Garbage pyrolysis and incineration harmless disposal equipment

A pyrolysis and garbage technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of purifying flue gas particles, unable to improve the removal efficiency of particles in flue gas, and unable to automatically promote garbage incineration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

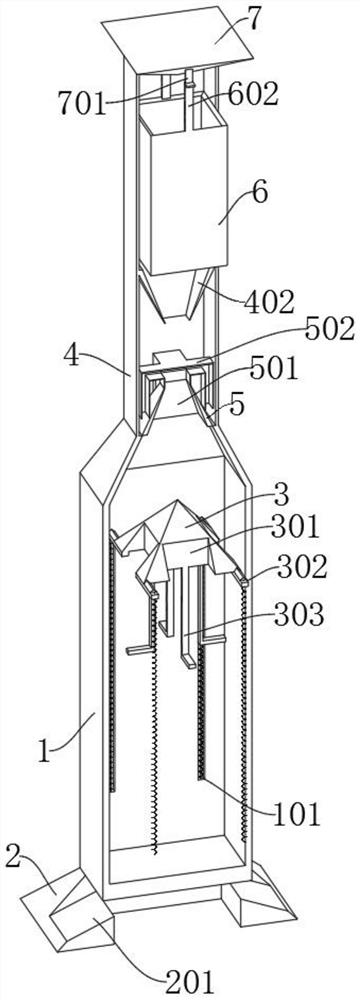

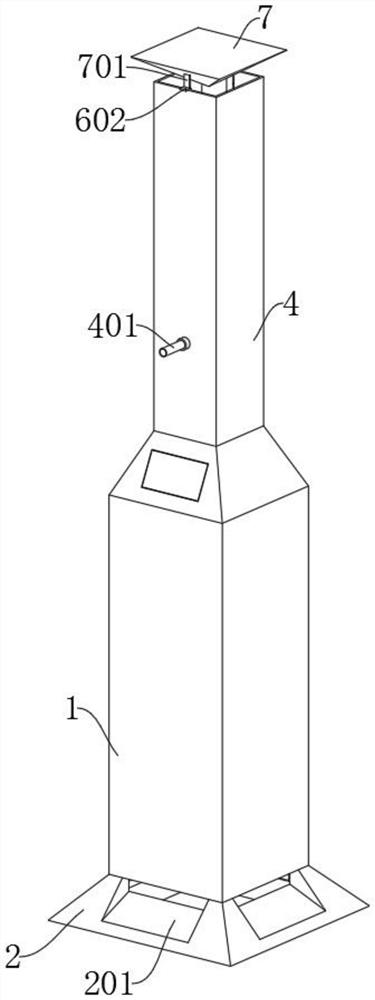

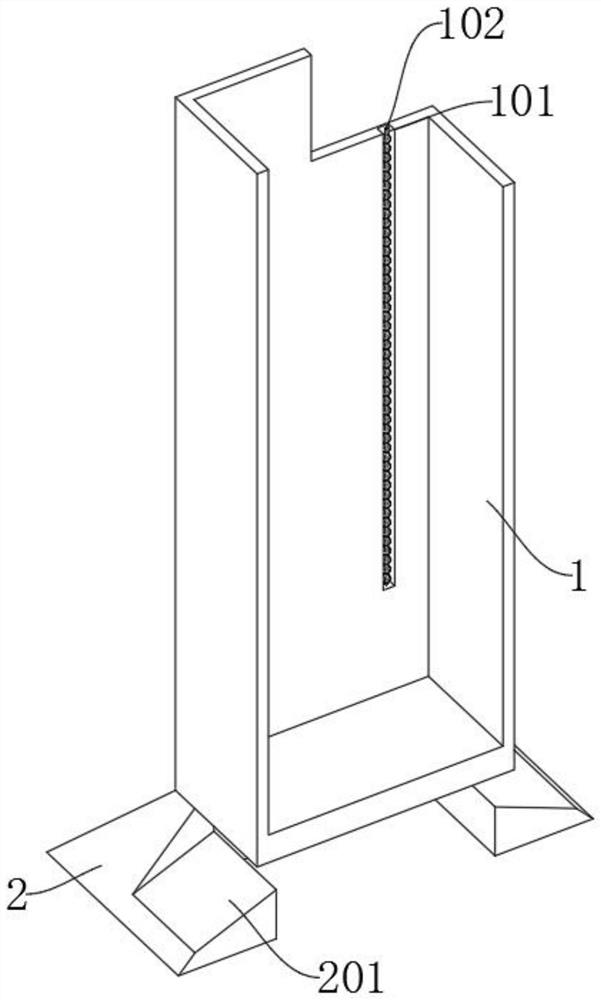

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The present invention provides a garbage pyrolysis and incineration harmless disposal equipment, comprising a main body 1, a bottom part 2, a moving part 3, a top part 4, a compression part 5, an installation part 6 and a stopper 7; the main body 1 is a rectangular structure, And the interior of the main body 1 is provided with an incineration bin; the top of the bottom part 2 is connected to the bottom of the main body 1 through a fixed connection; the top of the top part 4 is a rectangular tubular structure, and the bottom of the top part 4 is installed through a fixed connection At the top of the main body 1; the installation piece 6 is installed inside the top piece 4 by inserting, and the installation piece 6 is at the top of the auxiliary piece 402, and the two sides of the top end of the tie rod 602 of the installation piece 6 are on both sides of the top end of the top piece 4 The stopper 7 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com