High-strength and high-toughness steel for petroleum lifting ring and preparation method thereof

A petroleum and high-strength technology, applied in the field of steel materials, can solve the problems of poor low-temperature toughness and increase the cost of steel for petroleum lifting rings, and achieve the effects of improving hardenability, tempering stability, and tempering brittleness resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

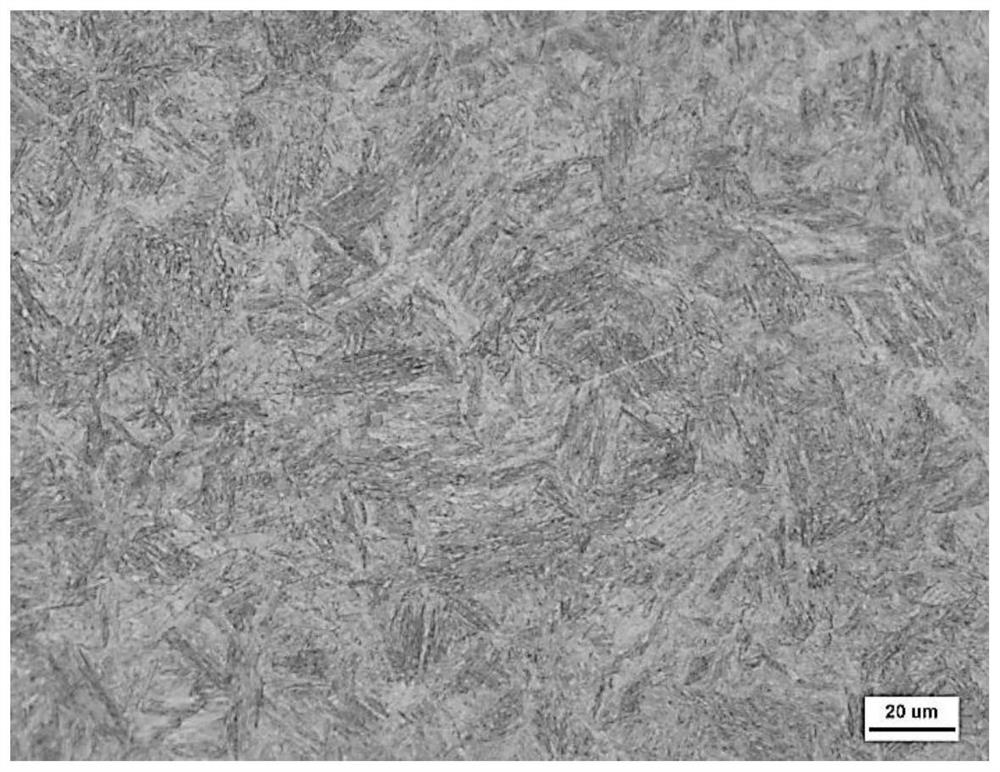

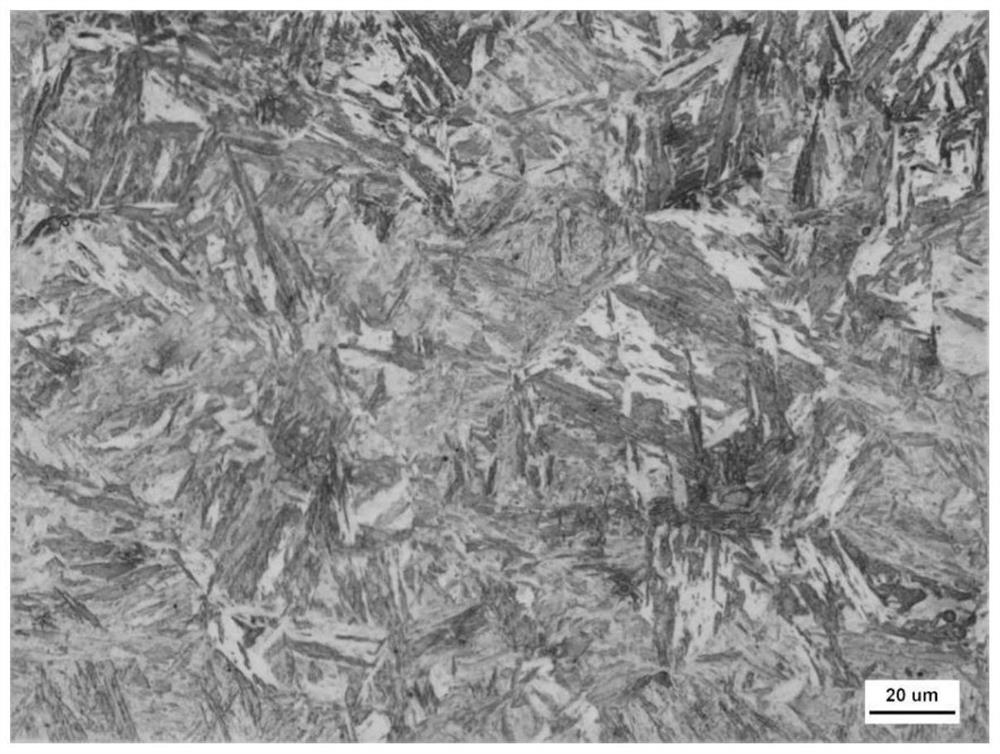

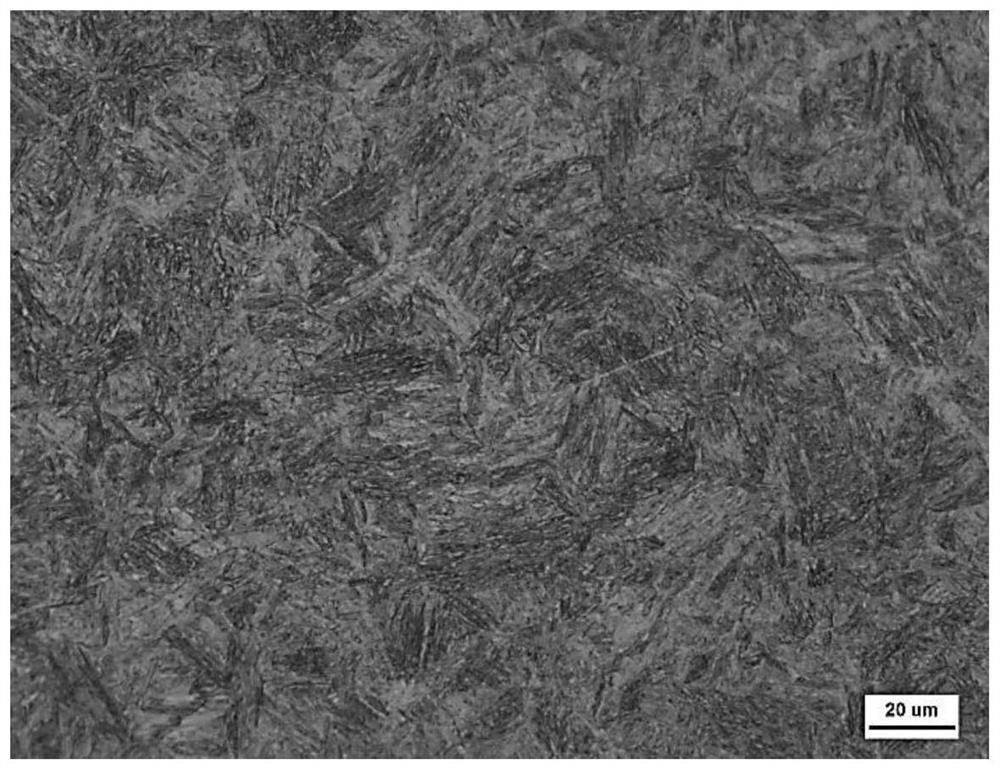

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of steel for high-strength and tough petroleum suspension rings, comprising:

[0047] Step 1: smelting the raw material of steel for high-strength and tough petroleum suspension rings to obtain steel ingots;

[0048] Step 2: Forging the steel ingot into a cylindrical billet for the first time;

[0049] Step 3: Continue to perform free forging on the cylindrical billet several times to obtain the required high-strength and tough steel for oil rings.

[0050] Specifically, in step 2, before the initial forging, in order to ensure that the steel ingot is thoroughly heated, it is necessary to heat the steel ingot to a temperature of 1100° C. to 1150° C. and keep it warm for more than 1 hour. Considering that if the heating temperature is too high, it will cause overburning and overheating. When the temperature is too low, the deformation resistance of the steel is large, and the plasticity is relatively poor, which i...

Embodiment 1

[0058] As shown in Table 1, the chemical composition (mass percentage%) of the steel for petroleum suspension rings in this embodiment is: C: 0.16, Si: 1.09, Mn: 3.70, S: 0.003, P: 0.003, Cr: 0.04, Mo: 0.02, V: 0.02, Ti: 0.02, and the balance is Fe and unavoidable impurities. The cross-sectional dimensions of the prepared steel for petroleum suspension rings are Φ30mm and Φ110mm.

[0059] The specific steps and process parameters are as follows:

[0060] Step 1: smelting the raw material of steel for high-strength and tough petroleum suspension rings to obtain steel ingots;

[0061] Step 2: Heating the steel ingot to a temperature of 1150°C and holding it for 1.5 hours, then forging it into a cylindrical billet for the first time;

[0062] Step 3: Carry out multiple free forgings on the cylindrical billet to obtain the required steel for oil lifting rings. The forging ratio is 10 during the forging process.

Embodiment 2

[0064] As shown in Table 1, the chemical composition (mass percentage%) of the steel for petroleum suspension rings in this embodiment is: C: 0.10, Si: 0.85, Mn: 3.50, S: 0.003, P: 0.003, Cr: 0.02, Mo: 0.03, V: 0.03, Ti: 0.02, and the balance is Fe and unavoidable impurities. The cross-sectional dimensions of the prepared steel for petroleum suspension rings are Φ60mm and Φ110mm.

[0065] The specific steps and process parameters are as follows:

[0066] Step 1: smelting the raw material of steel for high-strength and tough petroleum suspension rings to obtain steel ingots;

[0067] Step 2: Heating the steel ingot to a temperature of 1100°C and holding it for 1.2 hours, then forging it into a cylindrical billet for the first time;

[0068] Step 3: Carry out multiple free forgings on the cylindrical billet to obtain the required steel for oil lifting rings. During the forging process, the forging ratio is 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com