An automatic feeding device for shell sheets for intelligent manufacturing

A technology of automatic feeding and intelligent manufacturing, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing, etc., and can solve problems such as difficulty in ensuring the quality of the shell and uneven application of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

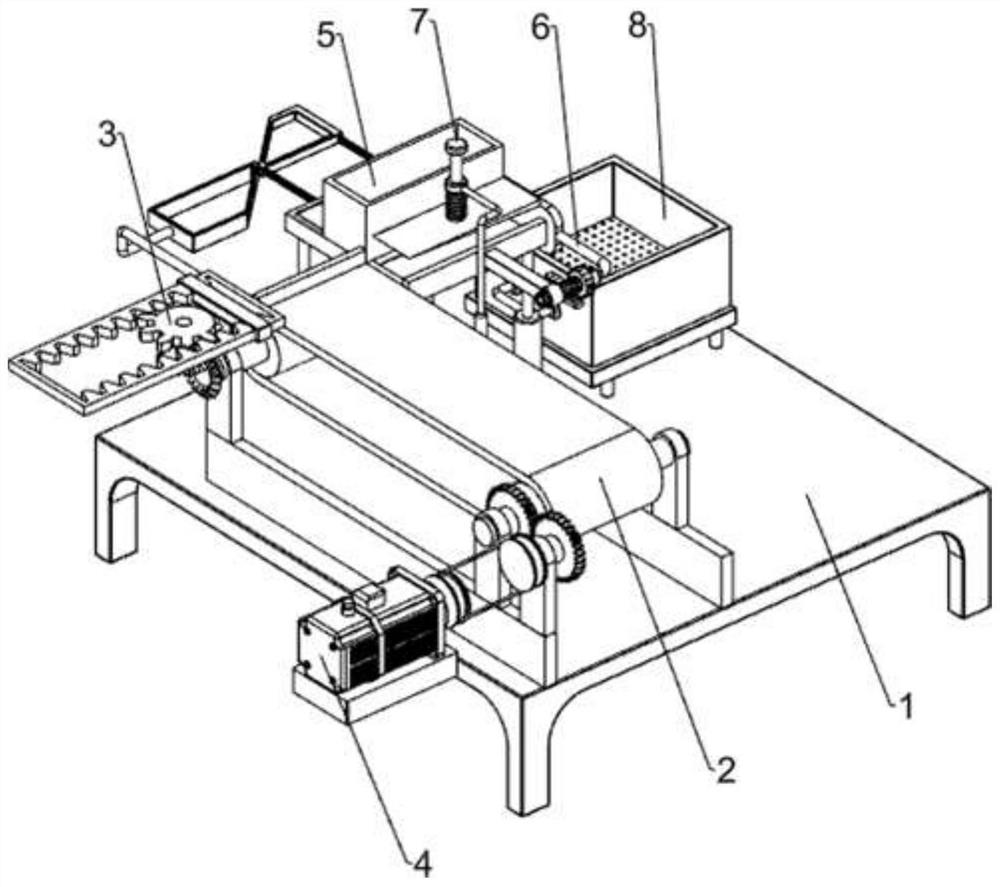

[0058] An automatic feeding device for shell sheets for intelligent manufacturing, such as Figure 1 to Figure 4 As shown, it includes a mounting seat 1, a feeding mechanism 2, a striking mechanism 3 and a driving mechanism 4. 2. The right front side is connected with a driving mechanism 4.

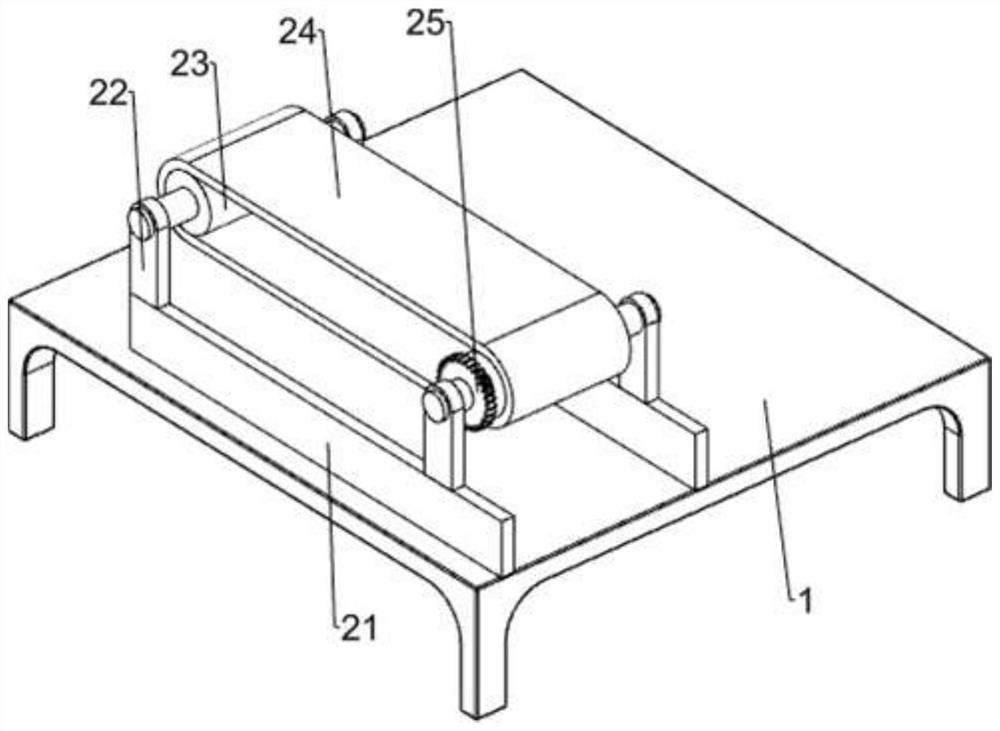

[0059] The feeding mechanism 2 includes a horizontal plate 21, a first mounting plate 22, a roller 23, a conveyor belt 24, and a first full-toothed gear 25. The first mounting plate 22 is arranged, and the first mounting plate 22 on the vertical same side is connected with rollers 23 in rotation, and the conveyor belt 24 is connected between the rollers 23, and the front side of the transmission shaft of the right roller 23 is connected with the first full body. toothed gear 25 .

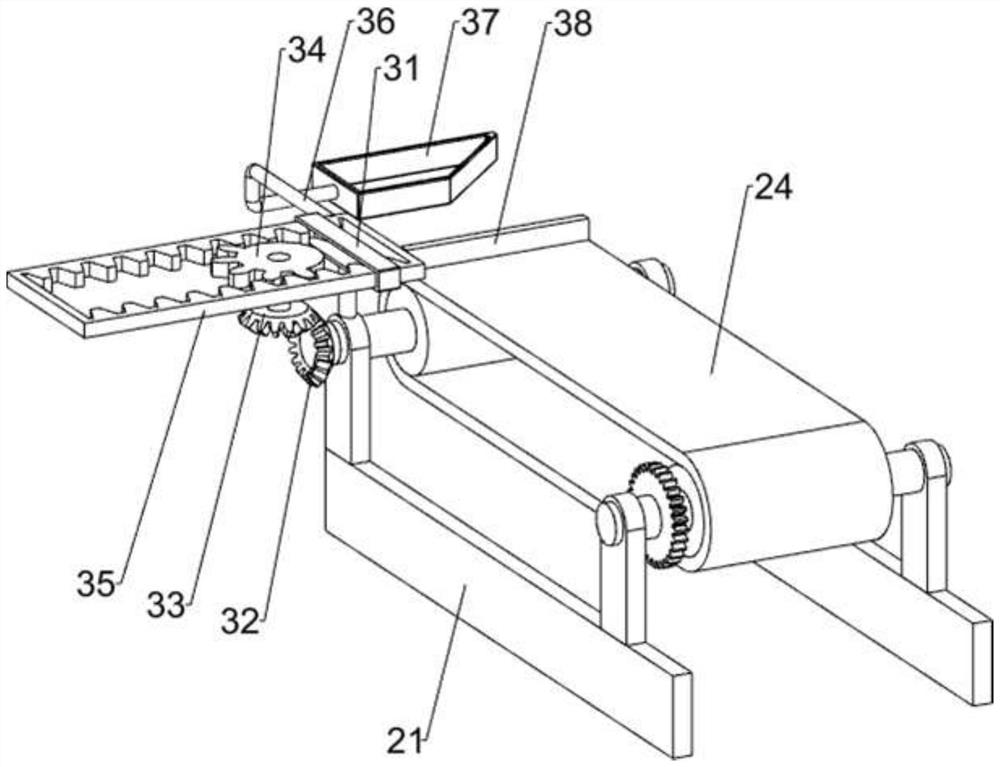

[0060]The striking mechanism 3 includes a first sliding sleeve 31, a first bevel gear 32, a second bevel gear 33, a missing gear 34, a rack frame 35, a first connecting rod 36, a first wedge block 37 and a bl...

Embodiment 2

[0064] On the basis of Example 1, such as Figure 5 to Figure 8 As shown, a blanking mechanism 5 is also included, and the blanking mechanism 5 includes a first mounting column 51, a placement plate 52, a blanking frame 54, a push plate 55, a second wedge block 56 and a first spring 57, and the mounting seat 1 There are four first installation columns 51 on the left rear side of the top, the top of the first installation column 51 is connected with a placement plate 52, the top of the placement plate 52 is provided with a through hole 53, and the middle side of the top of the placement plate 52 is connected with a blanking frame 54. The left side of the plate 52 is slidably connected with a push plate 55, the push plate 55 is slidably connected with the inner wall of the through hole 53, the left side of the push plate 55 is connected with a second wedge 56, and the second wedge 56 cooperates with the first wedge 37, Two first springs 57 are connected between the right side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com