Steel slag concrete stirring device convenient to clean

A steel slag concrete and mixing device technology, which is applied to cement mixing devices, clay preparation devices, cleaning hollow objects, etc., can solve the problems of unblocking of discharge pipes, waste water filtration, and inconvenient cleaning of mixing drums, etc., to achieve Avoid clogging and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

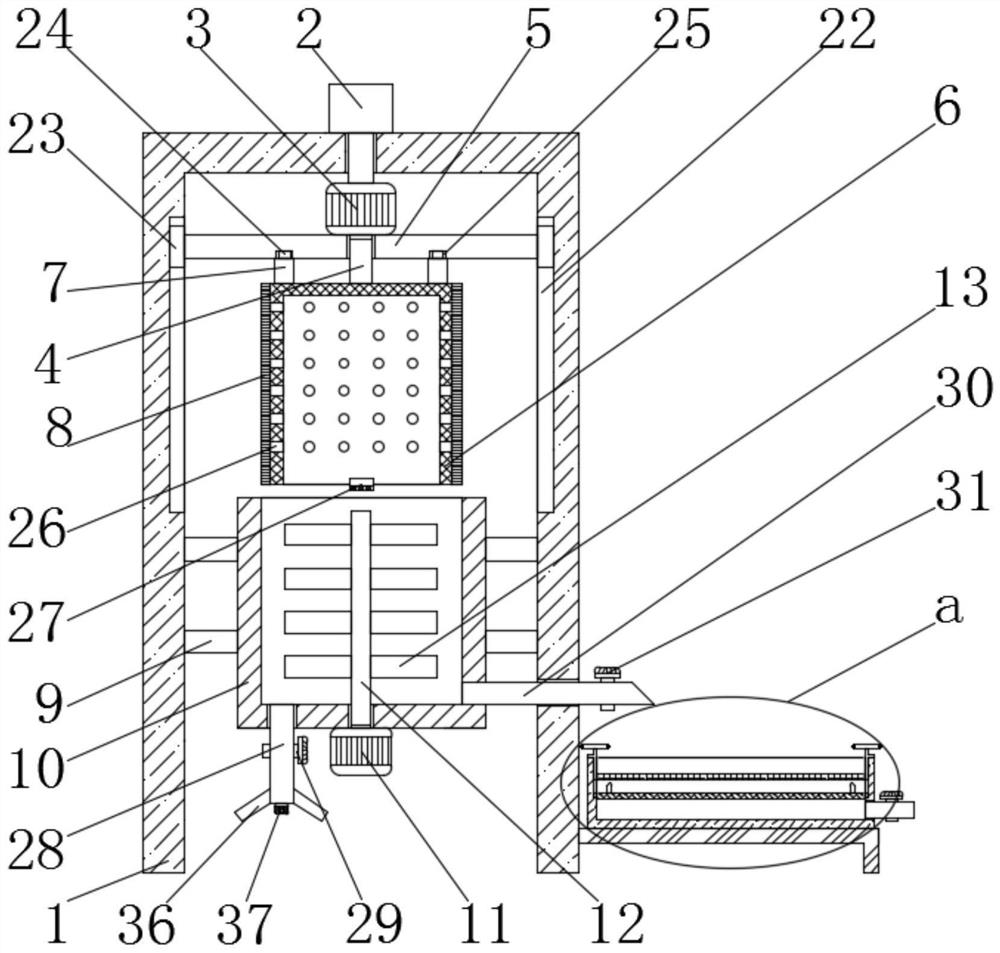

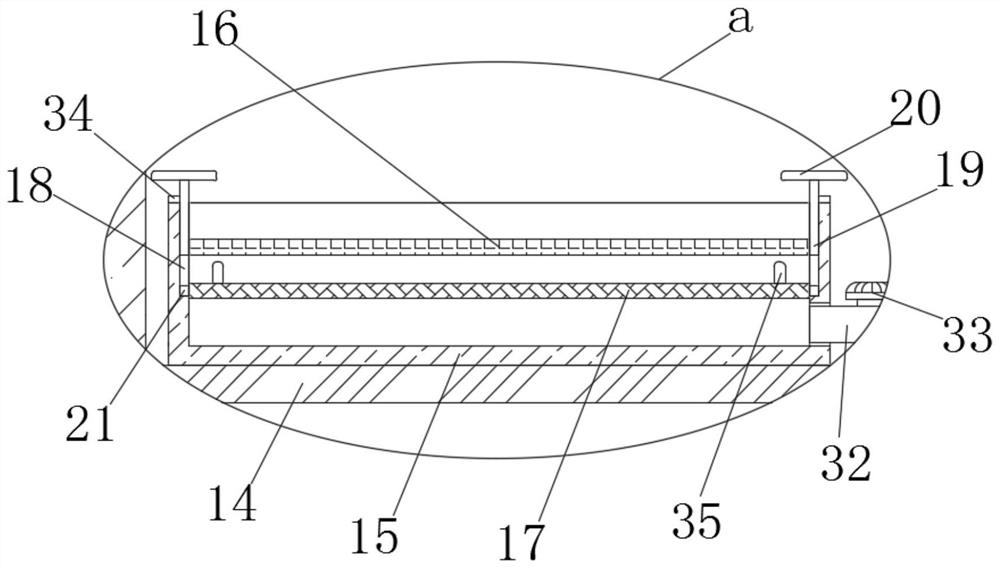

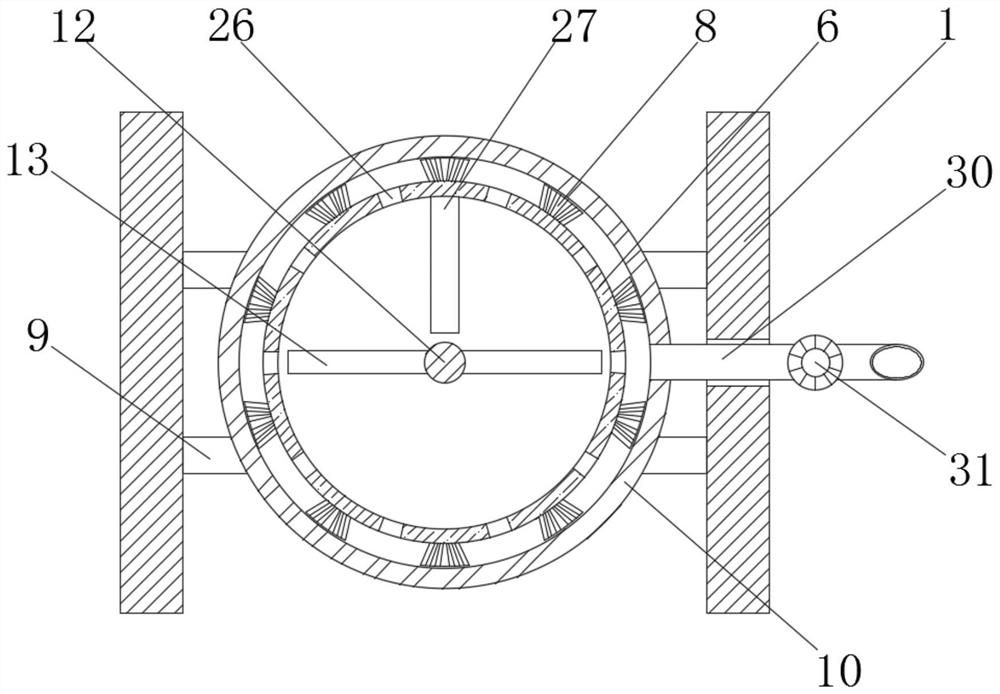

[0032] see Figure 1-6 , a steel slag concrete mixing device that is easy to clean, including a concave frame 1, an electric cylinder 2 is fixedly connected to the top of the concave frame 1, and the telescopic end of the electric cylinder 2 penetrates the concave frame 1 and extends to the inside of the concave frame 1 The telescoping end of the electric cylinder 2 is fixedly connected with the rotating motor 3 through the fixed block, the output end of the rotating motor 3 is welded with the shaft 4, the bottom of the rotating motor 3 is fixedly connected with the moving plate 5, and the bottom of the shaft 4 runs through the moving plate 5 and extends to the bottom of the moving plate 5 and is fixedly connected with a brush tube 6, and the left and right sides of the top of the brush tube 6 are fixedly connected with a cylinder 7, and the left and right sides of the brush tube 6 are uniformly provided with a brush 8, and the concave frame 1 The front and rear positions on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com