Laser lift-off masks

A positive photoresist and negative photoresist technology, applied in the manufacture of semiconductor devices, electrical components, semiconductor/solid-state devices, etc., can solve problems such as cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following description, for purposes of explanation, specific details are set forth in order to provide a thorough understanding of certain inventive embodiments. It will be apparent, however, that various embodiments may be practiced without these specific details. The drawings and descriptions are not intended to be limiting.

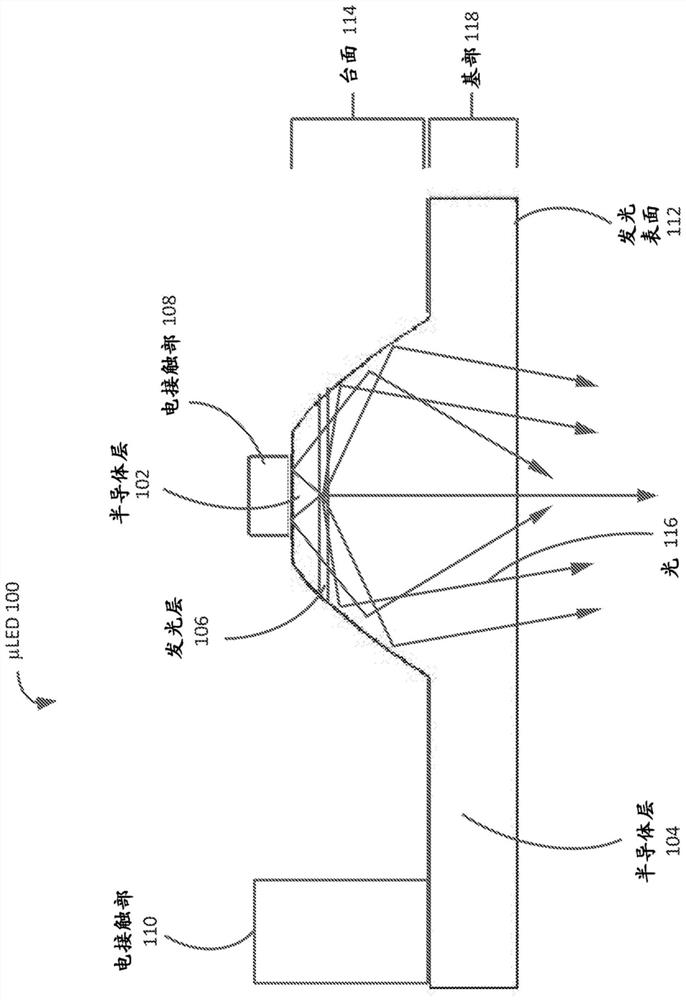

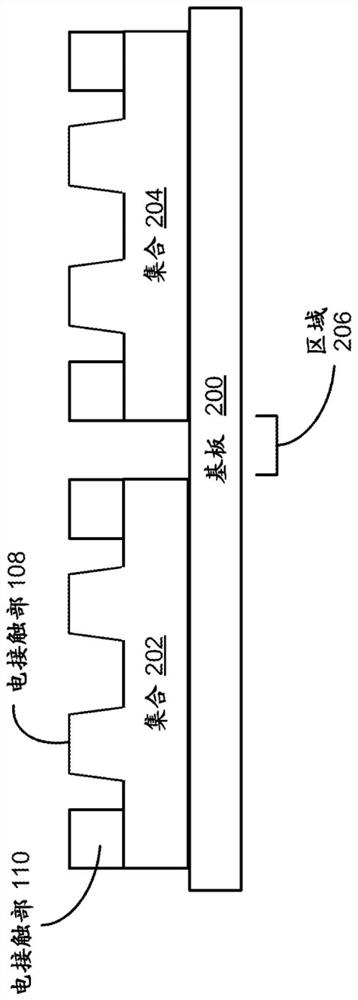

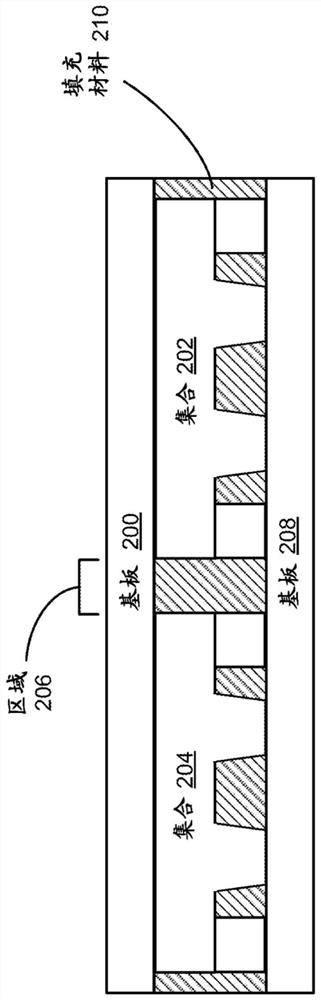

[0020] Techniques related to performing LLO during the fabrication of semiconductor devices, such as LEDs and photodiodes, are disclosed herein. In some embodiments, the fabricated semiconductor devices are tiny inorganic LEDs known as micro-LEDs. As used herein, a micro-LED may refer to an LED having an active light-emitting region with a linear dimension of less than 50 μm, less than 20 μm, or less than 10 μm. For example, linear dimensions can be as small as 2 μm or 4 μm. Their small size enables a display system to have a single pixel comprising three of them: a red micro-LED, a green micro-LED and a blue micro-LED. Their small si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com