Sludge treatment device for sewage sedimentation tank

A sludge treatment and sedimentation tank technology, which is applied to the feeding/discharging devices of sedimentation tanks, sedimentation separation, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

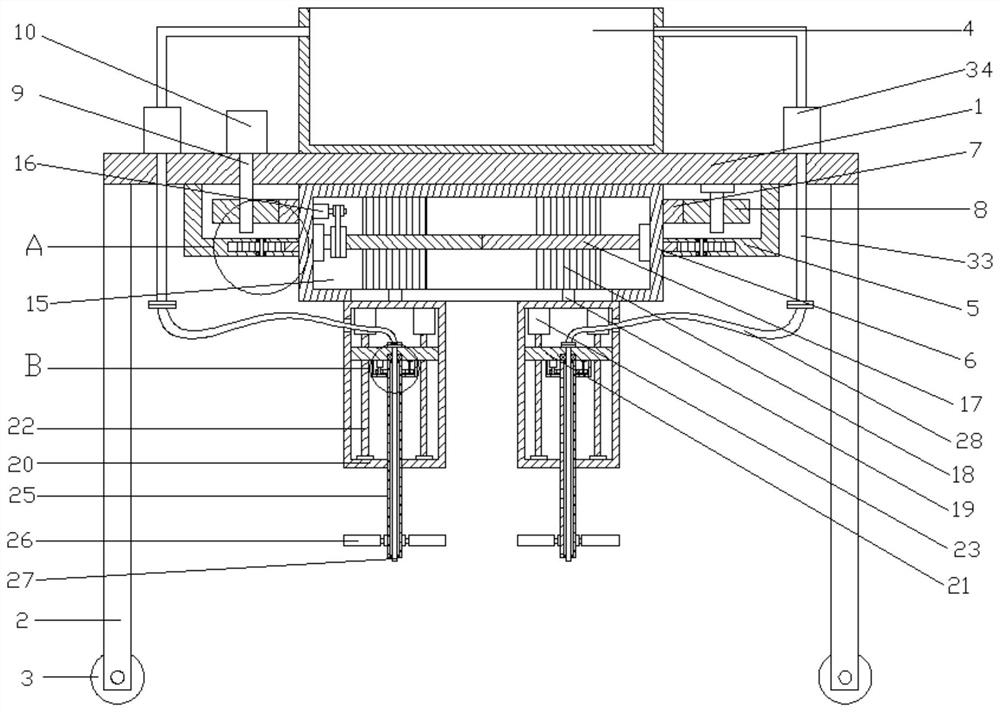

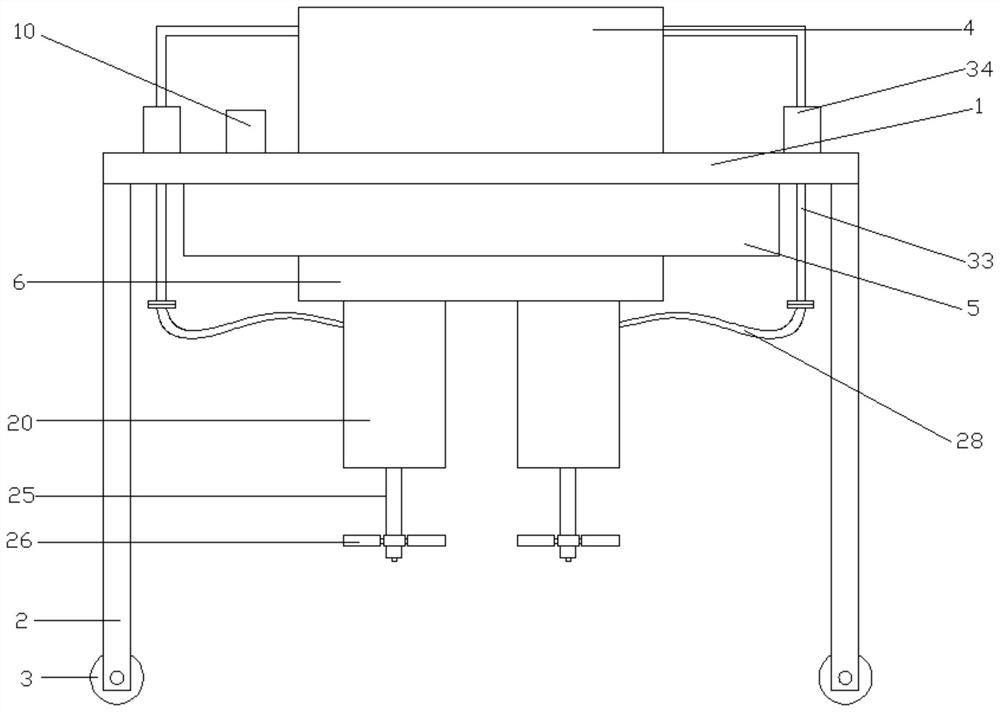

[0027] refer to Figure 1~5 , in an embodiment of the present invention, a sludge treatment device for a sewage settling tank includes a top plate 1, a support column 2 is fixedly installed at the four corners of the lower side of the top plate 1, and a roller 3 is provided at the lower end of the support column 2, which can facilitate the movement of the equipment. A silt storage tank 4 is installed in the middle of the upper side of the top plate 1 for storing the extracted silt. A first connection cover 5 is fixedly installed on the lower side of the top plate 1, and a swivel seat 6 is arranged in the middle of the first connection cover 5, which is located in the second A first external gear 7 is fixedly installed on the outer side of the rotary seat 6 inside the connecting cover 5, and the first external gear 7 is provided with a first connecting gear 8 on the left and right sides, and the first rotating shaft 9 is installed inside the first connecting gear 8, and the left...

Embodiment 2

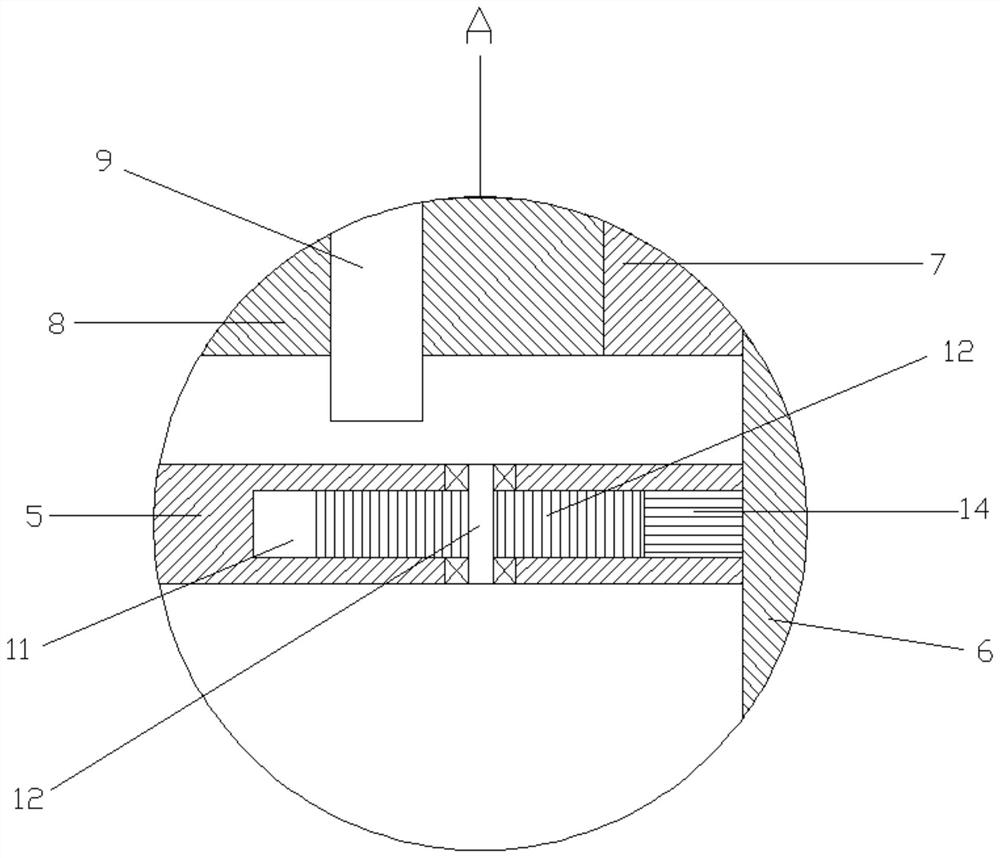

[0033] The difference from Embodiment 1 is that the connection pool between the rotating seat 6 and the first connection cover 5 is provided with a connection groove 11, and the left and right ends of the connection groove 11 are connected with the second connection gear 13 through the second rotating shaft 12, and the second A second external gear 14 is threadedly connected between the connecting gears 13, and the second external gear 14 is installed on the outside of the rotating base 6. During the rotation of the rotating base 6, the second external gear 24 drives the second connecting gear 13 to rotate. , so that the second connecting gear 13 can limit the rotation base 6, so as to facilitate the stable rotation of the rotation base 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com