Method for regulating and controlling integrated casting composite interface of nickel-based high-temperature alloy/SiC ceramic composite component

A nickel-based superalloy and ceramic composite technology, applied in the field of casting technology, can solve the problems of uneven distribution and large residual stress in the interface, and achieve the effects of wide applicability, solving interface micro-crack production, and preventing local overheating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of uncast SiC ceramics:

[0034] ①Powder preparation: mix nano-SiC nano-powder with an average particle size of 30nm and SiC micro-powder with an average particle size of 500 microns in a volume ratio of 1:1, and divide them into two parts, A and B. Part A and The volume ratio of part B is 2:8. Mix part A and SiC powder with an average particle size of 1.0mm at a volume ratio of 1:5 to obtain mixed powder C. Mix part B with Ti powder and TiAl powder according to Mix uniformly at a volume ratio of 5:4:1 to obtain a mixed powder D; the average particle size of the Ti powder is 100 microns, and the average particle size of the TiAl powder is 125 microns.

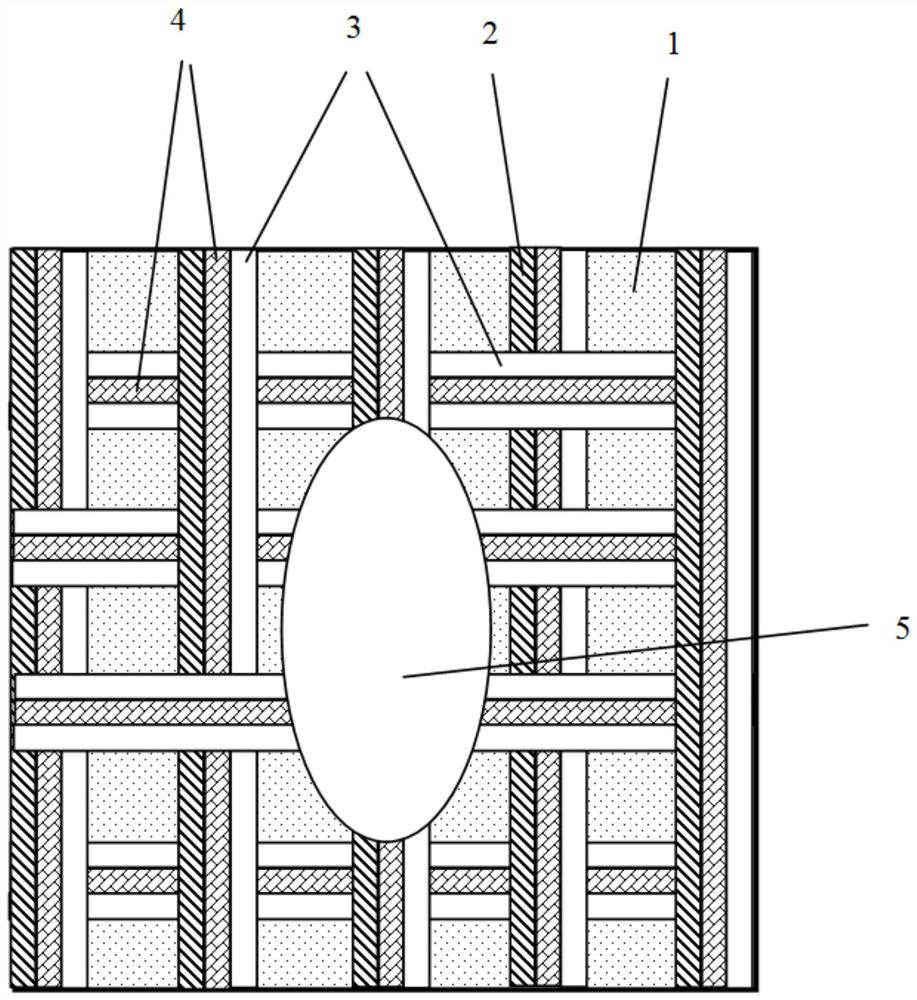

[0035] ②Preparation of cold-pressed ceramic blocks: evenly spread the mixed powder D along the surface of the pattern in the mold, then evenly spread the mixed powder C on the mixed powder D, and then evenly spread the SiC powder with an average particle size of 1.2mm Lay it on the mixed powder C, then p...

Embodiment 2

[0046] The differences between this example and Example 1 are: the nickel-based superalloy is K418 alloy, the pouring temperature is 1700°C, the diameter of pure copper wire is 500 microns, the average grain size is 20 microns, and the fine NiTi alloy wire wound outside is 200 microns , the average grain size is 20 microns; the diameter of a single NiTi alloy wire without winding is 500 microns, and the average grain size is 20 microns; The filament diameter was 300 microns, with an average grain size of 20 microns. The warp distance is 5mm and the weft distance is 7mm. Other operating procedures are the same as in Example 1.

[0047] The composite metal mesh described in this embodiment adjusts the interface to cast K418 alloy / SiC ceramic composite components, and the interface is integrated with a temperature sensor to fully ensure the integrity of the SiC ceramic side shape, and the K418 alloy / SiC ceramic interface has high bonding strength and bending strength. It can re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com