Replaceable waste gas treatment device for multi-pipeline filtration

A waste gas treatment device and multi-pipe technology, which is applied in the direction of dispersed particle filtration, transportation and packaging, and separation of dispersed particles, can solve the problems of affecting work efficiency, inconvenient replacement of filter elements, and long replacement time, so as to speed up the filtration work and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

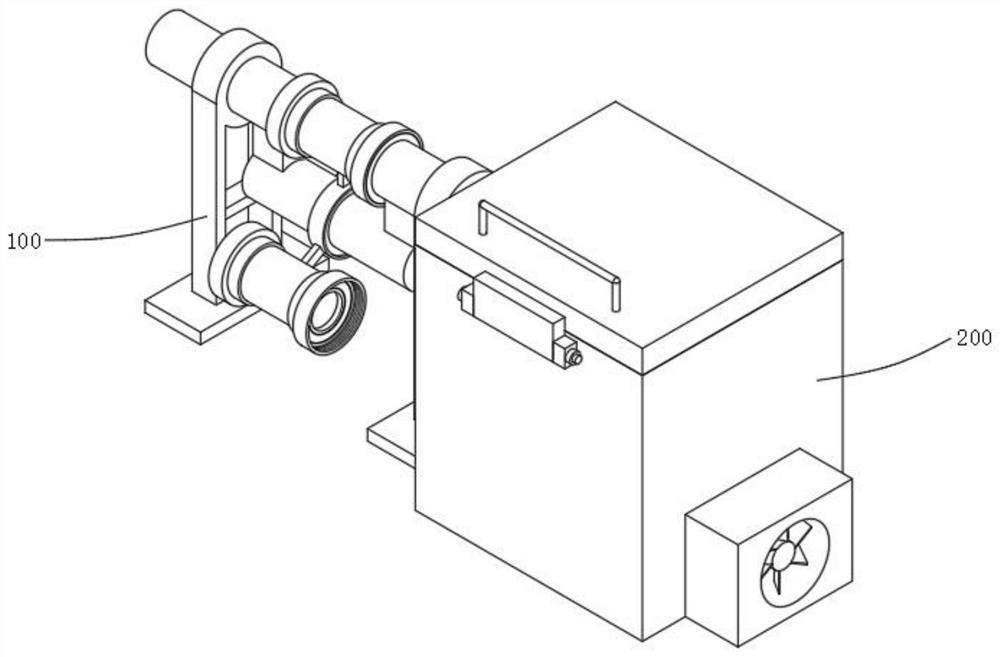

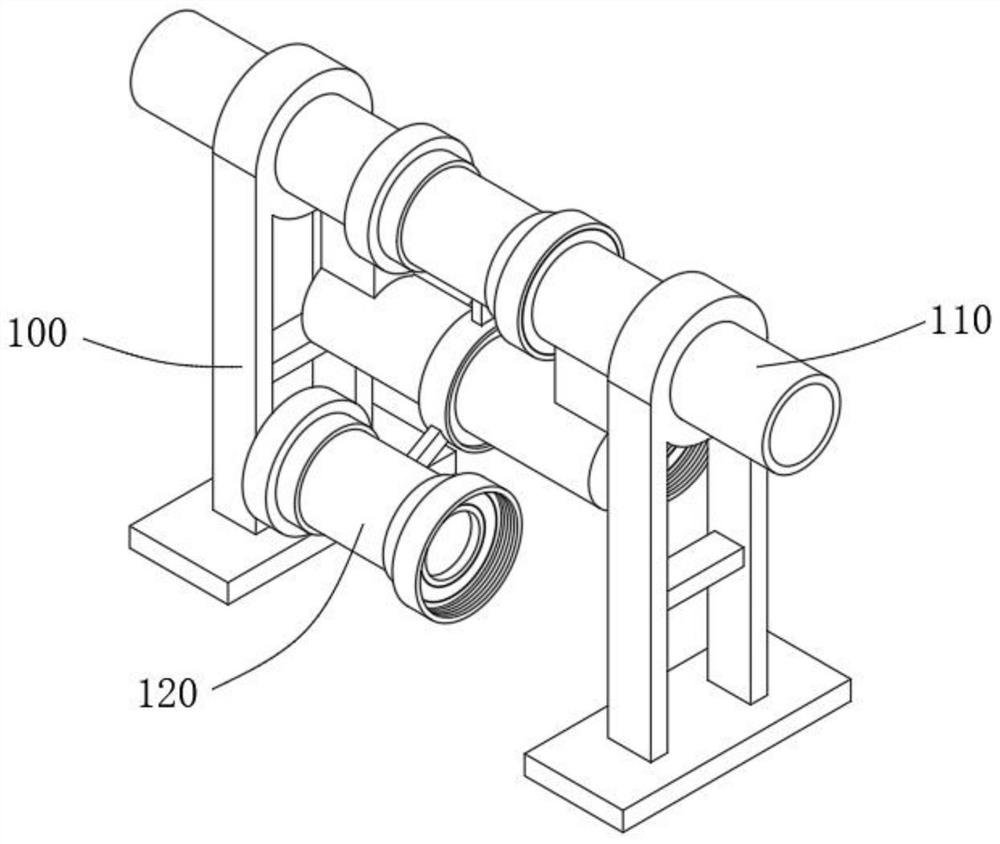

[0058]SeeFigure 1-Figure 15As shown, this embodiment provides an exhaust gas treatment device based on replaceable multi-pipe filtering, which includes a filter mechanism 100 and a filter box 200 fixedly connected to one end of the filter mechanism 100, the filter mechanism 100 at least includes;

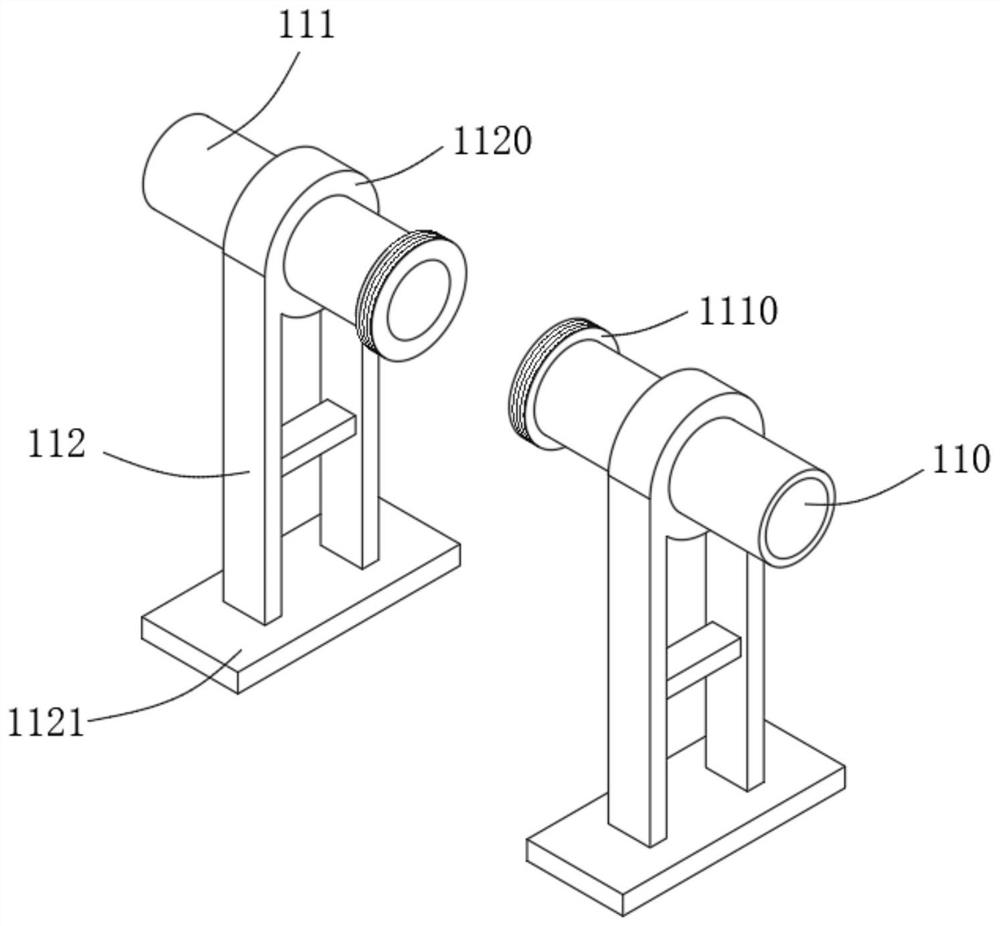

[0059]The connecting device 110 includes a connecting pipe 111, which plays a role of conveying waste gas. There are two connecting pipes 111. The side of the filter box 200 is provided with a connecting port 2000. The rear end of the connecting pipe 111 at the rear end is fixed to the connecting port 2000. The connection facilitates the connection and fixation between the filter mechanism 100 and the filter box 200, and the two connecting pipes 111 are provided with threaded heads 1110 at the ends close to each other;

[0060]The filter device 120 includes a filter pipe 121. Three filter pipes 121 are provided to facilitate the replacement and cleaning of the filter pipe 121. A filter block 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com