Circuit board production wastewater treatment method and wastewater treatment system thereof

A wastewater treatment system and wastewater production technology, applied in multi-stage water treatment, water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as large differences in pH value, different COD content, poor biodegradability, etc. Achieve the effects of high regeneration efficiency, simple process and high use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

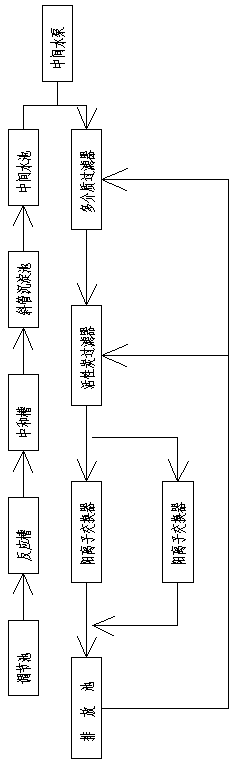

[0048] A method for treating waste water from circuit board production, comprising the steps of:

[0049] (1) Reaction treatment, the waste water is transported to the inside of the reaction tank of the regulating tank, and the reactant is added into the reaction tank, and after 30 minutes of reaction, the reaction treatment is completed; the reactant is a heavy metal scavenger and a PAM polymer coagulant;

[0050] (2) Neutralization treatment, transport the wastewater treated by the reaction in step (1) to the neutralization tank in the adjustment tank, add an acid-base regulator in the neutralization tank, carry out acid-base neutralization, and neutralize until the pH value is After 7, the acid-base reconciliation is completed; the acid-base regulator is NaOH and polyaluminum chloride;

[0051] (3) Sedimentation treatment. The wastewater neutralized in step (2) is transported to the sedimentation tank for sedimentation treatment. The sedimentation time is 2H. After sediment...

Embodiment 2

[0056] A method for treating waste water from circuit board production, comprising the steps of:

[0057] (1) Reaction treatment, the waste water is transported to the inside of the reaction tank of the regulating tank, and the reactant is added into the reaction tank, and after 10 minutes of reaction, the reaction treatment is completed; the reactant is a heavy metal scavenger and a PAM polymer coagulant;

[0058] (2) Neutralization treatment, transport the wastewater treated by the reaction in step (1) to the neutralization tank in the adjustment tank, add an acid-base regulator in the neutralization tank, carry out acid-base neutralization, and neutralize until the pH value is After 7, the acid-base reconciliation is completed; the acid-base regulator is NaOH and polyaluminum chloride;

[0059] (3) Sedimentation treatment. The wastewater neutralized in step (2) is transported to the sedimentation tank for sedimentation treatment. The sedimentation time is 1H. After sediment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com