Noncircular bevel gear indexing device

A technology of non-conical gears and indexing devices, which is applied in the direction of hoisting devices, transmission devices, portable lifting devices, etc., can solve the problems of difficult processing, high cost, low precision, etc., achieve good dynamic characteristics, improve bearing capacity, The effect of compact mechanism layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

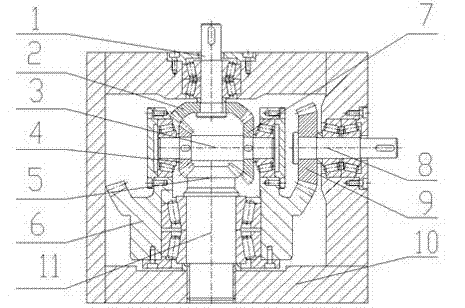

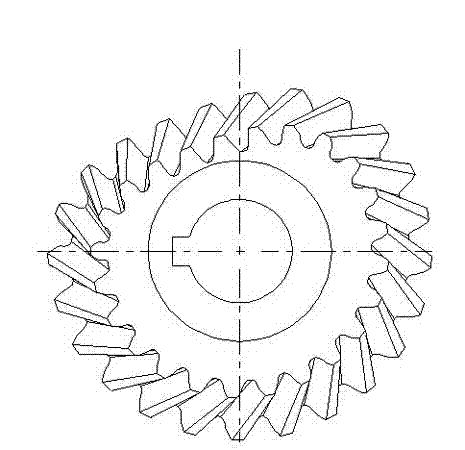

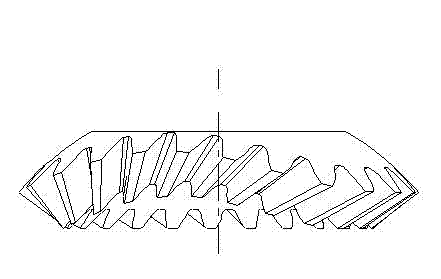

[0036] like figure 1 The shown non-conical gear indexing device includes a casing 10, which is characterized in that: the casing supports an input shaft 8 and an output shaft 1, a gear shaft 11 fixed on the casing 10, and a front end of the casing through bearings. Involute helical non-conical gear 5, planet carrier gear 6, input gear 9, planetary shaft 3, planetary non-conical gear 4, small bevel gear 7, large bevel gear 2. The input shaft 8 and the output shaft 1 are arranged alternately in space. 8 on the input shaft is connected with input gear 9 through a key, and input gear 9 meshes with planet carrier gear 6 . The planetary gear 6 is supported on the gear shaft 11 by a tapered roller bearing, the planetary shaft 3 is fixed on the bearing, and the involute helical non-conical gear 4 and the bevel gear 7 are fixed on both ends of the planetary shaft 3 through key grooves. One of the planetary gears is an involute helical non-conical gear 4 that meshes with the involute ...

specific Embodiment approach 2

[0039] like figure 1 The shown non-conical gear indexing device includes a casing 10, which is characterized in that: the casing supports an input shaft 8 and an output shaft 1, a gear shaft 11 fixed on the casing 10, and a front end of the casing through bearings. Arc helical non-conical gear 5, planet carrier gear 6, input gear 9, planetary shaft 3, planetary non-conical gear 4, small bevel gear 7, large bevel gear 2. The input shaft 8 and the output shaft 1 are arranged alternately in space. 8 on the input shaft is connected with input gear 9 through a key, and input gear 9 meshes with planet carrier gear 6 . The planetary gear 6 is supported on the gear shaft 11 by a tapered roller bearing, the planetary shaft 3 is fixed on the bearing, and the circular arc helical non-conical gear 4 and the bevel gear 7 are fixed on both ends of the planetary shaft 3 through key grooves. One of the planetary gears is a circular arc helical non-conical gear 4, which meshes with the circu...

specific Embodiment approach 3

[0042] like figure 1 The shown non-conical gear indexing device includes a casing 10, which is characterized in that: the casing supports an input shaft 8 and an output shaft 1, a gear shaft 11 fixed on the casing 10, and a front end of the casing through bearings. Involute spur non-conical gear 5, planet carrier gear 6, input gear 9, planetary shaft 3, planetary non-conical gear 4, small bevel gear 7, large bevel gear 2. The input shaft 8 and the output shaft 1 are arranged alternately in space. The input shaft 8 is connected with the input gear 9 through a key, and the input gear 9 meshes with the planetary gear 6; the gear shaft 11 supports the planetary gear 6 through a tapered roller bearing, and the planetary shaft 3 is fixed on the bearing, and the involute is straight Teeth non-bevel gear 4 and bevel gear 7 are fixed on both ends of the planetary gear shaft 3 through key grooves. One of the planetary gears is an involute straight-toothed non-conical gear 4, which mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com