Vertical fish killing device

A fish slaughtering and vertical technology, which is applied in the direction of slaughtering, processing fish, fish cleaning / descaling, etc., can solve the problems of high labor intensity, low work efficiency, high cost, etc., and achieve improved efficiency, low labor intensity and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

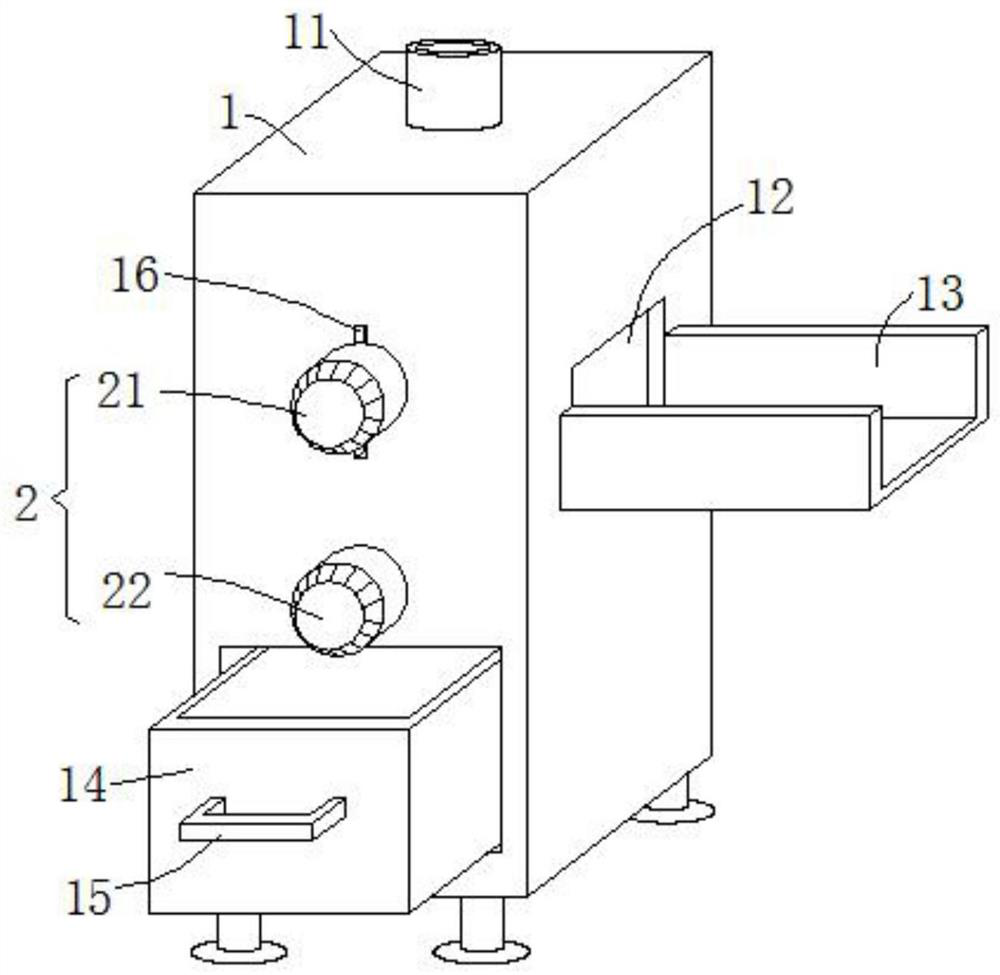

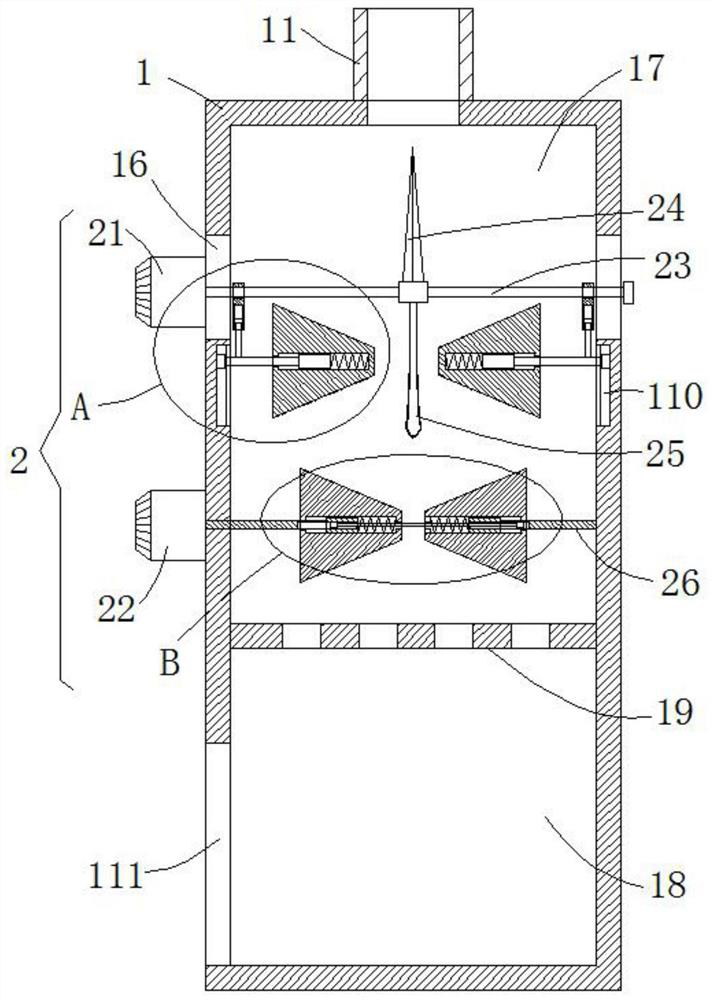

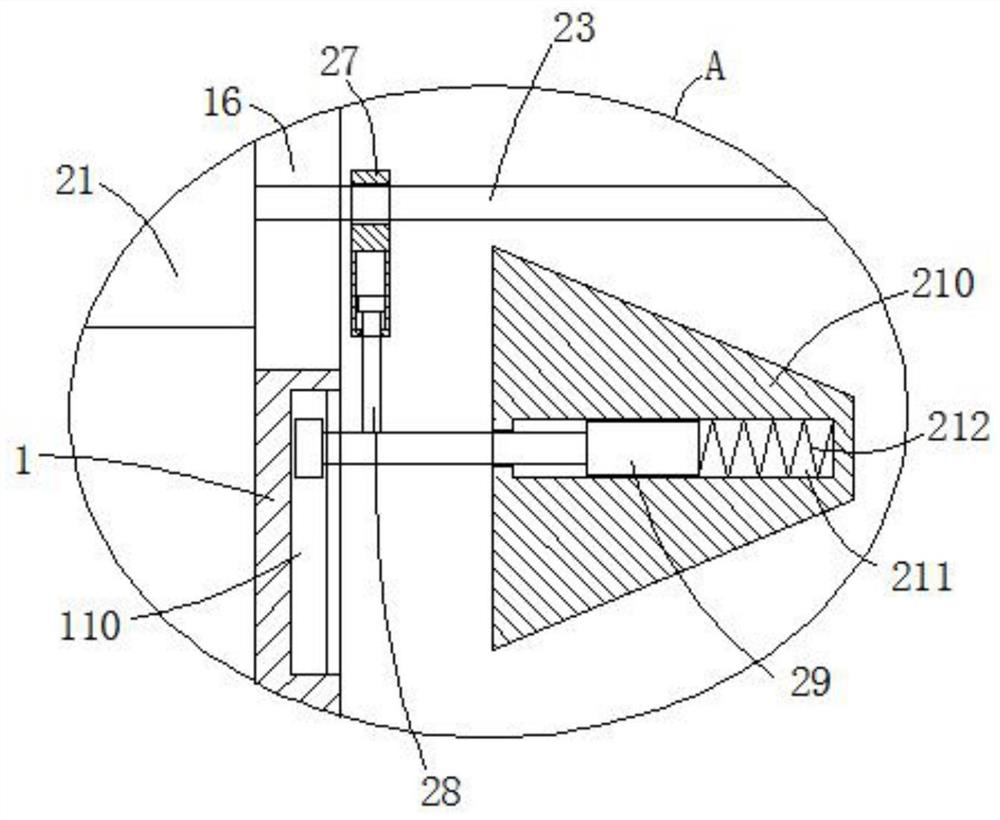

[0024] see Figure 1-4 , this embodiment provides a vertical fish slaughtering device, comprising a cabinet body 1, one side of the cabinet body 1 is provided with a feed port, and the other side is provided with a discharge port 12, and the discharge port 12 is horizontally provided with The receiving plate 13, in order to complete the slaughtering operation, it is necessary to put the fish to be slaughtered into the cabinet 1 through the feeding port, and the slaughtered fish is discharged through the discharging port 12 and falls on the receiving plate 13, which is convenient for centralized collection operation ;

[0025] In order to solve the problem of how to dissect the fish body, the interior of the cabinet 1 is a hollow structure, and is divided into an operation chamber 17 and a recovery chamber 18 by a filter plate 19 having a discharge hole. The operating mechanism 2 of the fish, the operating chamber 17 is used as the place where the operating mechanism 2 slaught...

Embodiment 2

[0035] see figure 2 with Figure 4 , further improvements have been made on the basis of Example 1:

[0036] In order to solve the problem of the linkage of the two frustum-shaped transmission rollers 213, two T-shaped transmission rods 26 are provided with T-shaped transmission grooves 216 at the ends close to each other, and the side view structure of the T-shaped transmission grooves 216 is a rectangular structure. The I-shaped connecting rod 217 that runs through the two transmission holes 214 is slidably inserted between the T-shaped transmission grooves 216, and the I-shaped connecting rod 217 that can be driven is set between the two truncated cone-shaped transmission rollers 213, so that During one of them truncated cone type transmission roller 213, also can drive another truncated cone type transmission roller 213 to rotate in the same direction synchronously, be convenient to play the purpose of transmission to fish body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com