Non-sinusoidal vibration waveform of continuous casting crystallizer

A continuous casting crystallizer and vibration waveform technology, applied in the field of continuous casting, can solve the problems of flexible impact of the driving device, poor control ability, equipment impact, etc., and achieve the effect of avoiding rigid and flexible impact and good dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

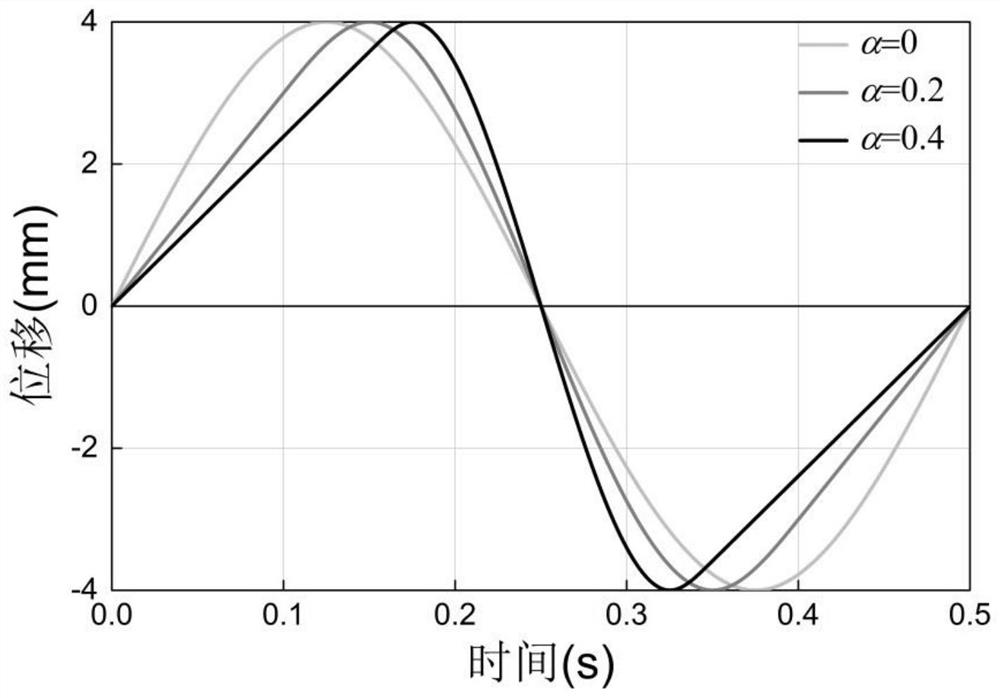

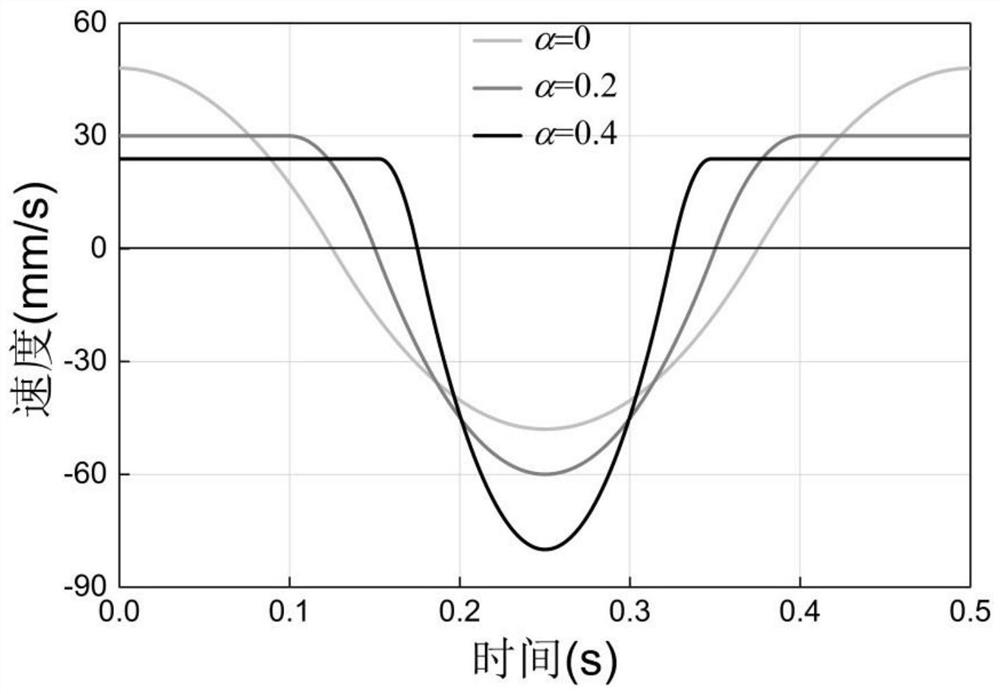

[0035] This embodiment provides a non-sinusoidal vibration waveform of a continuous casting mold.

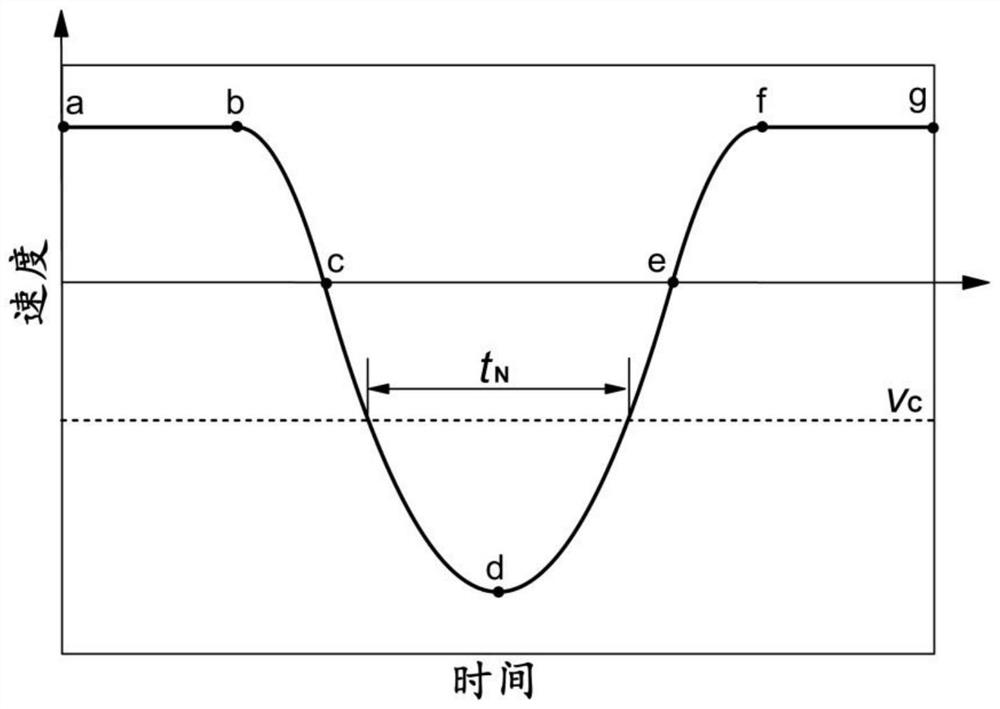

[0036] A non-sinusoidal vibration waveform of a continuous casting mold. Its velocity waveform curve is composed of a horizontal straight line and a parabola. The crystallizer driving device is controlled by a waveform function. The velocity waveform in each cycle is as follows:

[0037]

[0038] Among them, v(t) is the crystallizer vibration velocity (mm / s), t is the non-sinusoidal vibration time (s), k 1 、k 2 , A, B are constant values, t b , t c , t d , t e , t f , t g are the different moments (s) of the non-sinusoidal vibration velocity waveform.

[0039] The velocity waveform curve is continuous and smooth, the slope of each point changes continuously, and the ascending displacement and descending displacement are equal. There is a relationship between the openness of the parabolas with upward and downward openings in the curve, that is, k 1 =N*k 2 , N general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com