Surface napping machine for concrete prefabricated part

A technology for concrete prefabricated parts and a hair pulling machine, which is applied to manufacturing tools, ceramic molding machines, etc., can solve the problems such as the inability to quickly adjust the pulling depth and the complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

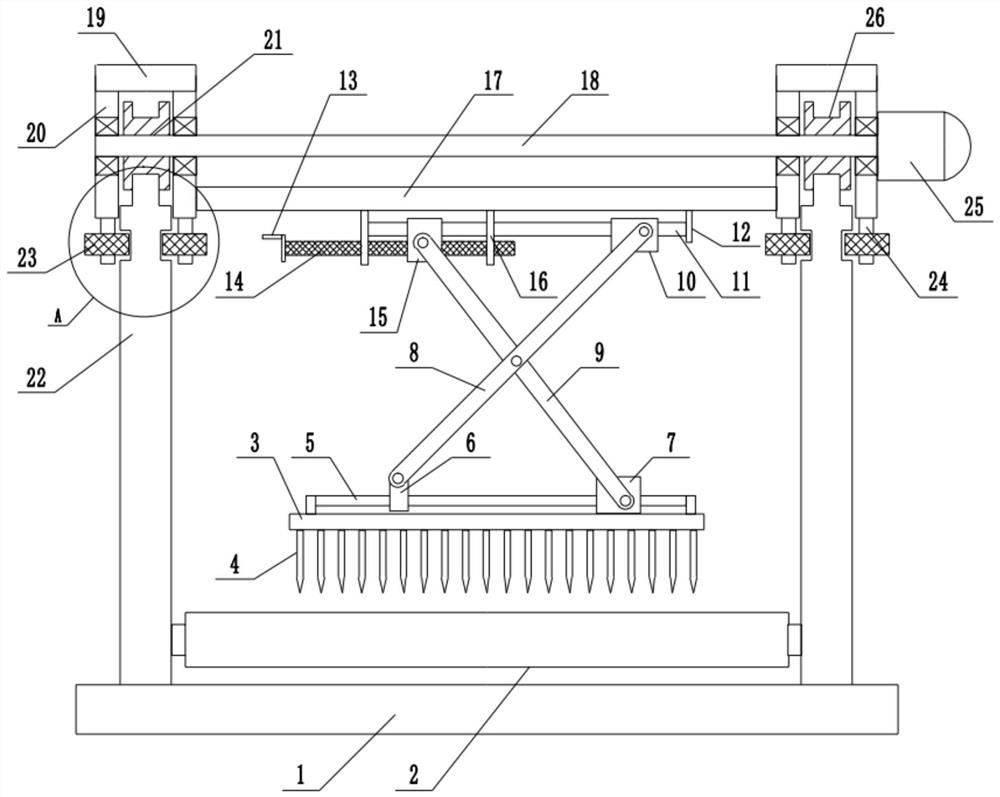

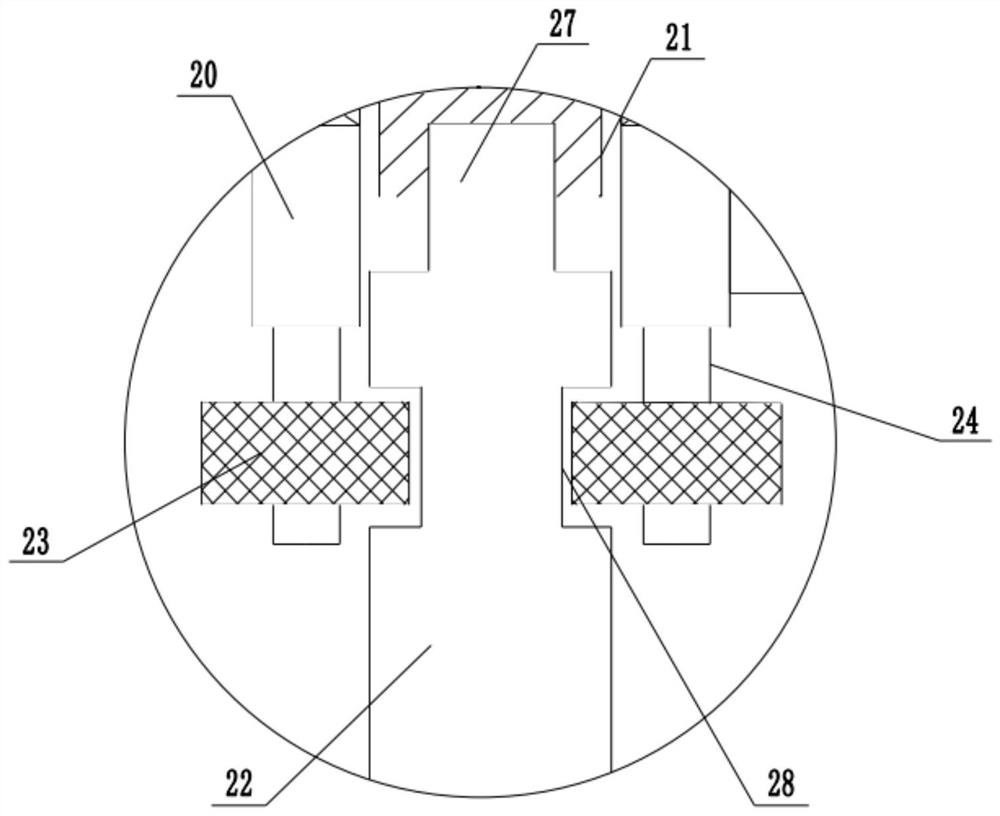

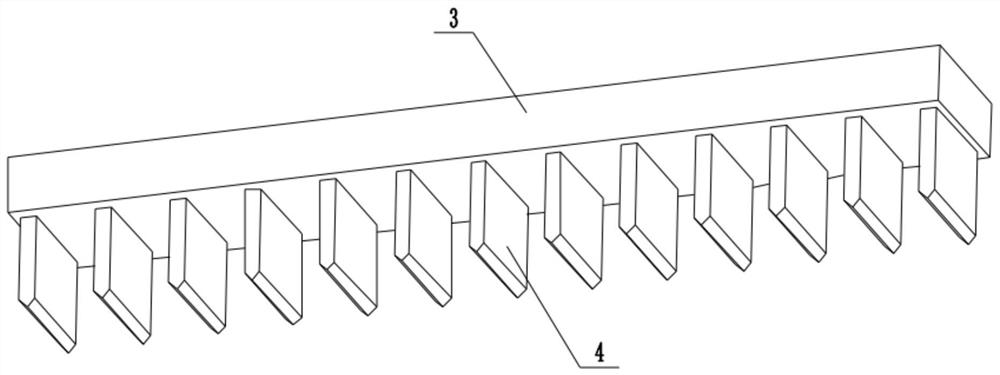

[0028] refer to Figure 1~3 , in an embodiment of the present invention, a surface roughening machine for concrete prefabricated parts, including a fixed base 1, fixed guide rails 22 are installed on both sides of the upper end of the fixed base 1, and walking roller groups 2 are installed between the bottoms of the fixed guide rails 22 , used to realize the effective transmission of concrete prefabricated parts, the top of the fixed guide rail 22 is slidably provided with a roller 21, thereby ensuring the forward and backward movement and conveyance at the top of the fixed guide rail 22, the outer side of the roller 21 is provided with a rolling groove 26, fixed The top of the guide rail 22 is provided with a raceway 27 that cooperates with the rolling groove 26. The setting of the raceway 27 and the rolling groove 26 can better ensure that the roller 21 will not shake left and right during the forward and backward movement, further increasing the moving effect A connecting s...

Embodiment 2

[0031]In another embodiment of the present invention, a fixed base 1 is included, fixed guide rails 22 are installed on both sides of the upper end of the fixed base 1 , walking roller sets 2 are installed between the bottoms of the fixed guide rails 22 , and rollers are slidingly provided on the top of the fixed guide rails 22 21, the outside of the roller 21 is provided with a rolling groove 26, the top of the fixed guide rail 22 is provided with a raceway 27 that cooperates with the rolling groove 26, and a connecting shaft 18 is installed between the middle parts of the roller 21, and the connecting shaft 18 is provided with a bearing through the rotation of the bearing. Walking plate 20, and connecting shaft 18 is fixedly connected with roller 21, and described connecting shaft 18 one ends are installed drive motor 25, and described driving motor 25 is double steering stepper motor, and driving motor 25 is fixed on the walking plate 20, and described roller Walking board 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com