electric locking mechanism

A technology of locking mechanism and transmission mechanism, applied in the field of locks, can solve the problems of unfavorable stable control, insufficient reliability, low precision, etc., and achieve the effect of ensuring single reliability, reliable control, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

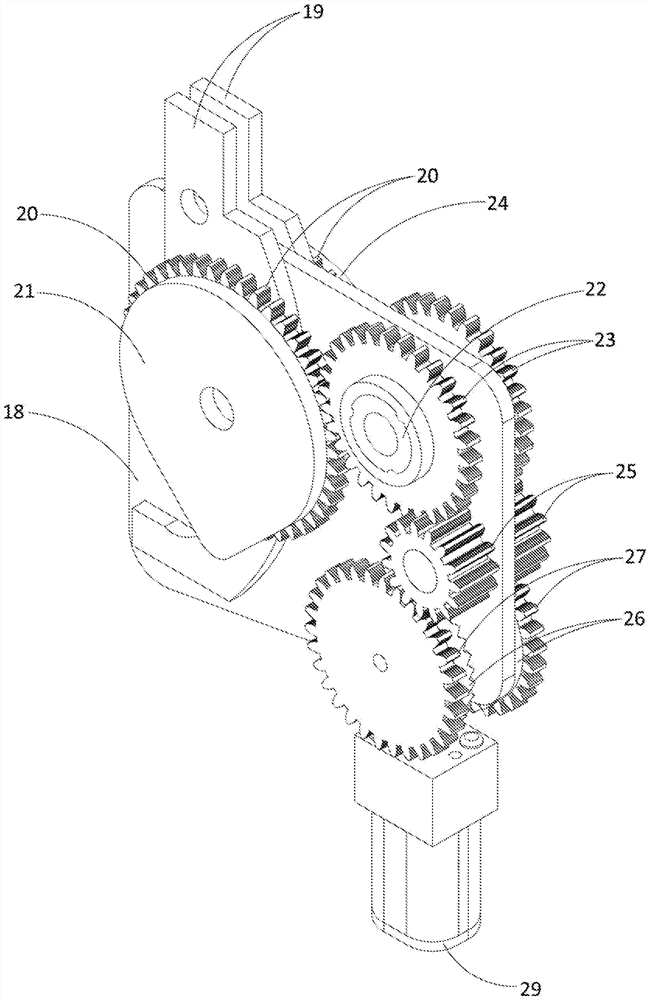

[0057] like figure 1As shown, 1. An electric locking mechanism, comprising a motor 29, two sets of mirror-symmetric transmission mechanisms and two mirror-symmetry output assemblies, the two sets of transmission mechanisms share one motor 29 for driving, and the transmission mechanisms will The kinetic energy of the motor 29 is transmitted to the output assembly; the output end of the motor 29 is provided with a drive gear 28, and the drive gear 28 is sleeved on the output shaft of the motor 29; the two groups of transmission mechanisms include input Gear 26, two described input gears 26 are face gears, and the rotating shafts of two described input gears 26 are parallel to each other; One described driving gear 28 meshes with two described input gears 26 respectively, two described input gears The gears 26 are spaced 180 degrees apart on the circumference where the drive gear 28 meshes.

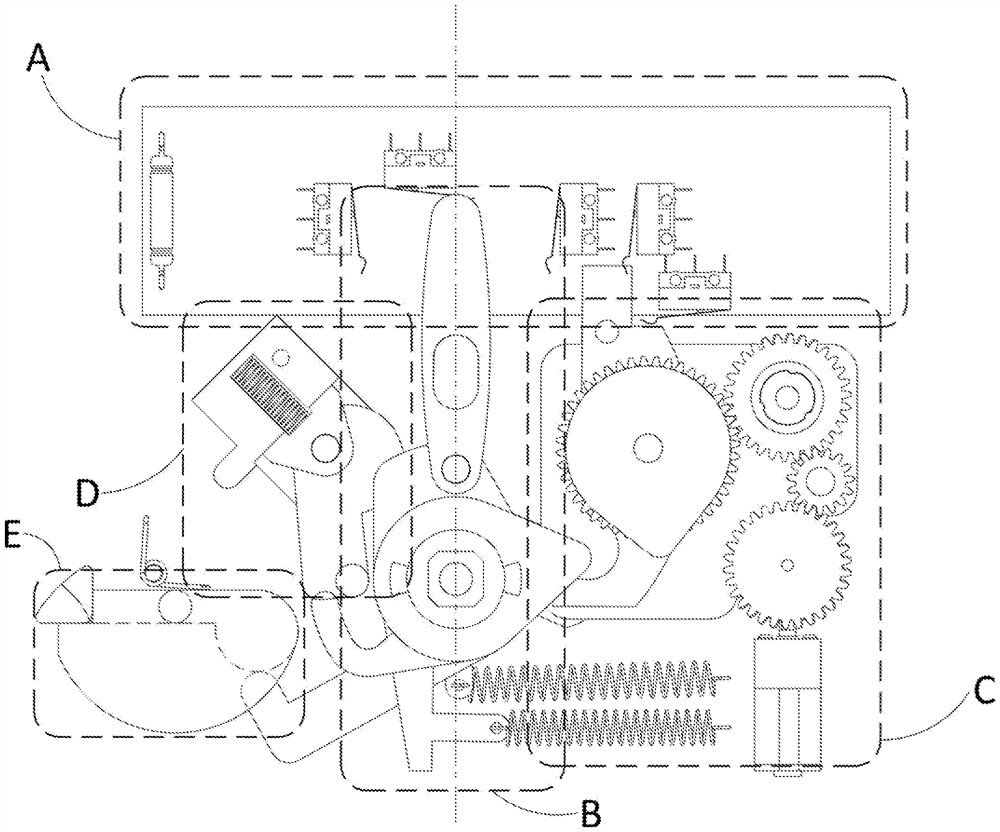

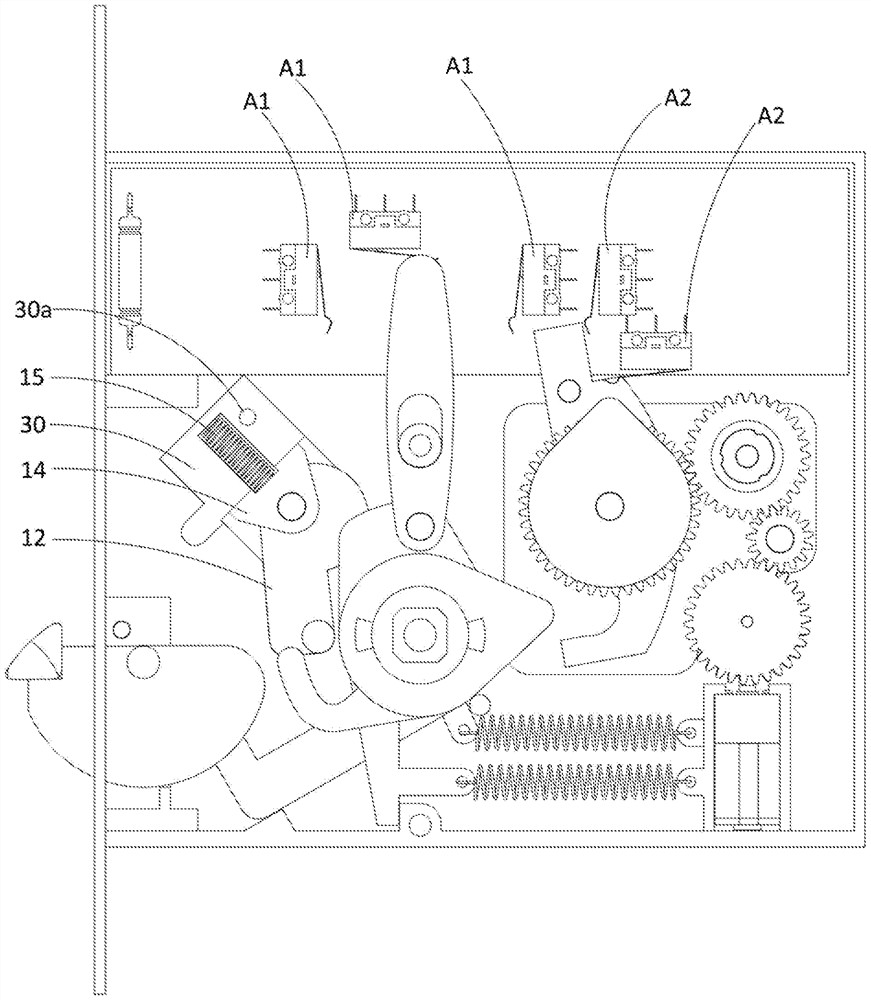

[0058] like Figure 2-Figure 13 As shown, a lock that does not distinguish between pub...

no. 2 example

[0106] In a further embodiment, such as Figure 16-25 As shown, in order to prevent the electronic lock system from being bypassed by items such as plastic cards and forcibly opening the door, on the basis of the foregoing embodiments, a first lock tongue synchronization member is provided on the side of the lock tongue 16 coaxially with the lock tongue rotation axis 163 and the second deadbolt synchronization member 164. Wherein, the second lock tongue synchronizing member 164 is disposed between the lock tongue 16 and the first lock tongue synchronizing member 163 . When the deadbolt 16 rotates along Z3 to lock the door, the second deadbolt synchronization member 164 is synchronized with the deadbolt 16 but extends outward in a straight line. In this embodiment, the limiting protrusion 1611 on the lock tongue 16 can be concave compared to the first embodiment, and its function is the same as that in the first embodiment, so it will not be repeated here. Due to the addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com