Cleaning device for fruit harvesting and packaging

A cleaning device and packaging technology, which is applied in the agricultural field, can solve the problems of simple structure and incomplete cleaning of fruits, and achieve the effect of improving cleaning effect and cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

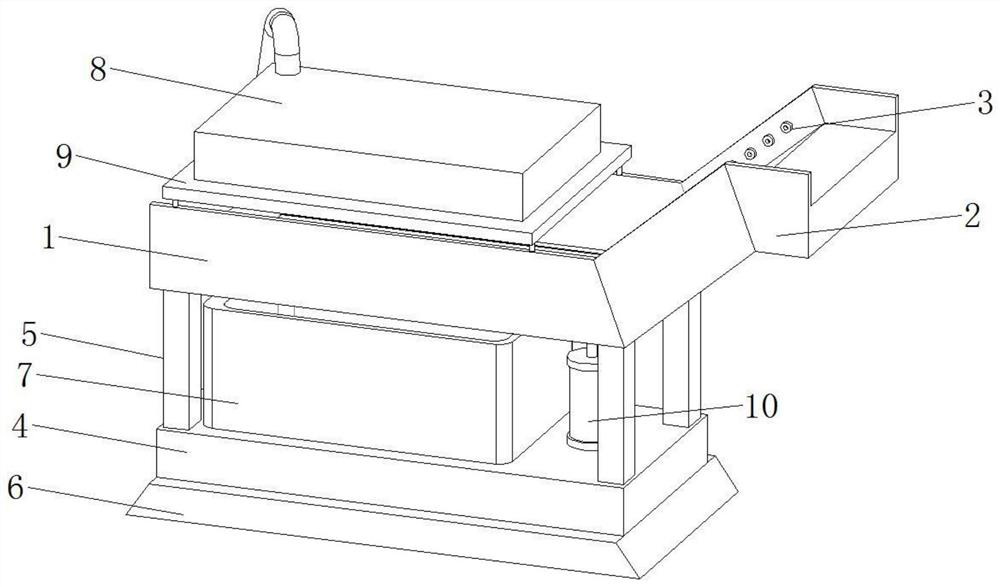

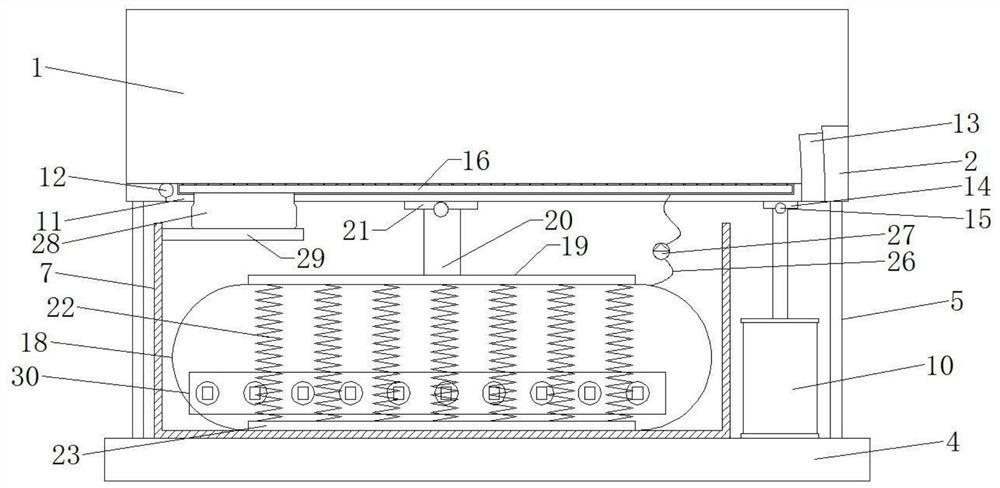

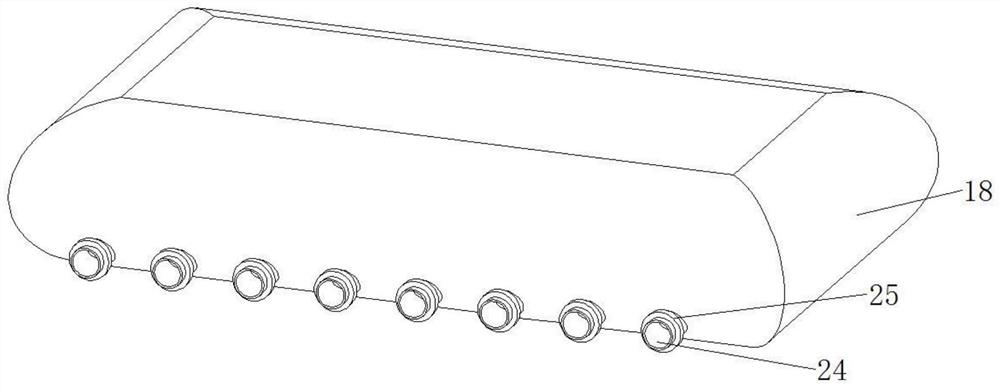

[0020] Please refer to the figure, in an embodiment of the present invention, a cleaning device for fruit harvesting and packaging includes a cleaning tank 1, a feeding tank 2, a nozzle 3, a base 4, a support column 5 and a shock absorbing seat 6; the cleaning tank 1 Horizontally arranged, the right end of the cleaning tank 1 is fixedly connected to the lowering tank 2, and the bottom of the lowering tank 2 is higher than the bottom of the cleaning tank 1, so that the fruits falling on the lowering tank 2 roll down into the cleaning tank 1, On the inner wall of the hopper 2, there are several nozzles 3 facing inwardly. The nozzles 3 are connected with the water supply equipment, and the clean water is passed into the hopper 2 to contact the incoming fruit; A vertical support column 5 is fixed, and the lower end of the support column 5 is fixedly connected on the horizontal base 4, and the cleaning tank 1 is supported by the support column 5, and a shock absorber 6 is fixedly in...

Embodiment 2

[0025] On the basis of Embodiment 1, the bottom of the cavity 16 is connected with a downward drainage sealing cover 28, and the lower end of the drainage sealing cover 28 is fixed with a sealing ring, and is arranged in the corresponding water tank 7 directly below the drainage sealing cover 28. There is a horizontal drainage sealing baffle 29, and the drainage sealing baffle 29 is fixed on the inner wall of the water tank 7. The area of the drainage sealing baffle 29 is greater than the area of the lower port of the drainage sealing cover 28, and the drainage sealing cover 28 moves up and down following the swing plate 11. Make the lower end of the drainage sealing cover 28 contact and separate from the upper surface of the drainage sealing baffle 29 to realize the discharge of internal water. Separated, the water in the cavity 16 flows downward from the drain sealing cover 28, and the water cleaned from above is discharged downward into the water tank 7, so as to facilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com