Swing type spike spinning extractor

A swing-type, extractor technology, applied to roads, tracks, laying tracks, etc., can solve the problems of danger, inconvenient construction, high cost, etc., and achieve the effects of saving construction period, extremely low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

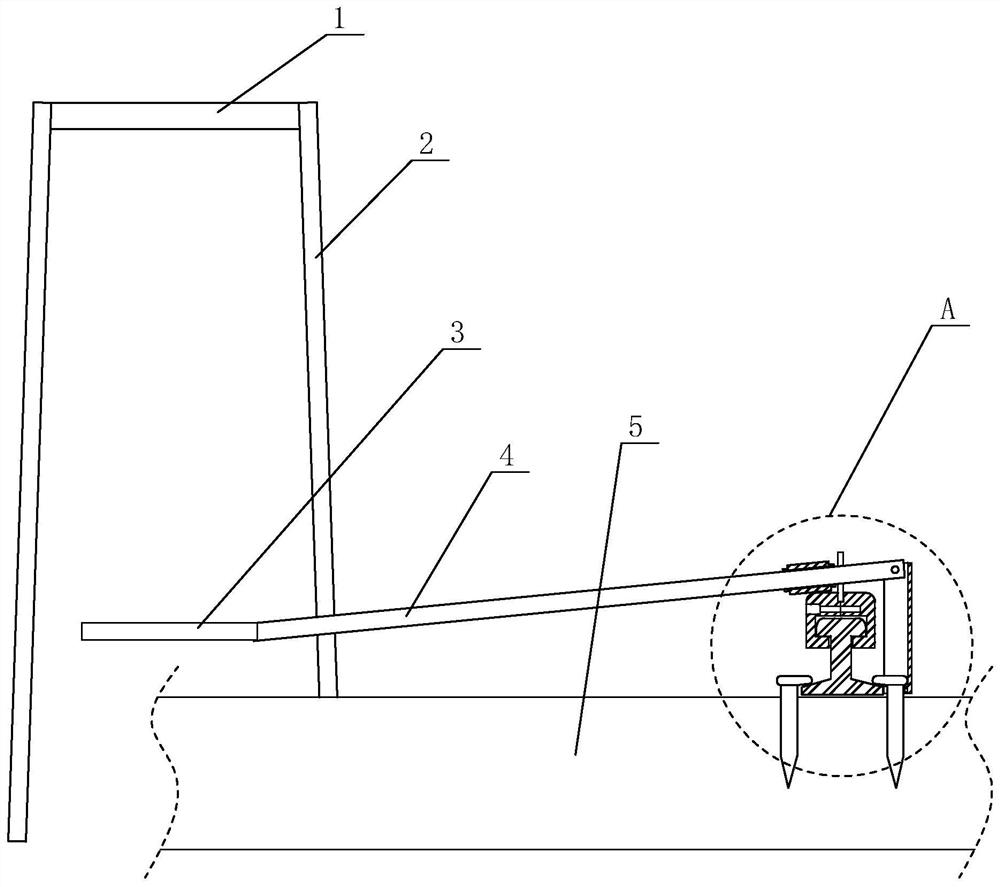

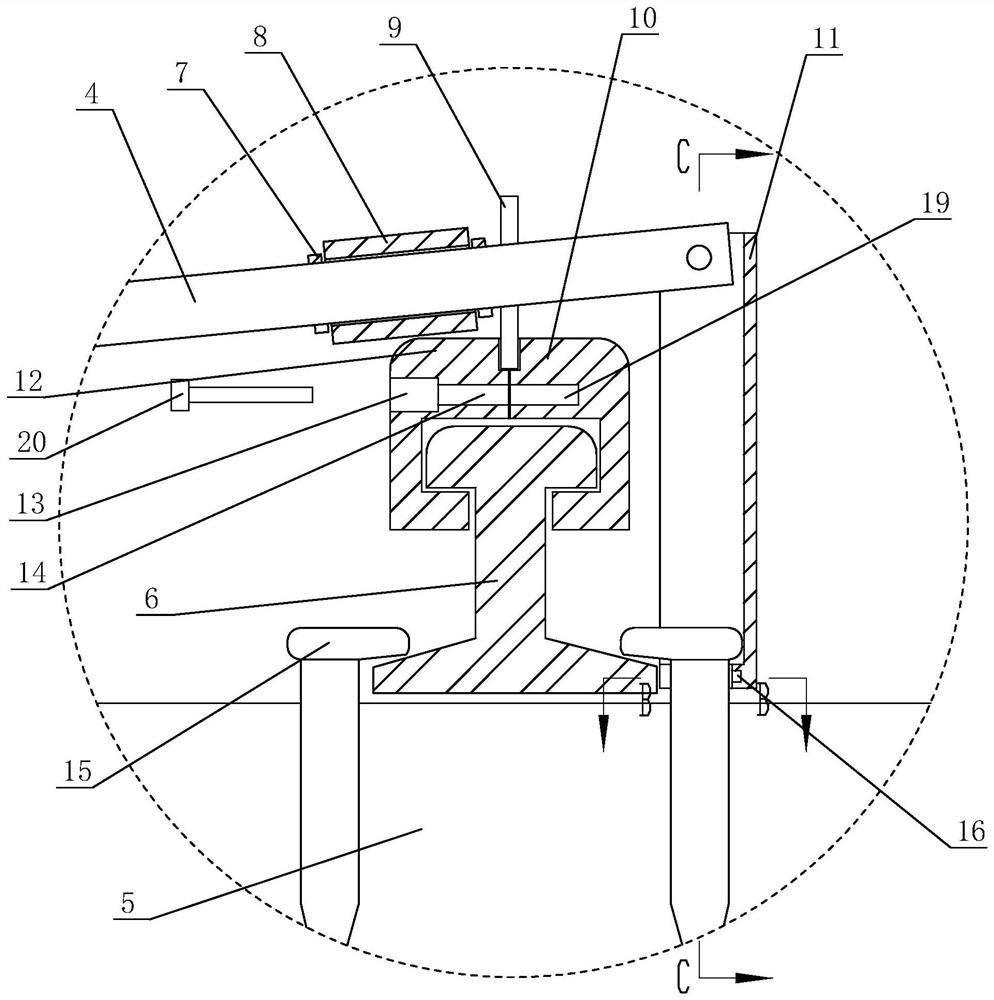

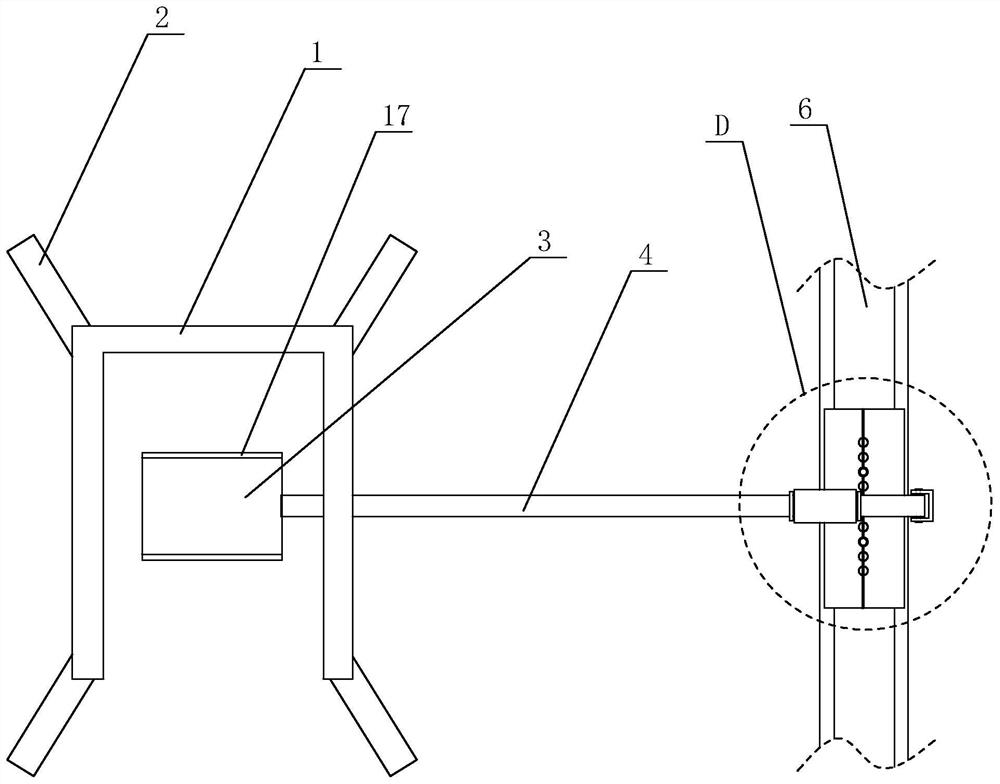

[0022] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0023] Such as Figure 1-Figure 6 As shown, the swing-type road stud spin puller of the present invention includes a pull-out slot 11, the slot body of which is narrow at the bottom and wide at the top, and is in the shape of a stepped slot, and the slot body of the slot 11 is The upper part matches the nail cap of Spike 15, the lower part of the groove body matches the nail body of Spike 15, the width of the lower part of the groove body is consistent with the width of the nail body, and the thickness of the lower part of the groove body is less than the nail cap to the sleeper 5 The upper end of the groove body of the pull-out slot 11 is hinged to the lever 4 through the pin shaft. After the pull-out slot 11 is matched with the spike 15, the axis of the pin shaft is perpendicular to and intersects with the center line of the spike 15, and the tail end of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com