Control method and system for top dead center position of free piston linear generator

A technology of linear generators and control methods, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as misfire, exceeding the top dead center position, knocking, etc., and achieve the effect of small position fluctuation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

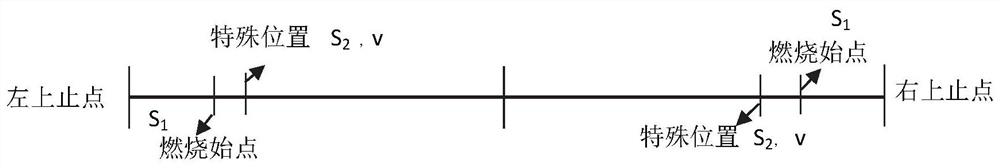

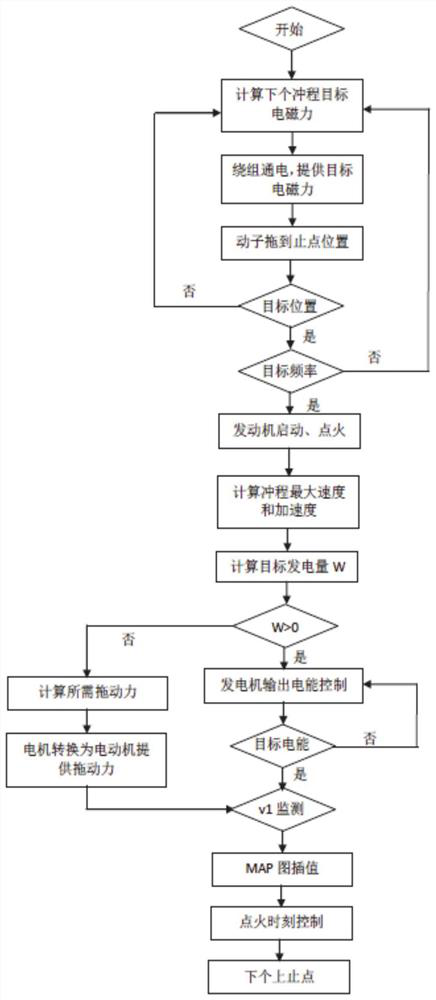

[0040]This embodiment discloses a method for controlling the top dead center position of a free-piston linear generator. On the one hand, according to the real-time combustion conditions in the engine cylinder, the generator load is adjusted so that the mover can reach near the top dead center; on the other hand, combined with the engine Ignition control, adjust the ignition timing according to the deviation between the target speed and the actual speed of the mover at a special position before the top dead center, so that the mover can reach the top dead center position required by the engine as much as possible, so as to realize the stable operation of FPLG and give full play to its advantages .

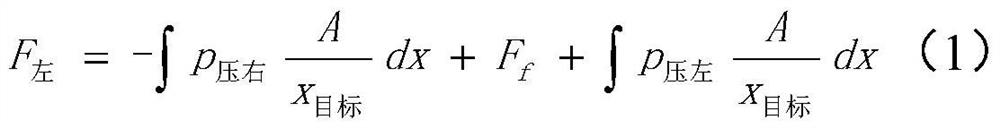

[0041] (1) During the start-up process, the linear motor is used as a motor to drag the piston to the designated top dead center position. In order to ensure that the mover moves to the designated top dead center position, the motor needs to provide a certain drag force. Assuming t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com