Injection molding equipment for mobile phone shell production

A technology of injection molding and mobile phone casings, applied in applications, household appliances, household components, etc., can solve problems such as worker hazards, low injection molding efficiency, and inconvenient unloading, and achieve the effects of improving efficiency, efficient cooling, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

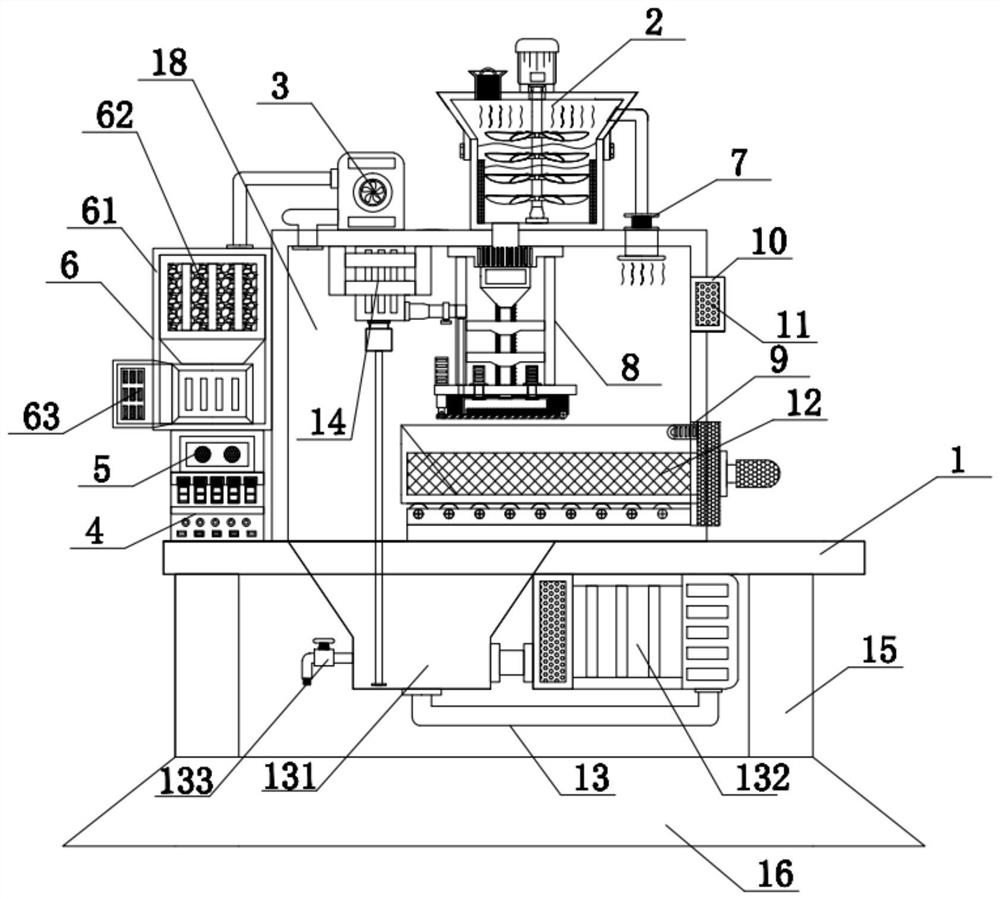

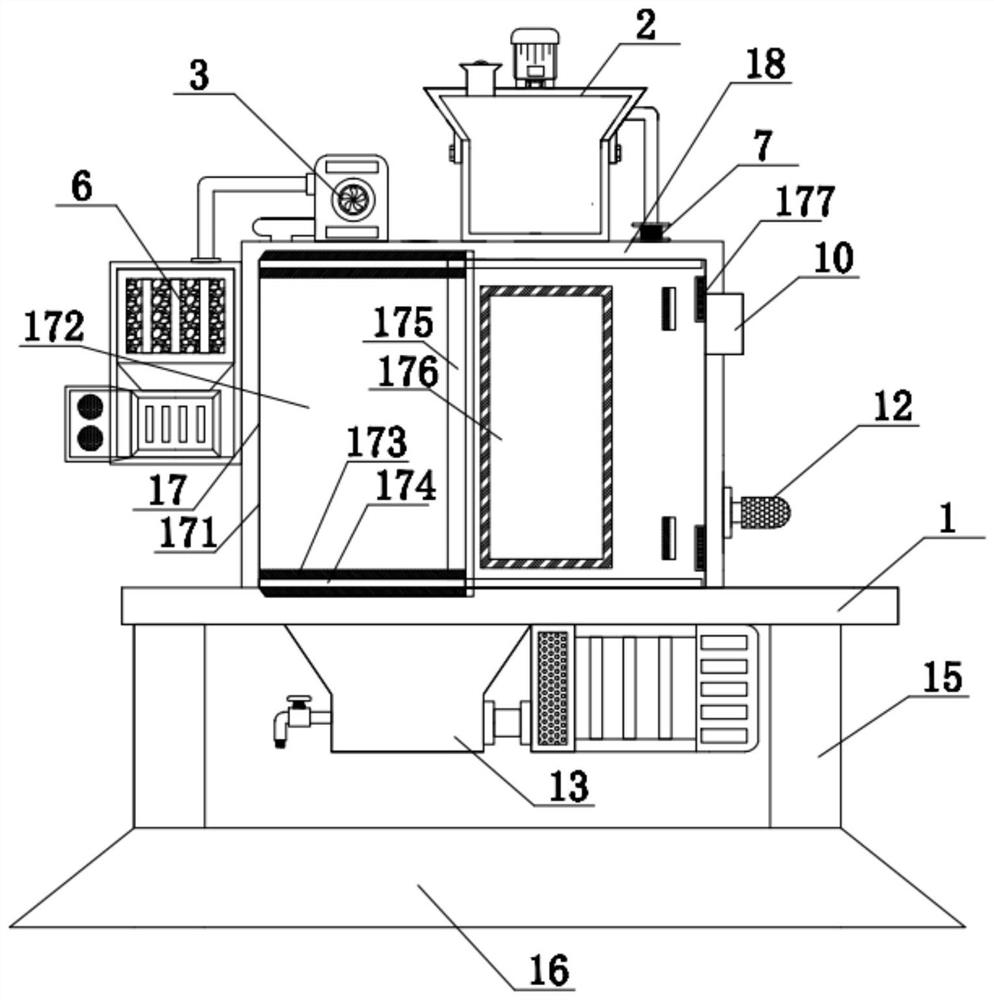

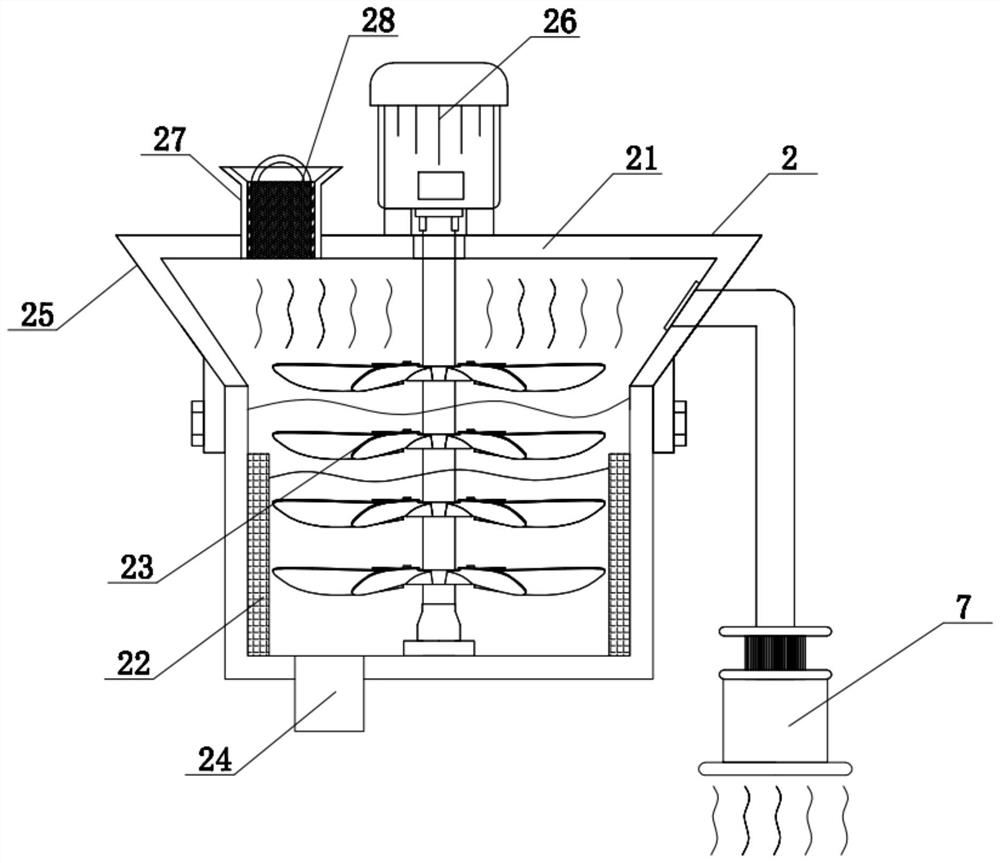

[0037] see Figure 1-7, a kind of injection molding equipment for the production of mobile phone shells, comprising an operation table 1, an injection molding box 18 is fixedly installed in the middle of the top of the operation table 1, and a hot-melt device 2 is fixedly connected to the right side of the top of the injection molding box 18, and the injection molding box 18 A suction fan 3 is fixedly installed on the left side of the top, a DSP controller 4 is fixedly installed on the left side of the top of the operating table 1, and a buzzer 5 is fixedly connected to the top of the DSP controller 4, and the top of the buzzer 5 is fixed An air filter device 6 is installed, and the input end of the top of the air filter device 6 communicates with the output end of the suction fan 3 through a ventilation pipe. The right side of the top of the injection molding box 18 is provided with a threaded interface 7, and the threaded interface 7 passes through the ventilation pipe. It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com