A kind of plastic valve and its processing and manufacturing method

A valve and plastic technology, applied in the field of plastic valves and their processing and manufacturing, can solve problems such as easy leakage, and achieve the effects of improving high pressure resistance, improving structural strength and wear resistance, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

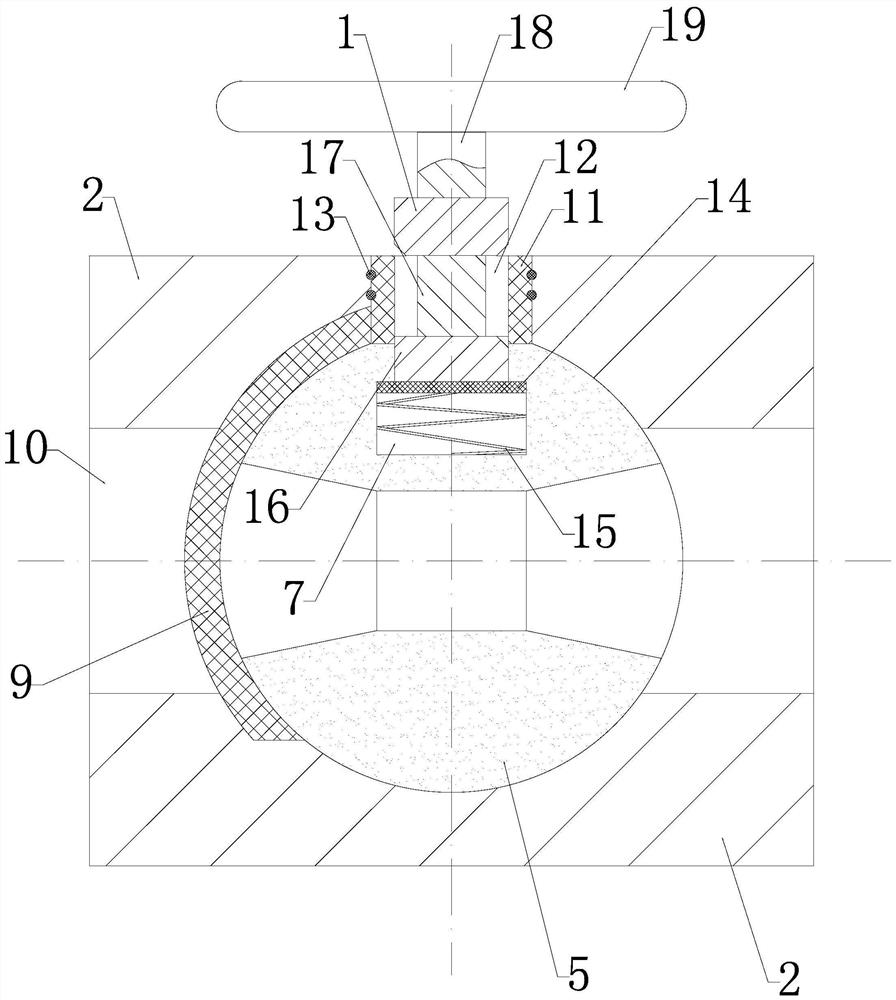

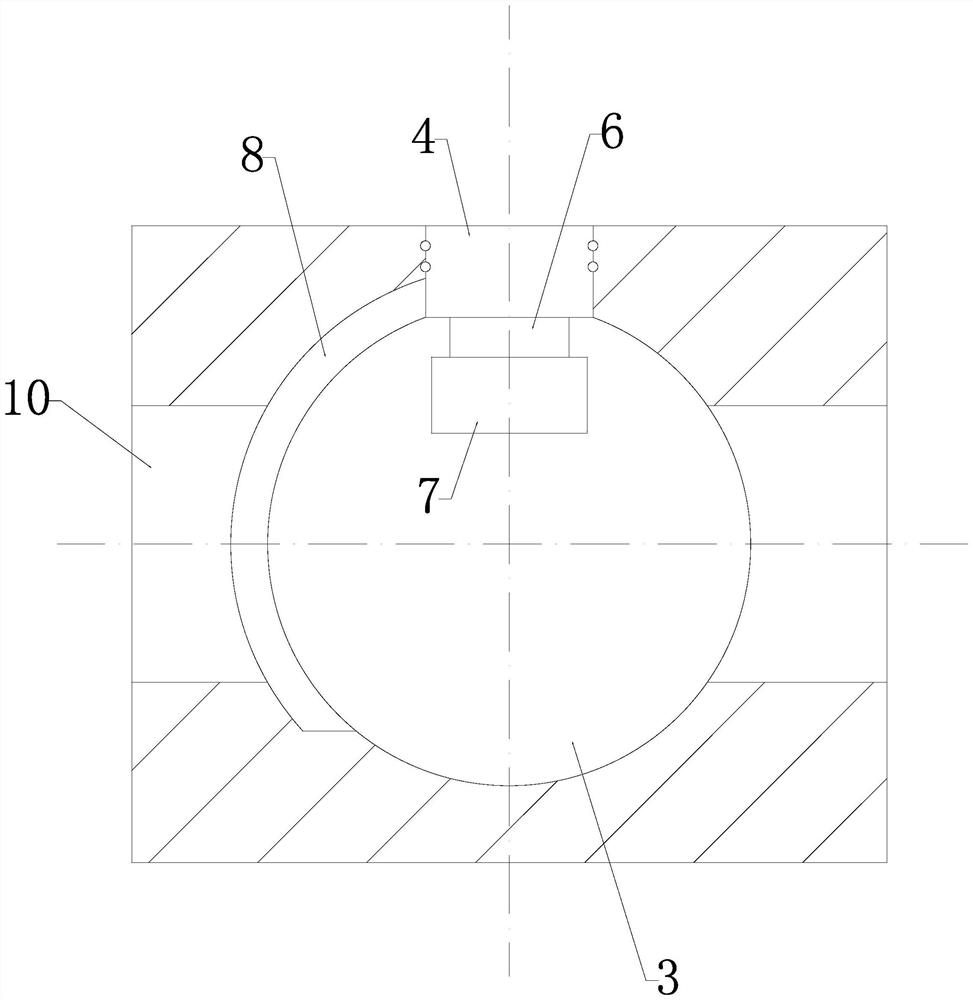

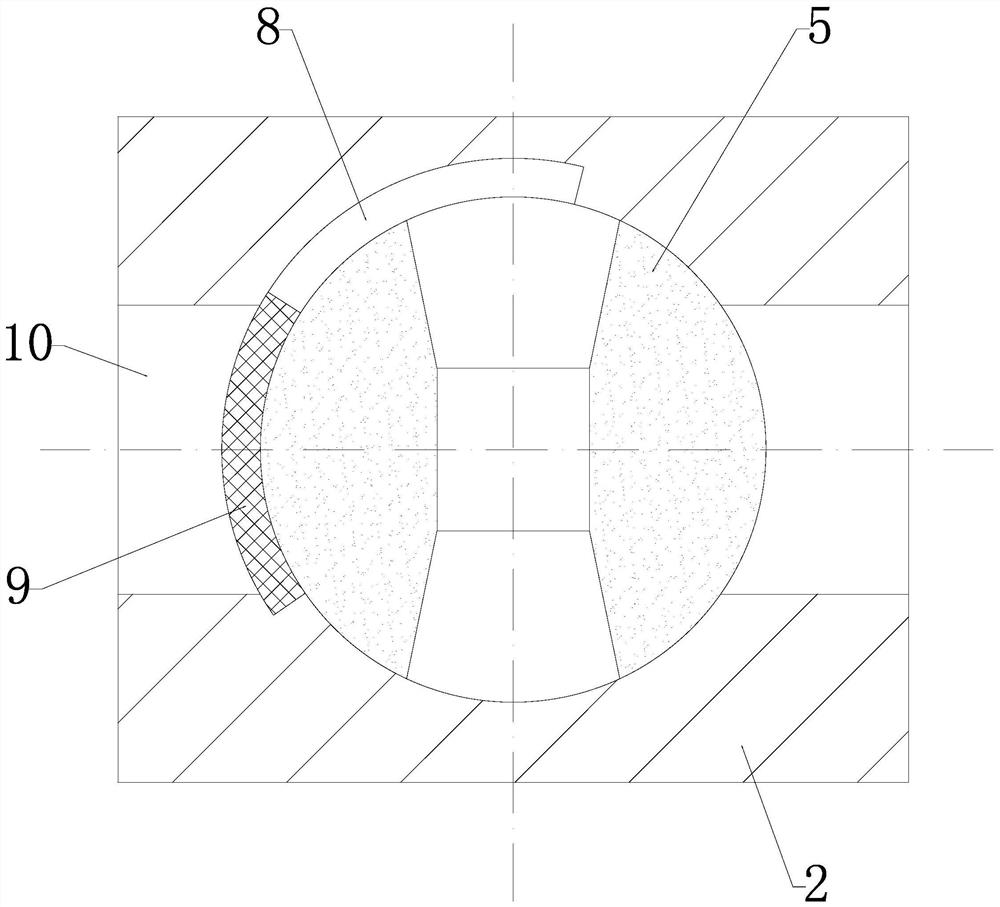

[0032] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0033] Such as Figure 1-5 As shown in , a plastic valve includes a valve body 2, a main valve cavity 3 is arranged in the middle of the valve body 2, and both sides of the main valve cavity 3 are connected with the delivery pipelines to be installed on both sides Through cooperation, the valve body 2 on the top of the main valve chamber 3 is provided with a plug-in round chamber 4 communicating with it, and a main ball valve assembly and a secondary valve assembly are installed in the main valve chamber 3, so that The main ball valve assembly is used to realize the cut-off seal under normal pressure. The main bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com