Gear box operation state online monitoring method and system, and storage medium

A technology of running state and gear box, which is applied in the direction of measuring devices, complex mathematical operations, and testing of mechanical components. It can solve the problems of wide energy dispersion, difficulty in capturing impact signals, and small amplitude of impact signals, so as to avoid modal confusion. overlapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

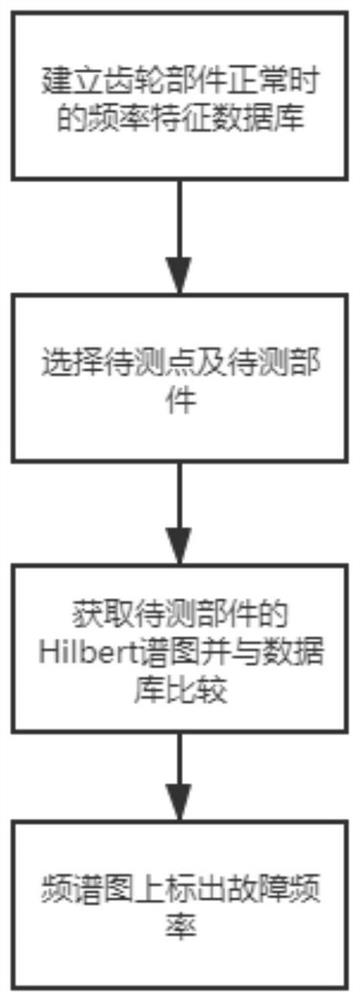

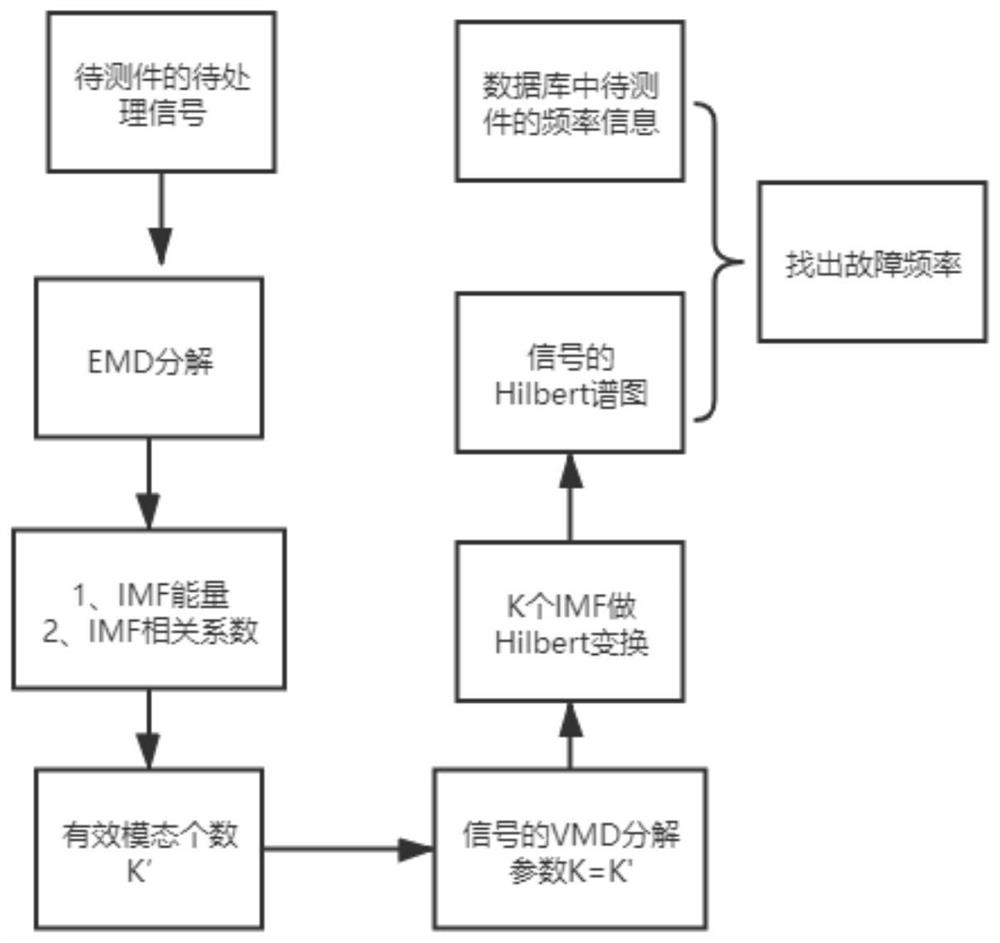

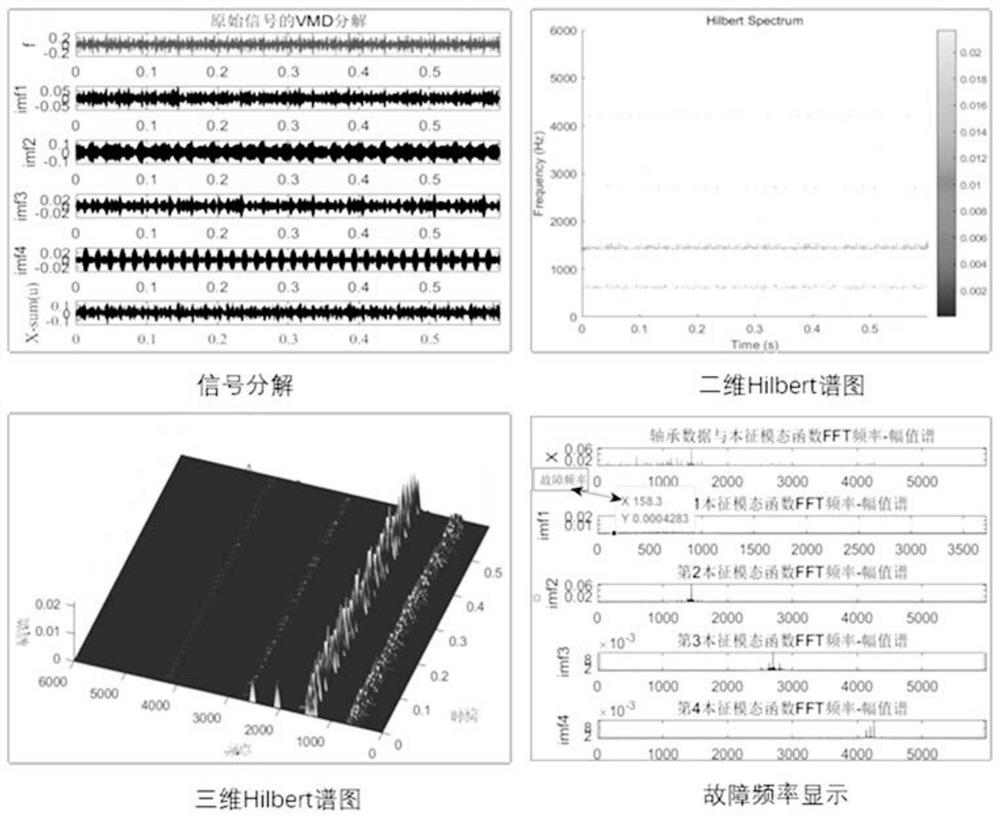

[0043] In this embodiment, a method for online monitoring of the operating state of the gearbox is provided, which can effectively solve the problem that it is difficult to directly display the fault characteristic frequency on the vibration spectrum analysis diagram in the online monitoring system of the gearbox. Such as figure 1 As shown, the monitoring method includes the following steps:

[0044] 1) Establish a frequency characteristic database of all parts to be tested of the gearbox during normal operation;

[0045] 2) Select the points to be tested and the parts to be tested to obtain real-time vibration signals, and at the same time display the important structural parameters and characteristic frequency spectrum of the selected parts to be tested on the existing man-machine interface;

[0046] Among them, the parts to be tested of the gearbox include various types of bearings, fixed shaft gear trains and planetary gear trains in the gearbox;

[0047] The important s...

Embodiment 2

[0082] In this embodiment, an online monitoring system for the operating state of a gearbox is provided, which includes a parameter setting module, a signal acquisition module, a data comparison and analysis module, and a fault early warning module;

[0083] The parameter setting module is used to establish the frequency characteristic database of all parts to be tested in the gearbox under normal operation; and perform part selection and signal analysis settings, wherein, (1) part selection: when performing fault diagnosis on the gearbox, in order to be able to accurately To monitor the running status of specific components, it is necessary to select the measured components. The main options include system component names, component categories, component structure information, etc.; (2) Signal analysis settings, mainly including setting the number of sampling points for the selected vibration signal , sampling accuracy and sampling frequency.

[0084] The signal acquisition m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com