Grain drying equipment with uniform heating function for agriculture

A technology of uniform heating and grain drying, applied in grain drying, lighting and heating equipment, drying and other directions, can solve the problems of inability to guarantee the uniformity of feeding, low drying efficiency, and inability to dry grains, so as to ensure uniformity , Reduce labor intensity and ensure uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

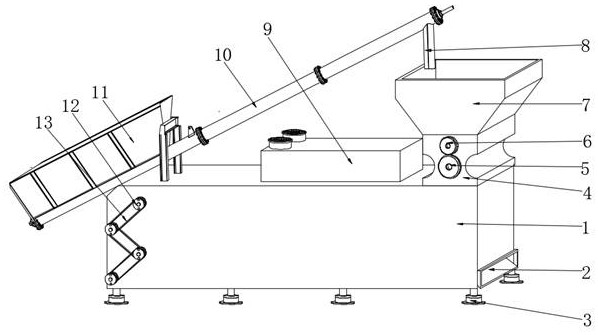

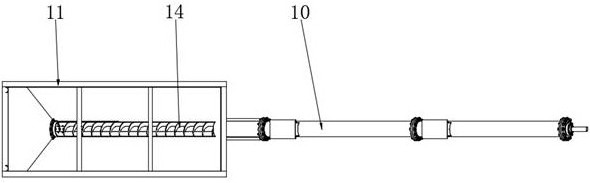

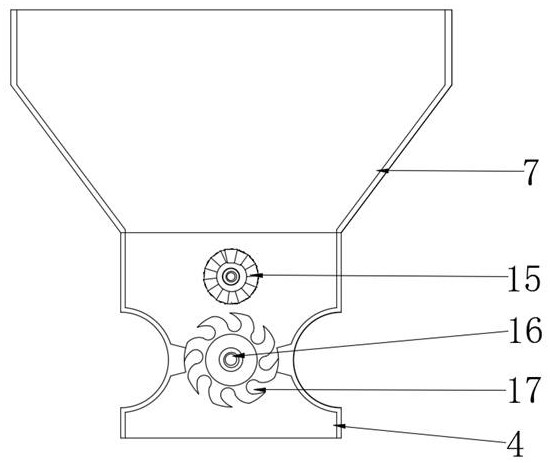

[0025] see Figure 1~6 , in an embodiment of the present invention, a uniformly heated grain drying equipment used in agriculture includes a drying box 1, a feeding mechanism is arranged at one end above the drying box 1, and the feeding mechanism includes a drying box fixed on The feed hopper 11 at one end above the dry box body 1, the bottom end of the feed hopper 11 is connected with a feeding pipe 10, the inner side of the feeding pipe 10 is connected with a screw conveying paddle 14, and the top of the feeding pipe 10 is connected with a discharge The pipe 8 and the feeding pipe 10 are inclined 30° upward relative to the horizontal direction of the drying box 1, and the inner diameter of the feeding pipe 10 is adapted to the outer diameter of the screw conveying paddle 14. When the grain is dried, the staff Put the grain into the feed hopper 11, and then work with the feeding motor supporting the screw conveyor paddle 14 to drive the screw conveyor paddle 14 to rotate. Un...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap