Automatic detection device for tool wear

An automatic detection device and tool wear technology, which is applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of high work intensity, low efficiency, and inability to detect tool wear in real time, so as to reduce work Strength, accurate detection of tool wear, and the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

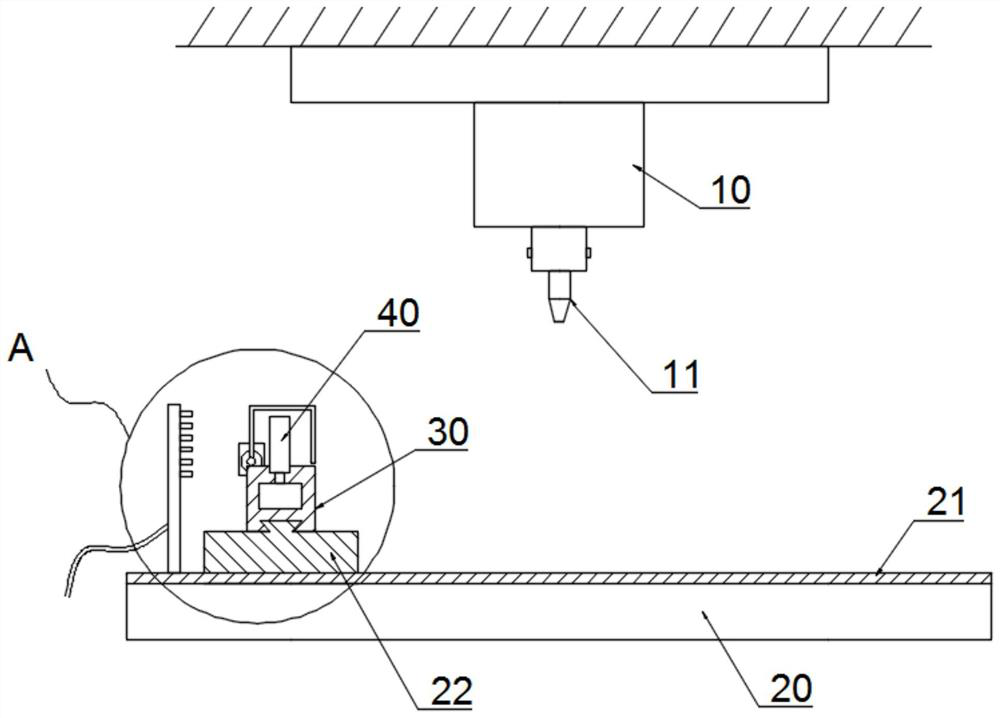

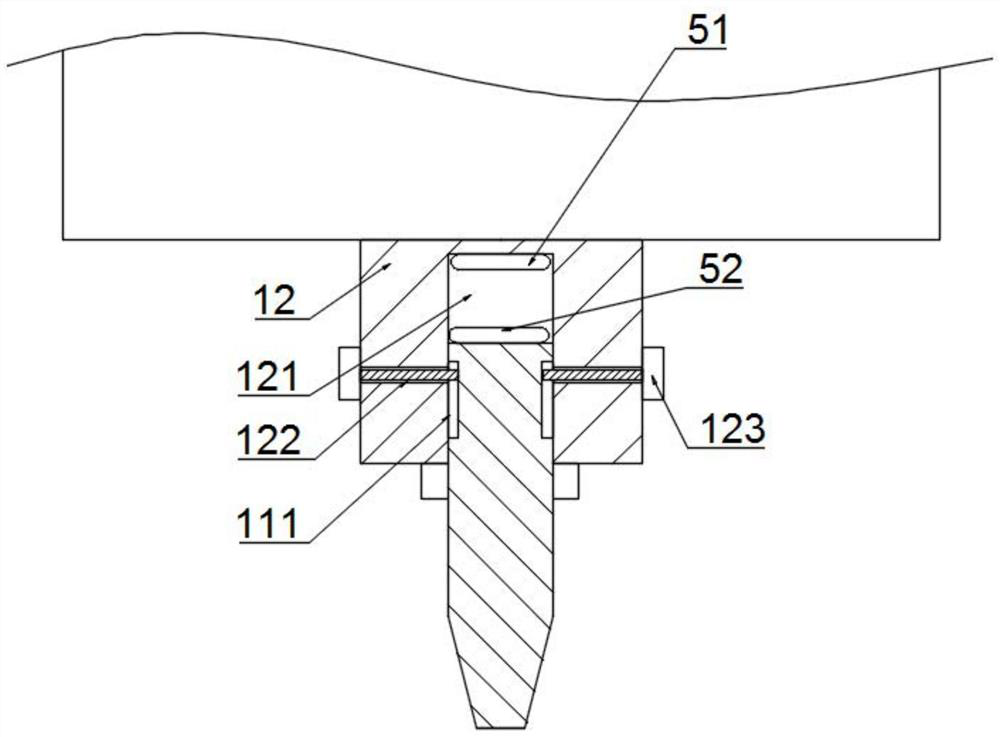

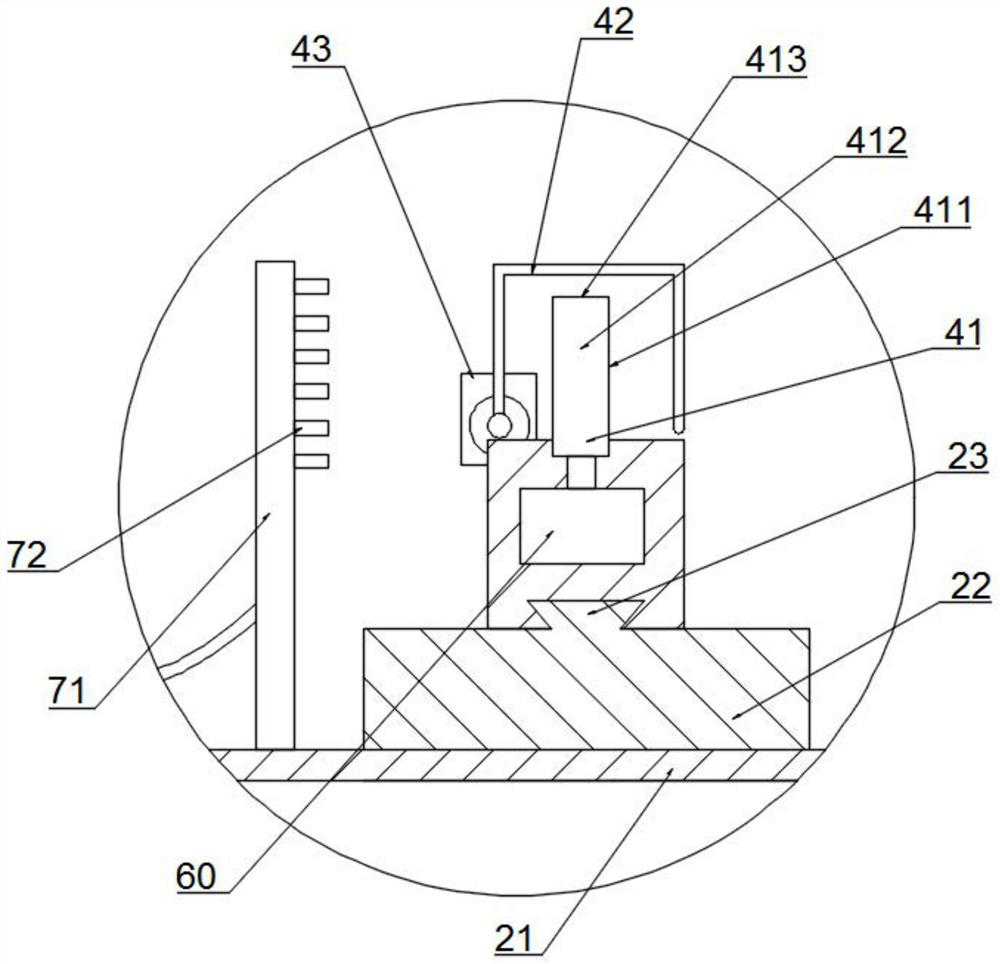

[0036] see Figure 1 to Figure 3 , a tool wear automatic detection device of the present embodiment, comprising a headstock 10, a working platform 20, a detection platform 30, a detection assembly 40, a compensation assembly and an air blowing assembly;

[0037] Specifically, the output end of the spindle box 10 is connected with a tool 11, the spindle box 10 can drive the tool 11 to move in X, Y, and Z directions, and the spindle box 10 can also drive the tool 11 to rotate;

[0038] Specifically, the working platform 20 is arranged below the headstock 10;

[0039] Specifically, the detection platform 30 is arranged on the work platform 20, and the detection platform 30 can move along the X direction and the Y direction on the work platform 20; to realize the movement of the detection platform 30 on the work platform 20, conventional technical means can be selected Realize, do not go into details again, preferably, X track 21 is set on described working platform 20, Y platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com