Device and method for emptying and monitoring fluid drained from an engine of an aircraft

A monitoring device and engine technology, applied in machine/engine, engine lubrication, engine level, etc., can solve problems such as integration difficulties and achieve accurate monitoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

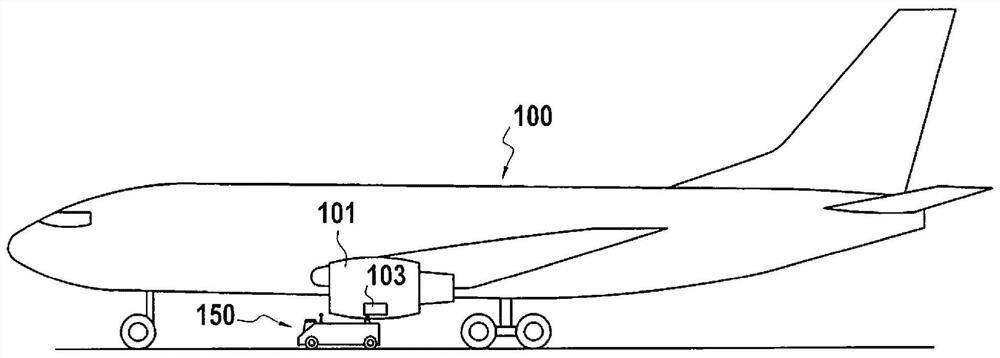

[0025] Such as figure 1 As shown in , the aircraft 100 may include, for example, in a nacelle surrounding the engine 101 , below the engine 101 , an onboard storage 103 for receiving fluid discharged from the engine 101 , in particular in flight. The evacuation and monitoring device 10 according to the first embodiment can be installed onboard on an airport service vehicle 150 to be moved to the aircraft 100 in order to continue to evacuate the fluid discharged from the engine 101 of the aircraft 100 .

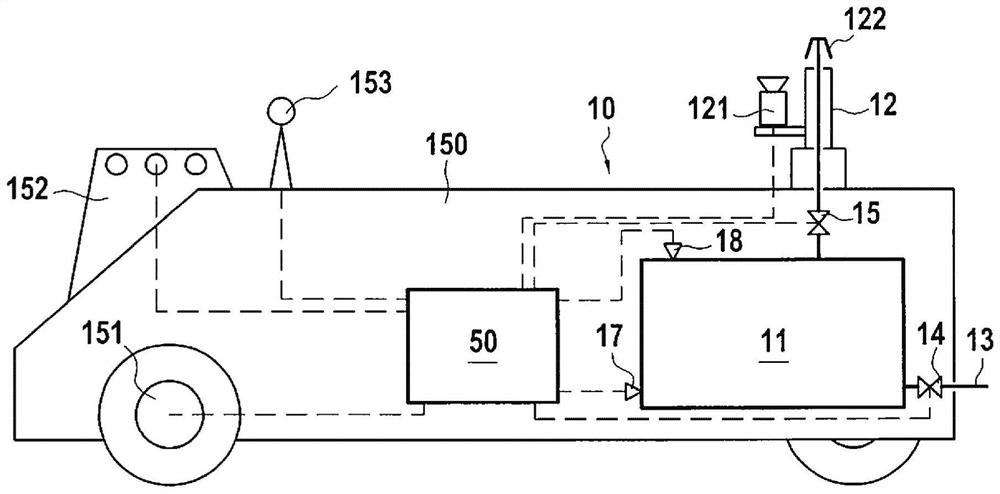

[0026] as in figure 2 As shown in more detail in , the emptying and monitoring device 10 may comprise a first inlet channel 12 with a valve 15, a first reservoir 11 connected to the first inlet channel 12, a valve 14 for exhausting Empty the channel 13 of the first reservoir 11 , the first mass sensor assembly 17 and the first liquid level sensor 18 installed in the first reservoir 11 .

[0027] The first inlet channel 12 can be configured to receive fluid expelled from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com