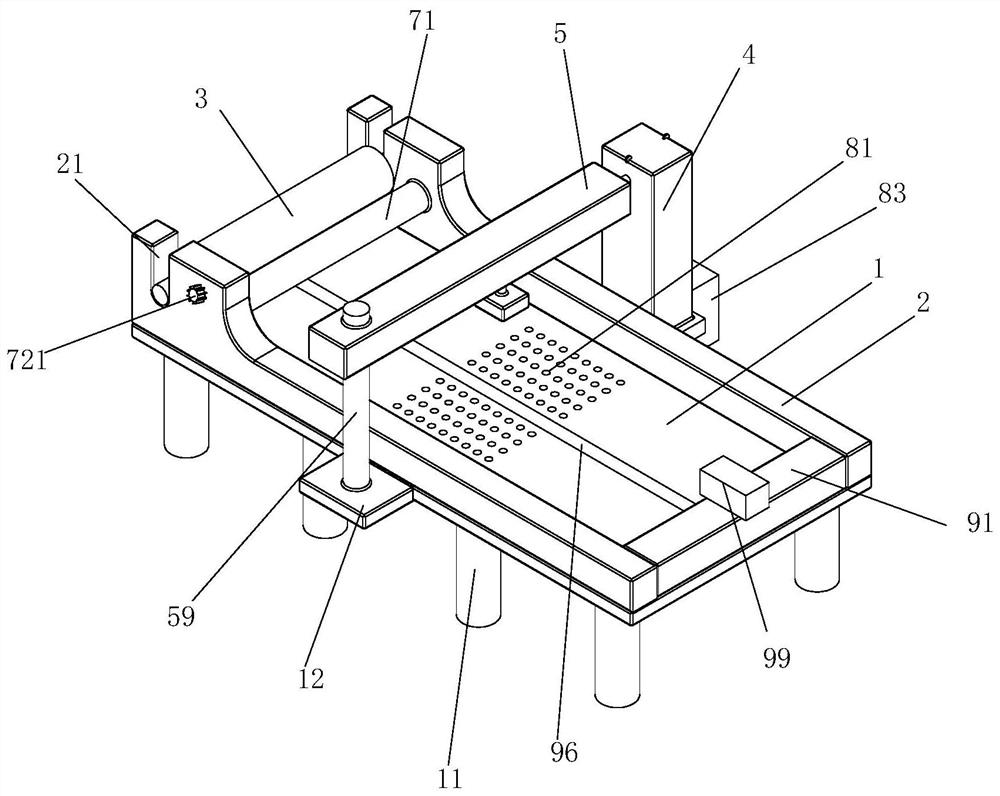

Rapid cutting equipment for crease-resistant clothing accessories

An auxiliary material and fast technology, which is applied in the field of garment processing, can solve the problems of fabric aesthetic effect, fabric cutting quality discount, etc., and achieve the effects of wide application range, precise cutting size and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

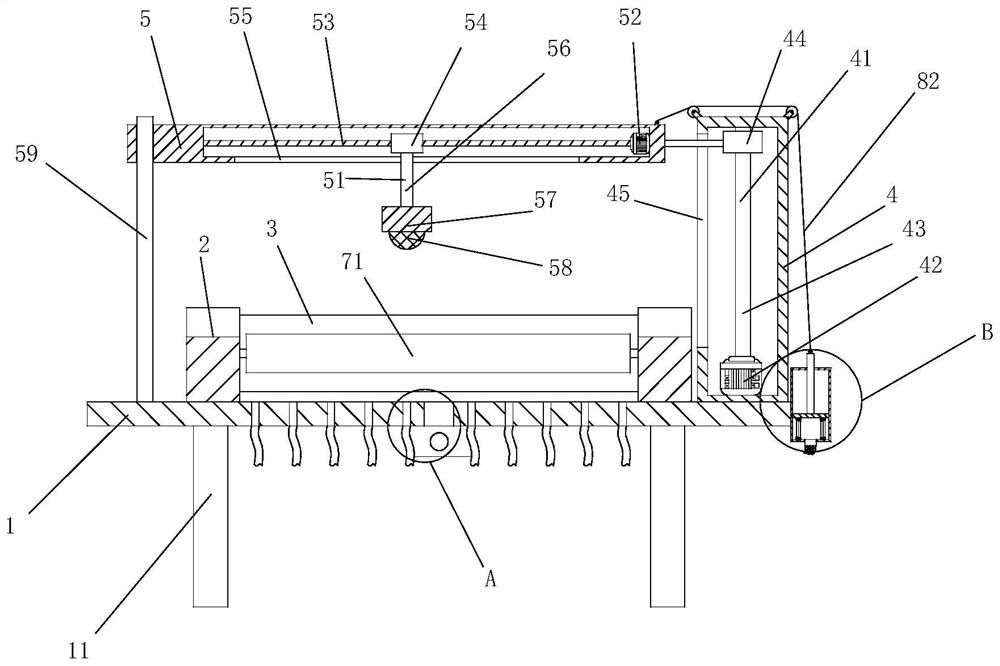

Method used

Image

Examples

Embodiment approach

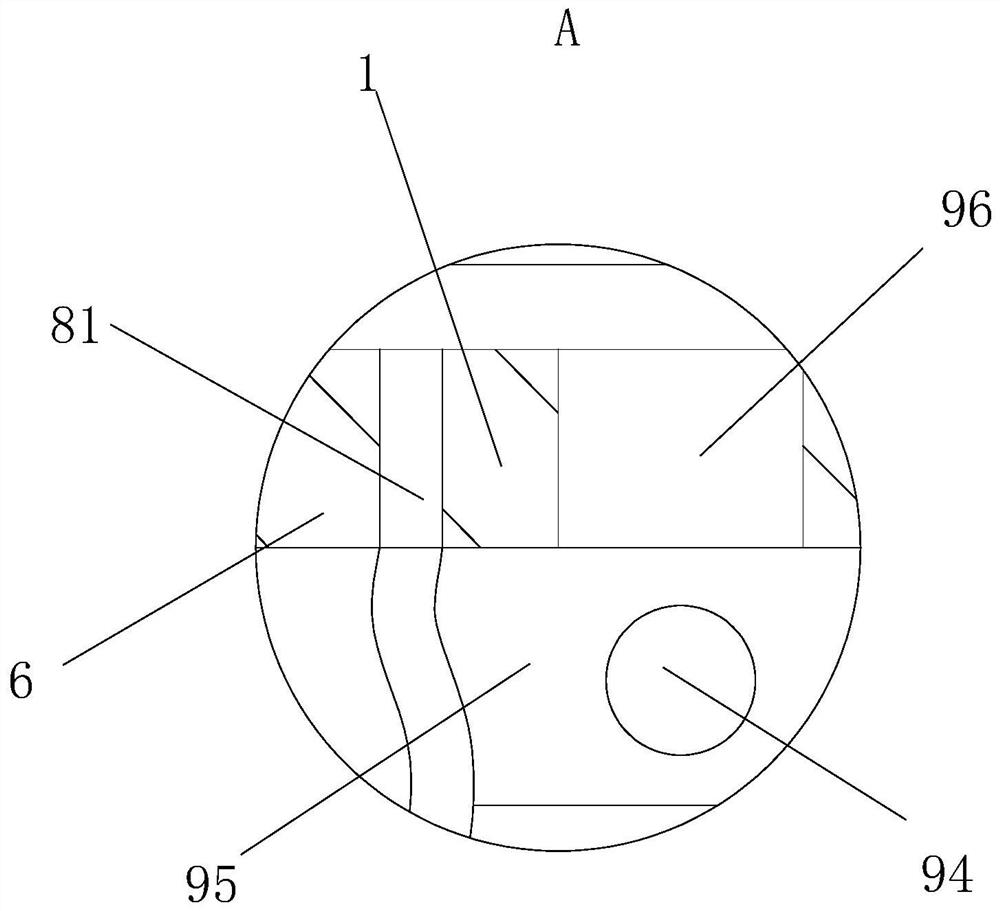

[0032] As an embodiment of the present invention, the flattening assembly 7 includes a pressing roller 71 and an adjustment unit 72; a first cavity 22 is opened in the edge plate 2 fixed on the left side of the top of the cutting table 1; An adjustment unit 72 is arranged in the first cavity 22; a chute 728 is provided on the side wall of the side wall 2 fixedly connected to the top right side of the cutting table 1; the adjustment unit 72 includes a first lead screw 725 and a first The rotating shaft 722; one end of the first rotating shaft 722 is fixedly connected with the rotating button cover 721, and the other end extends into the first cavity 22, and is fixedly connected with the first bevel gear 723, and is connected to the side of the first cavity 22 in rotation On the wall; the bottom end of the first lead screw 725 is rotatably connected to the inner wall of the bottom end of the first cavity 22; the shaft near the top of the first lead screw 725 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com