Punching forming equipment

A forming equipment and punching technology, applied in the field of stamping and forming dies, can solve the problems of low punching efficiency of punching equipment, and achieve the effects of improving service life, high efficiency and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Exemplary embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the scope of the present invention, and the descriptions and drawings therein are essentially used for illustration rather than limitation this invention.

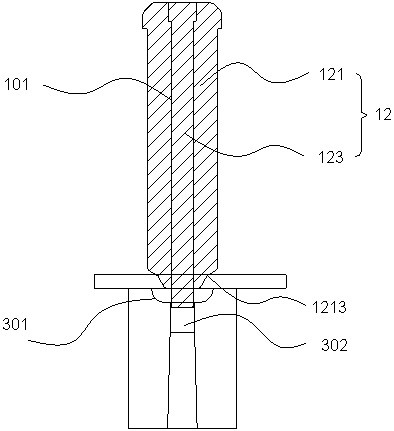

[0029] The present embodiment provides a punching and forming equipment, by using a combined punch structure, the pre-punching and punching forming can be completed at one time, thereby improving the production efficiency.

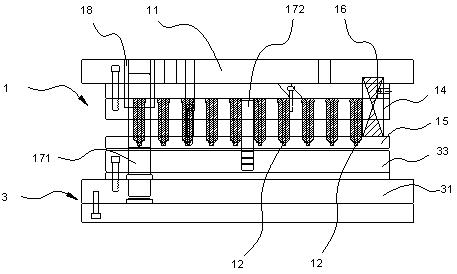

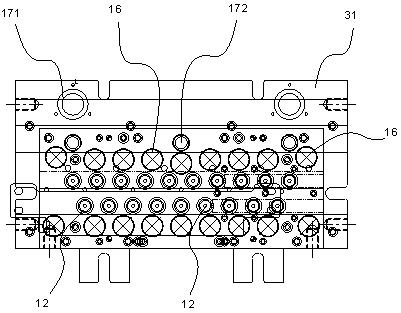

[0030] Please refer to figure 1 and figure 2 , the punching and forming equipment provided in this embodiment mainly includes an upper die assembly 1 and a lower die assembly 3 .

[0031] The punching and forming equipment is installed on the punching machine. In use, the upper die assembly 1 and the lower die assembly 3 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com