Carrier roller set of belt conveyor and belt conveyor

A technology of belt conveyors and idler rollers, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of reducing the service life of conveyor belts, affecting transportation efficiency, and stretching and deformation of conveyor belts. The effect of stability, ensuring transportation efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

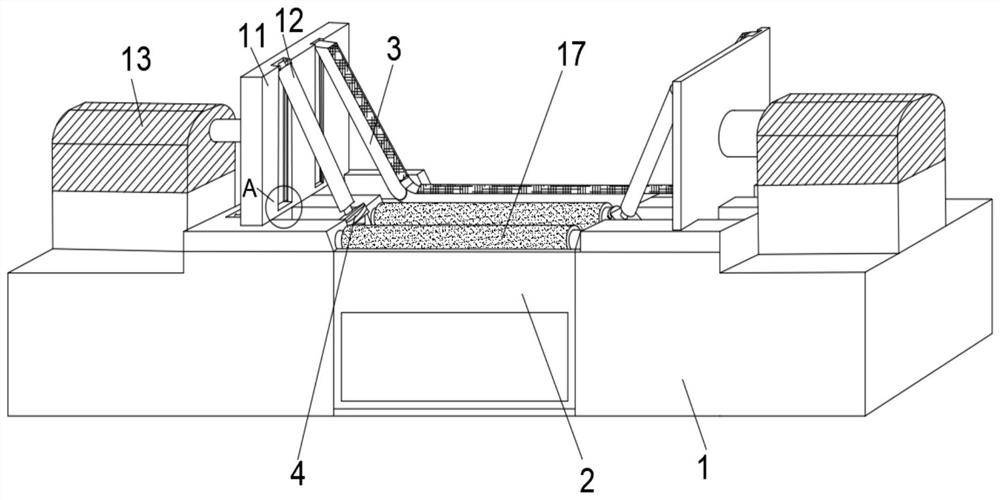

[0037] As an embodiment of the present invention, the horizontal roller 17 includes a roller shaft 171, a spring strut 172, and a dustproof plate 173. One end away from the roller shaft 171 is fixedly connected to the dustproof plate 173, and a rubber filling layer 174 is filled between the dustproof plate 173 and the roller shaft 171, and the rubber filling layer 174 is slidingly connected with the spring pole 172, and the anti-dust plate 174 The inner surface of the dust plate 173 is in close contact with the rubber filling layer 174. During operation, the horizontal roller 17 is located at the bottom of the conveyor belt and is the part subjected to the greatest pressure. In the actual operation process, the conveyor belt will produce Vibration, the vibration of the conveyor belt will directly act on the horizontal roller 17, causing the horizontal roller 17 to vibrate. If it runs for a long time, it will cause the stability of the horizontal roller 17 to decrease. Spring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com