Fabricated damping floor tile mounting structure

An installation structure and prefabricated technology, applied in the direction of earthquake resistance, building components, building structure, etc., can solve the problems of difficult installation of metal sound insulation blocks and sound absorption and permeable cotton, difficult sound absorption and shock absorption, inconvenient positioning and assembly, etc. , The effect of firm fixation and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

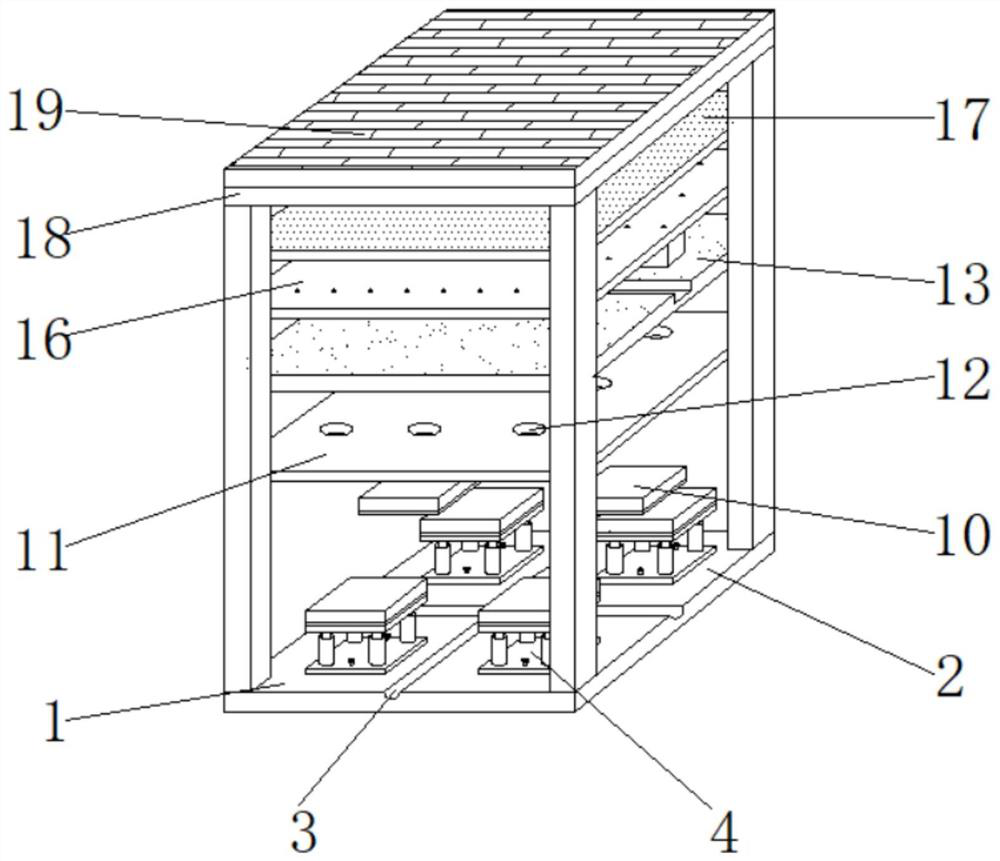

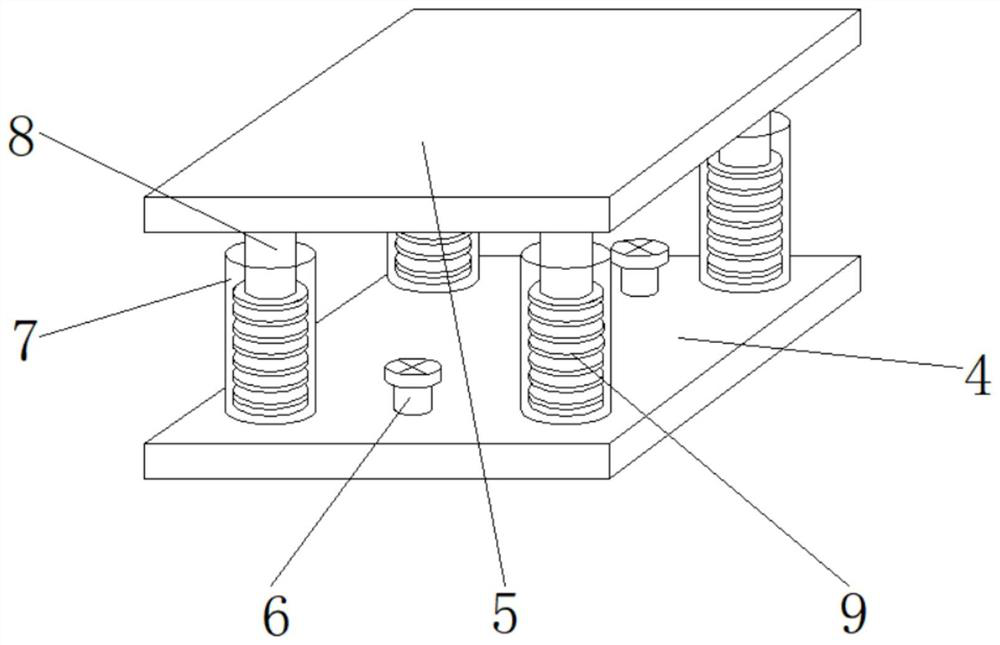

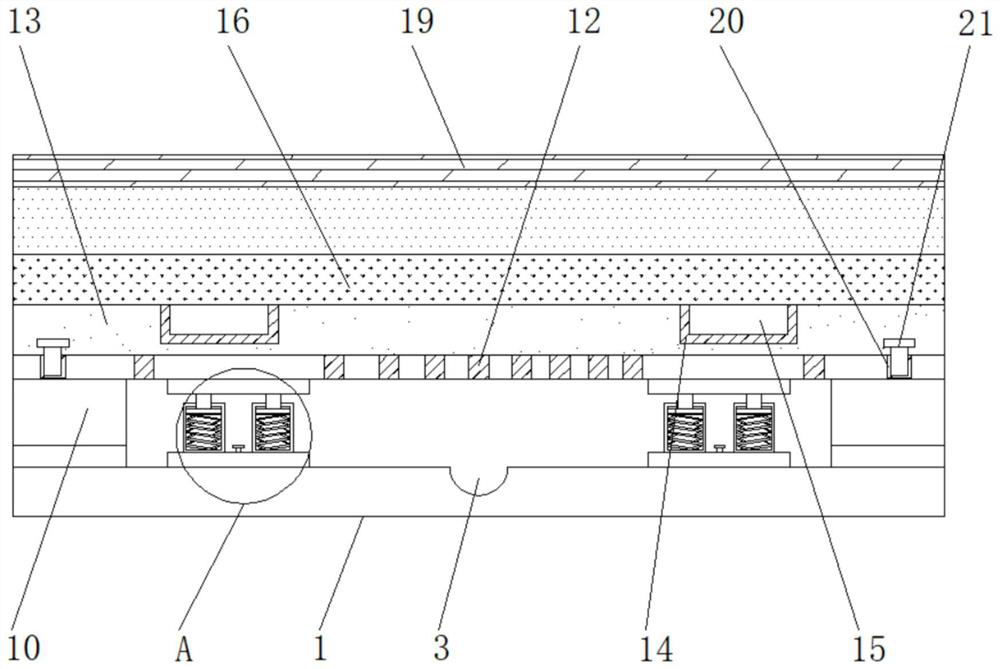

[0025] see Figure 1-4 , the present invention provides a technical solution: an assembled shock-absorbing floor tile installation structure, including a brick body 1, a ground surface layer 2, a drainage groove 3, a shock-absorbing assembly 4, a shock-absorbing brick 5, connecting screws 6, and a limit piece 7 , lifting column 8, spring 9, sound insulation board 10, water storage board 11, water permeable hole 12, sound-absorbing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap