A joint hydrogenation system of liquid hydrogen and high-pressure gas hydrogen based on injection mixed pressure

A technology of hydrogenation system and high-pressure gas, which is applied in the field of hydrogenation at hydrogenation stations, can solve the problems of safety hazards of vehicle-mounted gas cylinders, the problem of not mentioning temperature rise, etc., and achieves reduction of complexity and investment, operation and maintenance costs, and structure. Simple, to achieve the effect of cooling energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

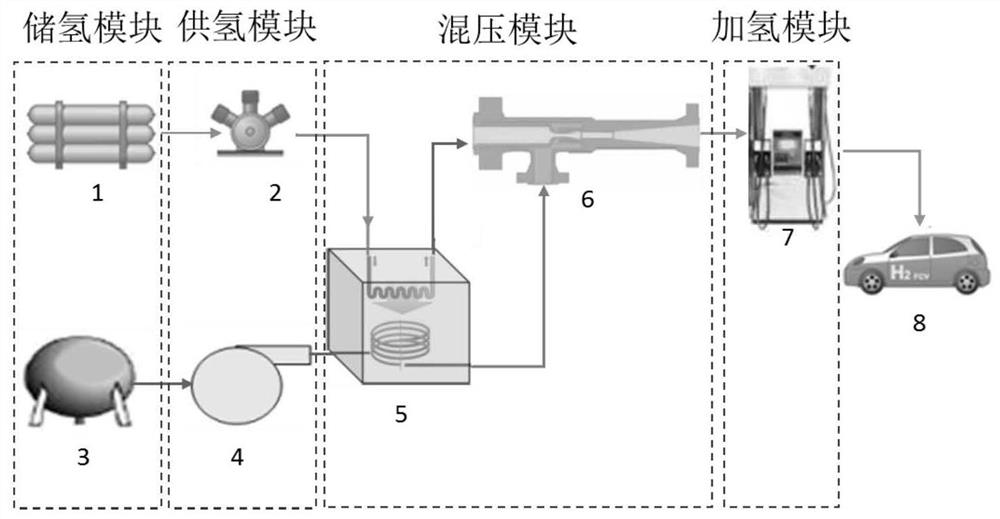

[0023] Such as figure 1 As shown, the combined hydrogenation system of liquid hydrogen and high-pressure gas hydrogen based on injection mixed pressure in the present invention includes a high-pressure hydrogen storage tank 1, a compressor 2, a liquid hydrogen tank 3, a cryopump 4, a heat exchanger 5, an injection 6 and hydrogenation gun 7, for the sake of easy understanding, the fuel cell vehicle 8 is also schematically shown. The outlet of high-pressure hydrogen storage tank 1 is connected to the inlet of compressor 2, the outlet of compressor 2 is connected to the gas inlet of heat exchanger 5, the outlet of liquid hydrogen tank 3 is connected to the inlet of cryopump 4, and the outlet of cryopump 4 is connected to the liquid of heat exchanger 5 The inlet is connected, the high-pressure gas of the heat exchanger 5 is connected with the first inlet of the ejector 6, and the low-pressure gas of the heat exchanger 5 is connected with the second inlet of the ejector 6 (the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com