Air sterilization filter in glutamic acid fermentation

A technology of air sterilization and glutamic acid, applied in the direction of dispersed particle filtration, gas treatment, chemical instruments and methods, etc., to achieve the effect of avoiding air pressure instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

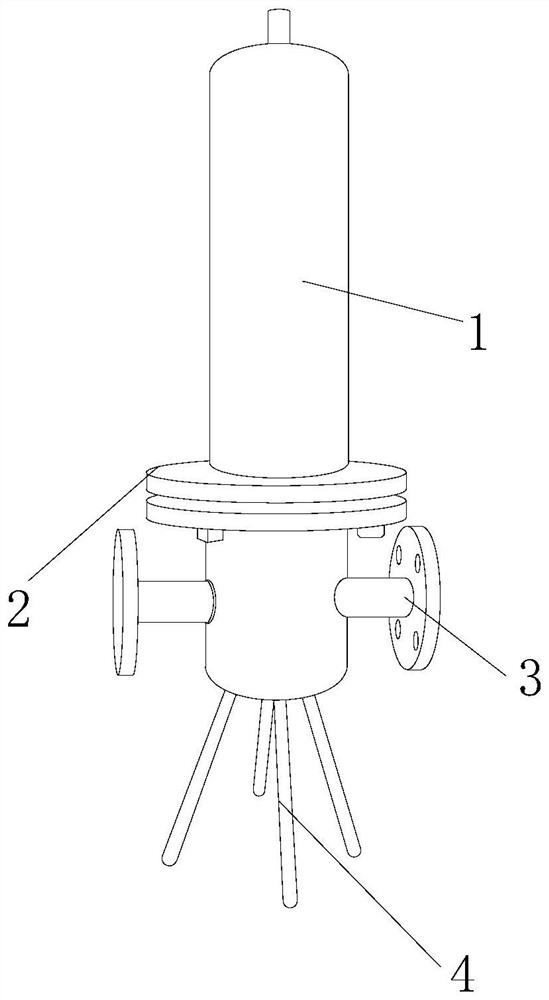

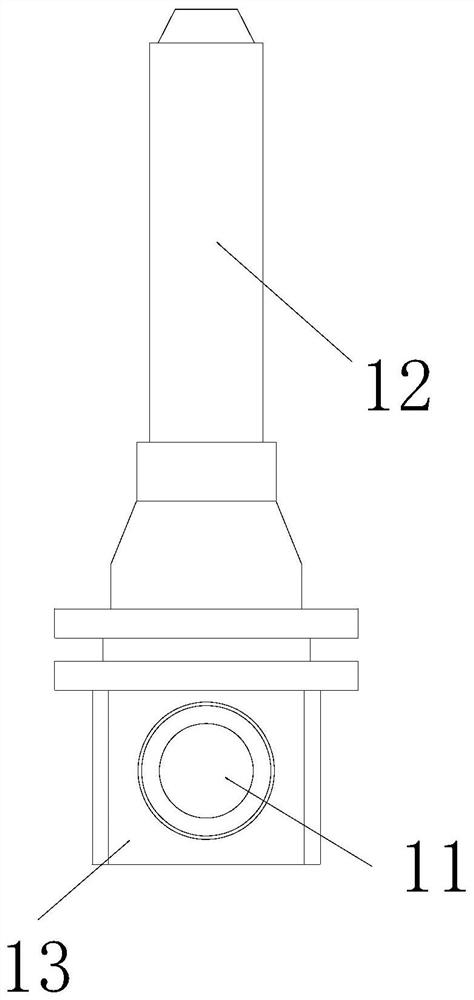

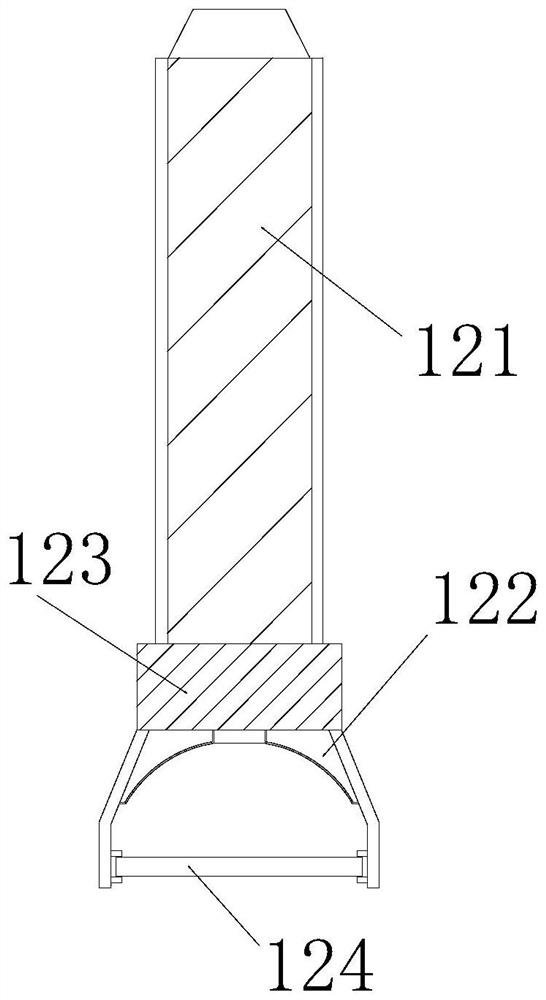

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides an air sterilization filter for glutamic acid fermentation, the structure of which includes a protective shell 1, a locking disc 2, an embedded connecting pipe 3, and a bracket 4. The protective shell 1 is inlaid on the positive side of the locking disc 2. Above, the left and right ends of the lower end of the locking disc 2 are inlaid and engaged with the embedded connection pipe 3, and the embedded connection pipe 3 is embedded and installed directly above the bracket 4, and the bracket 4 is inlaid on the front of the protective shell 1. Below: the protective shell 1 includes a series hole 11, a filter mechanism 12, and an embedded tube 13, the series hole 11 is arranged on the inner end surface of the embedded tube 13, and the filter mechanism 12 is embedded in the front of the embedded tube 13 Above, the outer end surface of the embedding pipe 13 is connected to the embedding pipe 3 by...

Embodiment 2

[0033] as attached Image 6 to attach Figure 7As shown: the one-way port 231 includes an adsorption magnetic block 311, a rubber strip 312, a tapered mouth 313, and an embedded block 314. The outer surface of the lower end of 312 is embedded and connected with the embedded block 314. The tapered mouth 313 is embedded in the inner end surface of the rubber strip 312. The embedded block 314 is embedded and installed on the left and right sides of the lower end of the magnetic block 311. The rubber strip 312 is made of rubber material. When the one-way opening 231 absorbs the suction force and sags inward, the left and right sides of the tapered opening 313 will be squeezed together to form a closed shape.

[0034] Wherein, the tapered mouth 313 includes a second embedding block 131, a rubber block 132, a rubber filling block 133, and an embedding plate 134, and the second embedding block 131 is cross-embedded on the inner end surface of the embedding plate 134, so The inner e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap