Steel bar weight deviation measuring instrument and measuring method

A technology of weight deviation and measuring instrument, which is applied in the direction of measuring devices, instruments, weighing, etc., can solve the problems affecting and affecting the accuracy of weight deviation, and achieve the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the steel bar weight deviation measuring instrument of the present invention will be described in detail below in conjunction with the accompanying drawings. Those skilled in the art should understand that the embodiments described below are only illustrative illustrations of the present invention, and are not intended to limit it in any way.

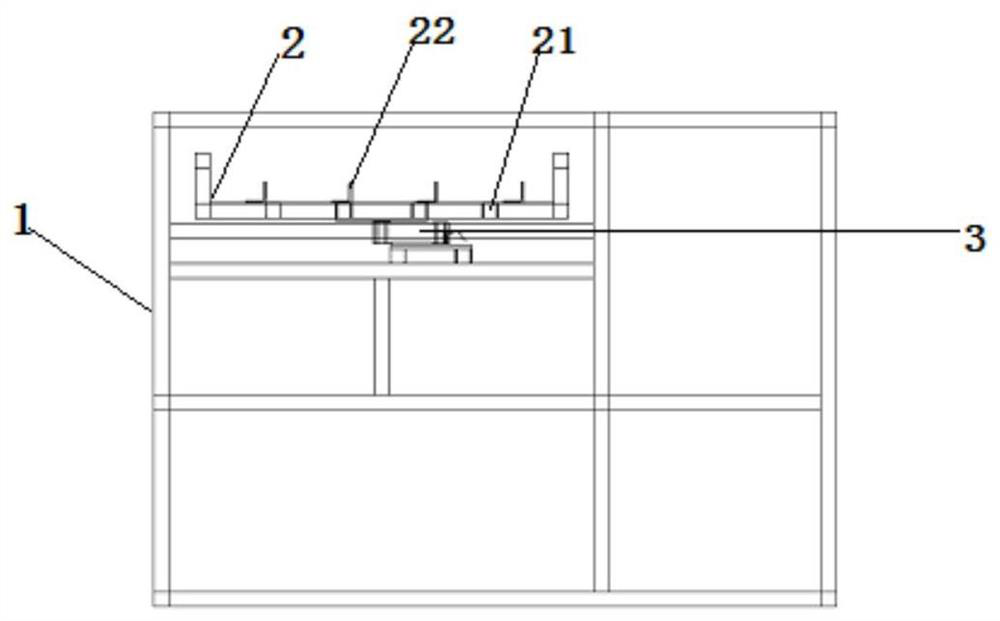

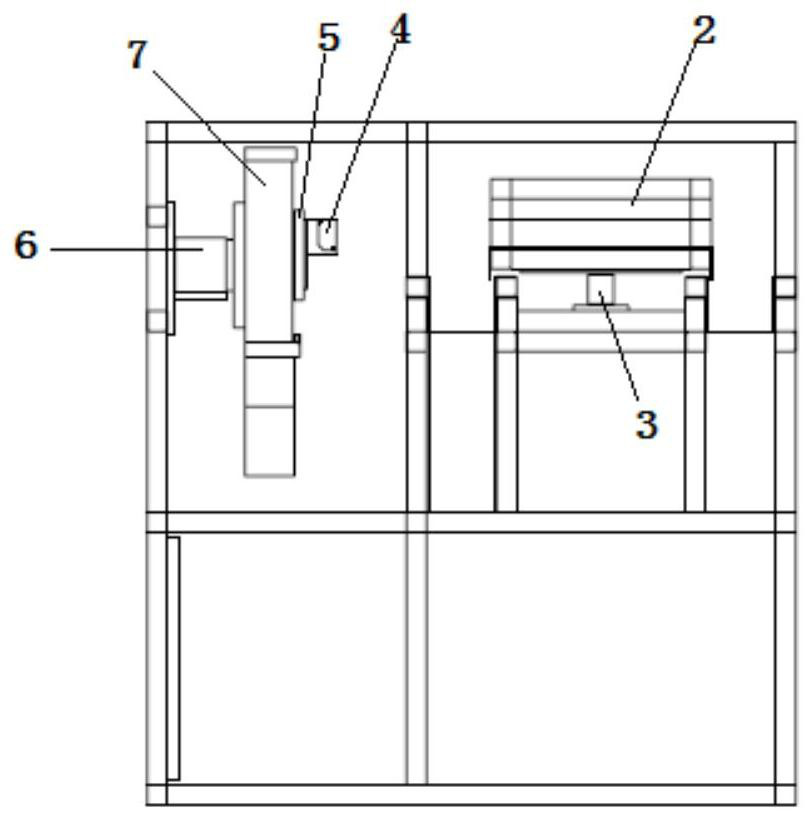

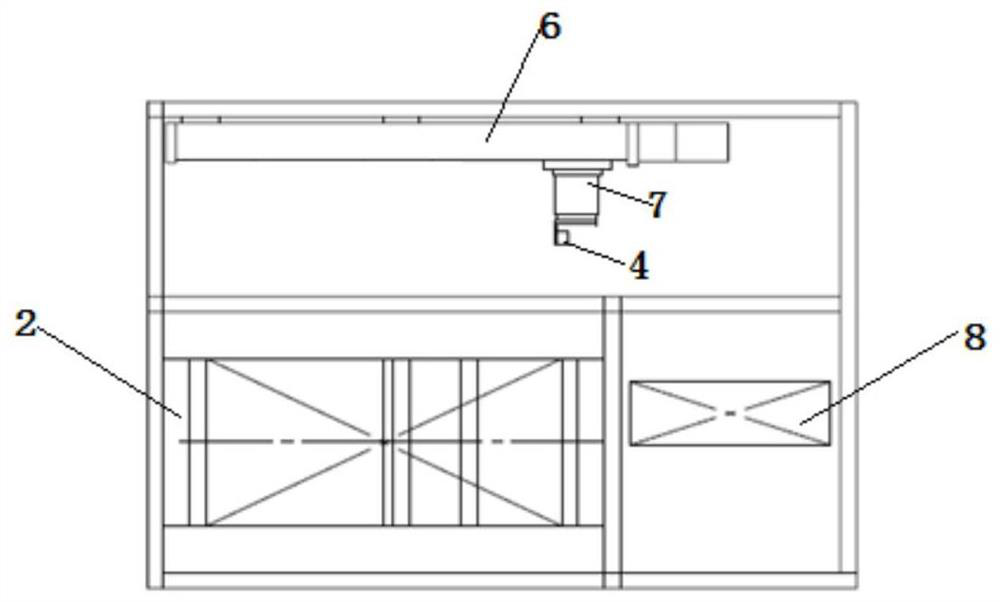

[0030] see Figure 1-3 , The steel bar weight deviation measuring instrument of the present invention mainly includes a frame 1, a sample platform 2, a weighing device 3 and a laser range finder.

[0031] The sample stage 1 includes a grid chassis 21 and a plurality of parallel and spaced legs 22 arranged on the grid chassis 21. The height of the legs 22 is 5-10 cm, and the legs 22 are as narrow as possible, preferably 3-5 mm. This arrangement of the outriggers prevents target interference when the laser rangefinder is used to detect the steel bar sample placed on the outriggers 22 . The weighing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com