Cleaning device for hardware tool machining

A technology for hardware tools and cleaning devices, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that hardware tools cannot be cleaned uniformly, and achieves the effect of being easy to take.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

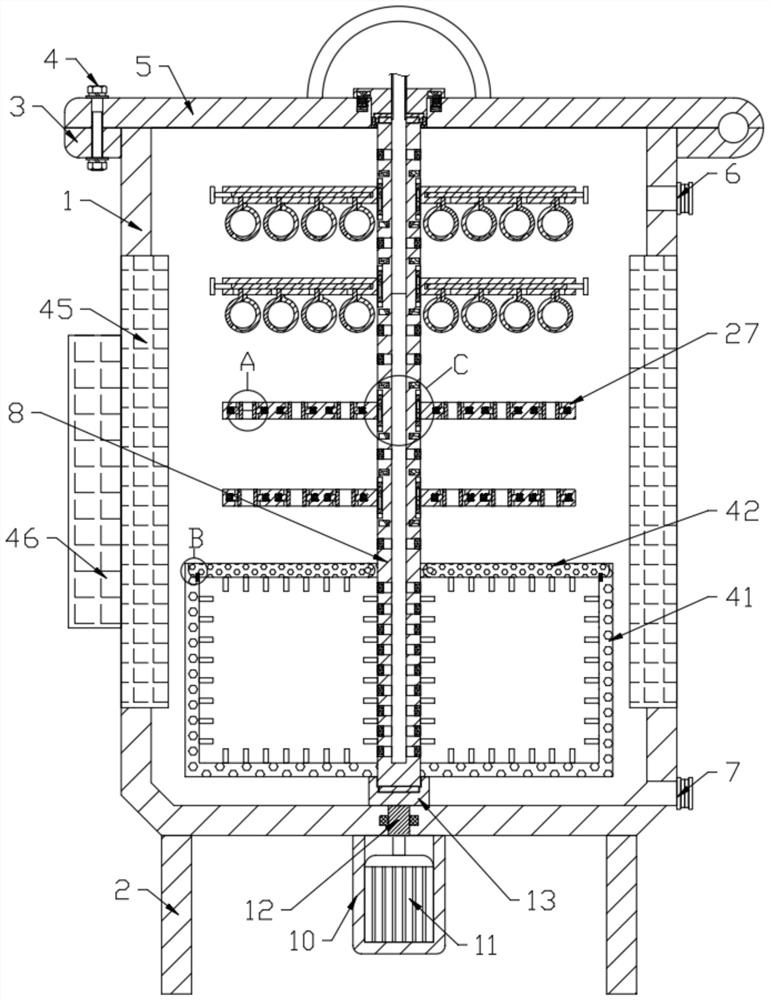

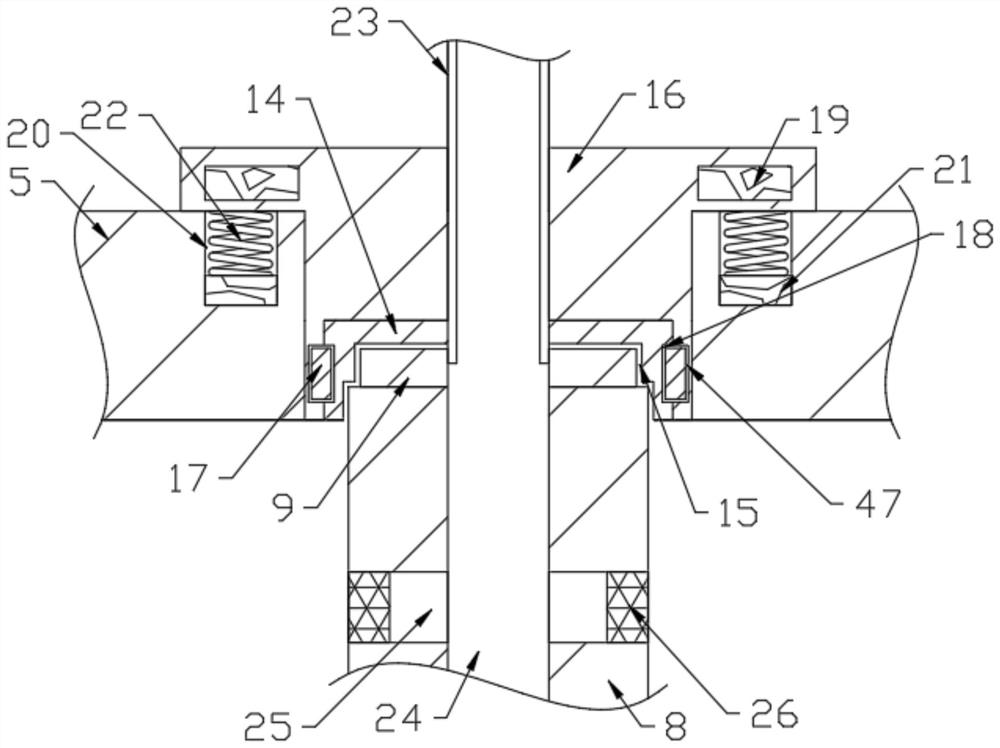

[0027] see Figure 1-7 , a cleaning device for hardware tool processing, comprising a box body 1 and a number of support columns 2 arranged at the lower end of the box body 1, the upper end of the box body 1 is rotatably connected with a cover plate 5, and the upper and lower sides of the side end of the box body 1 are respectively provided with inlets The liquid interface 6 and the liquid outlet interface 7 are connected with the rotating column 8 in the box body 1, and the upper and lower ends of the rotating column 8 are fixedly connected with the cross block 9, and the lower side of the box body 1 is provided with a driving assembly for driving the rotating column 8. The side cross block 9 is engaged with the clamping block 14. The clamping block 14 is provided with a draw-in groove 15 for the clamping of the cross block 9. The clamping block 14 is connected with the moving block 16 in rotation. As for the moving assembly, the box body 1 is provided with a drying assembly,...

Embodiment 2

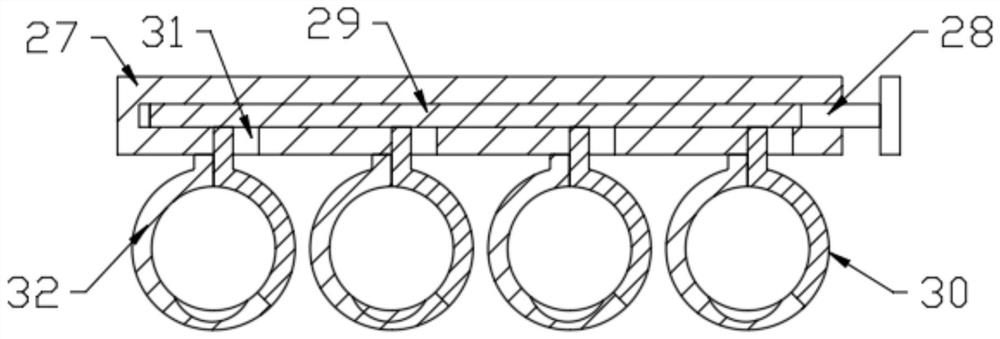

[0045] This embodiment makes further improvements on the basis of Embodiment 1, and the improvements are as follows: a number of ring cylinders 38 fixedly connected to the cross column 27 are slidably connected on the rotating column 8, and the rotating column 8 is provided with ring cylinders 38 for sliding The side groove 39 of the side groove 39, the ring cylinder 38 and the rotating column 8 on both sides of the ring cylinder 38 are respectively provided with the second permanent magnet 40 which is magnetically repulsive. Under the action of the permanent magnet 40, the ring cylinder 38 can be shaken up and down in the side groove 39 on the rotating column 8, and then the horizontal column 27 fixedly connected with the ring cylinder 38 can move up and down while rotating, thereby realizing the clamping on the horizontal column. The tool on the 27 moves up and down while rotating in the cleaning liquid, thereby making the cleaning effect of the tool better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com