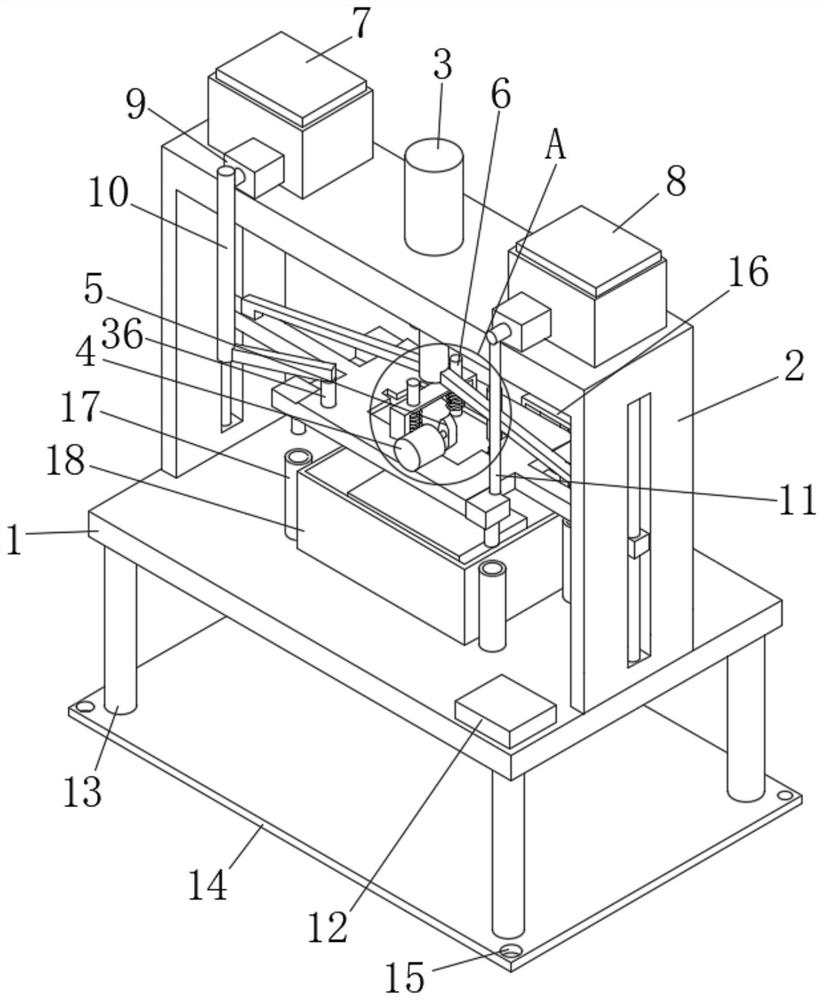

Packaging box with different-color mark and injection molding method and device thereof

A technology of injection molding and box packaging, applied in the directions of packaging, transportation and packaging, boxes, etc., can solve the problems of easily damaged box body, high requirements, and difficult development, to meet the needs of marking, flexible and convenient work, lightening The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

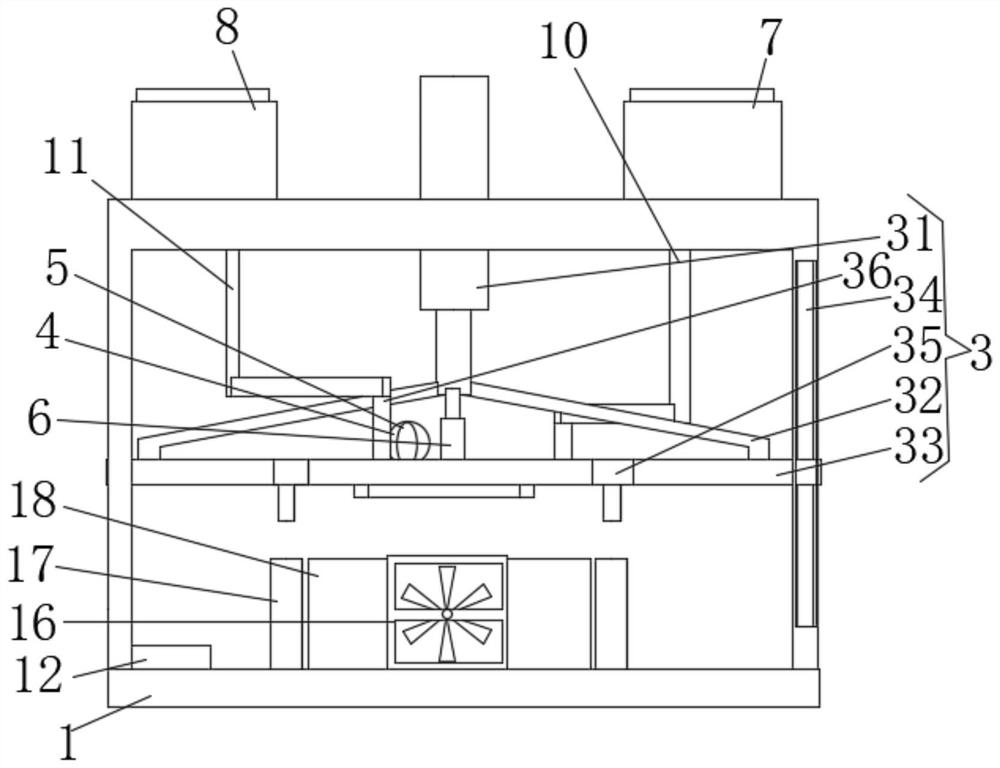

Method used

Image

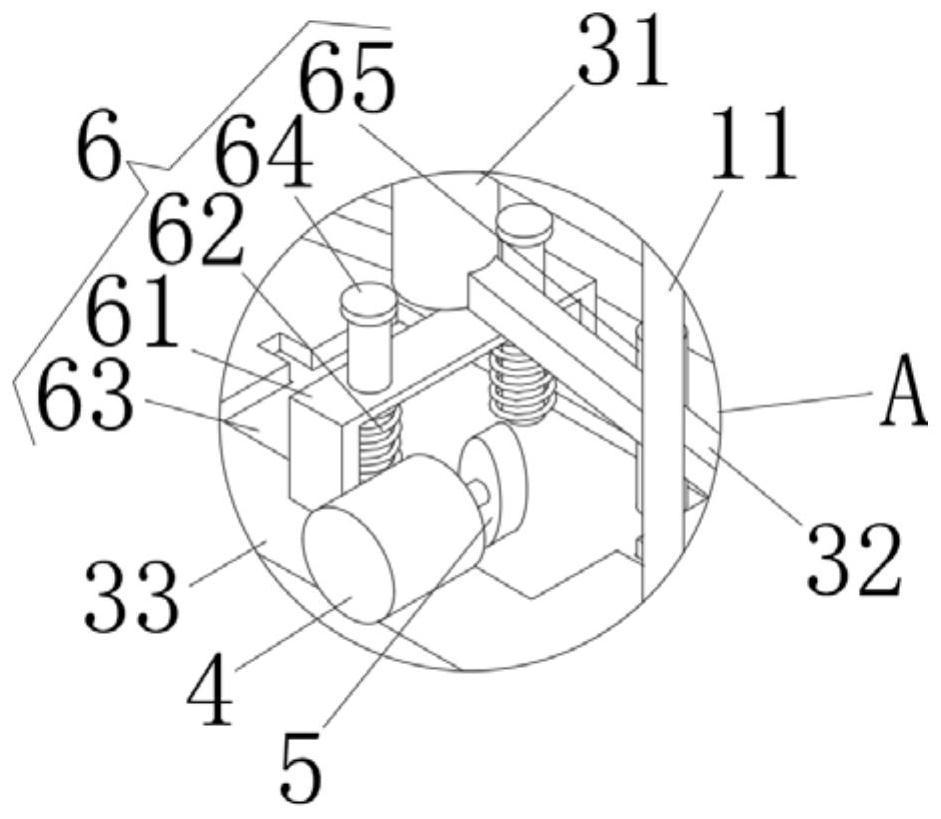

Examples

Embodiment 1

[0024] The invention provides a packaging box with different-color marks, which comprises a box body injection-molded from one color plastic material, and a different-color mark with a smooth surface injection-molded on the box body from another color plastic material. The above-mentioned injection molding method for packaging boxes with different-color markings includes the steps: S1. First, obtain a box body injection-molded from a plastic material of one color in the mold by injection molding, and form a box body at a position where an injection mark is required on the box body. Simultaneously injection molded grooves; S2. Then, a different color mark with a flat surface is formed by filling another color of plastic in the grooves.

Embodiment 2

[0026] The invention provides a packaging box with different-color marks, which comprises a box body injection-molded from one color plastic material, and a three-dimensional raised different-color mark injection-molded on the box body from another color plastic material. The above-mentioned injection molding method for a packaging box with a different color mark includes the steps: S1. First, obtain a box body injection-molded from a plastic material of one color in a mold by means of injection molding; S2. Directly inject molding on the surface plane of the box body Formed three-dimensional raised different-color marks.

Embodiment 3

[0028] The invention provides a packaging box with different-color markings, which comprises a box body injection-molded from a plastic material of one color, and a dotted combination of different-color markings injection-molded on the box body from another color plastic material. The above-mentioned injection molding method for a packaging box with a different color mark includes the steps: S1. First, obtain a box body injection-molded from a plastic material of one color in the mold by injection molding; S2. After the box body is injection-molded but before curing , Using needles arranged in the shape of marks to inject another color of plastic into the outer wall of the box, thus forming a dot-like combination of different-color marks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com