Method for controlling alkalinity of dephosphorized slag in double-slag-method converter steelmaking process

A converter steelmaking and control method technology, which is applied to the improvement of process efficiency, manufacturing converters, lime production, etc., can solve the problems of short time and difficulty in accurately controlling the basicity of dephosphorization final slag, so as to improve the slag conversion rate, The effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

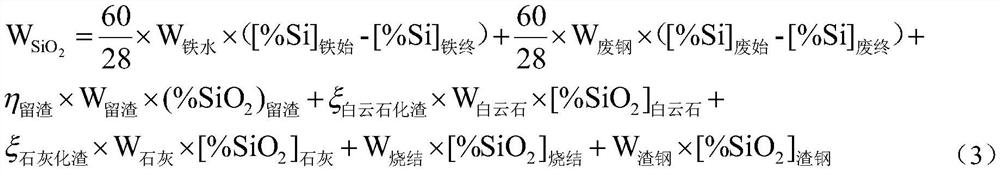

[0033] In this embodiment, a method for controlling the basicity of the dephosphorization slag in the double slag method converter steelmaking process is to spread lime on the bottom of the furnace before adding molten iron to the converter; content, the amount of slag left in the previous furnace, the addition of lightly burned dolomite, iron oxide auxiliary materials and slag steel, and the CaO and SiO 2 Lime and light-burned dolomite slag rate, as well as the target alkalinity to determine; thus control the basicity of the end point of dephosphorization slag, thereby improving the dephosphorization rate of the dephosphorization stage and the slag dumping rate of dephosphorization slag, including The following steps:

[0034] (1) After tapping at the end of the previous furnace, as shown in Table 4, add 5.73 kg / ton of light-burned dolomite as a curing agent, and then perform slag splashing to protect the furnace and solidify the decarburized slag, and then remove the decarbu...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, and the special features are:

[0046] In this embodiment, a method for controlling the basicity of the dephosphorization slag in the double slag method converter steelmaking process is to spread lime on the bottom of the furnace before adding molten iron to the converter. , the amount of slag left in the previous furnace, the amount of lightly burned dolomite, iron oxide auxiliary materials and slag steel, and the CaO and SiO 2 content, lime and light-burned dolomite slag rate, and the target alkalinity to determine the basicity of the end point of the dephosphorization slag, thereby increasing the dephosphorization rate of the dephosphorization stage and the slag dumping rate of the dephosphorization slag, including The following steps:

[0047] (1) After tapping at the end of the previous furnace, as shown in Table 4, add 5.55 kg / ton of light-burned dolomite as a curing agent, and then perform slag splashing to ...

Embodiment 3

[0080] This embodiment is basically the same as the previous embodiment, and the special features are:

[0081] In this embodiment, a method for controlling the basicity of the dephosphorization slag in the double-slag method converter steelmaking process is to spread lime on the bottom of the furnace before adding molten iron to the converter. content, the amount of slag left in the previous furnace, the addition of lightly burned dolomite, iron oxide auxiliary materials and slag steel, and the CaO and SiO 2 content, the slag rate of lime and light-burned dolomite, and the target alkalinity are determined, thereby controlling the alkalinity at the end of the dephosphorization slag. In this embodiment, at least one of sintered ore, returned ore, and OG briquettes is used as an auxiliary material for iron oxide, instead of using sintered ore as an auxiliary material for iron oxide in Example 1, thereby improving the dephosphorization rate in the dephosphorization stage and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com