A kind of drilling pipe processing equipment

A technology for processing equipment and drilling pipes, applied in cleaning methods and tools, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as indiscriminate cleaning methods, impact on finished product quality, residue, etc., to improve cleaning effect and maintain accuracy degree, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

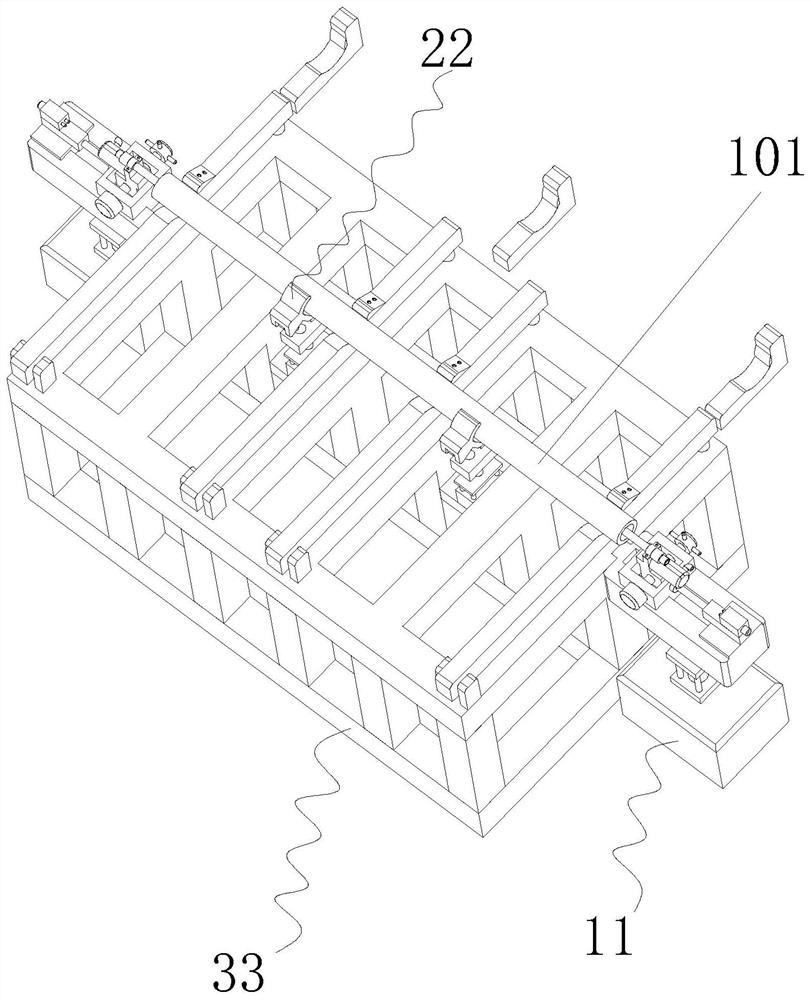

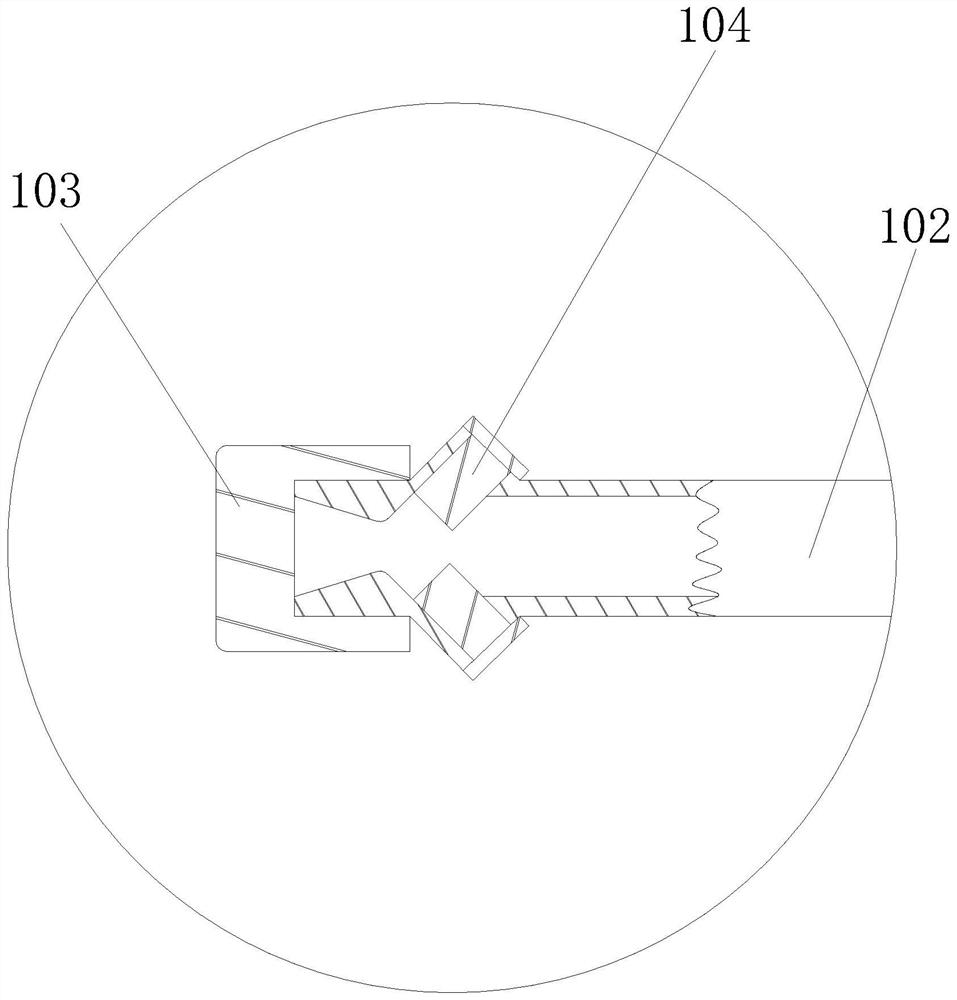

[0033] As a specific embodiment of the present invention, the fixing mechanism 22 includes a fixed insert 201, a first rotating seat 202, a telescopic rod 203 and an installation box 204; two fixed inserts 201 are installed on the outside of the processed pipe 101, and the fixed insert The bottom end of 201 is rotatably connected with the first swivel base 202, the bottom end of the first swivel base 202 is welded with telescopic rod 203, and the bottom end of telescopic rod 203 is equipped with installation box 204; It is used to fix the processing pipe 101, the first rotating seat 202 and the fixed insert 201 rotate mutually, the telescopic rod 203 drives the fixed insert 201 to move, pushes the fixed insert 201 to rotate, and the installation box 204 is used to install the telescopic Rod 203 .

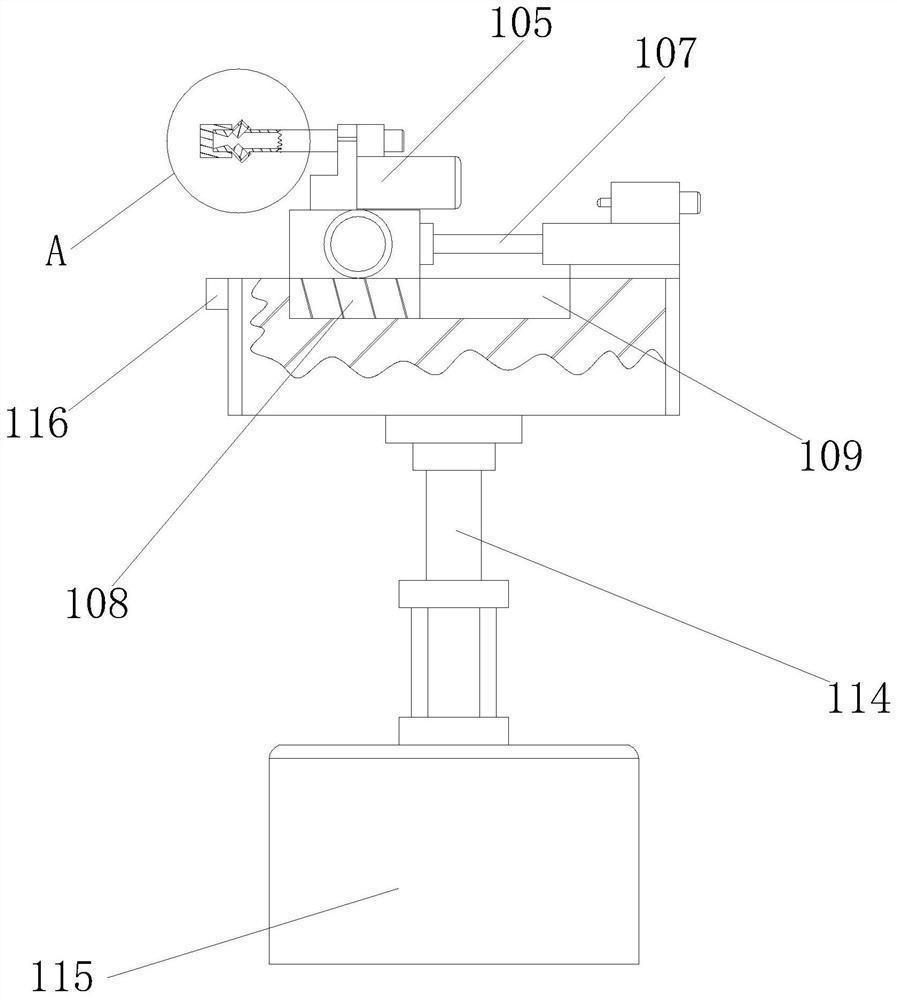

[0034] As a specific embodiment of the present invention, the top of the installation box 204 is provided with a connecting column 205, and the top of the connecting column 205 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com